Concentration and separation two-section cyclone

A technology of concentrating cyclone and cyclone, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, solid separation, etc. Choice effect, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

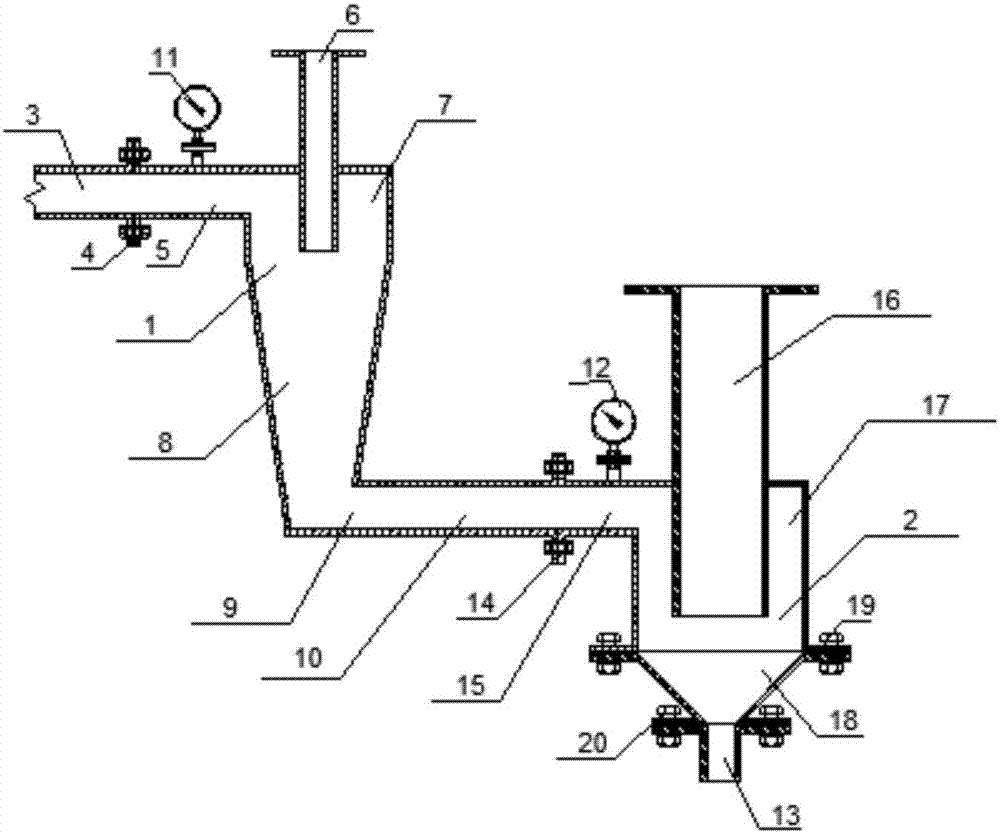

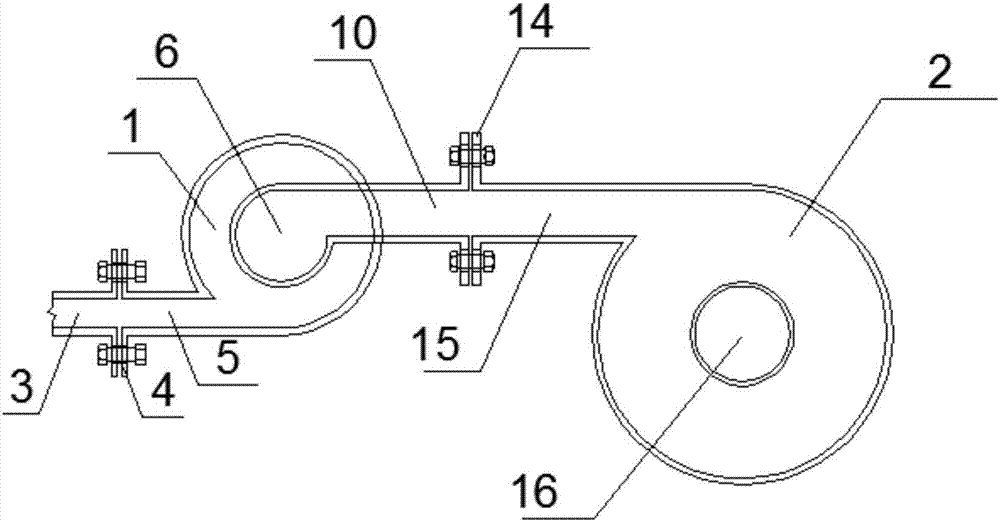

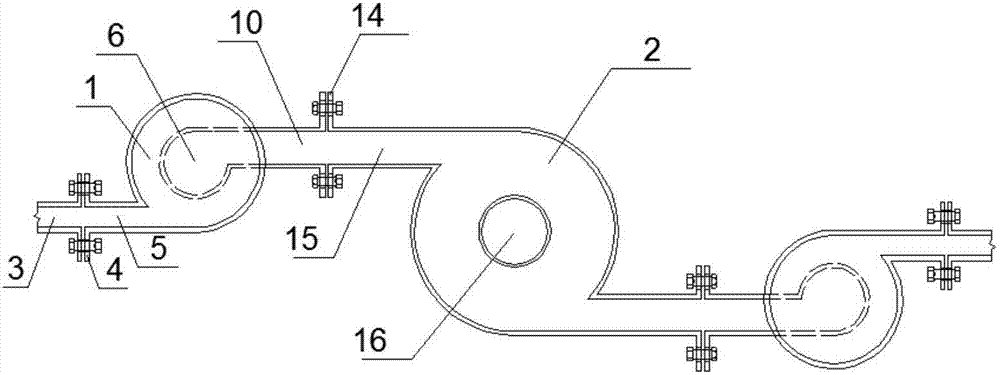

[0024] Exemplary embodiments of embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] The two-stage cyclone for concentration and separation of the present invention has a structure comprising: a concentration cyclone 1, an aqueous medium separation cyclone 2, a connecting pipe with a rectangular section 3, a first flange 4, a first feeding pipe 5 and a second An overflow pipe 6, the first cylinder 7, the first cone 8, the bottom outlet 9, the connecting pipe 10, the first pressure gauge 11, the second pressure gauge 12, the bottom flow pipe 13, the second flange 14, the first Two feeding pipes 15, a second overflow pipe 16, a second cylindrical body 17, a second cone 18, a third flange 19 and a fourth flange 20 are composed of several parts. The connecting pipe 3 with a rectangular section is connected to the first feeding pipe 5 through the first flange 4, the first feeding pipe 5 is connected to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com