Plasma reactor and method for decomposing a hydrocarbon fluid

A technology of plasma and hydrocarbon fluids, applied in the direction of plasma, chemical methods for reacting gases with non-granular solids, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following description, the terms "top", "bottom", "right side" and "left side" and similar terms relate to the orientation and configuration shown in the drawings and are only intended to describe the embodiments. These terms may indicate preferred configurations and are not intended to be limiting. In the context of this specification, the term "hydrocarbon fluid" means a fluid (gas, aerosol, liquid) containing hydrocarbons.

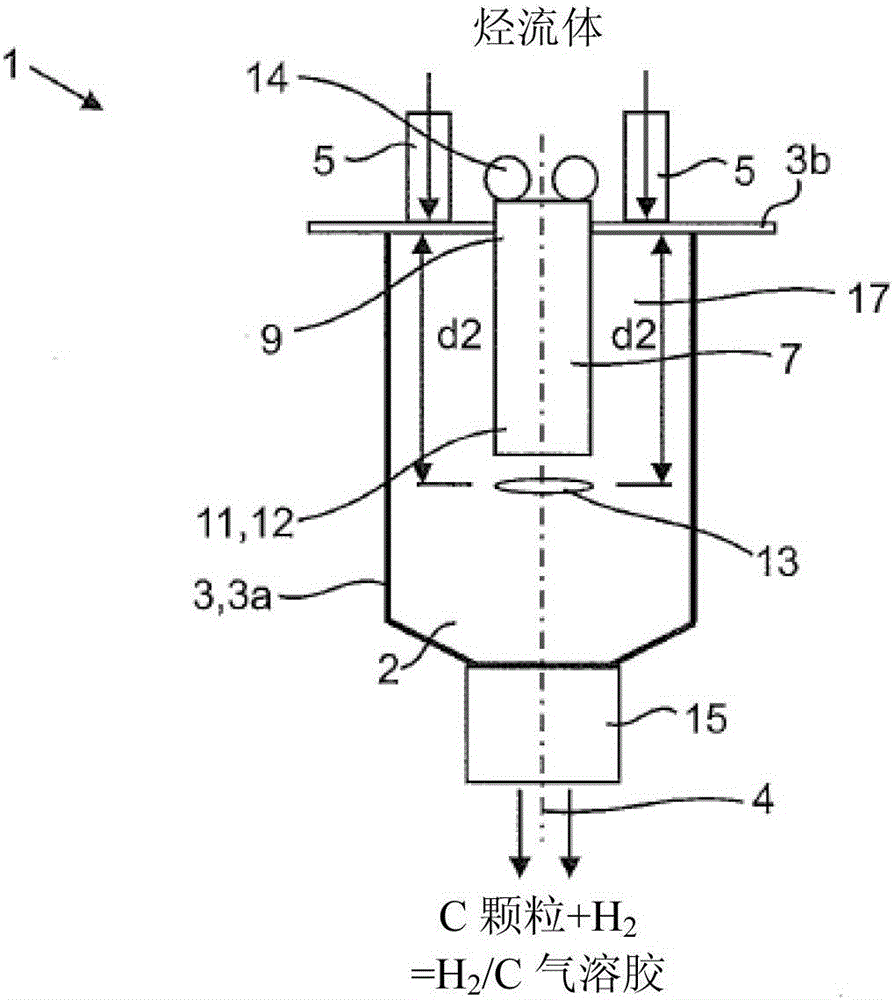

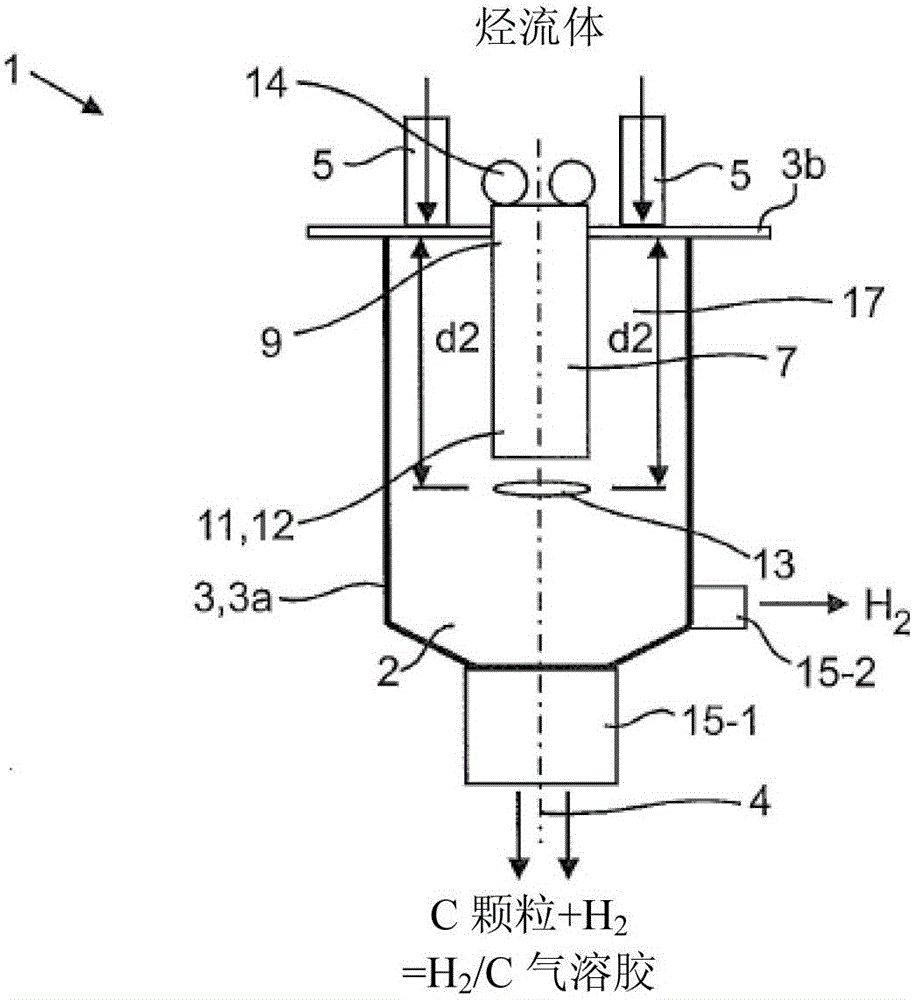

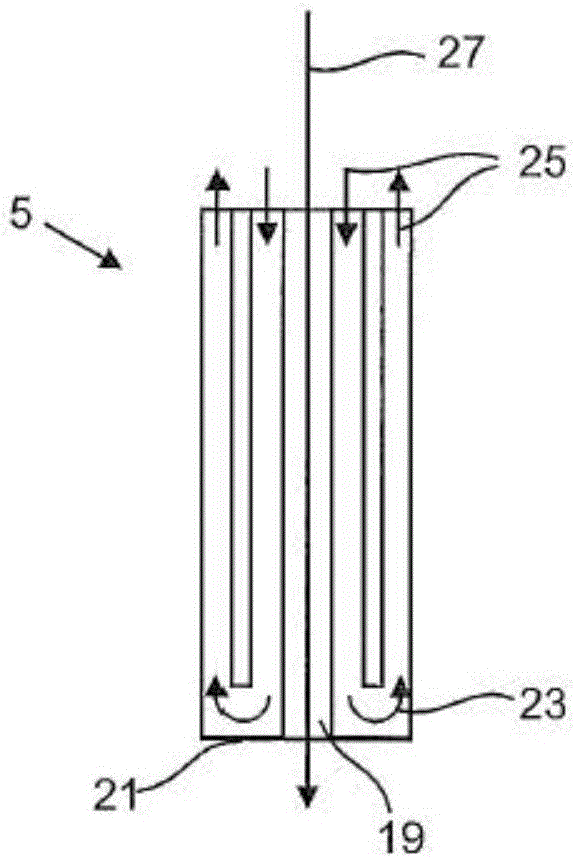

[0023] A plasma reactor 1 according to the present disclosure comprises a reactor chamber 2 closed by a reactor wall 3 having a lower portion 3a and a cover 3b. The reactor chamber 2 can also be divided at positions other than those shown in the figures. The reactor chamber 2 is substantially cylindrical and has a central axis 4 . A plasma burner 7 with elongated electrodes (not shown in detail) is fixed to the cover 3b of the reactor wall 3 . The plasma burner 7 has a base part 9 fixed to the reactor wall 3 (here, in particular, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com