Isoprene rubber and continuous production method thereof

A technology of isoprene rubber and production method, applied in the field of isoprene rubber, can solve the problems of poor catalyst stability, no comparability, and influence on the performance of isoprene rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

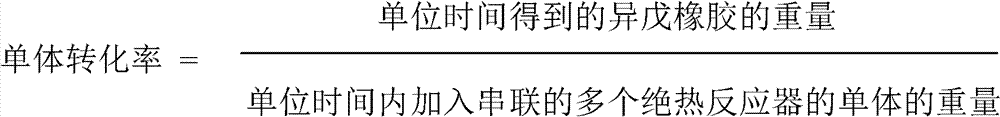

Method used

Image

Examples

Embodiment 1

[0039] The preparation of the rare earth catalyst uses hexane as a solvent. In the rare earth catalyst, the molar ratio of neodymium naphthenate, triisobutylaluminum, ethyl aluminum sesquichloride and isoprene is 1:10:2:40.3 Two reaction kettles with a volume of 120L are connected in series, and the rare earth catalyst, isoprene and hexane (reaction material) with a temperature of -20℃ are continuously added to the first kettle at -20°C, and the moles of neodymium in isoprene and rare earth catalyst The ratio is 1:1.6×10 -4 , the concentration of isoprene monomer in the first kettle was 16% by weight, and the residence time of the reaction materials was 47 minutes. Add-20 DEG C hexane in the second kettle and the third kettle, so that the concentration of the isoprene monomer in the second kettle is 14% by weight, and the residence time of the reaction mass is 41 minutes. The concentration was 13% by weight and the residence time of the reaction mass was 38 minutes. After 20...

Embodiment 2

[0045] Polymerization of isoprene was carried out according to the method of Example 1, except that the temperature of adding hexane in the second kettle and the third kettle was 10°C. After 20 hours of polymerization, the temperature of each reactor tended to be stable, the first reactor was 36°C, the second reactor was 45°C, and the third reactor was 51°C.

[0046] The methanol solution of 2,6-di-tert-butylhydroquinone is added to the glue liquid flowing out from the three kettles, and then the isoprene rubber is obtained after coagulation, dehydration, drying and packaging. After the temperature of each reaction kettle tended to be stable, the glue and the obtained isoprene rubber were tested. As a result, the Mooney viscosity of the isoprene rubber was 69, and the cis 1,4-structure content was 98% by weight; the isoprene The monomer conversion rate is 99%.

Embodiment 3

[0048] Polymerize isoprene according to the method of Example 1, the difference is that the amount of solvent added in the second kettle and the third kettle makes the concentration of isoprene monomer in the second kettle 14% by weight, and the residence time of the reaction materials The time was 44 minutes, the concentration of isoprene monomer in the three-pot was 12% by weight, and the residence time of the reaction materials was 38 minutes. After 20 hours of polymerization, the temperature of each reactor tended to be stable, the first reactor was 36°C, the second reactor was 39°C, and the third reactor was 42°C.

[0049] The methanol solution of 2,6-di-tert-butylhydroquinone is added to the glue liquid flowing out from the three kettles, and then the isoprene rubber is obtained after coagulation, dehydration, drying and packaging. After the temperature of each reaction kettle tended to be stable, the glue and the obtained isoprene rubber were tested. As a result, the Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com