A method for purifying resistant dextrin by sequential simulated mobile chromatography

A technology for simulating mobile chromatography and resistant dextrin, which is applied in the field of sequential simulated mobile chromatography separation and purification, can solve problems such as inability to efficiently and continuously purify resistant dextrin, and achieves increased resin utilization, production efficiency, and operating costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

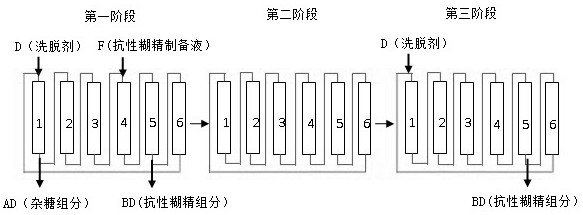

[0029] This sequential simulated mobile chromatography method for the purification of resistant dextrins:

[0030] Using resistant dextrin preparation solution as raw material, the mass content of resistant dextrin in the resistant dextrin preparation solution is 40%, and the mass content of miscellaneous sugars is 40%; the quality of resistant dextrin preparation solution is The percentage concentration is adjusted to 60%, and the eluent is deionized water; the pretreated resistant dextrin preparation solution is sent to the sequential simulated mobile chromatography;

[0031] The pretreated resistant dextrin preparation solution is purified by sequential simulated mobile chromatography, the sequential simulated mobile chromatography includes 6 chromatographic columns, with 1 inlet, 1 inlet for eluent, and the first outlet 1, 1 second outlet, the eluent inlet is at the front end of the corresponding chromatographic column at the first outlet, and the feed inlet is at the fron...

Embodiment 2

[0039] This sequential simulated mobile chromatography method for the purification of resistant dextrins:

[0040] Using resistant dextrin preparation solution as raw material, the mass content of resistant dextrin in the resistant dextrin preparation solution is 40%, and the mass content of miscellaneous sugars is 40%; the quality of resistant dextrin preparation solution is The percentage concentration is adjusted to 60%, and the eluent is deionized water; the pretreated resistant dextrin preparation solution is sent to the sequential simulated mobile chromatography;

[0041]Sequential simulated mobile chromatography for purifying the pretreated resistant dextrin preparation, the sequential simulated mobile chromatography is the same as in Example 1, the process of sequentially simulated mobile chromatography for continuous purification of spectrum resistant dextrin:

[0042] The first stage: feeding material, eluent and discharging at the same time. Column 1 enters eluent ...

Embodiment 3

[0049] This sequential simulated mobile chromatography method for the purification of resistant dextrins:

[0050] Using resistant dextrin preparation solution as raw material, the mass content of resistant dextrin in the resistant dextrin preparation solution is 40%, and the mass content of miscellaneous sugars is 40%; the quality of resistant dextrin preparation solution is The percentage concentration is adjusted to 60%, and the eluent is deionized water; the pretreated resistant dextrin preparation solution is sent to the sequential simulated mobile chromatography;

[0051] Sequential simulated mobile chromatography for purifying the pretreated resistant dextrin preparation, the sequential simulated mobile chromatography is the same as in Example 1, the process of sequentially simulated mobile chromatography for continuous purification of spectrum resistant dextrin:

[0052] The first stage: feeding material, eluent and discharging at the same time. Column 1 enters eluent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com