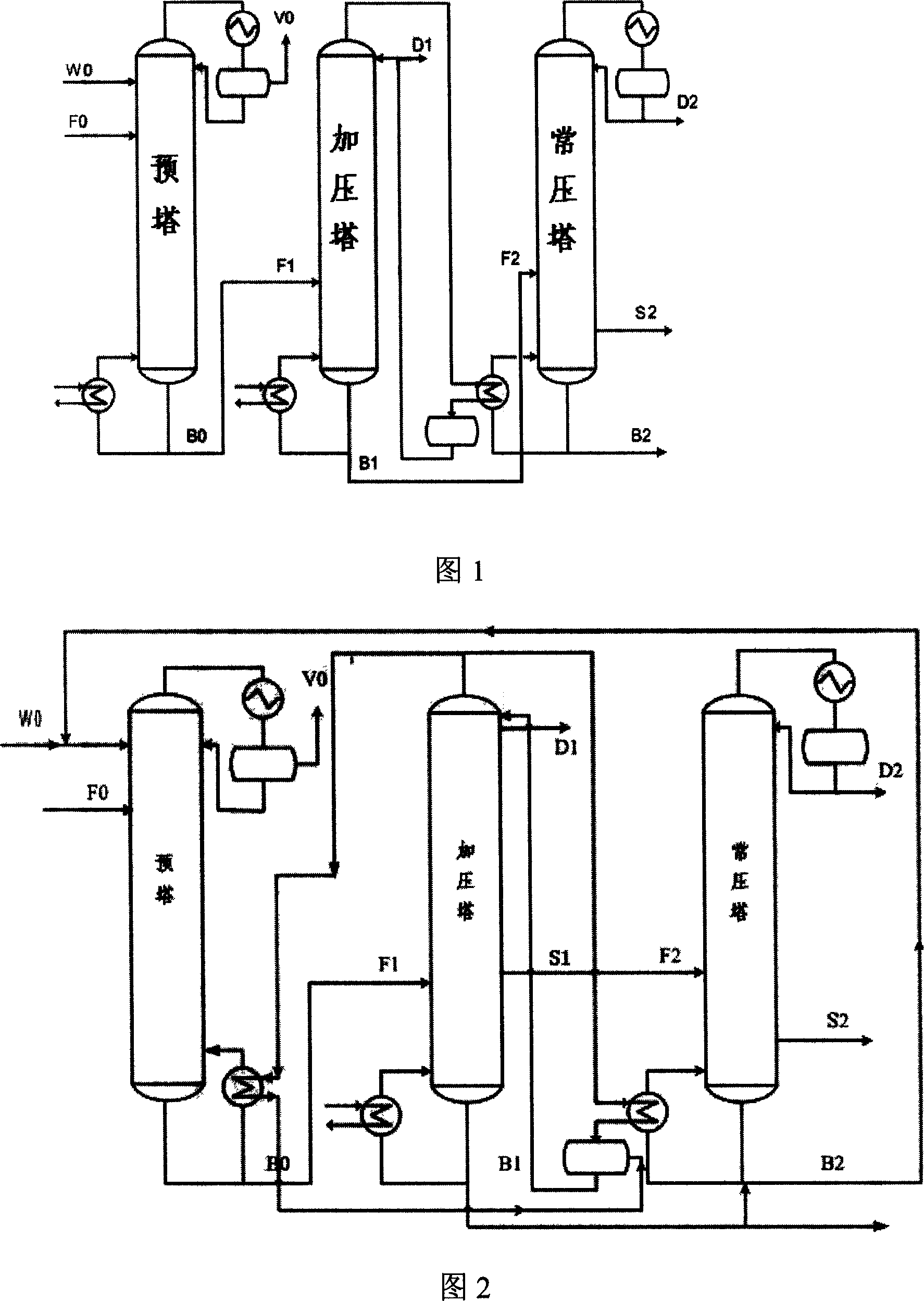

Method of refining synthetic methanol with heat integration

A technology for synthesizing methanol and a refining method, applied in the field of synthetic methanol refining, can solve the problems of increased steam unit consumption, large reflux ratio and high degree of separation in an atmospheric column, and achieve the advantages of reducing dosage, reducing reflux ratio and increasing feed concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The crude methanol feed flow rate is 14000kg / h, the composition is shown in Table 1, and the tower equipment parameters are shown in Table 2. Tables 3 to 6 show the comparison data of the two three-tower processes, among which Table 3 is the comparison of material flow, Table 4 is the comparison of feed composition of the atmospheric tower, Table 5 is the comparison of steam consumption, and Table 6 is the comparison of soft water consumption.

[0014] Table 1 crude methanol composition (mass fraction)

[0015] Methanol

water

Fusel oil

n-Hexane

n-octane

0.934

0.007

5.70×l0 -4

0.056

0.001

1.00×10 -5

1.00×10 -5

8.56×10 -5

4.00×10 -4

2.86×10 -4

[0016] Table 2 Tower Equipment Parameters

[0017] Pre-tower

pressurized tower

Atmospheric tower

Top pressure

Column...

Embodiment 2

[0027] The crude methanol feed flow rate is 14000kg / h, the composition is shown in Table 1, and the tower equipment parameters are shown in Table 2. Tables 3 to 6 show the comparison data of the two three-tower processes, among which Table 3 is the comparison of material flow, Table 4 is the comparison of feed composition of the atmospheric tower, Table 5 is the comparison of steam consumption, and Table 6 is the comparison of soft water consumption.

[0028] Table 1 crude methanol composition (mass fraction)

[0029] Methanol

water

Fusel oil

n-Hexane

n-octane

0.87

0.02

3.0×10 -4

0.1

0.0068

1.00×10 -5

1.00×10 -3

2.77×10 -3

3.90×10 -6

1.00×10 -4

[0030] Table 2 Tower Equipment Parameters

[0031] Pre-tower

pressurized tower

Atmospheric tower

Top pressure

Column pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com