A kind of method for preparing rare earth isoprene rubber

A technology of rare earth isoprene rubber and isoprene, which is applied in the field of preparing rare earth isoprene rubber, can solve the problems of low feed concentration, large energy and material consumption, and the introduction of a large amount of hot water, so as to increase the feed concentration and reduce the The effect of energy consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

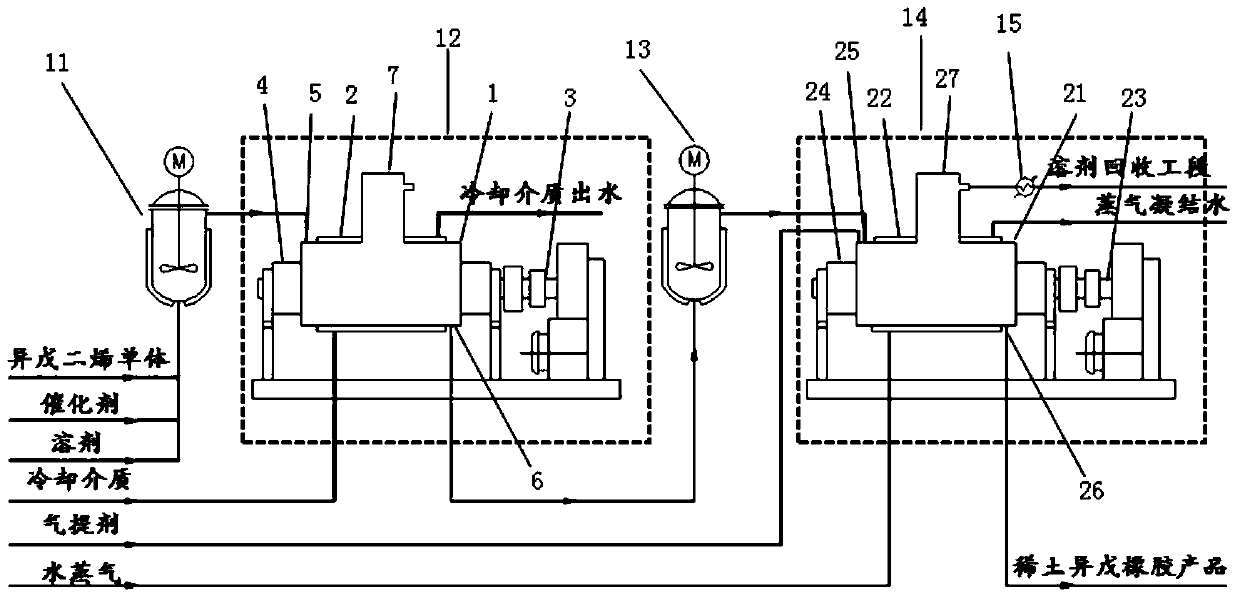

[0026] The method for preparing rare earth isoprene rubber provided by the present invention will be described below in conjunction with the accompanying drawings.

[0027] The solvent, isoprene monomer and catalyst are passed into the premix tank 11 respectively, and premixed at normal temperature. The pre-mixing tank 11 can be a tank-type pre-mixer commonly used in the art.

[0028] The pre-mixed reaction materials are passed into the first horizontal twin-shaft stirring mixer 12 to carry out solution polymerization reaction. Wherein, the structure of the first horizontal twin-shaft stirring mixer 12 may include: a horizontally placed shell 1 with a jacket 2 on the outer surface and two horizontally placed stirring shafts penetrating through the inside of the shell 1 . Wherein, the two stirring shafts are the main stirring shaft 3 and the cleaning shaft 4; the main stirring shaft 3 is attached with a stirring paddle perpendicular to it and has a kneading rod; the cleaning ...

preparation example

[0038] This preparation example is used to prepare the neodymium-based catalysts used in the following examples and comparative examples.

[0039] The preparation method of neodymium series catalyst is as follows:

[0040] Triisobutylaluminum and diethylaluminum chloride were respectively prepared into 2 mol / L solutions with cyclohexane for later use. Then under the protection of nitrogen, add cyclohexane to the aging kettle, then add isoprene and neodymium neodecanoate into the aging kettle, and then add diethylaluminum chloride solution at 50°C under stirring conditions In an aging kettle, react isoprene, neodymium neodecanoate and diethylaluminum chloride at 50°C for 10 minutes; then add triisobutylaluminum solution and age at 50°C for 50 minutes.

[0041] The composition of the obtained neodymium catalyst is: according to the molar ratio of each component, isoprene:neodymium neodecanoate:triisobutylaluminum:diethylaluminum chloride=50:1:10:3. The neodymium catalyst was d...

Embodiment 1

[0043] First, under normal temperature and pressure, use premixing kettle 11 (traditional kettle type premixer, purchased from Beijing Xiandali Petrochemical Science and Trade Co., Ltd.) to prepare isoprene monomer (45.5kg / h, purchased from Shanghai Petrochemical Co., Ltd.) Co., Ltd.’s polymer grade commodity), cyclohexane (152kg / h, purchased from Beijing Yanshan Petrochemical Co., Ltd.) and neodymium catalysts are premixed, the premixing time is 10min, and the feed concentration of isoprene monomer is 25% by weight.

[0044] Then, follow figure 1 The process shown in the operation is to inject the premixed reaction materials into the first horizontal twin-shaft stirring mixer 12 to carry out the polymerization reaction, wherein the charging coefficient is 60%, and the reaction materials are in the first horizontal twin-shaft stirring mixer 12 The average residence time within 12 was 15min. The reaction temperature in the first horizontal twin-shaft stirring mixer 12 was con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com