Horizontal stirring methane fermentation device with vertical cylindrical tank

A biogas fermentation and cylinder technology, applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactor/fermenter combinations, etc., can solve the problem of not exceeding 500 cubic meters, not too high concentration, high construction cost, etc. problems, to achieve the effect of strong overwintering ability, high feed concentration, low operating cost and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

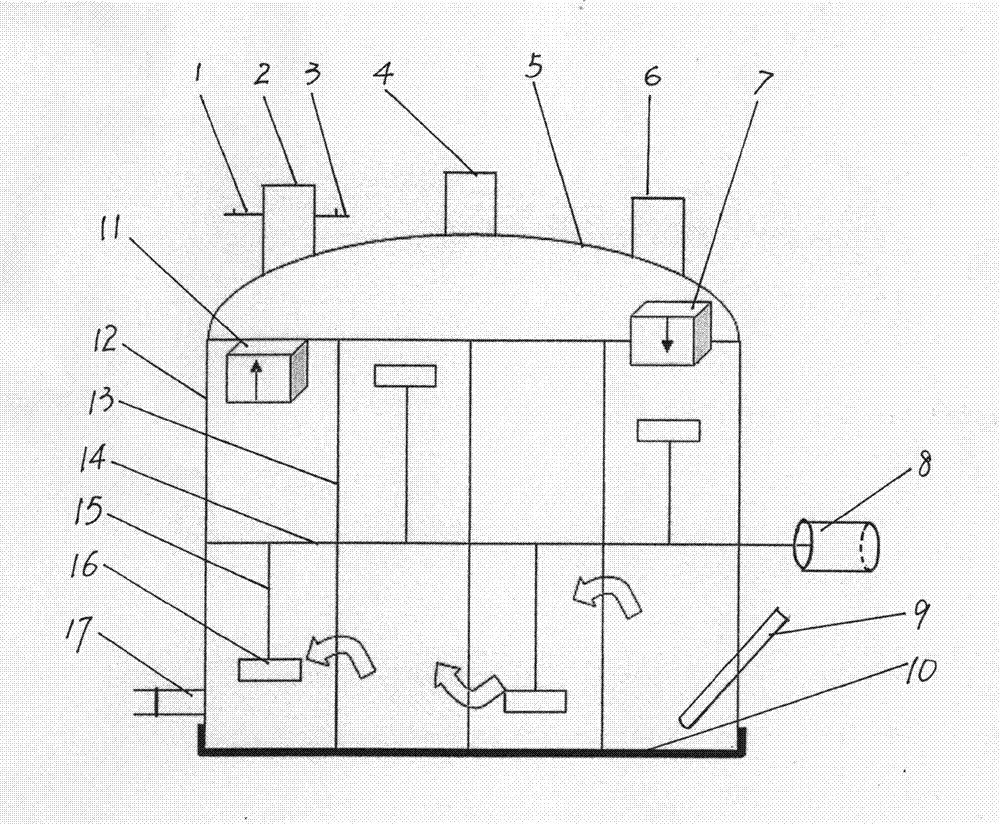

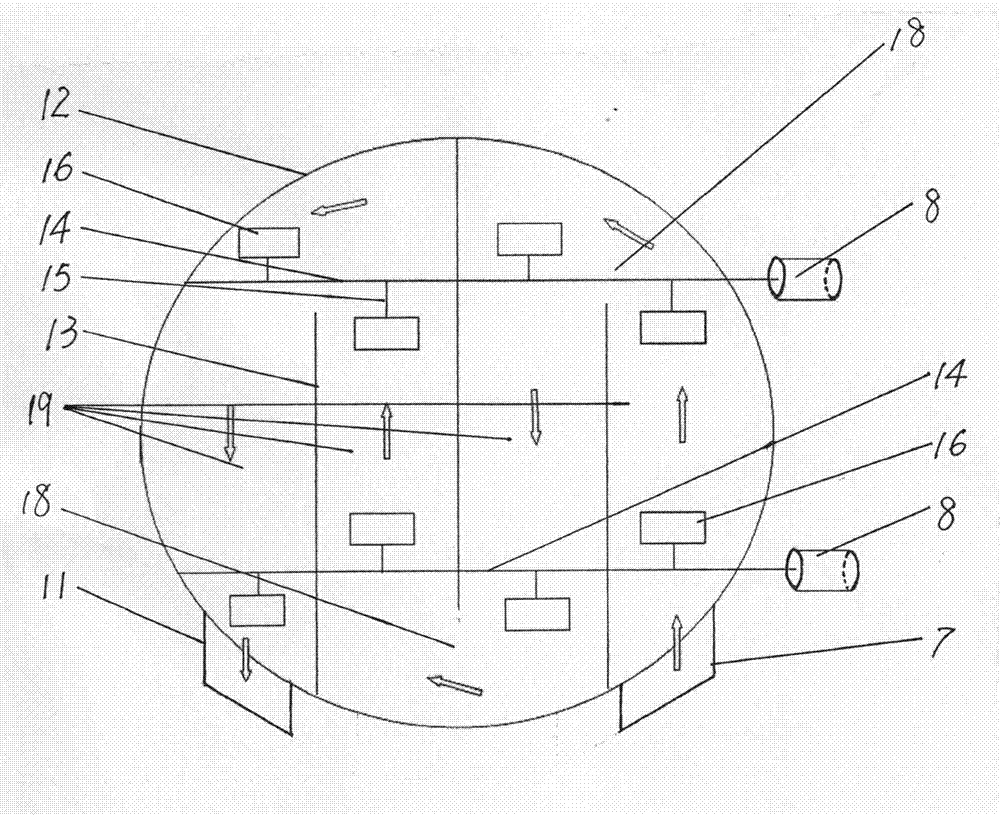

[0013] as attached figure 1 , 2 As shown, the biogas fermentation device is a cylindrical vertical fermentation tank with a diameter of 16 meters. Three partitions 13 are longitudinally arranged in the tank body 12. The partitions 13 are parallel to each other, and the distance between each partition 13 is 4 meters. The bottom of the dividing plate 13 is fixed on the bottom plate of the tank body 12, one side is fixed on the inner wall of the tank body 12, and the other side has a space 18 with the inner wall of the tank body 12. The width of the space 18 is equivalent to the distance between the two dividing plates. The three partitions 13 are arranged in a staggered manner, and the upper part is flush with the top of the tank body 12 and fixed by transverse ribs. The three partitions 13 divide the interior of the tank body 12 into four relatively independent but interconnected fermentation rooms 19; There are two sets of horizontal agitators in the middle of the body 12. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com