Cylindrical milling rotor with quick grading and working method thereof

A milling and rotor technology, applied in grain processing, etc., can solve problems such as easy agglomeration, wall sticking, low classification efficiency, excessive power consumption, etc., and achieve the effects of eliminating slow circulation, improving milling efficiency, and increasing effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings.

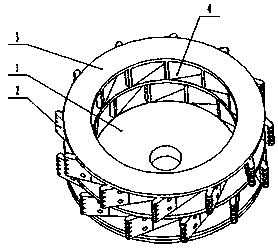

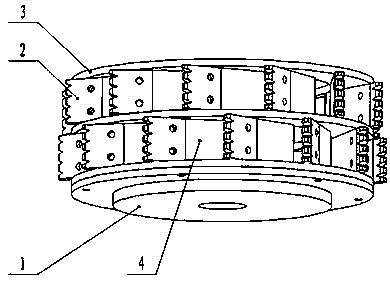

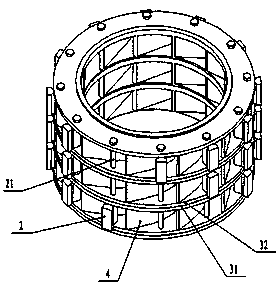

[0031] figure 1 , figure 2 It is a structural schematic diagram of a specific embodiment 1 of the present invention. In the embodiment, the power disc 1 is threaded and image 3 The grinding cylinder connection, image 3 The grinding cylinder is welded together by three ring-shaped shell parts (3) through two sets of blade-shaped centrifugal guide parts (4), and the centrifugal guide parts (4) are uniform around the axis of the ring-shaped shell part (3). Distribution, between the two annular shell parts (3), the evenly distributed return channel is divided by the centrifugal guide part (4), the hammer knife (2) is connected to the centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com