High concentration multi-feedstock mixed anaerobic fermentation method

An anaerobic fermentation, high-concentration technology, applied in fermentation, biosynthesis, waste fuel, etc., can solve the problems of limiting anaerobic fermentation feed concentration and gas production efficiency, and achieve high solvent gas production rate, stable fermentation state, The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

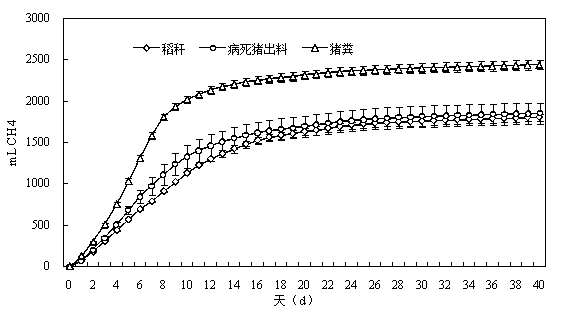

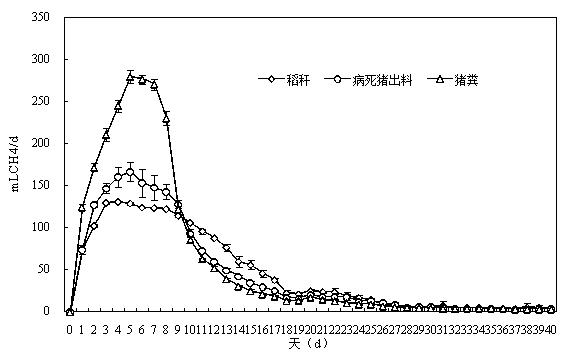

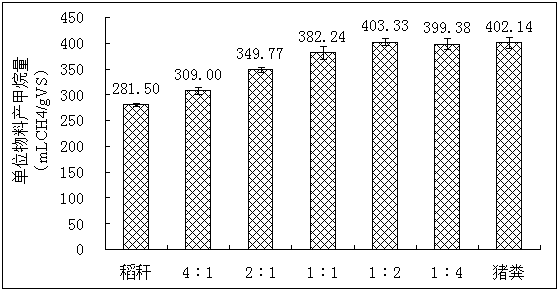

[0042] The high-concentration multi-raw material mixed anaerobic fermentation method comprises the following steps:

[0043] ① After the pig manure settles and removes sand in the homogenization tank, adjust the feed solids concentration (TS) to 6-8%, preheat and enter the fermenter for anaerobic fermentation;

[0044] ② After the rice straw is pretreated in the hydrolysis tank, adjust the feed solids concentration (TS) to 11-13%, and enter the fermenter for anaerobic fermentation;

[0045] ③Dead pigs are harmlessly treated by high-temperature digestion, and the discharged material enters the homogenization tank, and is preheated and enters the fermenter for anaerobic fermentation.

[0046] In steps ①, ②, and ③, VS pig manure in the fermentation tank: VS rice straw = 4:1-1:1, and the solids concentration (TS) of the mixed material is about 10%.

[0047] In step ③, the feeding amount of sick and dead pigs is 1% of the total feeding amount.

[0048] The fermentation temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com