Patents

Literature

36results about How to "Increase feed concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

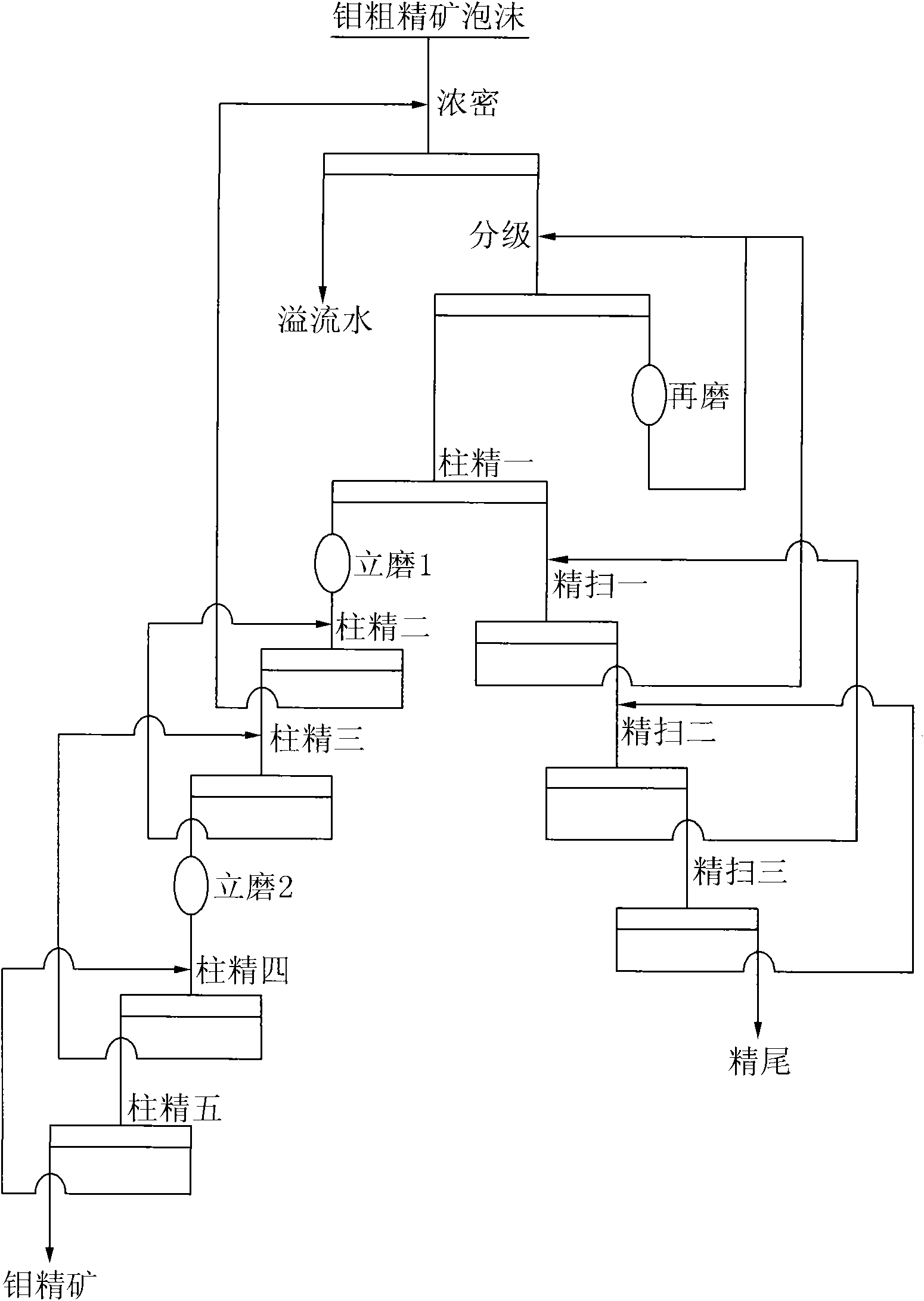

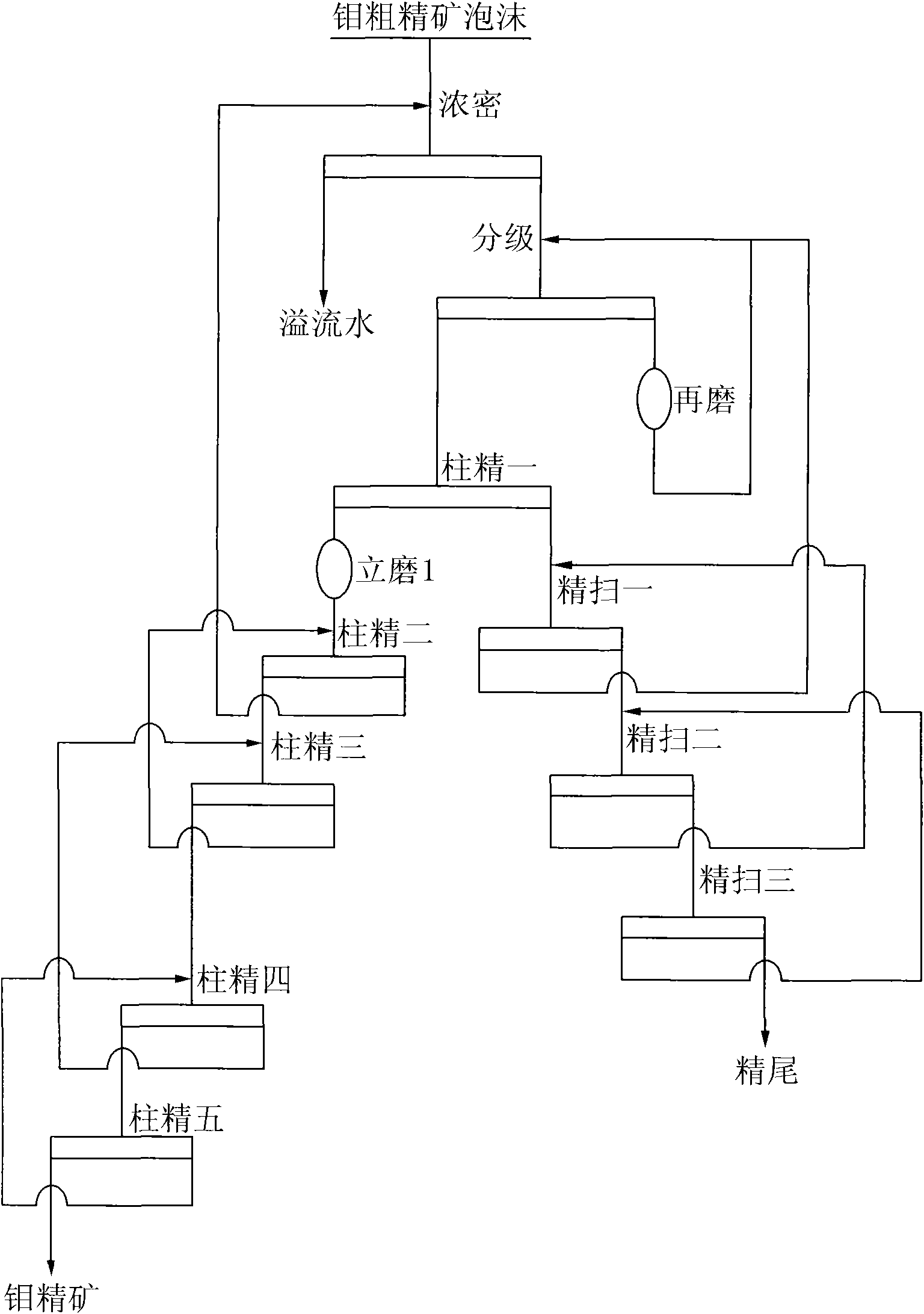

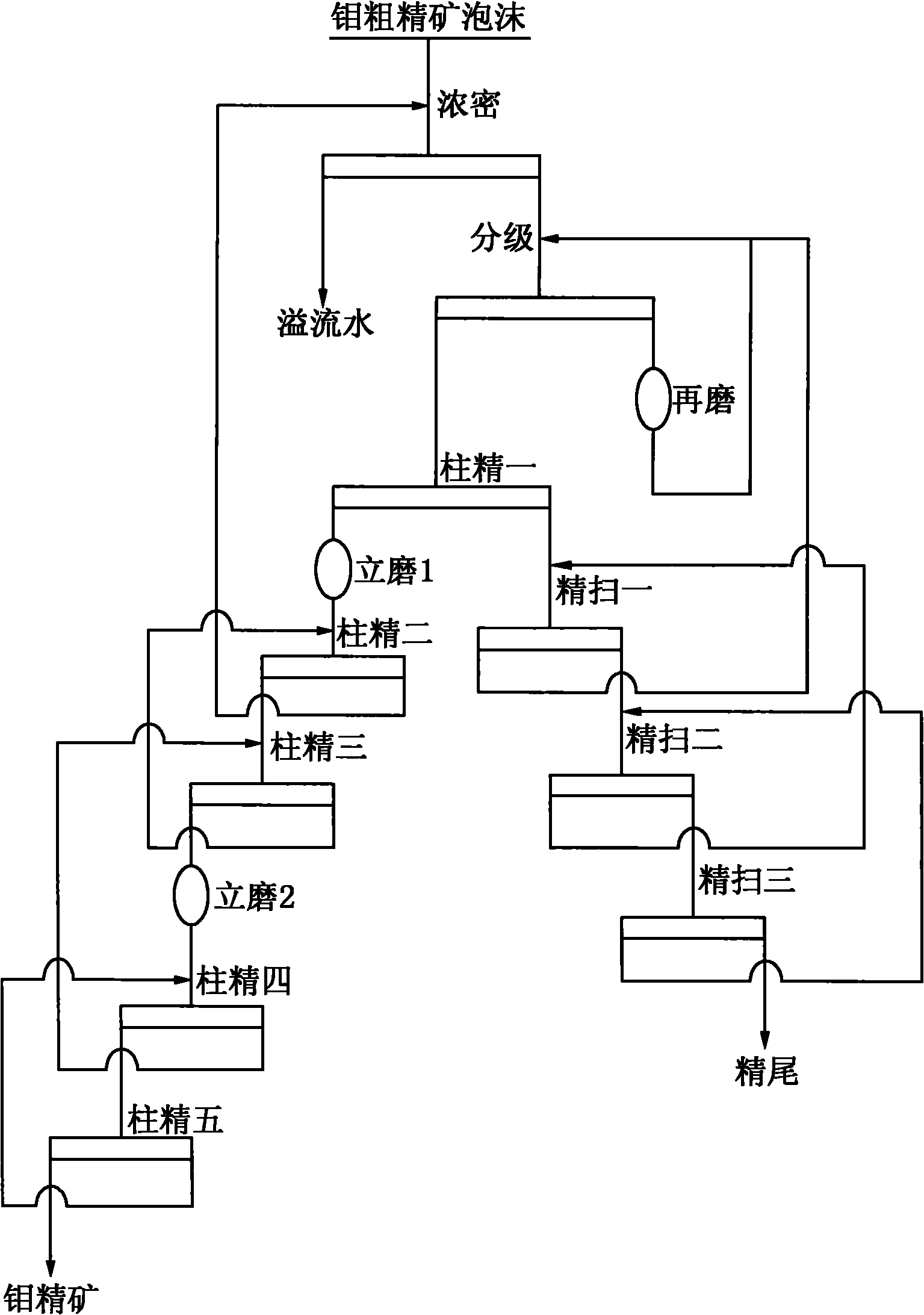

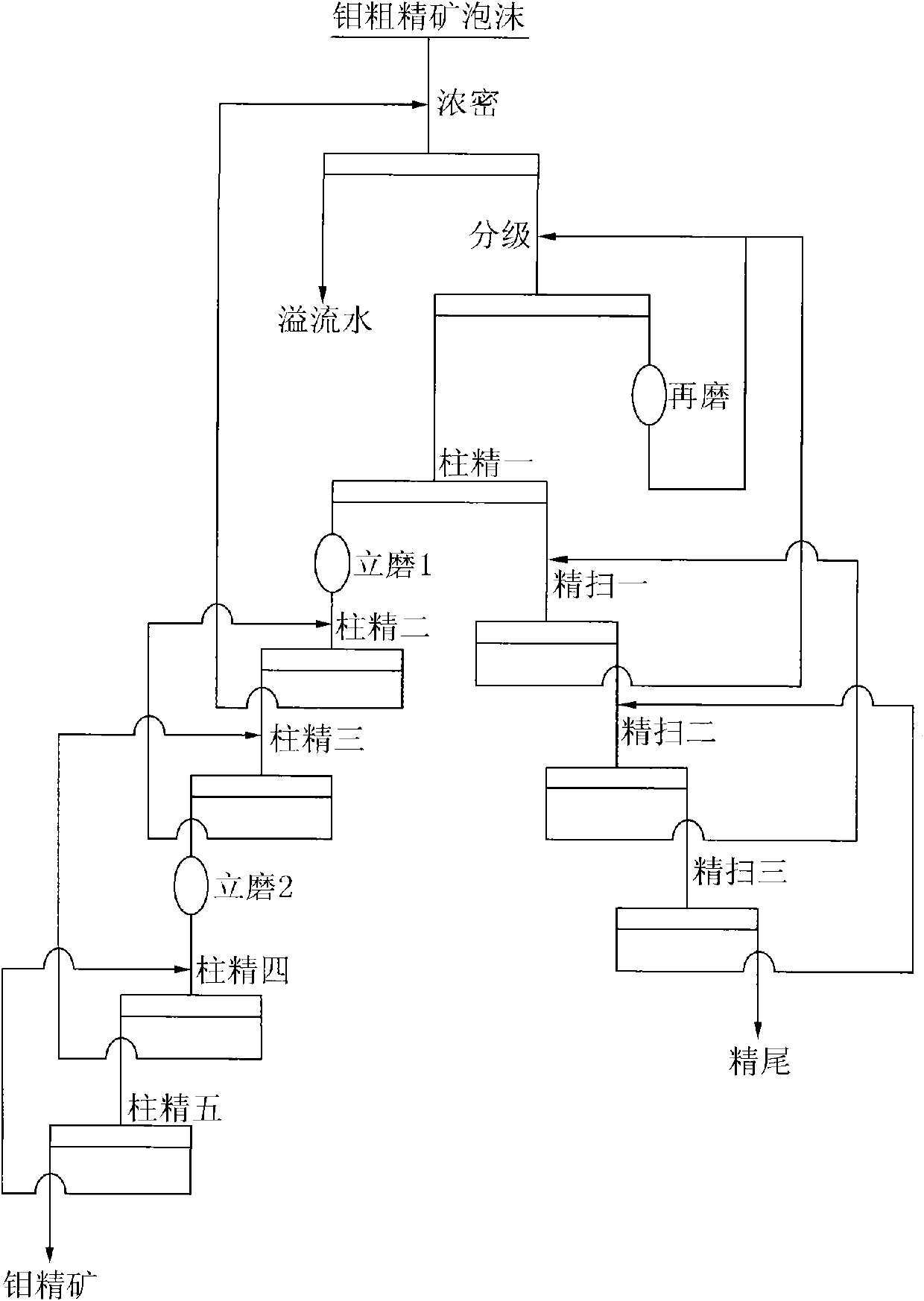

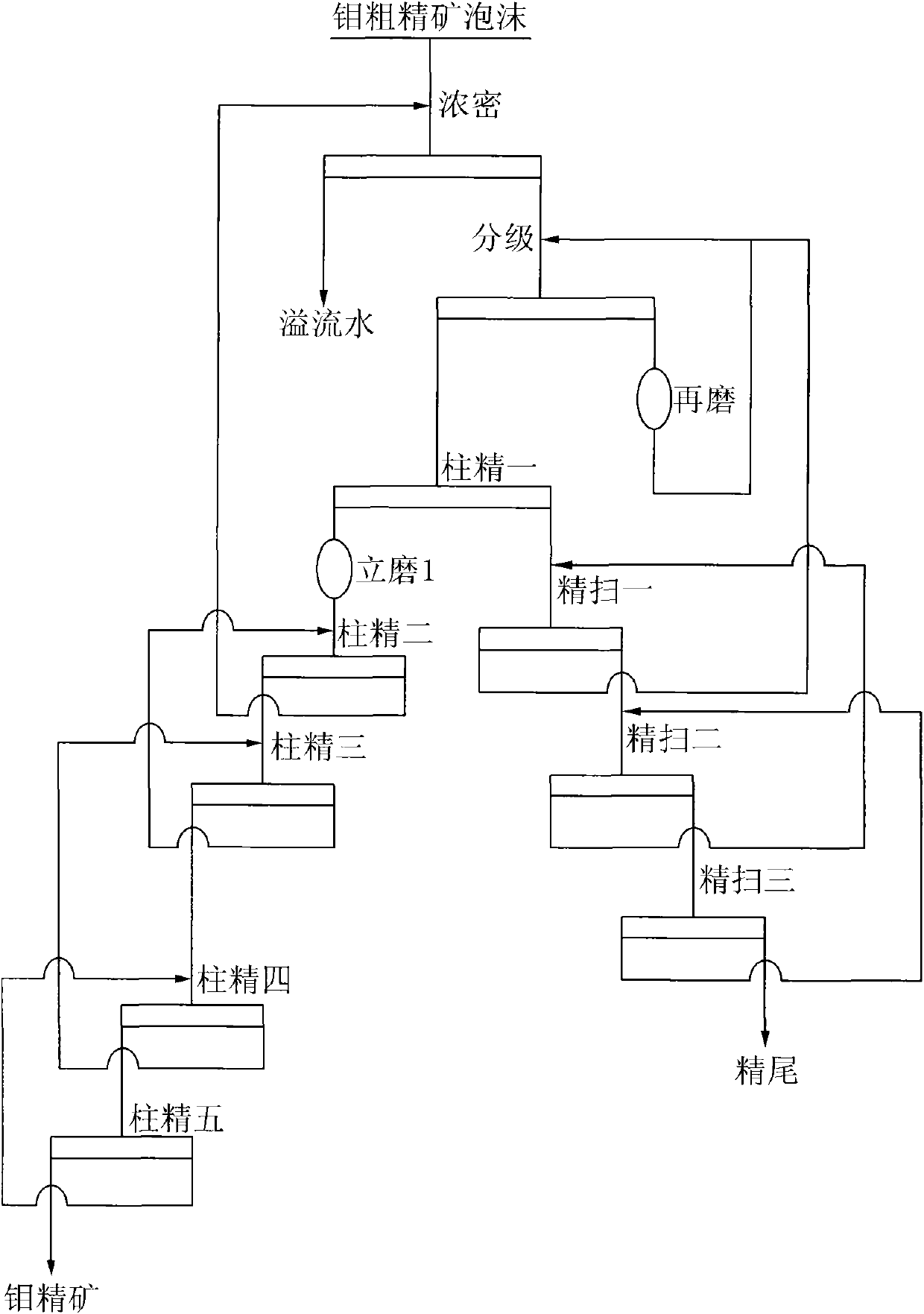

Production technology of high-grade molybdenum concentrate

ActiveCN101773871AReduce pollutionIncrease feed concentrationFlotationWet separationBall millReagent

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

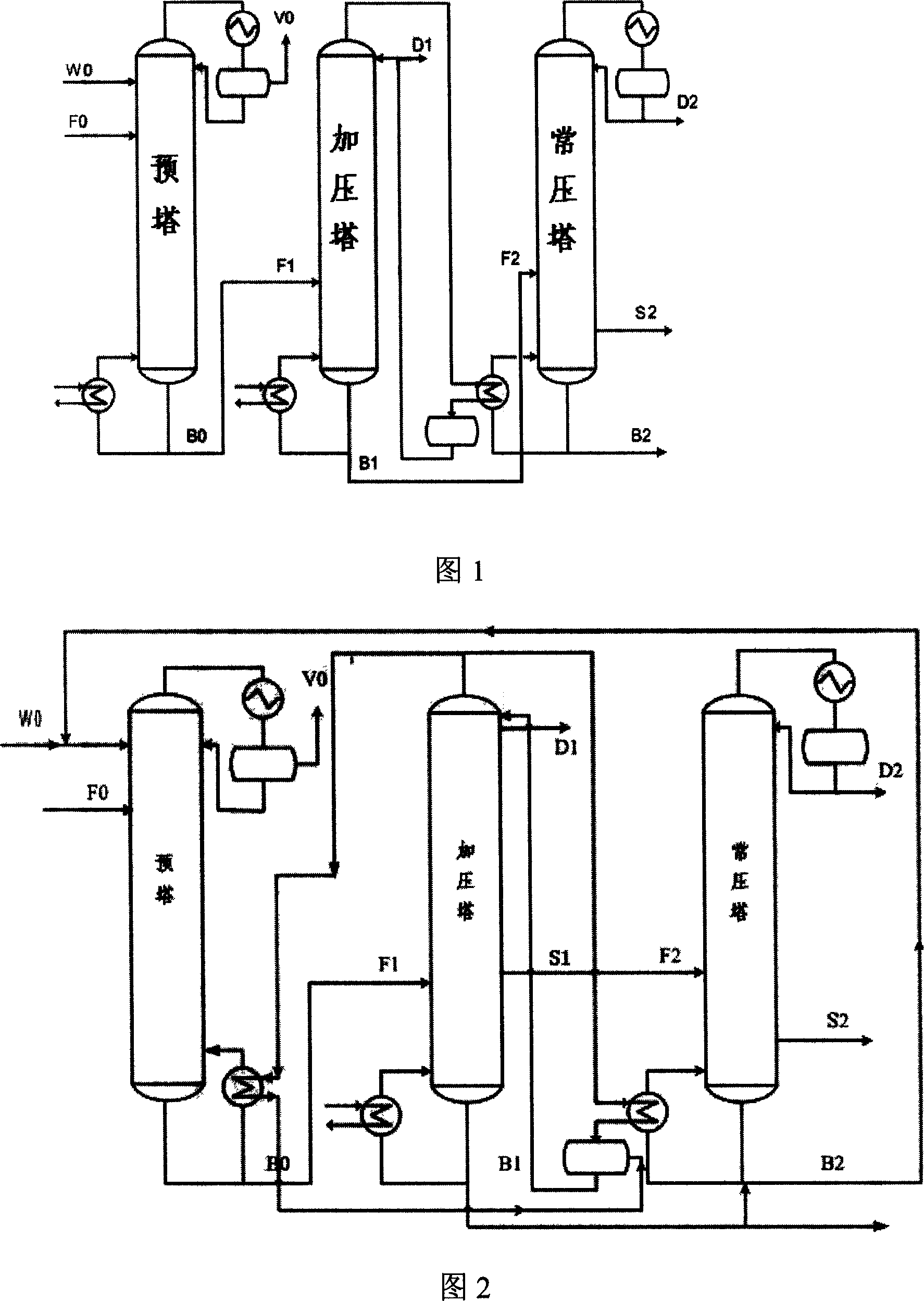

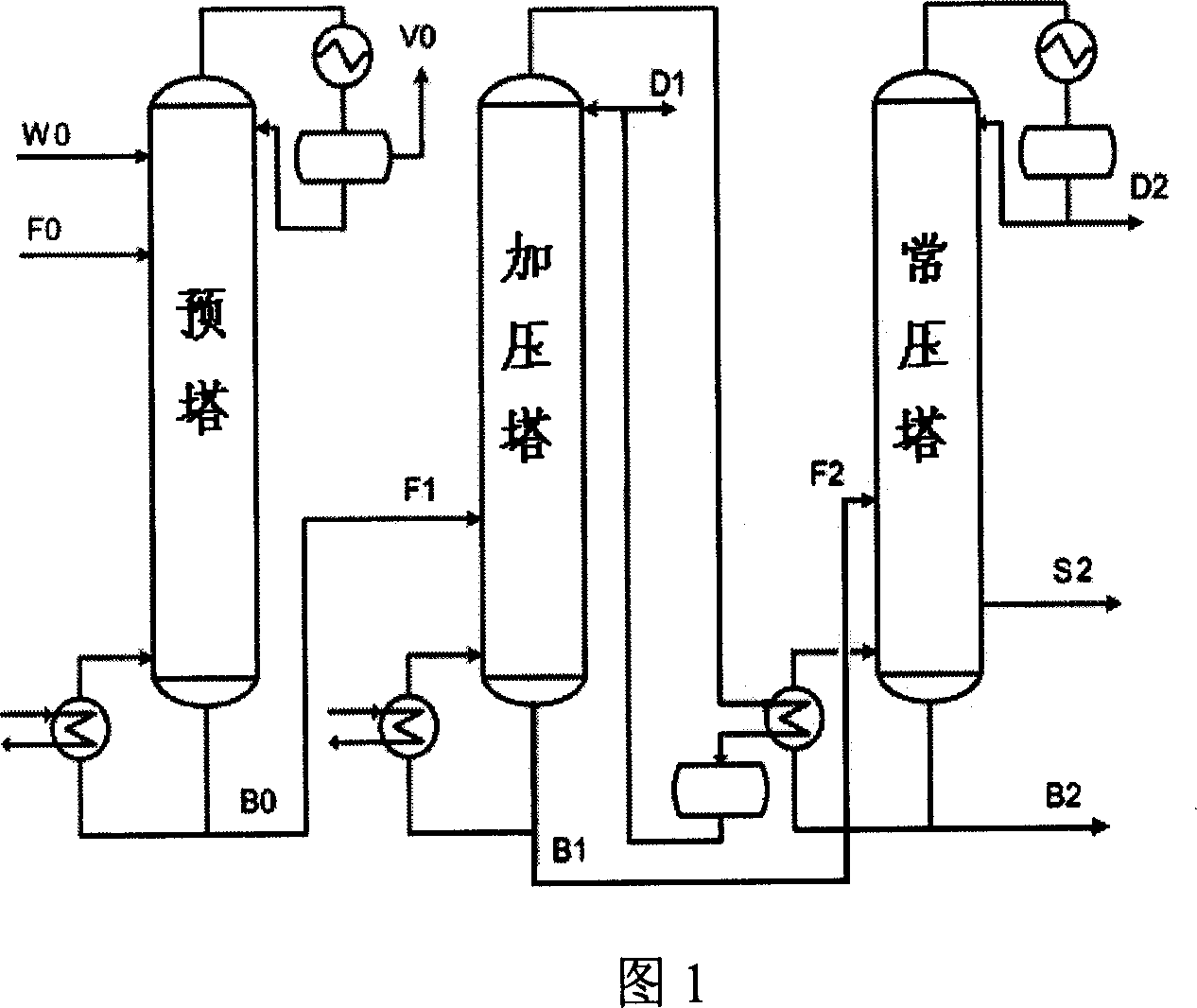

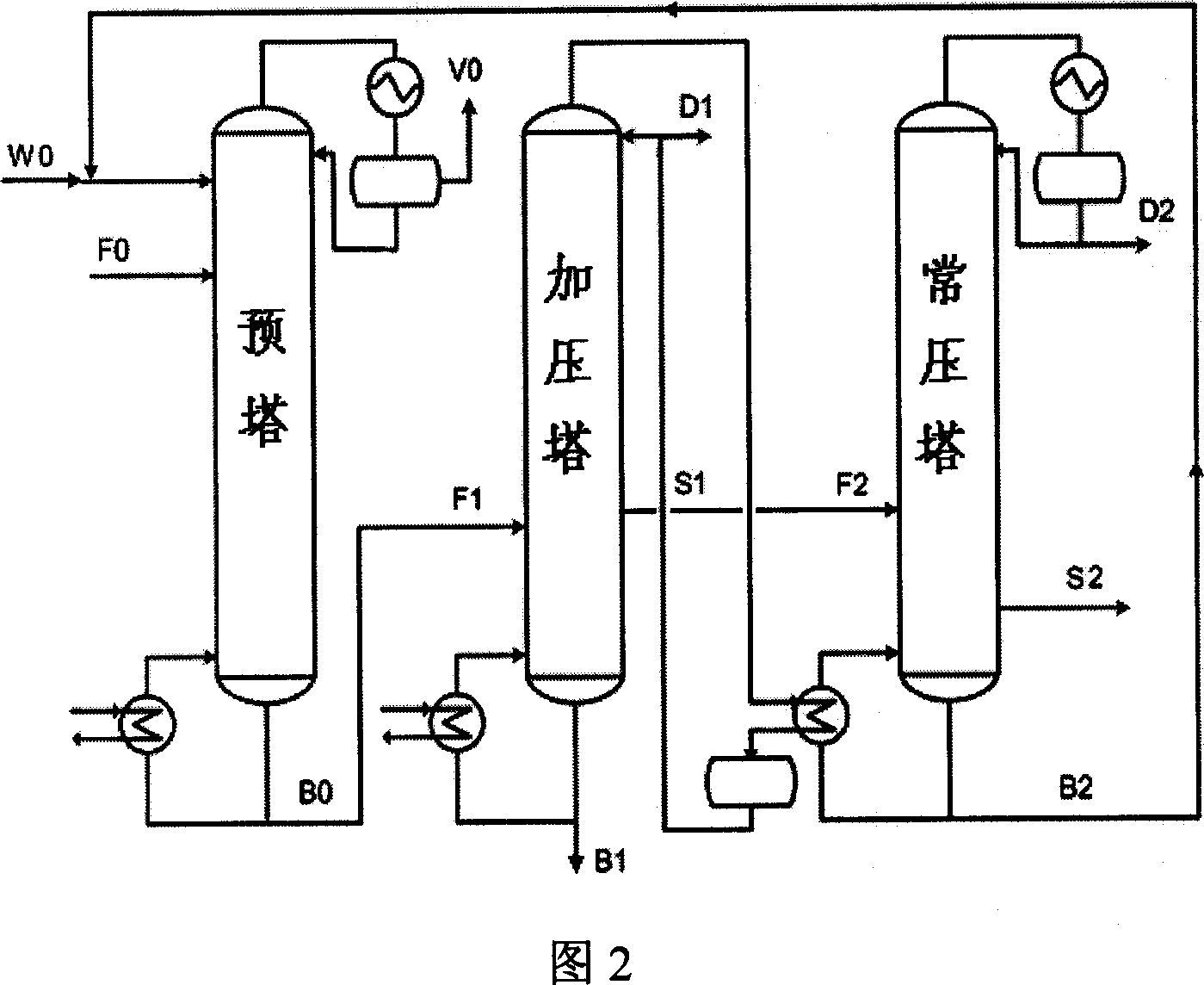

Method of refining synthetic methanol with heat integration

InactiveCN101012150AIncrease feed concentrationReduce the amount of separated waterHydroxy compound separation/purificationReboilerMethanol

The invention discloses a finishing method to synthesize carbinol, which is characterized by the following: rectifying rough carbinol in the pre-tower; adding extracting water from the top of pre-tower; discharging light component from the top of pre-tower; entering rought carbinol into middle part of pressurizing tower to rectify; making residual rough carbinol into middle part of normal pressure tower to rectify; draining waste water from the bottom of tower; dividing the steam of pressurizing tower into two parts to transmit into reboiler on the bottom of pre-tower and reboiler on the bottom of normal pressure tower as heat providing dielectric.

Owner:ZHEJIANG UNIV

Method for preparing ethanol by one-step fermentation after ion liquid stage treatments from native cellulose material

InactiveCN101298620AAchieve full utilizationReduce accumulationBiofuelsMicroorganism based processesHigh concentrationNatural fiber

The invention relates to a method that prepares ethanol through the grading processing with ionic liquids and one-step zymolysis and utilizes a raw material of native cellulose. The raw material of native cellulose is orderly processed by the ionic liquids A and B so as to respectively remove hemicellulose and lignin, and the obtained cellulose is used as a substrate so as to be further fermented to prepare the ethanol; the ionic liquid A is an acid or alkalic ionic liquid, the ionic liquid B is a halogenated-imidazole-like ionic liquid. The method utilizes the ionic liquids to implement the grading processing of the raw material of native cellulose, removes the substances of the hemicellulose and the lignin that are harmful to the zymolysis production of the ethanol, uses the substances for other purposes, and only utilizes the cellulose as the substrate so as to implement the ethanol zymolysis, thus realizing complete utilization of the raw material of native cellulose. Simultaneously the method can avoid adsorption of the hemicellulose and the lignin by cellulose enzyme and improve the activity of the cellulose enzyme; the accumulation of the substances that are not fermented in a reactor is reduced, and the method can realize continuous zymolysis in a long time, has high input concentration, recycles yeast and cellulose enzyme, has high concentration of recycled ethanol, and saves water.

Owner:HENAN UNIV OF SCI & TECH

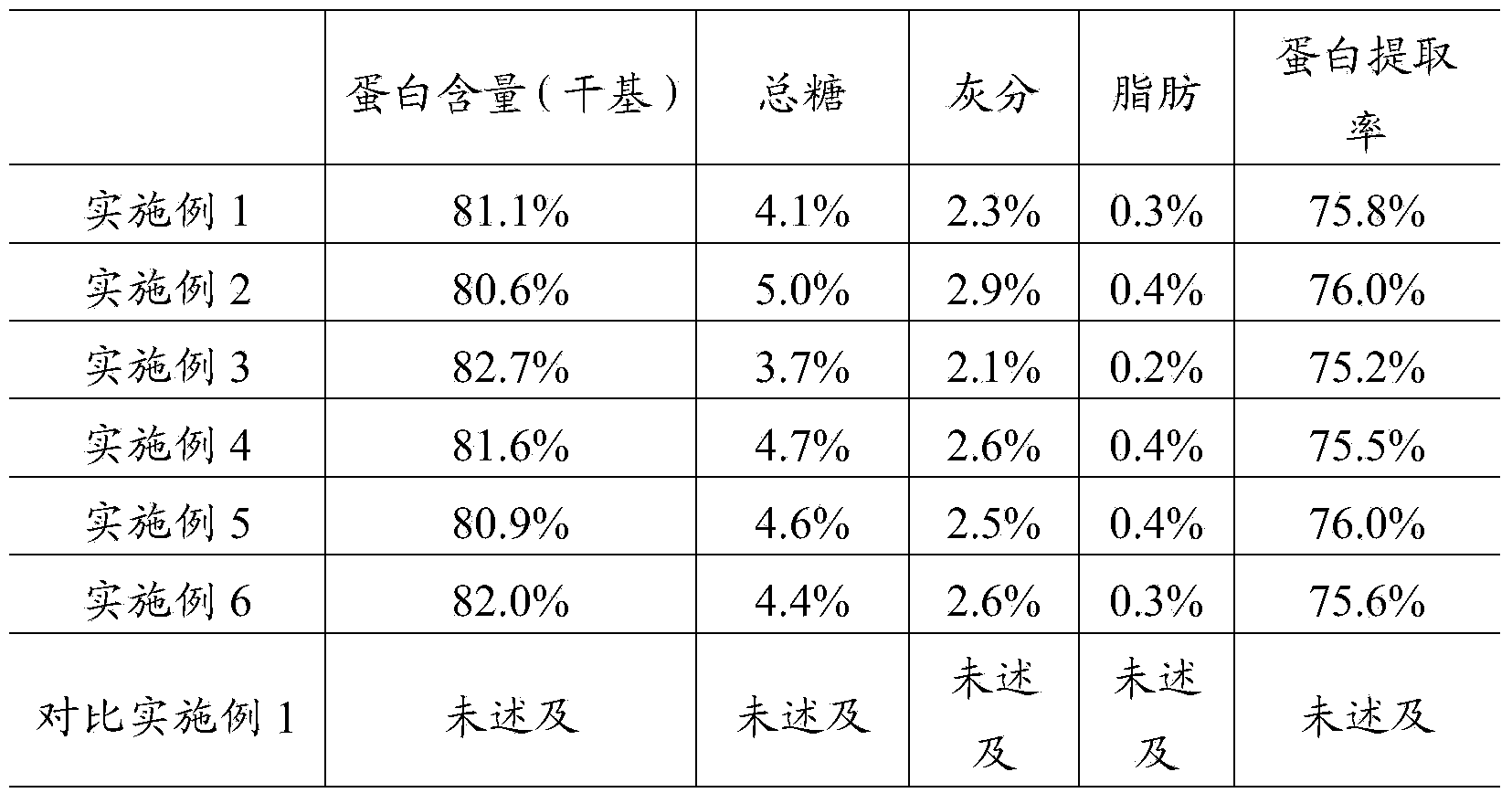

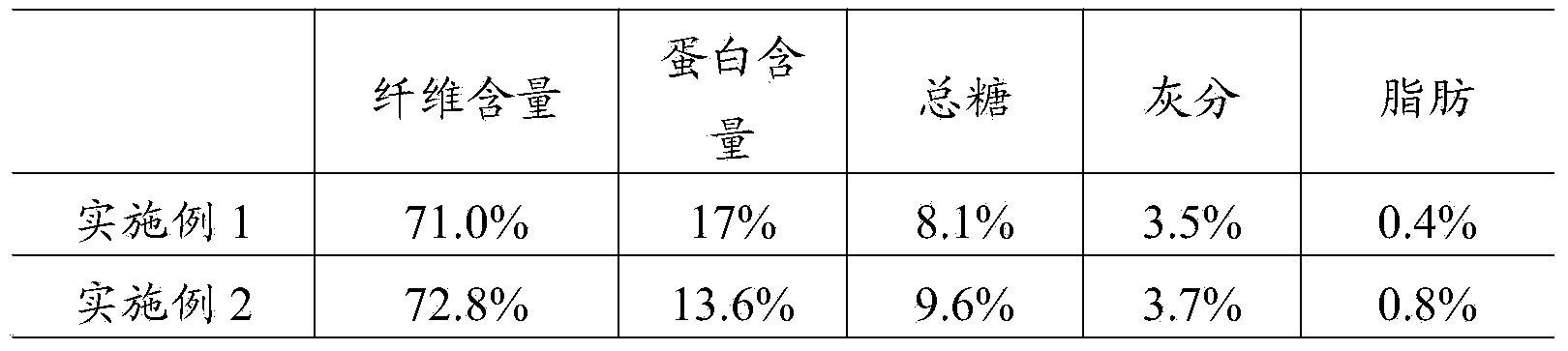

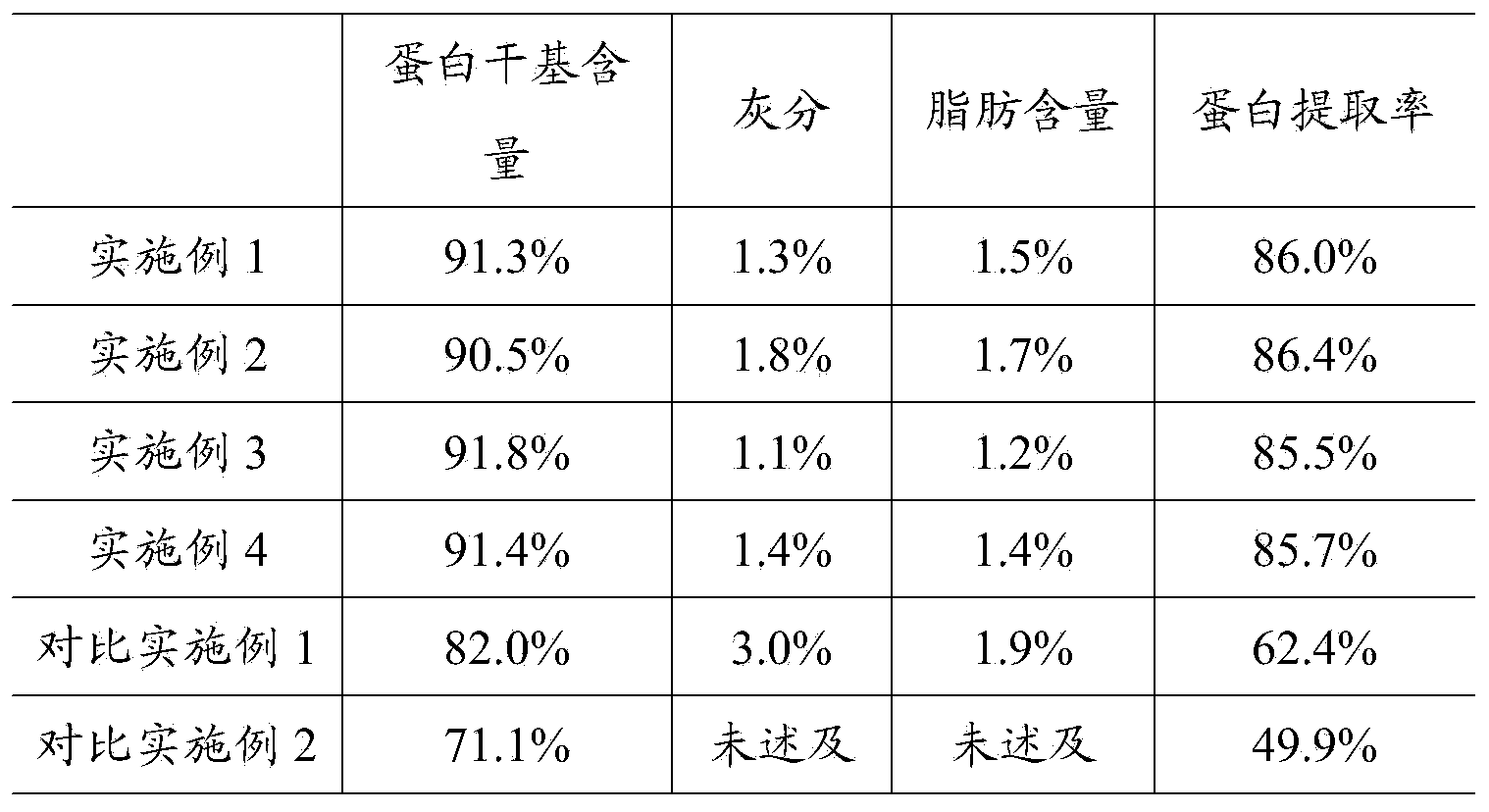

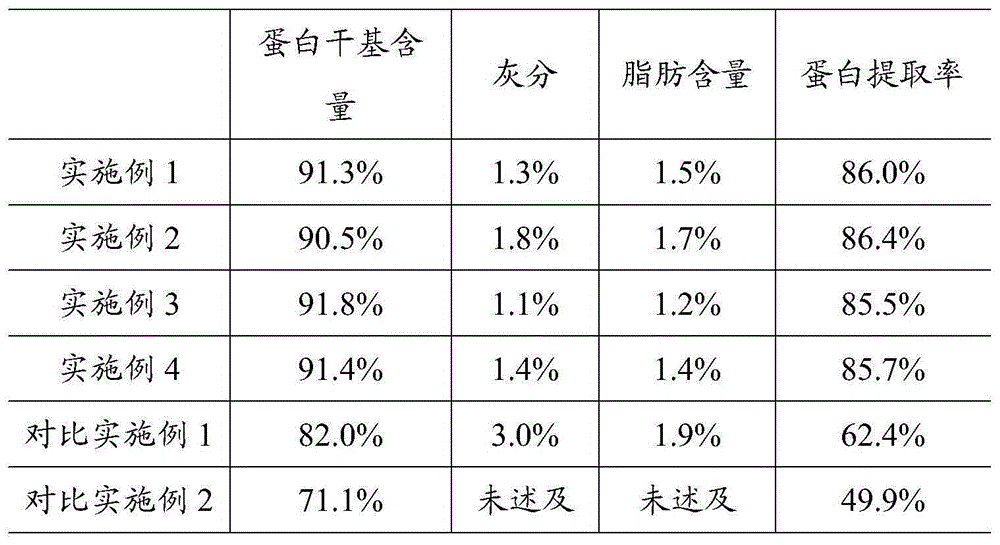

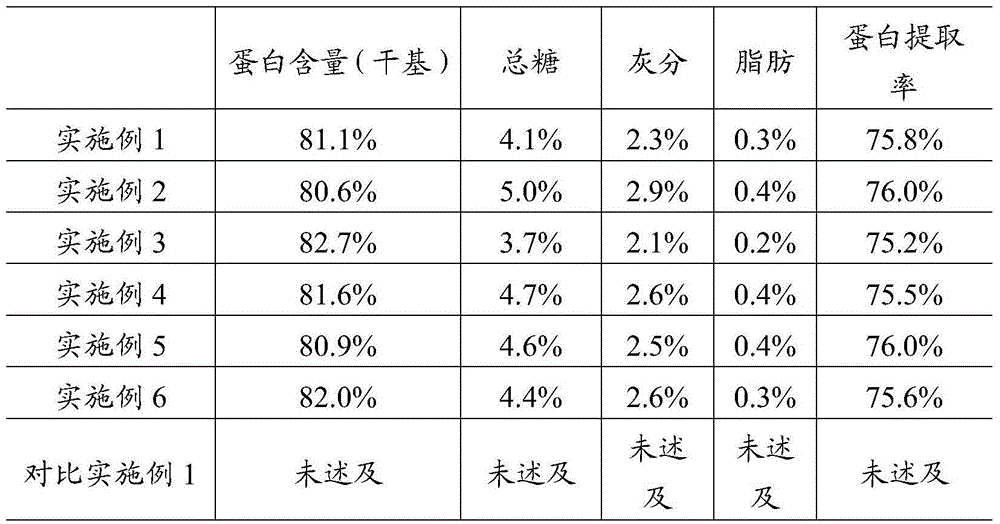

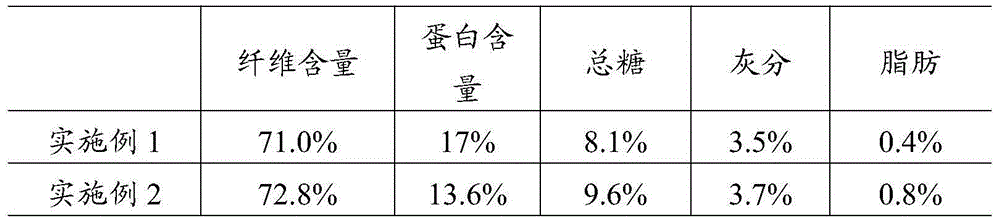

High-purity rice bran protein and rice bran fibers and preparation method thereof

The invention relates to high-purity rice bran protein and rice bran fibers, and further relates to a preparation method of the high-purity rice bran protein and the rice bran fibers. The preparation method includes the steps of raw material pretreatment, first size mixing and enzyme reaction, second size mixing and enzyme reaction, separate washing, drying and the like. According to the method, through superfine grinding and amylase and cellulose hydrolyzing, components of defatted rice bran are effectively separated, a whirlcone is utilized to conduct the washing treatment, and therefore separate washing efficiency is greatly improved. Compared with spray drying, flash drying equipment is utilized, investment is saved by about 40%, operating cost is saved by about 35%, in rice bran protein products, the protein content is over 80%, the ash content is below 3%, the fat content is below 0.5%, the protein extraction ratio is over 75%, and in rice bran fiber products, the fiber content is over 70%, the ash content is below 4%, and the fat content is below 1%. The high-purity rice bran protein and the rice bran fibers all can be widely applied to the field of health food, nutritious food and the like, and additional value of rice deep processing is greatly improved.

Owner:格乐瑞(无锡)营养科技有限公司

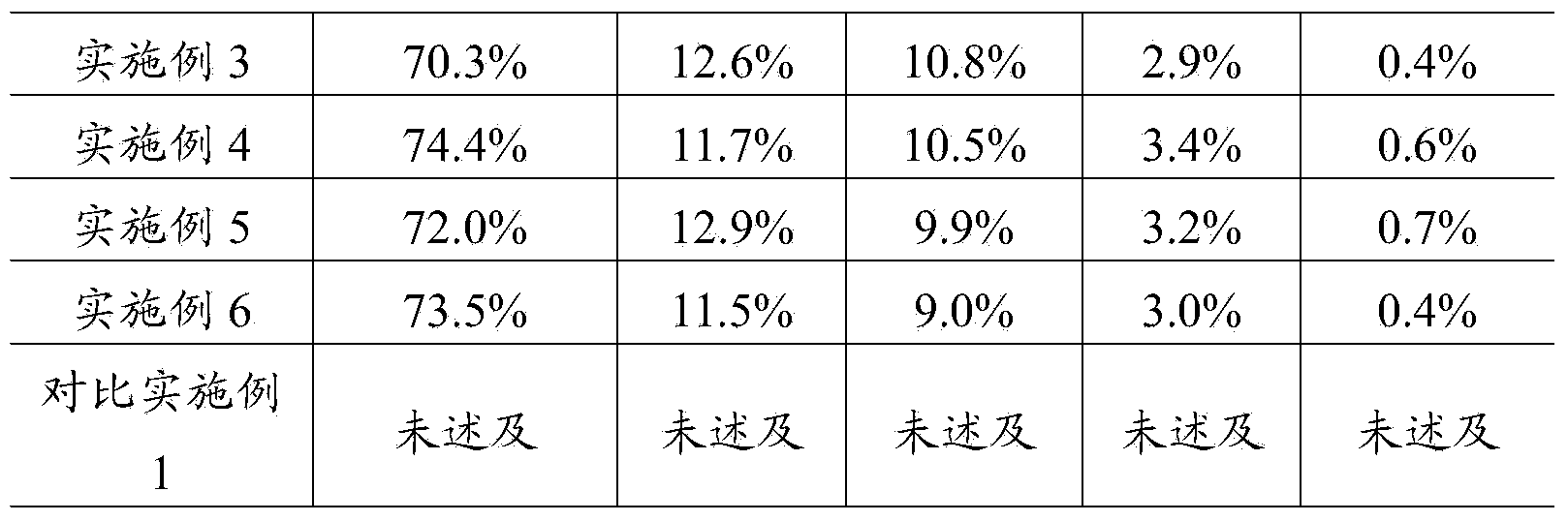

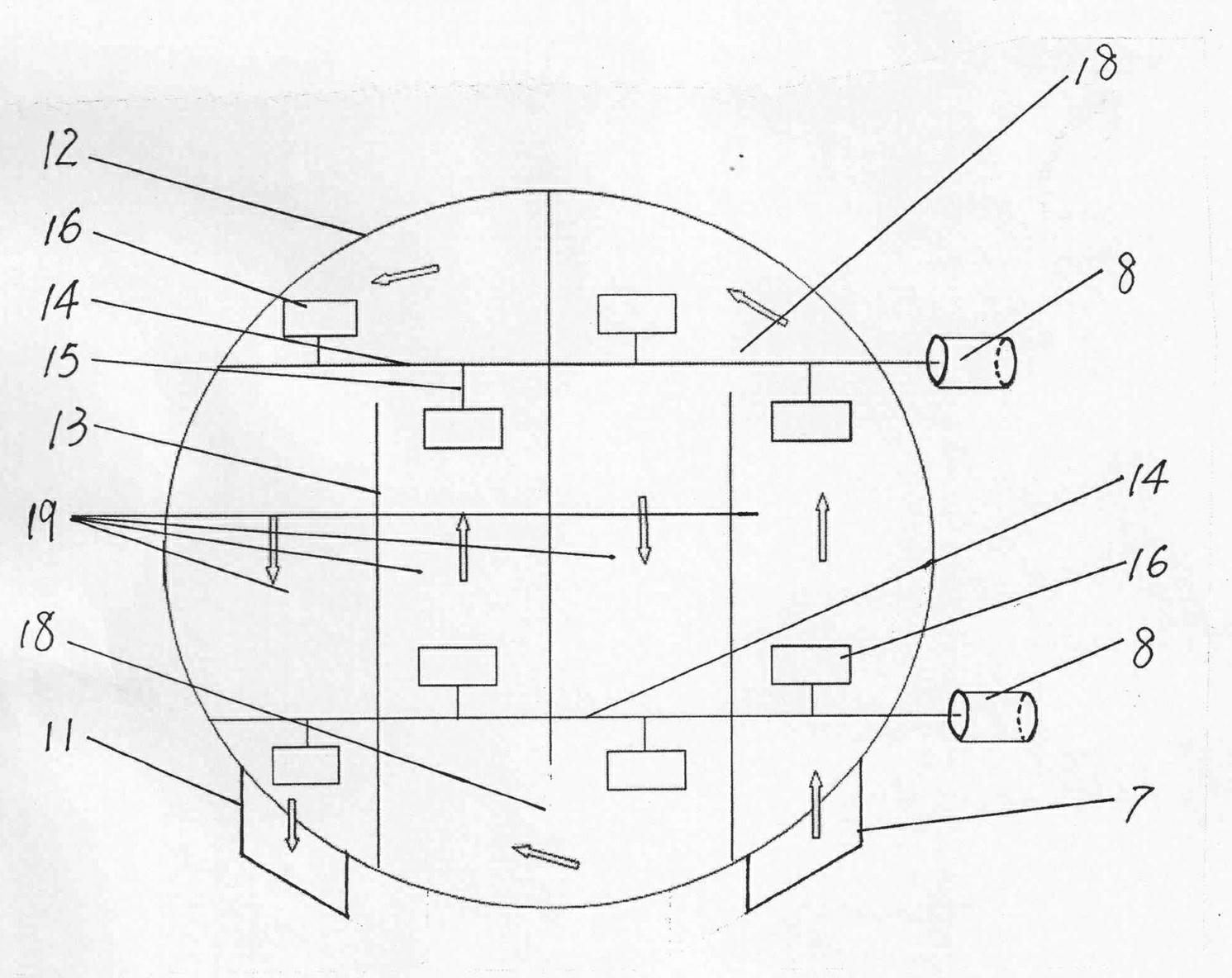

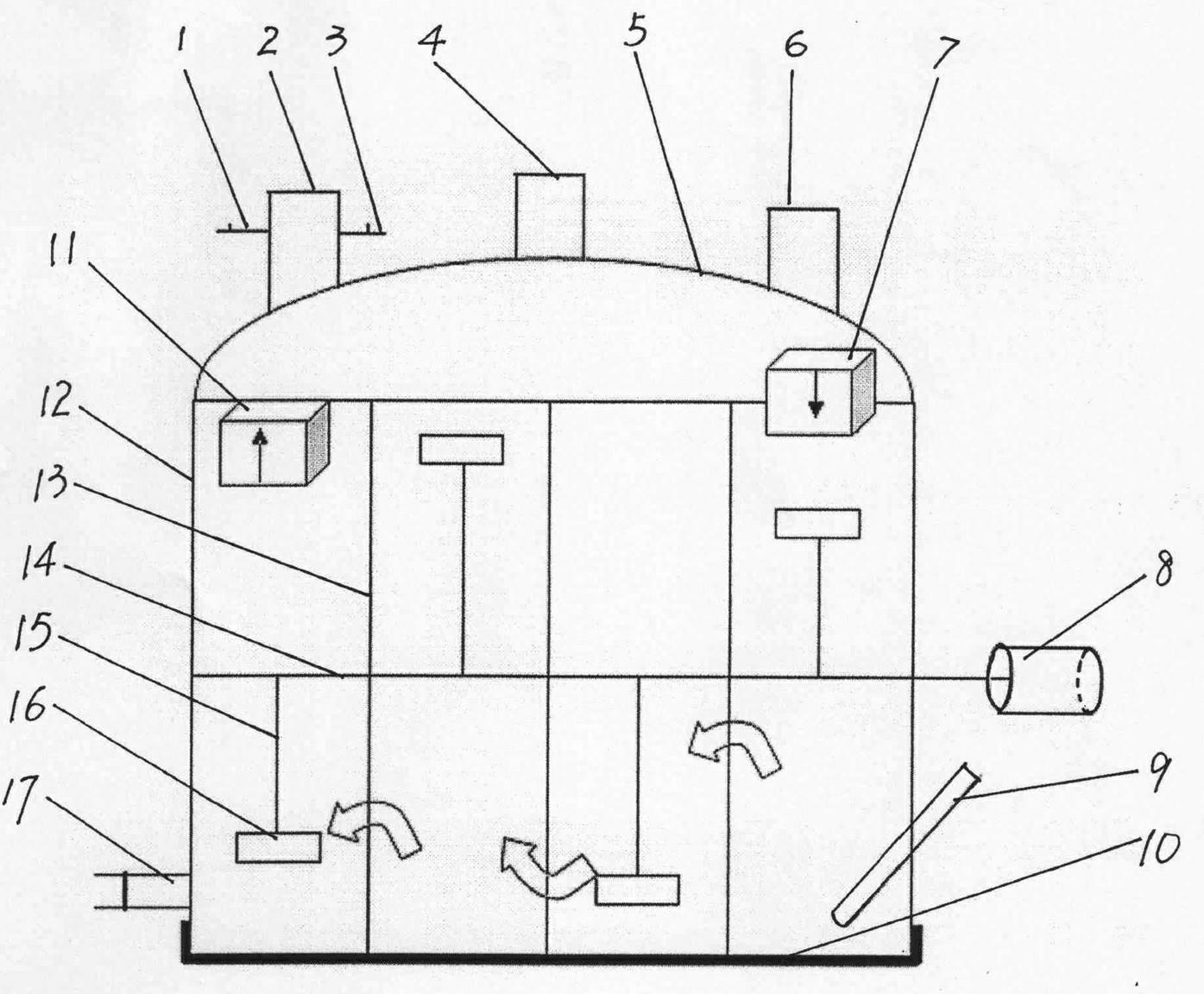

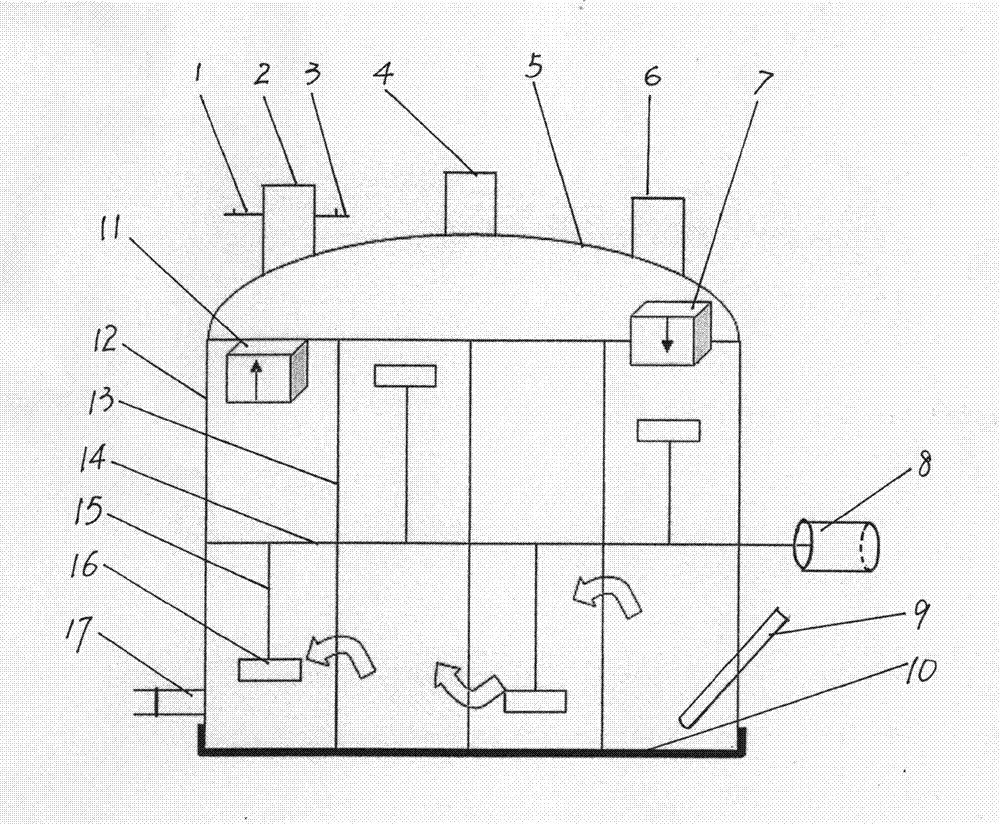

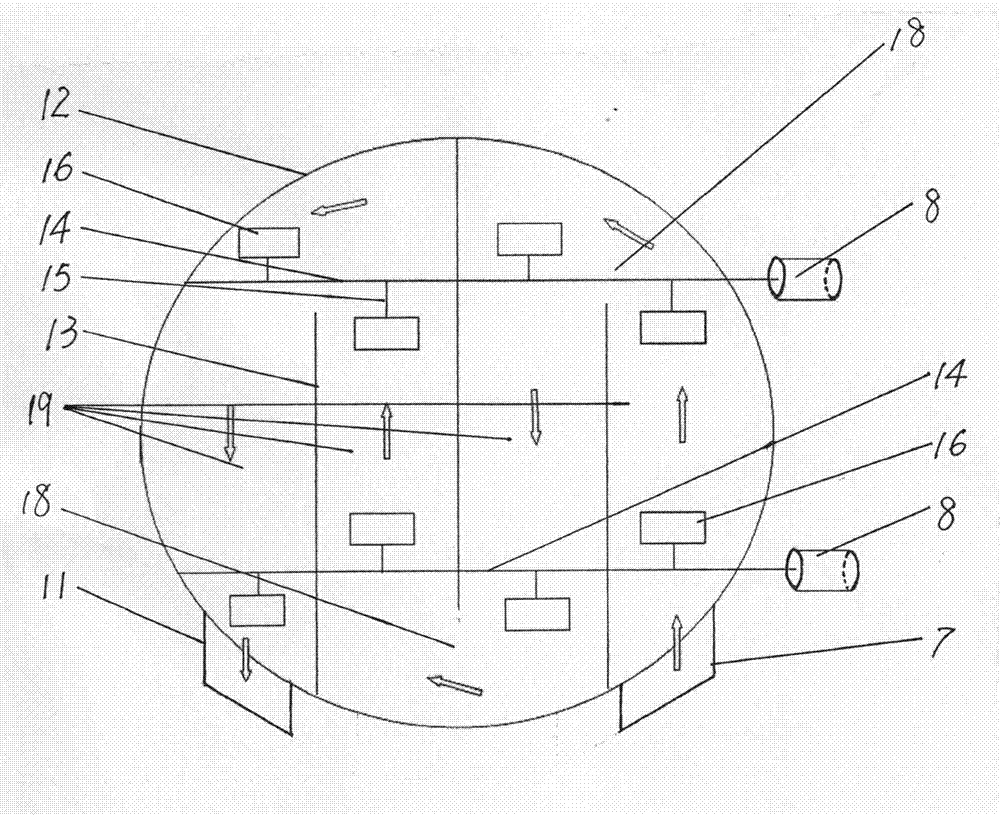

Horizontal stirring methane fermentation device with vertical cylindrical tank

ActiveCN102321528ALow thermal conductivityLow costBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateBiochemical engineering

The invention relates to a horizontal stirring methane fermentation device with a vertical cylindrical tank. The device is a cylindrical vertical fermentation tank, wherein clapboards are longitudinally arranged in a tank body and parallel to one another; the middle part of the tank body is provided with at least one group of horizontal stirrers; a feeding hole is formed outside the tank body corresponding to the first clapboard; a discharge hole is formed outside the tank body corresponding to the last clapboard, is lower than the feeding hole and is connected with a liquid delivery pipeline; an overhaul well is arranged outside the semispherical top of the tank body; and a gas guide pipe and a gas exhaust pipe are arranged on the side wall of a shaft of the overhaul well. The device effectively solves the problems of miniaturization, low concentration, high construction cost, high operating cost, incomplete reaction, abnormal gas production in winter and the like of the conventionalmethane tank, effectively solves the problems of direct current and non-uniform mixing, is high in gas production rate, cannot be incrusted, is low in operating cost and construction cost, and is particularly suitable for the large-scale industrial, intensive and commercial production of methane.

Owner:朱林

Rectifying and refining process of synthetic coarse methanol

InactiveCN1931807AIncrease feed concentrationReduce the amount of waterOrganic compound preparationHydroxy compound preparationAlcoholWastewater

The rectifying and refining process of synthetic coarse methanol includes the following steps: initial rectification of coarse methanol in a pre-rectifying tower with sodium hydroxide and extracting water fed from the tower top, and discharging the initially rectified methanol through the tower bottom while exhausting light impurity through the tower top; rectification in the pressurized tower and recovering rectified methanol from the tower top while exhausting waste water and discharging residual coarse methanol; rectification in the normal pressure tower and recovering rectified methanol while exhausting hetero alcohol oil from the side of the tower and returning industrial soft water from the tower bottom to the pre-rectifying tower. The present invention has low steam consumption and circular utilization of industrial soft water.

Owner:ZHEJIANG UNIV

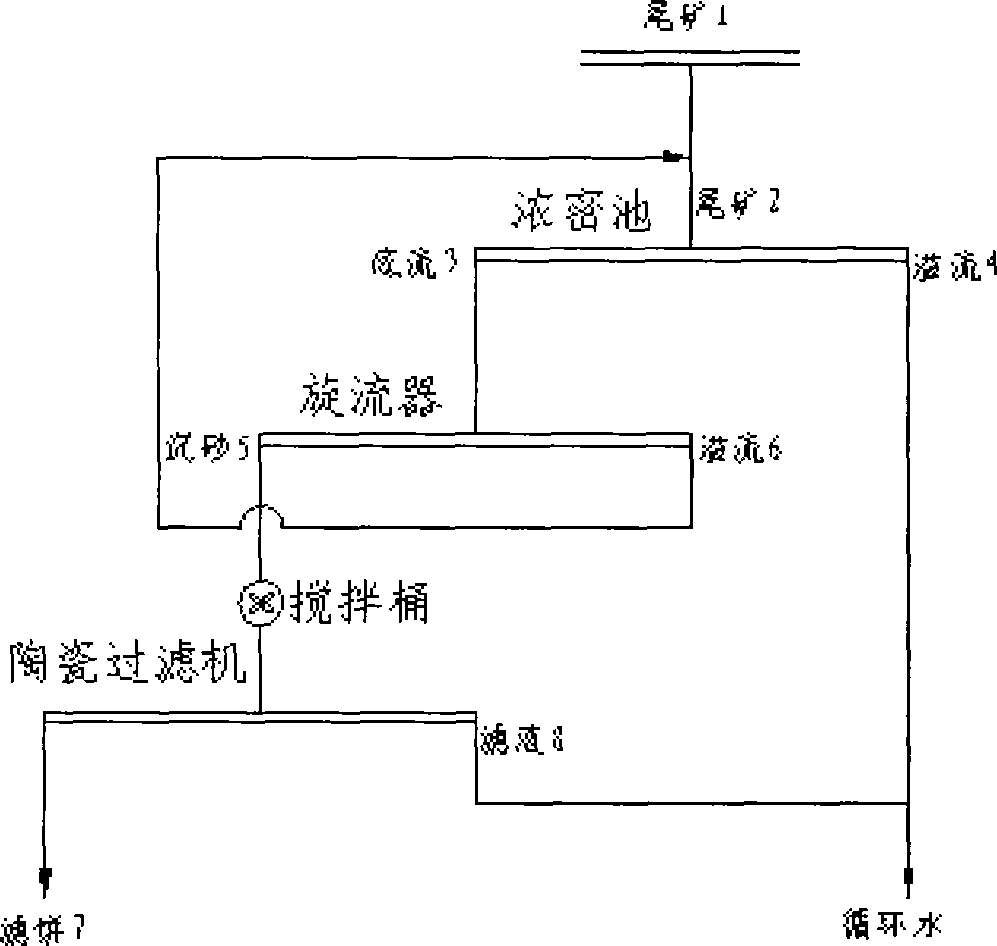

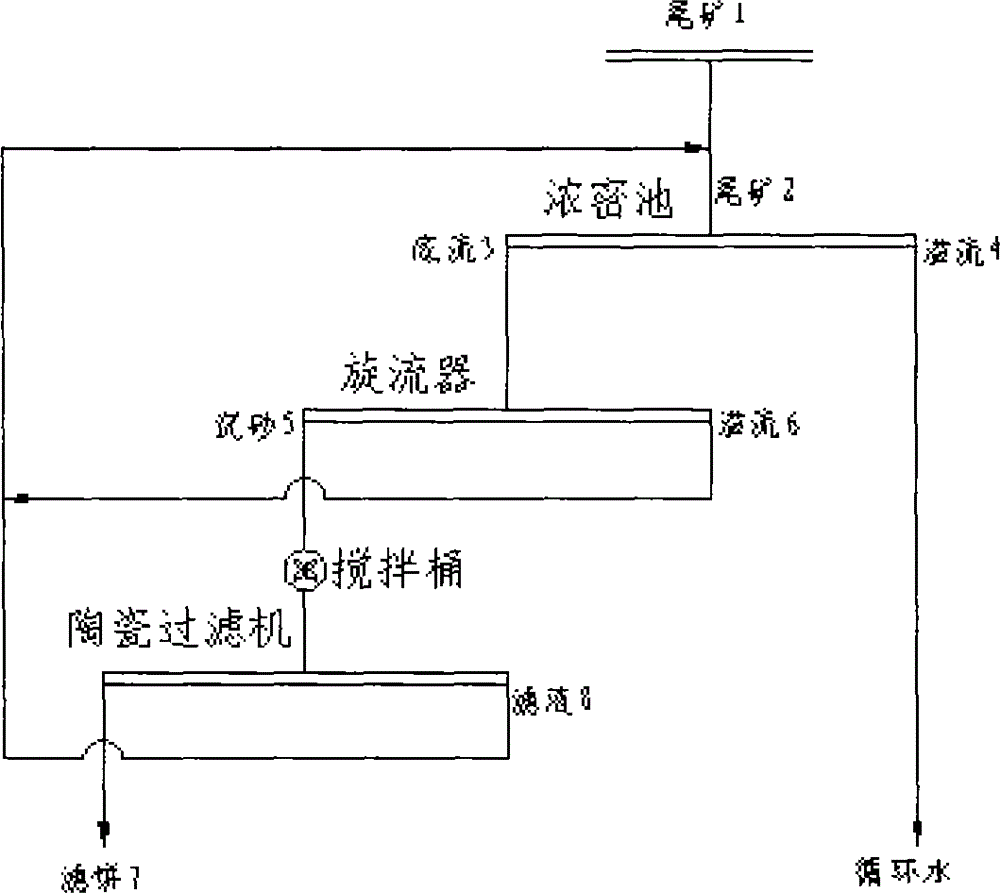

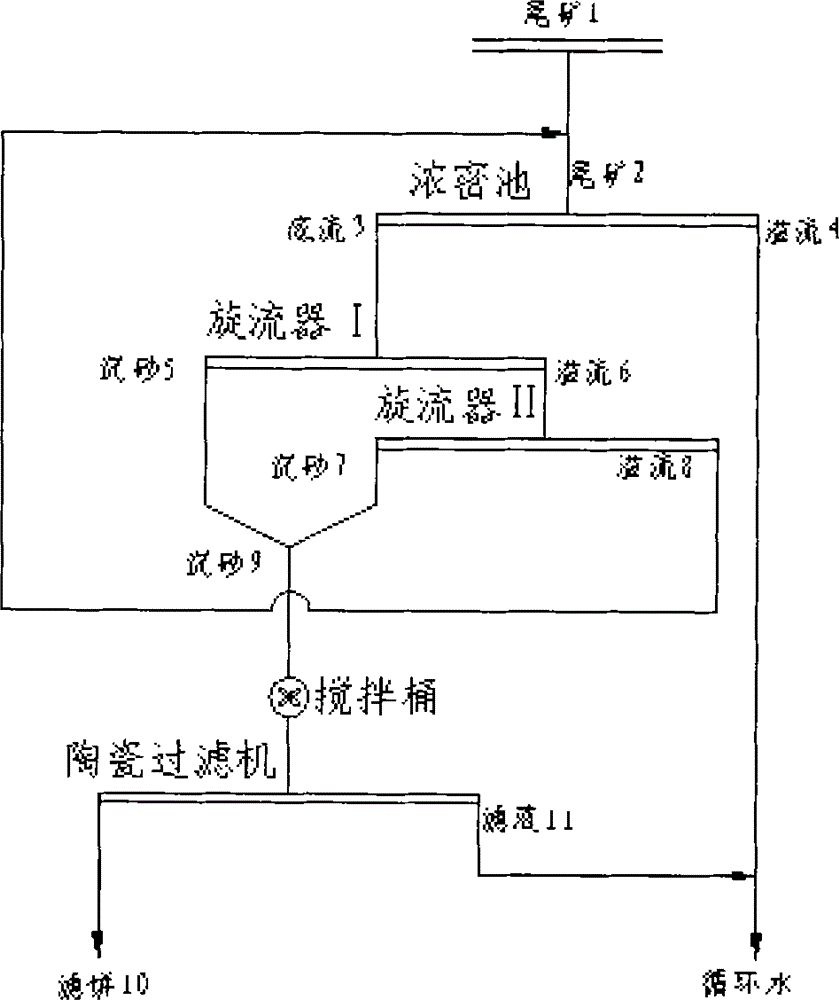

A thickening and dewatering method for tailings and applications thereof

InactiveCN105363275AIncrease feed concentrationImprove dehydration efficiencyFiltration circuitsMaterials scienceTailings

The invention relates to a thickening and dewatering method for tailings. The method is suitable for thickening and dewatering fine-granule tailings adopting dry stockpiling or a comprehensive utilization plan. According to the method, tailings fed into a stirring barrel are subjected to secondary thickening by adopting a hydrocyclone so as to increase the concentration of tailings fed into a ceramic filter, overflow of the hydrocyclone and filtrate of the ceramic filter are returned to a thickening pond and mixed with fine-granule tailings discharged from an ore dressing process so as to reduce the concentration of the tailings and to increase the deposition speed of the tailings, thus finally achieving the objectives of increasing the efficiency of the ceramic filters and reducing the cost of dewatering.

Owner:范思远 +1

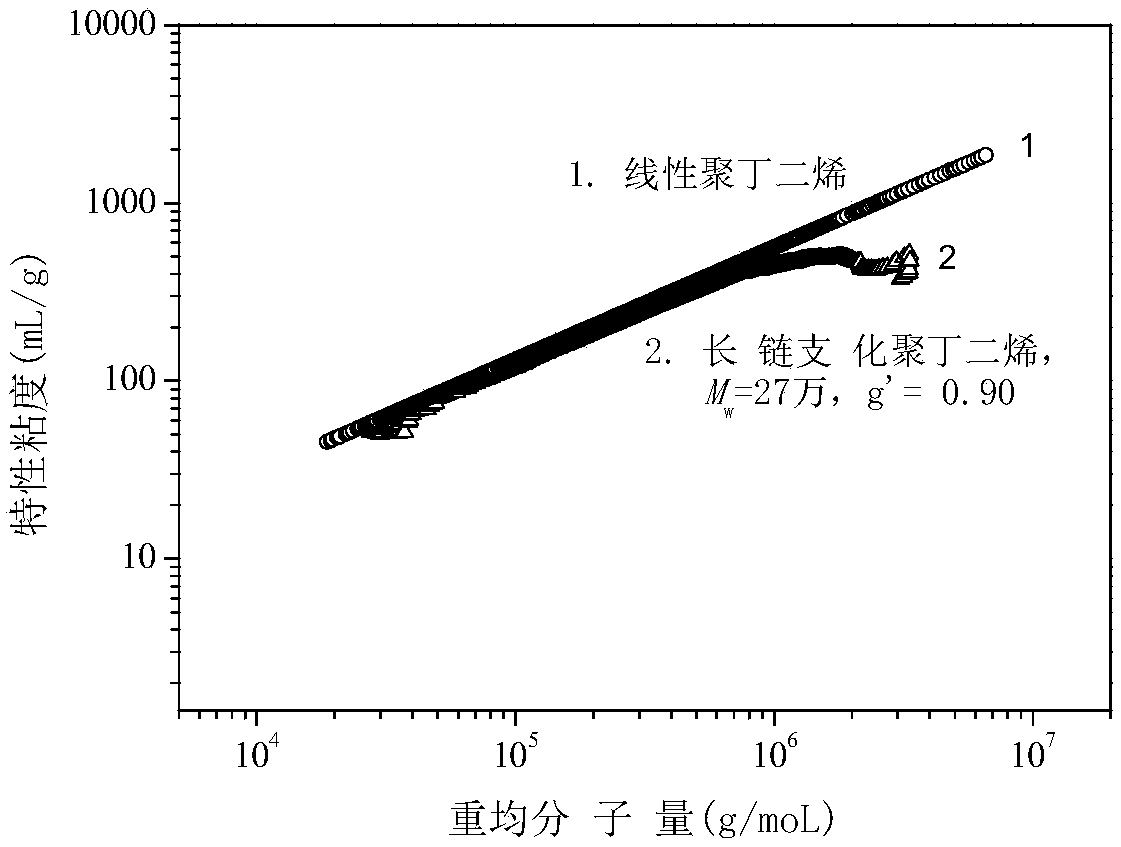

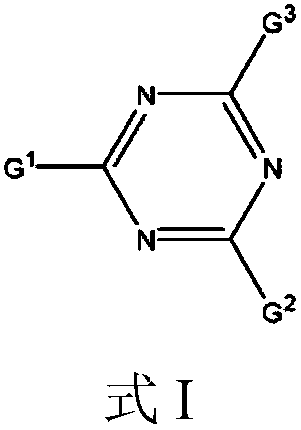

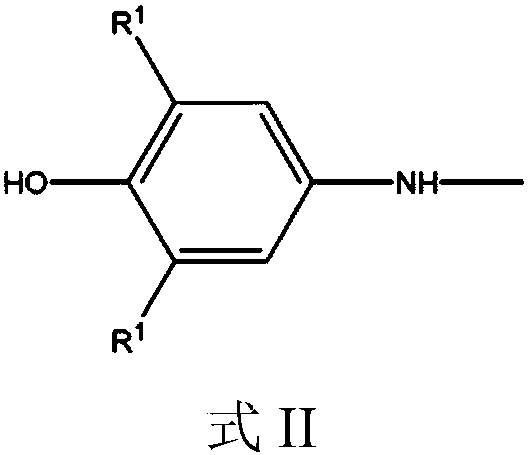

Rare earth metal catalyst system and method for preparing high cis-conjugated diene polymer

ActiveCN108929396AEliminate the process of cross-linking reactionEasy to preparePolymer scienceHalogen

The invention relates to the field of rare earth metal catalysts, and provides a rare earth metal catalyst system and a method for preparing a high cis-conjugated diene polymer. The catalyst includes:(A) rare earth salts, (B) organic aluminum compounds, (C) at least one of halogen-containing hydrocarbon compounds and halogen-containing carboxylic ester compounds, (D) C6-C20 carboxylic acids, (E)compounds with phenolic hydroxyl groups, and (F) conjugated olefin compounds, wherein the molar ratio of all the components is A:B:C:D:E:F=1:(7-30):(0.8-20):(0.1-4.5):(1.0*10<-6>-8.0*10<-4>):(0-700).The method includes the steps: under the protection of inert gas, the catalyst makes contact with conjugated olefin monomers, and the conjugated olefin monomers are initiated to carry out coordinationpolymerization reaction to prepare the linear or long-chain branched high cis-conjugated diene polymer. The branching degree of the obtained polymer can be adjusted in a wide range. The method is simple and high in efficiency.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of edible rice protein

ActiveCN103404688AImprove the efficiency of separation and washingSave washing waterVegetable proteins working-upCycloneFood sector

The invention relates to a preparation method of edible rice protein. The method comprises the following steps of pre-treating raw materials, crushing, mixing, reacting, separating and washing, drying and the like. According to the method provided by the invention, macromolecular dextrin in rice dreg is washed by using hot water before being aged; impurities in the rice dreg can be separated from protein which is not dissolved in water by crushing and a salt forming reaction of fat; then a cyclone is used for separating and washing so that the separating and washing efficiency is greatly improved; compared with flash drying and spray drying, the preparation method has the advantages that the equipment investment is saved by about 40% and the operation cost is saved by about 35%; the edible rice protein with the protein dry basis content more than 90%, fat content less than 2% and ash content less than 2% is obtained; the extraction rate of the rice protein is more than 85%; the obtained product can be widely applied in food industries, particularly infant foods; compared with a manner of using the raw material rice dreg as a feed, the preparation method has the advantage that the added value of products is greatly increased.

Owner:无锡新禾创工食品科技有限公司

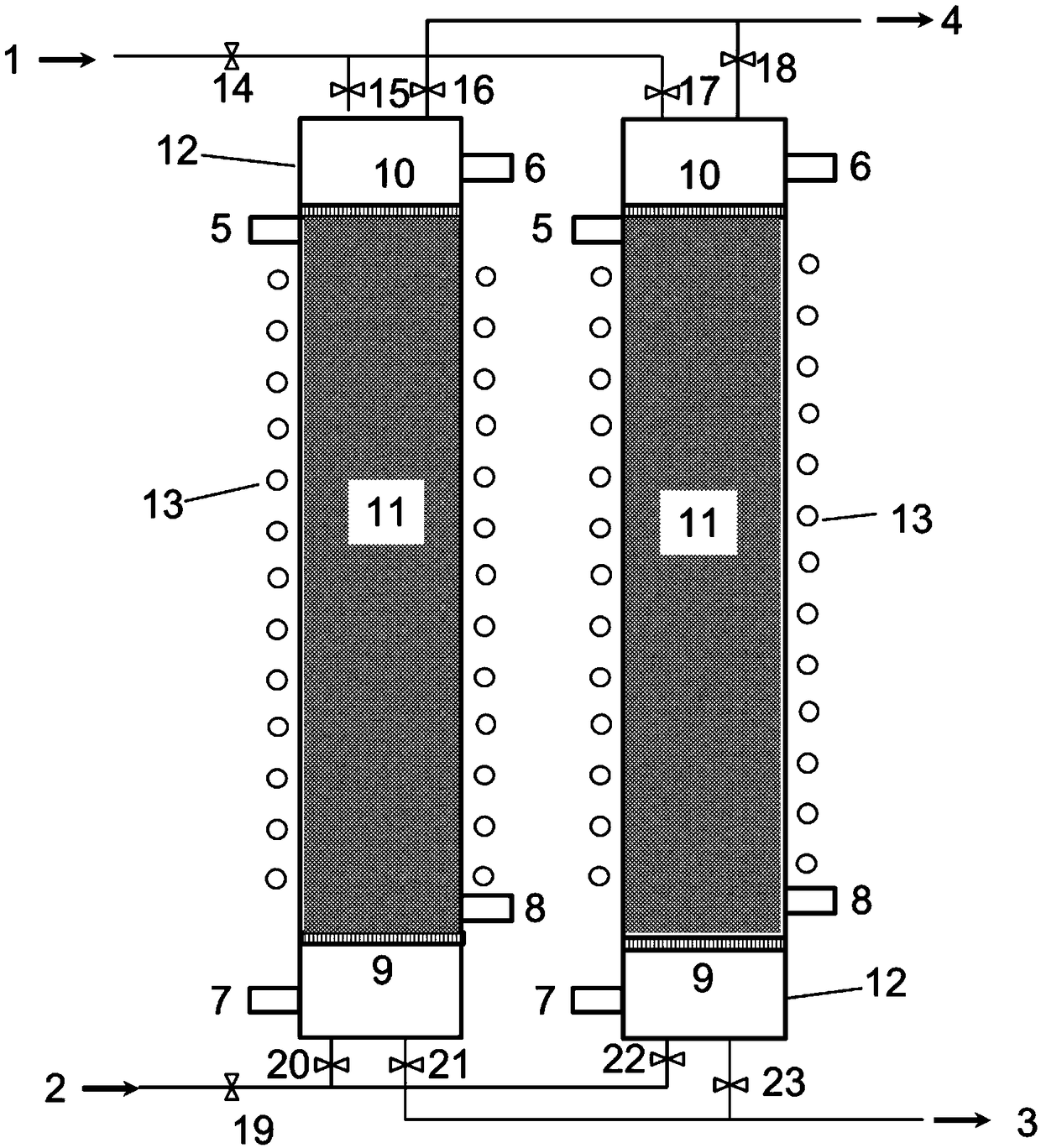

Macroporous resin and ion exchange device for adsorbing high-concentration rhenium

ActiveCN109336998AReduce the degree of crosslinkingShorten the diffusion pathCation exchanger materialsOther chemical processesHigh concentrationRhenium

The invention discloses macroporous resin for adsorbing high-concentration rhenium. The macroporous resin for adsorbing the high-concentration rhenium is prepared by the following preparation steps: preparing a macroporous divinyl benzene-methyl acrylate copolymer skeleton by adopting a suspension polymerization method, and then performing chloromethylation on small copolymer spheres; soaking theprepared chlorine spheres in methyl alcohol for swelling after the chlorine spheres are washed and dried; and adding diaminopro to perform amination reaction to obtain macroporous weak alkaline ion exchange resin. The invention also provides a columnar ion exchange device using the resin; a set of heat exchange component is arranged on the periphery of an ion exchange column, so that the temperature of the ion exchange column is reduced to promote the adsorption of rhenium. According to the ion exchange resin and the device provided by the invention, the problems of low adsorption rate and lowexchangeable capacity of the common ion exchange resin under high rhenium concentration and common operation conditions are solved; the rhenium ion exchange efficiency is greatly improved; and high-efficiency enrichment and recycling of the rhenium are promoted.

Owner:ZHEJIANG UNIV OF TECH

Magnetic separation process of fine lean hematite

The invention belongs to the technical field of separation of hematite in ferrous metals and in particular provides a magnetic separation process of fine lean hematite. The process comprises coarse and fine classified overflow and is characterized by comprising the following steps: feeding the coarse and fine classified overflow with concentration being less than 25% into a concentrator before high-intensity magnetic separation, feeding the bottom flow with concentration being 35-40%, which is concentrated by the concentrator before high-intensity magnetic separation into a low-intensity magnetic separator for low-intensity magnetic separation, wherein the overflow in the concentrator before high-intensity magnetic separation is tailing, feeding the concentrates after low-intensity magnetic separation into concentration operation before floatation, feeding the tailing after low-intensity magnetic separation into a slag remover to remove the slag, feeding the concentrates after the slag remover removes the slag into a high-intensity magnetic separator for high-intensity magnetic separation, feeding the high-intensity magnetic concentrates separated by the high-intensity magnetic separator into concentration before floatation and combining the concentrated tailing before high-intensity magnetic separation, the slag removed tailing and the tailing after high-intensity magnetic separation into the final tailings. The process improves the feeding conditions during low-intensity magnetic operation, reduces the number of the low-intensity magnetic separators needing to be operated and reduces the low-intensity magnetic operation and the final tailings grade.

Owner:ANSTEEL GRP MINING CO LTD

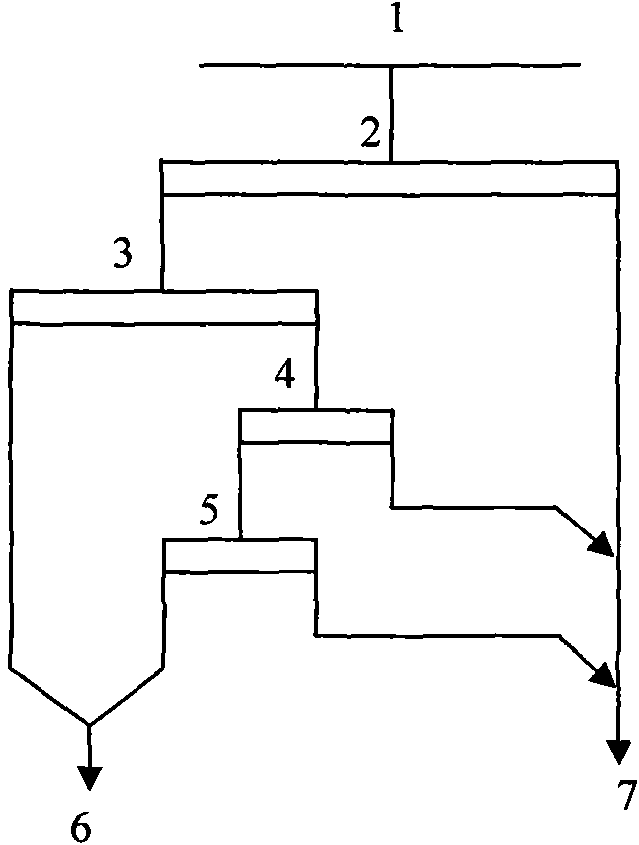

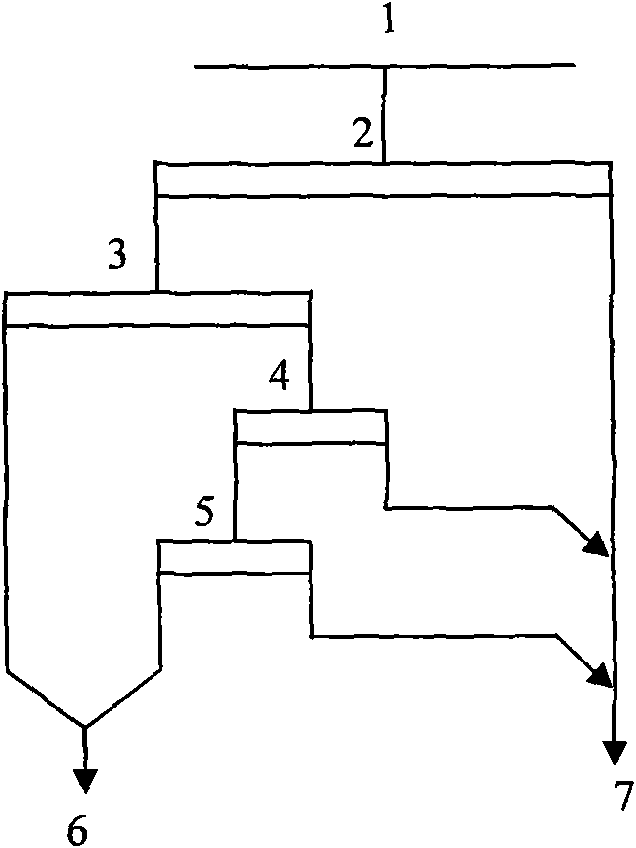

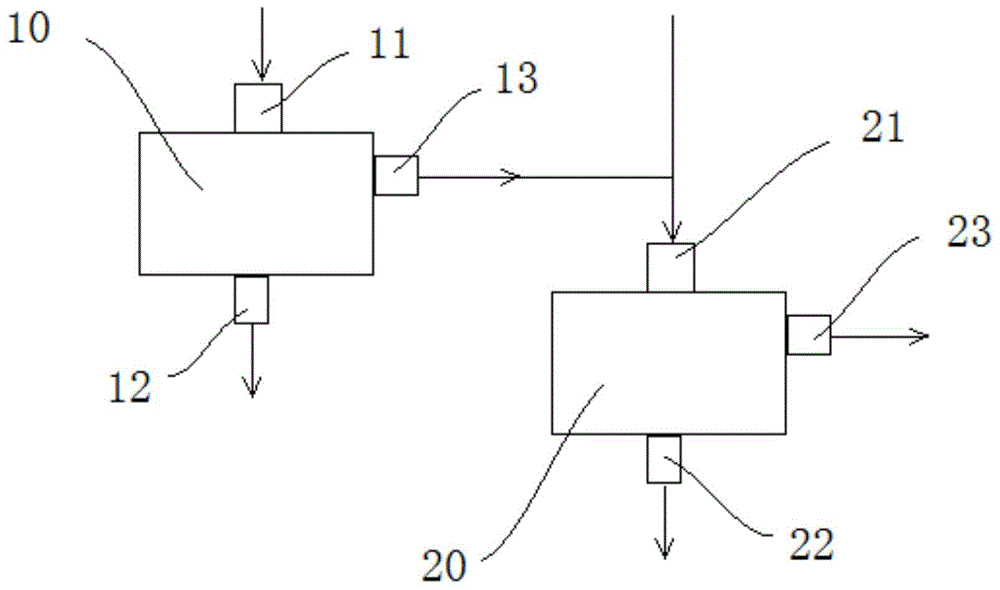

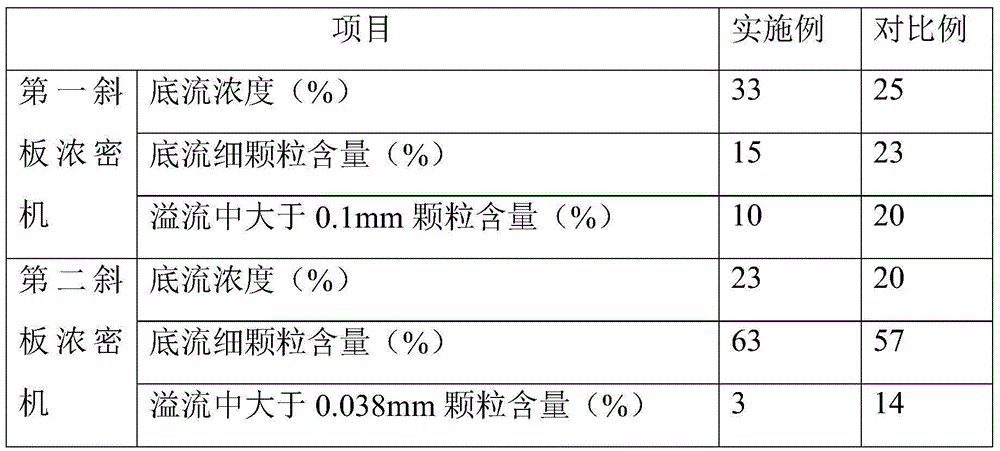

Method and system for concentrating and separating two segments of low-intensity magnetic separation iron tailings to obtain ilmenite

InactiveCN104923389AReduce workloadHigh underflow concentrationSolid separationSedimentation settling tanksTitaniumSlurry

The invention discloses a method for concentrating and separating two segments of low-intensity magnetic separation iron tailings to obtain ilmenite and a corresponding separation system. The method comprises the following steps: concentrating a first segment of low-intensity magnetic separation iron tailings by using a first sloping-plate thickener (10), and thus obtaining first overflow and first underflow as a coarse ilmenite raw material; mixing the first overflow with a second segment of low-intensity magnetic separation iron tailings, then feeding the mixture into a second sloping-plate thickener (20) for concentration, and thus obtaining second underflow as a fine ilmenite raw material and second overflow as slurry. The concentrations of the first underflow and the second underflow are increased, the particle size separation effect of the first underflow and the second underflow is better, and the phenomenon of coarse particle overflowing of the first overflow and the second overflow is decreased.

Owner:PANGANG GRP MINING

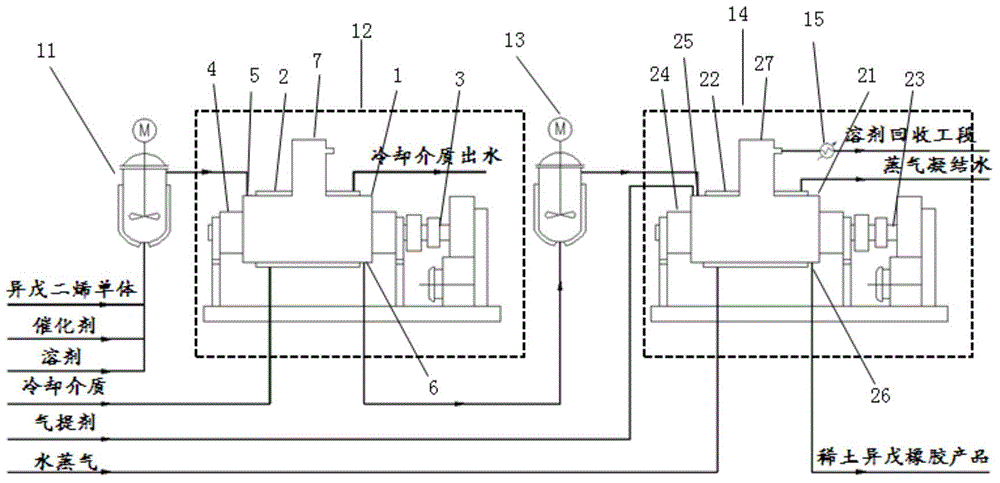

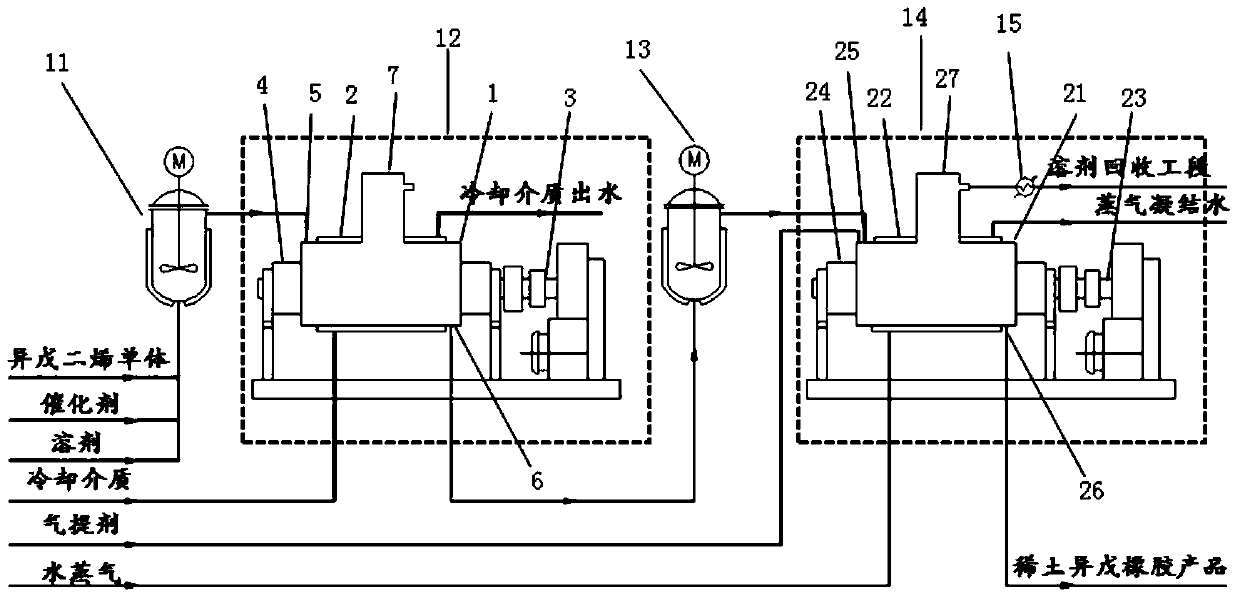

Method of producing rare earth isoprene rubber

The invention discloses a method of producing rare earth isoprene rubber, wherein the method includes the steps of: in the presence of a solvent and under a solution polymerization reaction condition, performing a contact reaction to an isoprene monomer with a rare earth catalyst in a first horizontal bi-axial stirring mixer to obtain a mixture; and performing devolatilization to the mixture in a second horizontal bi-axial stirring mixer. The two horizontal bi-axial stirring mixers are both operated in an isothermal manner. Through the method, not only is material feeding concentration of the isoprene monomer improved but also the rare earth isoprene rubber liquid can be directly devolatilized. The method is free of addition of hot water in the rubber liquid, so that rubber granules are free of dehydration, thereby greatly reducing energy and material consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

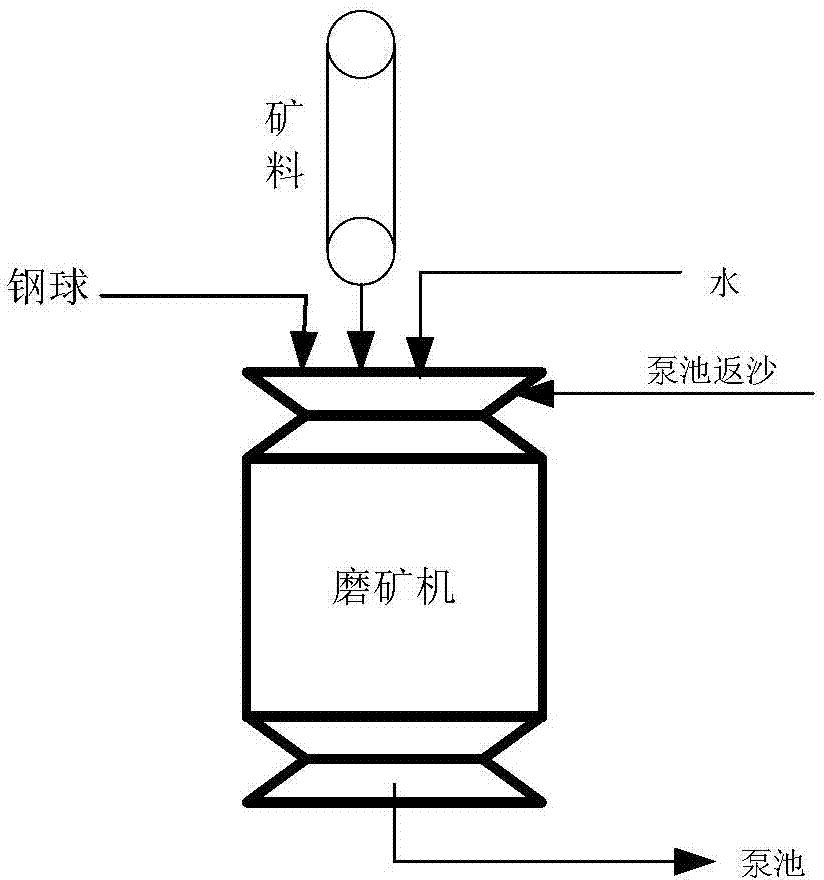

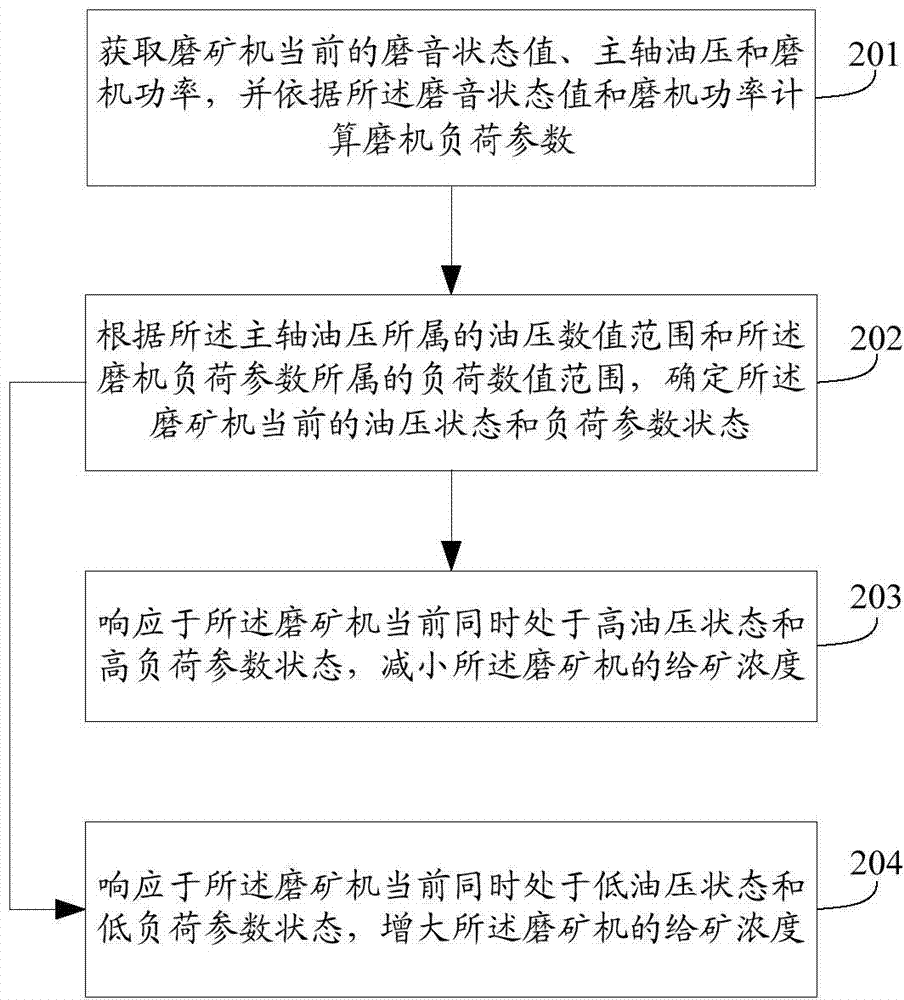

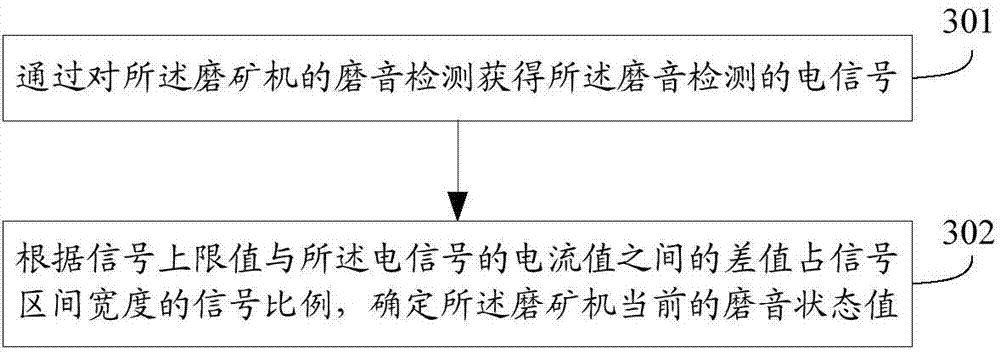

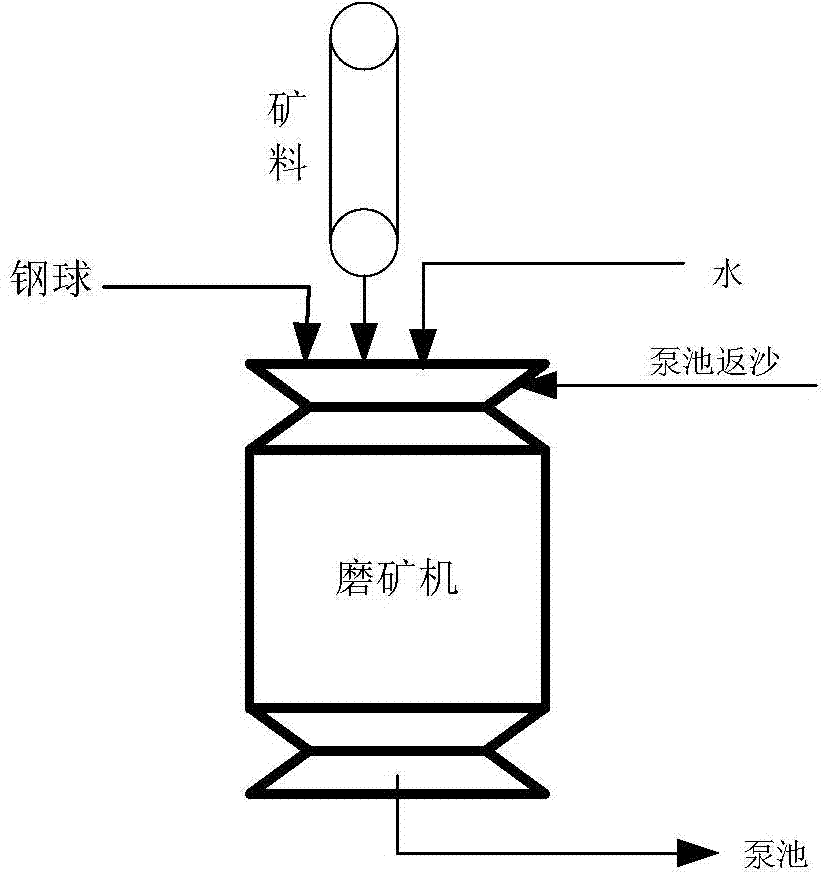

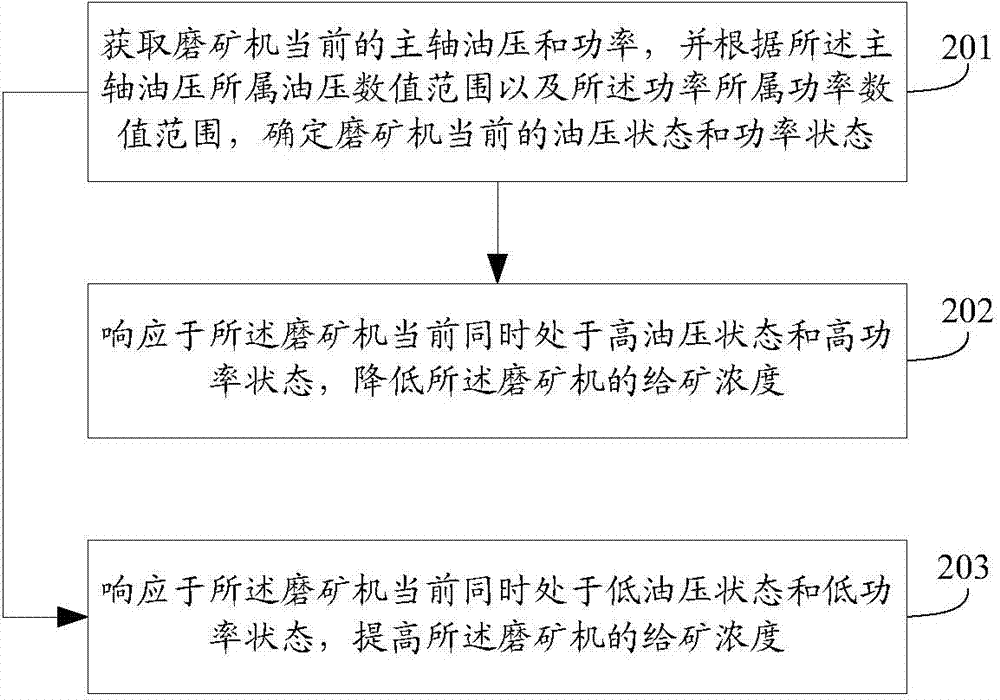

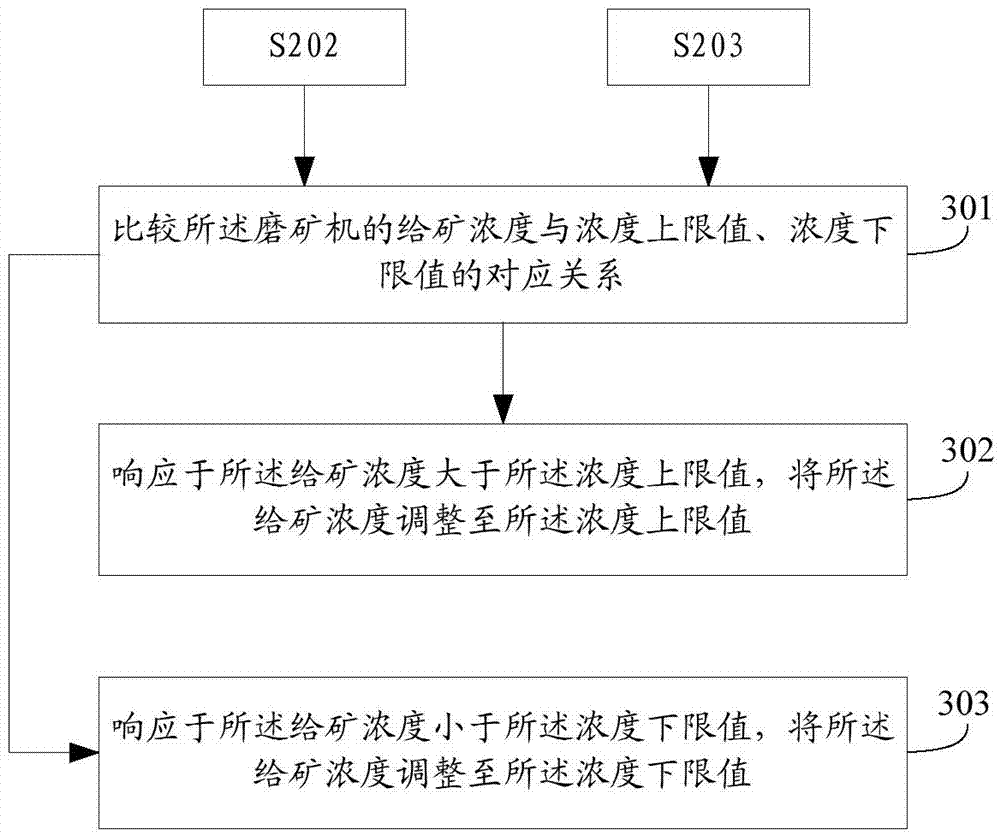

Method and device for controlling feeding concentration of ore grinder

The invention discloses a method and a device for controlling feeding concentration of an ore grinder. The method comprises the following steps of obtaining a current sound grinding state value of the ore grinder, an oil pressure of a main shaft and an ore grinder power, and calculating a load parameter of the ore grinder according to the current sound grinding state value and the ore grinder power; determining the current oil pressure state and a load parameter state of the ore grinder according to an oil pressure numerical range of the oil pressure of the main shaft and a load numerical range of the ore grinder; reducing the feeding concentration of the ore grinder in response to a high oil pressure state and a high load parameter state that the ore grinder are simultaneously positioned currently; and increasing the feeding concentration of the ore grinder in response to a low oil pressure state and a low load parameter state that the ore grinder is simultaneously positioned currently. According to the technical scheme provided by the invention, when the load state of the ore grinder is high, the feeding concentration is reduced, the load of the ore grinder is reduced, and a mine material is fully smashed; when the load state of the ore grinder is low, the feeding concentration is improved, the efficiency of an ore grinding process is improved, and the energy consumption of the unit ton finished ore is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

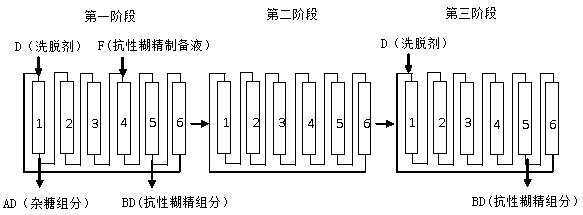

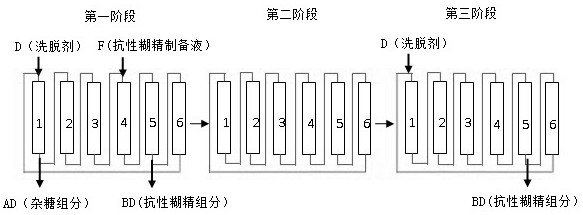

Sequential simulated moving chromatographic purification method for resistant dextrin

The invention relates to a sequential simulated moving chromatographic purification method for resistant dextrin. According to the method, a resistant dextrin preparation liquid is taken as a raw material and contains 40% of resistant dextrin and 40% by mass of impurity sugars; concentration of the pretreated resistant dextrin preparation liquid is regulated to be 60%, and deionized water is usedas an eluent; for sequential simulated moving chromatographic purification of the resistant dextrin preparation liquid, in a first stage, the resistant dextrin preparation liquid and the eluent are fed into a system simultaneously, and discharge is performed at the same time; in a second stage, materials are not fed or discharged, large cycle is performed, and liquid flows from column 1 to column6; in a third stage, only the deionized water as the eluent is fed from the column 1, and part of resistant dextrin components is discharged from a discharge port in the lower end of column 5; a feedport, an eluent feed port, a first discharge port and a second discharge port are moved to next column from the column 1 to the column 6 sequentially to repeat purification cycle until purification isended. The process has low operation cost, and continuous production can be realized.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

A kind of preparation method of edible rice protein

ActiveCN103404688BImprove the efficiency of separation and washingSave washing waterVegetable proteins working-upFood industryCyclone

Owner:无锡新禾创工食品科技有限公司

Method for preparing ethanol by one-step fermentation after ion liquid stage treatments from native cellulose material

InactiveCN101298620BAchieve full utilizationReduce accumulationBiofuelsMicroorganism based processesHigh concentrationNatural fiber

The invention relates to a method that prepares ethanol through the grading processing with ionic liquids and one-step zymolysis and utilizes a raw material of native cellulose. The raw material of native cellulose is orderly processed by the ionic liquids A and B so as to respectively remove hemicellulose and lignin, and the obtained cellulose is used as a substrate so as to be further fermentedto prepare the ethanol; the ionic liquid A is an acid or alkalic ionic liquid, the ionic liquid B is a halogenated-imidazole-like ionic liquid. The method utilizes the ionic liquids to implement the grading processing of the raw material of native cellulose, removes the substances of the hemicellulose and the lignin that are harmful to the zymolysis production of the ethanol, uses the substances for other purposes, and only utilizes the cellulose as the substrate so as to implement the ethanol zymolysis, thus realizing complete utilization of the raw material of native cellulose. Simultaneously the method can avoid adsorption of the hemicellulose and the lignin by cellulose enzyme and improve the activity of the cellulose enzyme; the accumulation of the substances that are not fermented in a reactor is reduced, and the method can realize continuous zymolysis in a long time, has high input concentration, recycles yeast and cellulose enzyme, has high concentration of recycled ethanol, and saves water.

Owner:HENAN UNIV OF SCI & TECH

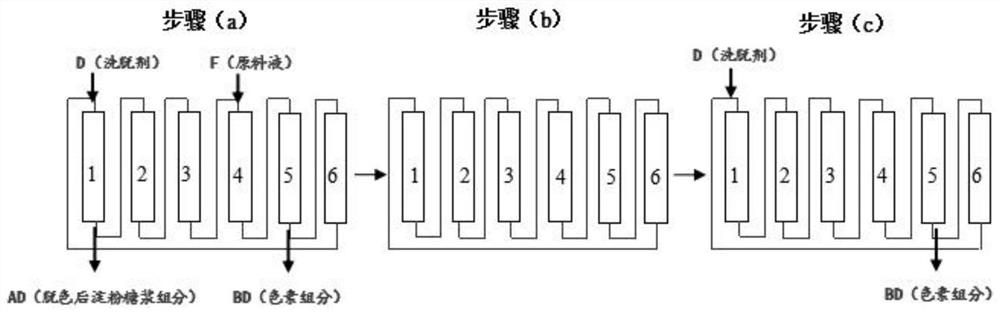

Starch syrup decolorization method based on simulated moving chromatography

ActiveCN114213477ASmall footprintIncrease feed concentrationSugar derivativesDisaccharidesFood industryProcess engineering

The invention discloses a starch syrup decolorizing method based on simulated moving chromatography, and belongs to the technical field of food industry. The method comprises the following steps: blending starch syrup to 20-30wt% to obtain a raw material solution, and decolorizing the raw material solution on simulated moving chromatography equipment by taking deionized water as an eluent. The decolorization treatment comprises the following specific steps: (a) feeding a raw material solution and an eluent into a system at the same time, and discharging; (b) carrying out major circulation when the materials are not fed or discharged; and (c) only adding an eluent to carry out small circulation. When the method is used for decolorization treatment, the decolorization rate of starch syrup reaches 70% or above, the high yield is achieved, and the product quality is remarkably improved. The whole process is low in operation cost, low in production energy consumption and high in automation degree; and continuous industrial production can be realized, and the production efficiency is improved.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

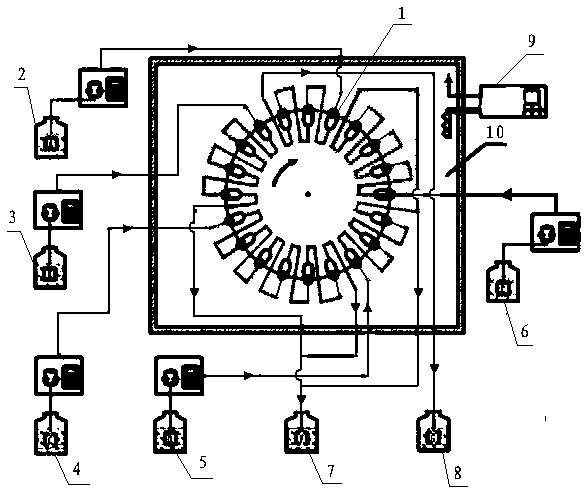

Method for purifying anthocyanin of black kidney bean peel through simulated moving bed chromatography

ActiveCN109336858AReduce dosageIncrease profitOrganic chemistryBulk chemical productionDesorptionFreeze-drying

The invention relates to a method for purifying anthocyanin of black kidney bean peel through simulated moving bed chromatography. The method comprises the following steps: preparing an anthocyanin extract from the black kidney bean peel, pretreating, then adjusting the concentration of the anthocyanin extract to 100-300mg / mL, and conveying into simulated moving bed chromatography equipment; purifying the pretreated anthocyanin extract through the simulated moving bed chromatography, wherein simulated moving bed chromatography equipment consists of 20 chromatographic columns and is divided into an adsorption zone, a refining zone, a desorption zone, a regeneration zone and a water washing zone, the numbers of the chromatographic columns in the five zones are 6, 4, 3, 4 and 3 respectively,and the zones are serially connected; all the zones work at the same time during operation, each chromatographic column moves by one column position clockwise after the operating time reaches the switching time, and continuous operation is achieved by operating in such a way; the obtained purified anthocyanin is further concentrated in vacuum and freeze-dried to obtain refined anthocyanin. By themethod, continuous production can be achieved and the production efficiency is improved.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

High-purity rice bran protein and rice bran fibers and preparation method thereof

Owner:格乐瑞(无锡)营养科技有限公司

Method and device for controlling ore feeding concentration of ore grinding machine

ActiveCN103480465AIncrease raw ore processing capacityReduce feed concentrationGrain treatmentsEngineeringEnergy consumption

The invention discloses a method and a device for controlling an ore feeding concentration of an ore grinding machine. The method comprises the following steps: obtaining current main shaft oil pressure and power of the ore grinding machine and determining a current oil pressure state and a current power state of the ore grinding machine according to an oil pressure numerical value range of the main shaft oil pressure and a power numerical value range of the power; as response to the condition that the ore grinding machine is at a high-oil-pressure state and a high-power state simultaneously and reducing the ore feeding concentration of the ore grinding machine; and as response to the condition that the ore grinding machine is at a low-oil-pressure state and a low-power state simultaneously and improving the ore feeding concentration of the ore grinding machine. According to the technical scheme provided by the invention, when the load state of the ore grinding machine is too high, the ore feeding concentration can be reduced so as to reduce the load of the ore grinding machine and crush mineral aggregates sufficiently, and when the load state of the ore grinding machine is too low, the ore feeding concentration is improved so that the yield and the efficiency of an ore grinding process are improved and the energy consumption of concentrates per tonnage is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Production technology of high-grade molybdenum concentrate

ActiveCN101773871BReduce pollutionIncrease feed concentrationFlotationWet separationConcentration ratioBall mill

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

A traditional Chinese medicine compound preparation for promoting angiogenesis

ActiveCN107281449BImproving and Regulating Imbalance ProcessesReasonable compositionPowder deliveryPharmaceutical non-active ingredientsMedicinal herbsOfficinalis

The invention provides a Chinese herbal medicine compound preparation for promoting angiogenesis. The Chinese herbal medicine compound preparation contains the following components in parts by weight: 65 parts of main herb including radix peucedani, radix rehmanniae preparata and bighead atractylodes rhizome at weight ratio of 3:1:1, ministerial drug including 10-12 parts of arisaema aridum, 10-12 parts of radix ophiopogonis, 8-12 parts of elecampane, 6-8 parts of fructus aurantii and 6-8 parts of schisandra chinensis, adjuvant including 30-50 parts of corns officinalis, 20-40 parts of tea tree root and 10-15 parts of fresh ginger and conductant drug including 12 parts of radix paeoniae alba. The Chinese herbal medicine compound preparation provided by the invention is based on the principle of assistant and guide, the composition is reasonable in compatibility, various medicinal materials mutually coordinate and match with one another and the Chinese herbal medicine compound preparation has toxicity-reducing and synergic effect and has excellent angiogenesis adjusting activity. A spray drying technology is adopted and the compound ingredients prepared from dextrin, galactose, lactitol and SiO2 are added into the Chinese traditional medicine extract provided by the invention, so that the wall adhering phenomenon in the spray drying process of the Chinese traditional medicine extract is improved under the synergic effect, and meanwhile, the feeding concentration of the spray drying is increased and the time and energy consumption of the spray drying are obviously reduced.

Owner:YANTAI UNIV

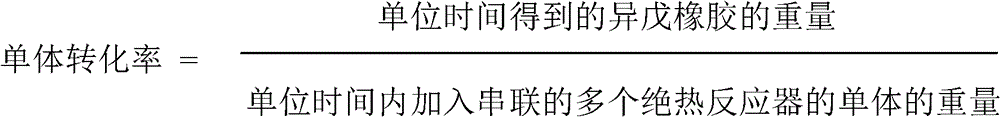

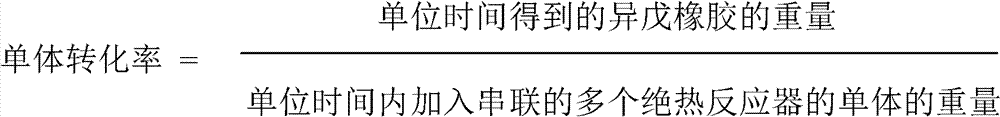

A kind of isoprene rubber and its continuous production method

The invention provides a continuous production method of isoprene rubber and the isoprene rubber produced thereby. The method is carried out in a plurality of adiabatic reactors which are connected in series. The method comprises the following steps of: continuously feeding a reactant containing isoprene, a rare earth catalyst and a solvent from a first adiabatic reactor of the plurality of series-connected adiabatic reactors; refilling the solvent to at least one of the adiabatic reactor following the first adiabatic reactor in order to polymerize isoprene to obtain a rubber solution; and treating the rubber solution by coagulating, dewatering and drying in sequence, wherein an isoprene monomer in the material fed in the first adiabatic reactor is at the concentration of 14 to 50 wt%; and the rare earth catalyst contains neodymium carboxylate with 7 to 14 carbon atoms, aluminum alkyl, halide and conjugated diene. According to the method, the output can be increased, the monomer conversion rate of isoprene reaches more than 96%, and the prepared isoprene rubber contains at least 98wt% of cis-1,4-structure based on the content.

Owner:CHINA PETROLEUM & CHEM CORP +1

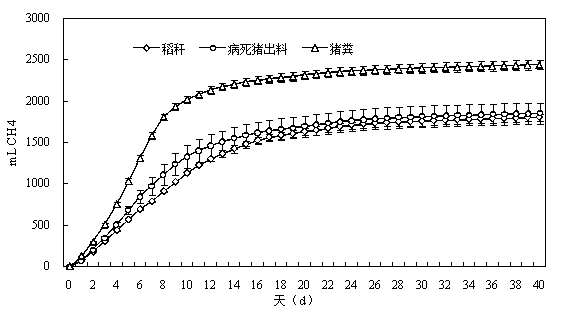

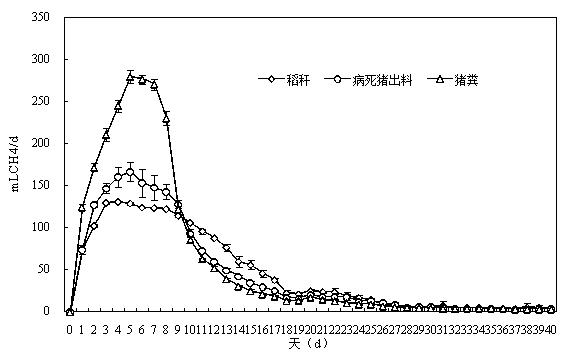

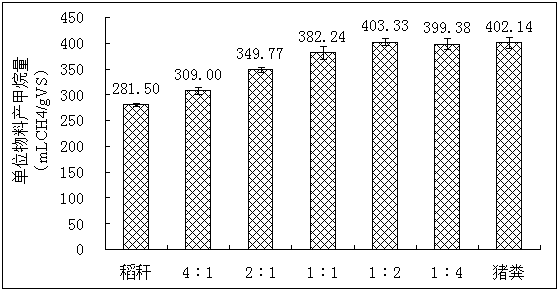

High concentration multi-feedstock mixed anaerobic fermentation method

InactiveCN109680014AIncrease feed concentrationHigh solvent gas generation rateWaste based fuelFermentationRice strawDigestion

The invention discloses a high concentration multi-feedstock mixed anaerobic fermentation method, and belongs to the field of renewable energy development and utilization. The method includes the following steps that: pig manure is subjected to precipitation and degritting in a homogenization tank, preheated and put into a fermenter for anaerobic fermentation; rice straw is pretreated in a hydrolysis tank and put into the fermenter for anaerobic fermentation; pigs that die from disease are treated by high temperature digestion for harmless treatment, and the discharged materials enter into thehomogenization tank and are preheated and put into the fermenter for anaerobic fermentation. The method has the advantages of simple method, strong adaptability and simple operation, and can realizecontinuous, large-volume, automatic production and processing, and greatly improve the production efficiency of methane.

Owner:江西省农业科学院农业应用微生物研究所

A method for purifying resistant dextrin by sequential simulated mobile chromatography

The invention relates to a method for purifying resistant dextrin by sequential simulated mobile chromatography. The method uses a preparation solution of resistant dextrin as a raw material, wherein the content of resistant dextrin is 40%, and the mass content of miscellaneous sugars is 40%. After pretreatment, the concentration of the resistant dextrin preparation solution is adjusted to 60%, and the eluent is deionized water; the pretreated resistant dextrin preparation solution is purified by sequential simulated mobile chromatography, the first stage: the system simultaneously enters the resistant dextrin preparation solution Dextrin preparation liquid, enter eluent, and discharge; second stage: the material does not enter and exit, and a large cycle is carried out, and the direction of liquid flow is from column 1 to column 6; third stage: only enter eluent for deionization Water, eluent deionized water into column 1, part of the resistant dextrin component from the outlet at the lower end of column 5; feed inlet, eluent inlet, first outlet, and second outlet Move to the next column sequentially along the direction of column 1 to column 6, and repeat the purification cycle until the purification is completed. The process of the invention has low operating cost and can be continuously produced.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

A kind of method for preparing rare earth isoprene rubber

The invention discloses a method for preparing rare-earth isoprene rubber. The method comprises: in the presence of a solvent and under the conditions of solution polymerization, isoprene monomer and rare-earth catalyst are mixed in a first horizontal twin-shaft stirring mixer The contact reaction is carried out within the contact reaction, and then the mixture obtained after the contact reaction is devolatilized in the second horizontal twin-shaft stirring mixer; wherein, the first horizontal twin-shaft stirring mixer and the second horizontal twin-shaft stirring mixer Stirring mixers were all operated isothermally. Using the method for preparing rare earth isoprene rubber provided by the present invention can not only increase the feed concentration of isoprene monomer, but also directly devolatilize the obtained rare earth isoprene rubber glue, and at the same time, because it does not introduce Hot water does not need to dehydrate the colloidal particles, which greatly reduces energy and material consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

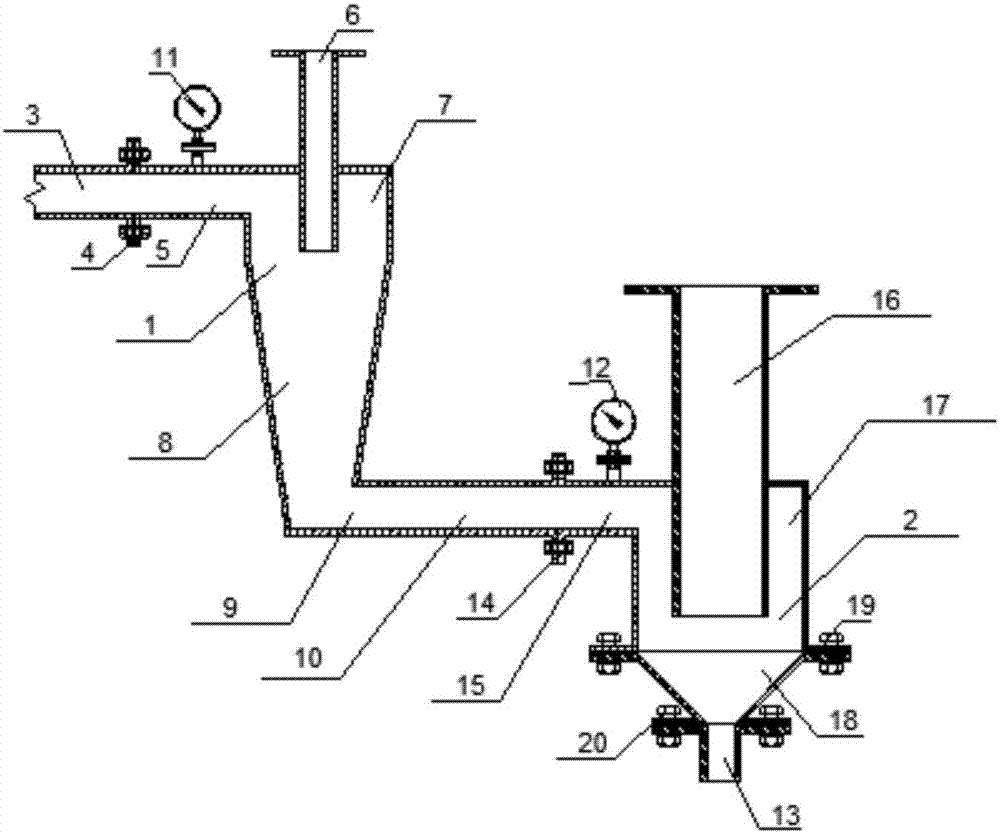

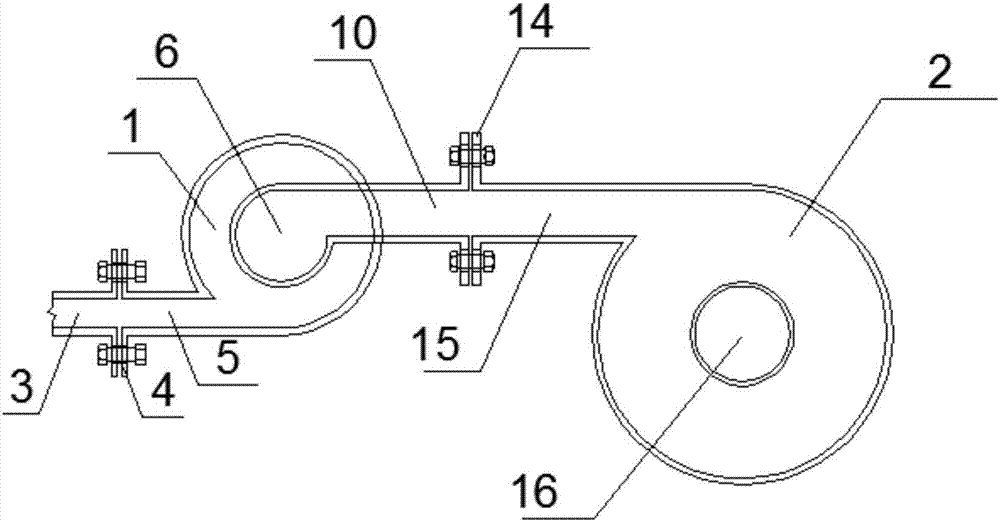

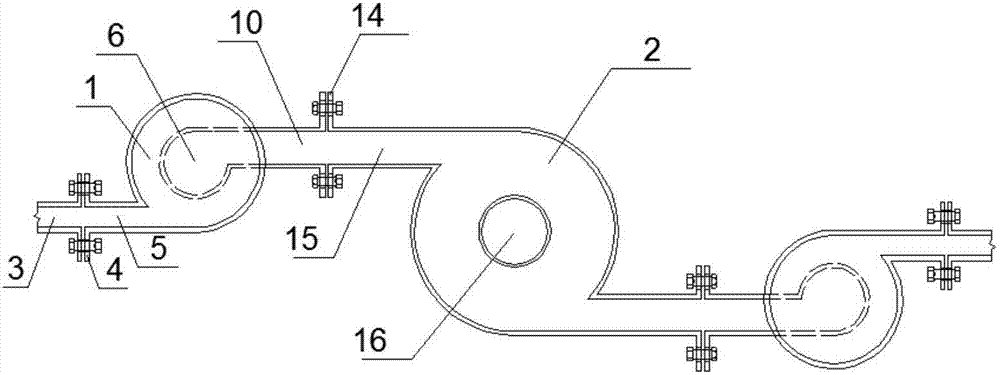

Concentration and separation two-section cyclone

PendingCN107020205AIncrease feed concentrationImprove sorting effectReversed direction vortexWet separationGastric tube feedingProcess systems

The invention discloses a concentration and separation two-section cyclone. The innovation point is that the concentration and separation two-section cyclone is formed by combining a concentration cyclone and a water medium separation cyclone in series, and the concentration cyclone and the water medium separation cyclone are separately arranged; and the concentration cyclone is positioned at the lateral upper side of the water medium separation cyclone. Each of the concentration cyclone and the water medium separation cyclone comprises elements such as a feeding tube, a barrel body, a cone body, an overflow tube, a bottom-flow tube and a flange plate; and a bottom flow hole of the concentration cyclone is connected with the feeding tube of the water medium separation cyclone through a connecting tube. The concentration cyclone can improve concentration of fed materials of the water medium separation cyclone, and also discharges a portion of fine particles, so that the separation effect of the water medium separation cyclone is improved. The concentration and separation two-section cyclone disclosed by the invention can be used for simplifying a process system of a coal preparation plant, is convenient to manage, is small in floor space, and reduces mounting cost and production operation cost.

Owner:SHANDONG UNIV OF SCI & TECH

Horizontal stirring methane fermentation device with vertical cylindrical tank

ActiveCN102321528BLow thermal conductivityLow costBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateBiochemical engineering

Owner:朱林

Isoprene rubber and continuous production method thereof

The invention provides a continuous production method of isoprene rubber and the isoprene rubber produced thereby. The method is carried out in a plurality of adiabatic reactors which are connected in series. The method comprises the following steps of: continuously feeding a reactant containing isoprene, a rare earth catalyst and a solvent from a first adiabatic reactor of the plurality of series-connected adiabatic reactors; refilling the solvent to at least one of the adiabatic reactor following the first adiabatic reactor in order to polymerize isoprene to obtain a rubber solution; and treating the rubber solution by coagulating, dewatering and drying in sequence, wherein an isoprene monomer in the material fed in the first adiabatic reactor is at the concentration of 14 to 50 wt%; and the rare earth catalyst contains neodymium carboxylate with 7 to 14 carbon atoms, aluminum alkyl, halide and conjugated diene. According to the method, the output can be increased, the monomer conversion rate of isoprene reaches more than 96%, and the prepared isoprene rubber contains at least 98wt% of cis-1,4-structure based on the content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com