Preparation method of edible rice protein

A technology for rice protein and rice dregs protein, which is applied in the field of edible rice protein preparation, can solve the problems of increased processing capacity of drying equipment, poor hydrolysis effect, large process loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

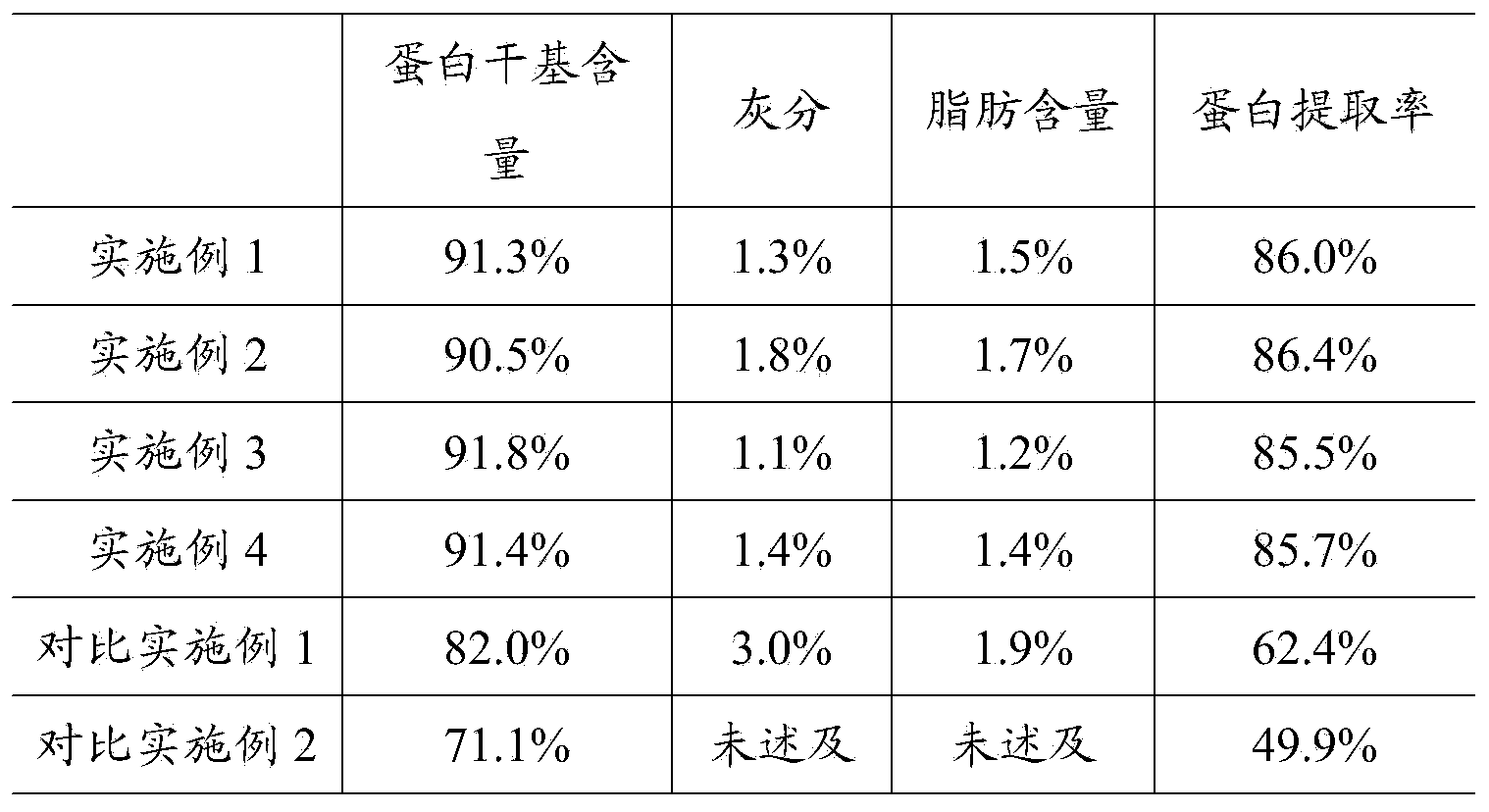

Examples

Embodiment 1

[0100] Embodiment 1: Adopt the method of the present invention to prepare edible rice protein

[0101] The implementation steps of this embodiment are as follows:

[0102] A. Raw material pretreatment

[0103] With 1500kg of rice dregs sold by Jiangxi Hengtian Industrial Co., Ltd., with a protein content of 22.4% by weight and a moisture content of 58.5% by weight, as raw material, use a temperature of 70°C on a plate and frame filter press sold by Hangzhou Guorui Filter Press Co., Ltd. Wash with water until the soluble solids content in the eluent is 2% by weight or less.

[0104] B. smash

[0105] The washed rice dregs protein obtained in step A is pulverized with a pulverizer produced by Wuxi Hepu Light Industry Equipment Technology Co., Ltd., sieved, and the grain fineness is collected from rice dregs protein with a particle size of 100 to 120 mesh, and the bran that is not easy to be crushed is removed and sieved Shangwu;

[0106] C. Mixing and reaction

[0107] Add ...

Embodiment 2

[0116] Embodiment 2: Adopt the method of the present invention to prepare edible rice protein

[0117] The implementation steps of this embodiment are as follows:

[0118] A. Raw material pretreatment

[0119] With 2000kg of rice dregs sold by Jiangxi Zhongchao Biotechnology Co., Ltd., with a protein content of 23.1% by weight and a moisture content of 58.0% by weight, as raw material, use a temperature of 75°C on a plate and frame filter press sold by Hangzhou Xingyuan Filtration Technology Co., Ltd. Wash with water until the soluble solids content in the eluent is 2% by weight or less.

[0120] B. smash

[0121] The washed rice dreg protein obtained in step A is pulverized with a grinder produced by Jiangsu Muyang Group Co., Ltd., sieved, and the grain fineness is collected from rice dreg protein with a particle size of 100 to 120 mesh, and the sieved materials such as bran that are not easy to be crushed are removed;

[0122] C. Mixing and reaction

[0123] Add water to...

Embodiment 3

[0132] Embodiment 3: Adopt the method of the present invention to prepare edible rice protein

[0133] The implementation steps of this embodiment are as follows:

[0134] A. Raw material pretreatment

[0135] With 2000kg of rice dregs sold by Wuhan Jindege Sugar Industry Co., Ltd., with a protein content of 21.7% by weight and a moisture content of 62.2% by weight, it is used as a raw material on a plate and frame filter press sold by Hangzhou Kunyuan Filtration Machinery Co., Ltd. Washing was performed with water at 75°C until the soluble solids content in the eluate was 2% by weight.

[0136] B. smash

[0137] The washed rice dregs protein obtained in step A is pulverized with a pulverizer produced by Jiangxi Hongxing Machinery Factory Co., Ltd., sieved, and the grain fineness is collected from rice dregs protein with a particle size of 100 to 120 mesh, and the sieved materials such as bran that are not easy to be crushed are removed;

[0138] C. Mixing and reaction

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com