Biomass cell dissolving treatment process of solid-liquid mixed phase by quick flash evaporation

A technology of solid-liquid mixing and treatment process, applied in the direction of solid waste removal, etc., can solve the problems of high organic content and moisture content of biomass waste, increase the burden on landfill facilities, and low biodegradation rate, and achieve high-efficiency cell structure, Improve the performance of anaerobic digestion and dehydration, and improve the stability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

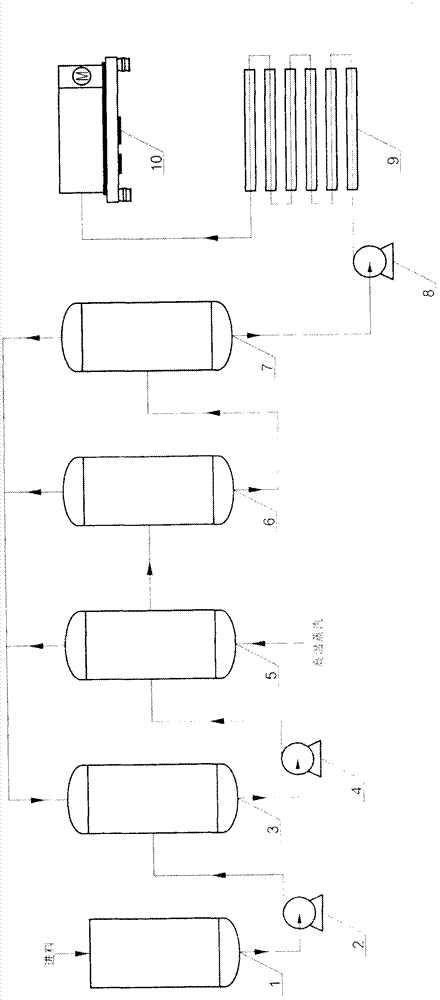

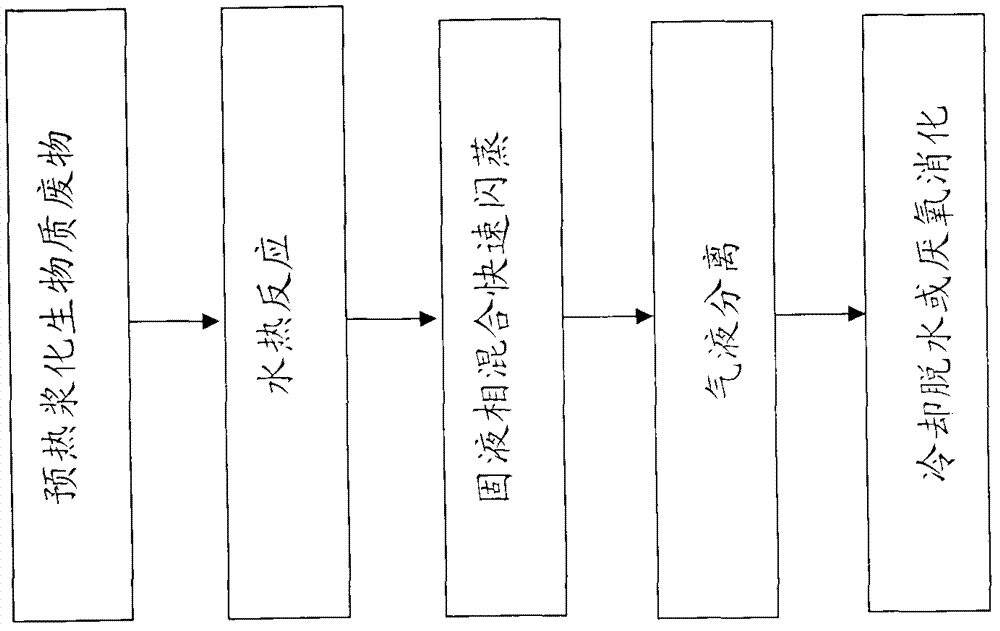

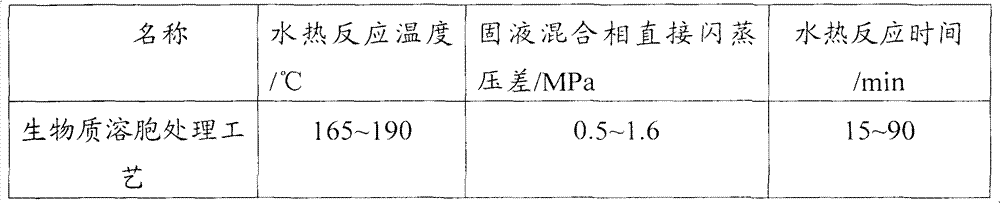

Method used

Image

Examples

Embodiment 1

[0045] Example 1. A mixture of municipal sludge and kitchen waste, the mass ratio is 1:2, the hydrothermal reaction temperature is 170°C, and the reaction time is 30min. After hydrothermal treatment, the sludge is cooled to 60°C by a heat exchanger for dehydration . After the hydrothermal reaction, the pressure difference of the direct flashing of the solid-liquid mixed phase is 0.8MPa. As a result of the reaction, the suspended solids (SS) were dissolved by 31%, and the supernatant COD (SCOD) was 20040 mg / L. The solids content of the dewatered cake was 52%.

Embodiment 2

[0046] Example 2, a mixture of municipal sludge and kitchen waste, the mass ratio is 1:1, the hydrothermal reaction temperature is 180°C, and the reaction time is 30min. After hydrothermal treatment, the sludge is cooled to 60°C by a heat exchanger for dehydration . After the hydrothermal reaction, the pressure difference of the direct flashing of the solid-liquid mixed phase is 1.2MPa. As a result of the reaction, the suspended solids (SS) were dissolved by 38%, and the supernatant COD (SCOD) was 25100 mg / L. The solids content of the dewatered cake was 61%.

Embodiment 3

[0047] Example 3. A mixture of municipal sludge and kitchen waste, the mass ratio is 1:1, the hydrothermal reaction temperature is 190°C, and the reaction time is 30min. After hydrothermal treatment, the sludge is cooled to 60°C by a heat exchanger for dehydration . After the hydrothermal reaction, the pressure difference of the direct flashing of the solid-liquid mixed phase is 1.6MPa. As a result of the reaction, 45% of the suspended solids (SS) were dissolved, and the supernatant COD (SCOD) was 35300 mg / L. The solids content of the dewatered cake was 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com