Starch syrup decolorization method based on simulated moving chromatography

A technology that simulates mobile chromatography and starch syrup, applied in the field of food industry, can solve the problems of high efficiency and decolorization of starch syrup, and achieve the effect of increasing resin utilization, less eluent consumption, and high outlet concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

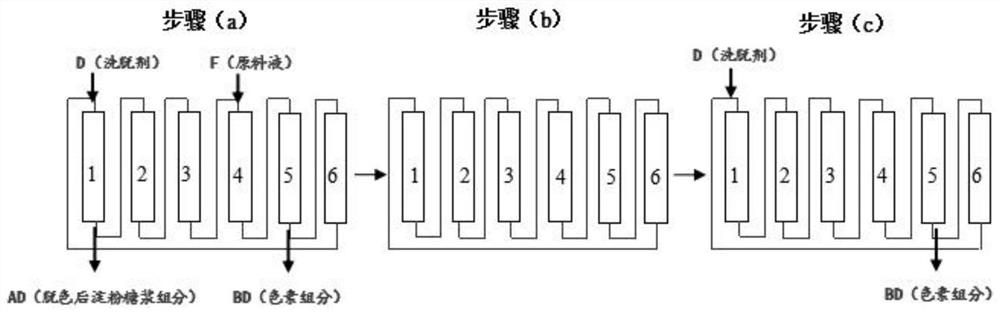

[0037] Such as figure 1 As shown, the simulated mobile chromatographic equipment used in this embodiment is composed of 6 chromatographic columns (inner diameter 35mm, length 1000mm), the volume of each chromatographic column is 1L, and the volume of 6 chromatographic columns is 6L in total. Discharge. The decolorization of starch syrup is realized through the following steps:

[0038] (A) Raw material preparation: adding water to the filtered starch syrup to obtain a raw material solution;

[0039] (B) Simulated mobile chromatographic decolorization: the raw material liquid obtained above is decolorized through simulated mobile chromatographic equipment, and the decolorization method is as follows:

[0040] (a) feed raw material liquid, eluent, and discharge at the same time: column 1 enters the eluent port and enters eluent D (deionized water), and the first discharge port at the lower end of column 1 exits component AD (starch after decolorization) syrup component); the ...

Embodiment 2

[0047] Such as figure 1 As shown, the simulated mobile chromatographic equipment used in this embodiment is composed of 6 chromatographic columns (inner diameter 35mm, length 1000mm), the volume of each chromatographic column is 1L, and the volume of 6 chromatographic columns is 6L in total. Discharge. The decolorization of starch syrup is realized through the following steps:

[0048] (A) Preparation of raw materials: adding water to the filtered starch syrup to obtain a raw material solution;

[0049] (B) Simulated mobile chromatographic decolorization: the raw material liquid obtained above is decolorized through simulated mobile chromatographic equipment, and the decolorization method is as follows:

[0050] (a) Feed raw material liquid, eluent, and discharge at the same time: column 1 enters eluent port and enters eluent D (deionized water), and column 1 lower end discharge port 1 exits component AD (starch syrup after decolorization) Component); the raw material liqui...

Embodiment 3

[0057] Such as figure 1 As shown, the simulated mobile chromatographic equipment used in this embodiment is composed of 6 chromatographic columns (inner diameter 35mm, length 1000mm), the volume of each chromatographic column is 1L, and the volume of 6 chromatographic columns is 6L in total. Discharge. The decolorization of starch syrup is realized through the following steps:

[0058] (A) Raw material preparation: adding water to the filtered starch syrup to obtain a raw material solution;

[0059] (B) Simulated mobile chromatographic decolorization: the raw material liquid obtained above is decolorized through simulated mobile chromatographic equipment, and the decolorization method is as follows:

[0060] (a) feed raw material liquid, eluent, and discharge at the same time: column 1 enters the eluent port and enters eluent D (deionized water), and the first discharge port at the lower end of column 1 exits component AD (starch after decolorization) syrup component); the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com