Online sludge conditioning and concentrating system and process

A thickening system and sludge conditioning technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems that the separation of sludge and water cannot be guaranteed, and it is not conducive to concentration treatment, etc., to achieve Save civil costs, reduce power, and achieve control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

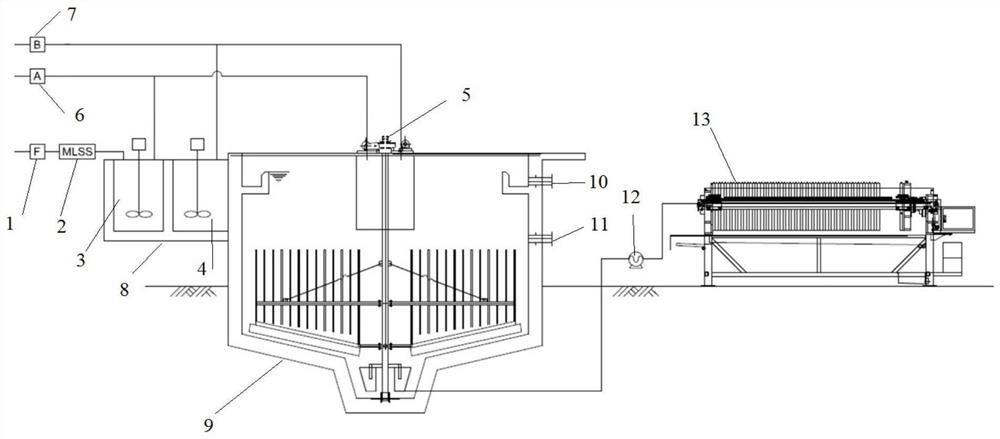

[0030] refer to figure 1 , an on-line sludge conditioning and concentration system, comprising a sludge conditioning tank 8, a sludge concentration tank 9 and a plate-and-frame filter press 13 sequentially connected through a sludge pipeline along the sludge feeding direction, and the sludge conditioning tank 8 is The mud feeding direction is divided into a coagulation tank 3 and a flocculation tank 4. The coagulation tank 3 is connected with a coagulant dosing device 6, the flocculation tank 4 is connected with a flocculant dosing device 7, and the sludge thickening tank 9 is provided with a sludge Mud Thickener5.

[0031] A coagulation agitator is provided in the coagulation tank 3 , and a flocculation agitator is provided in the flocculation tank 4 . The flocculant fed by the flocculant dosing device 7 is cationic polyacrylamide.

[0032] The sludge thickening tank 9 is connected with the coagulant dosing device 6 and the flocculant dosing device 7 .

[0033] The side wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com