Preparation method of ultrafine cobalt powder

A technology of ultrafine cobalt powder and cobalt salt, which is applied in the field of preparation of ultrafine cobalt powder, can solve the problems of high cost and large consumption, and achieve the effects of low production cost, high production efficiency and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

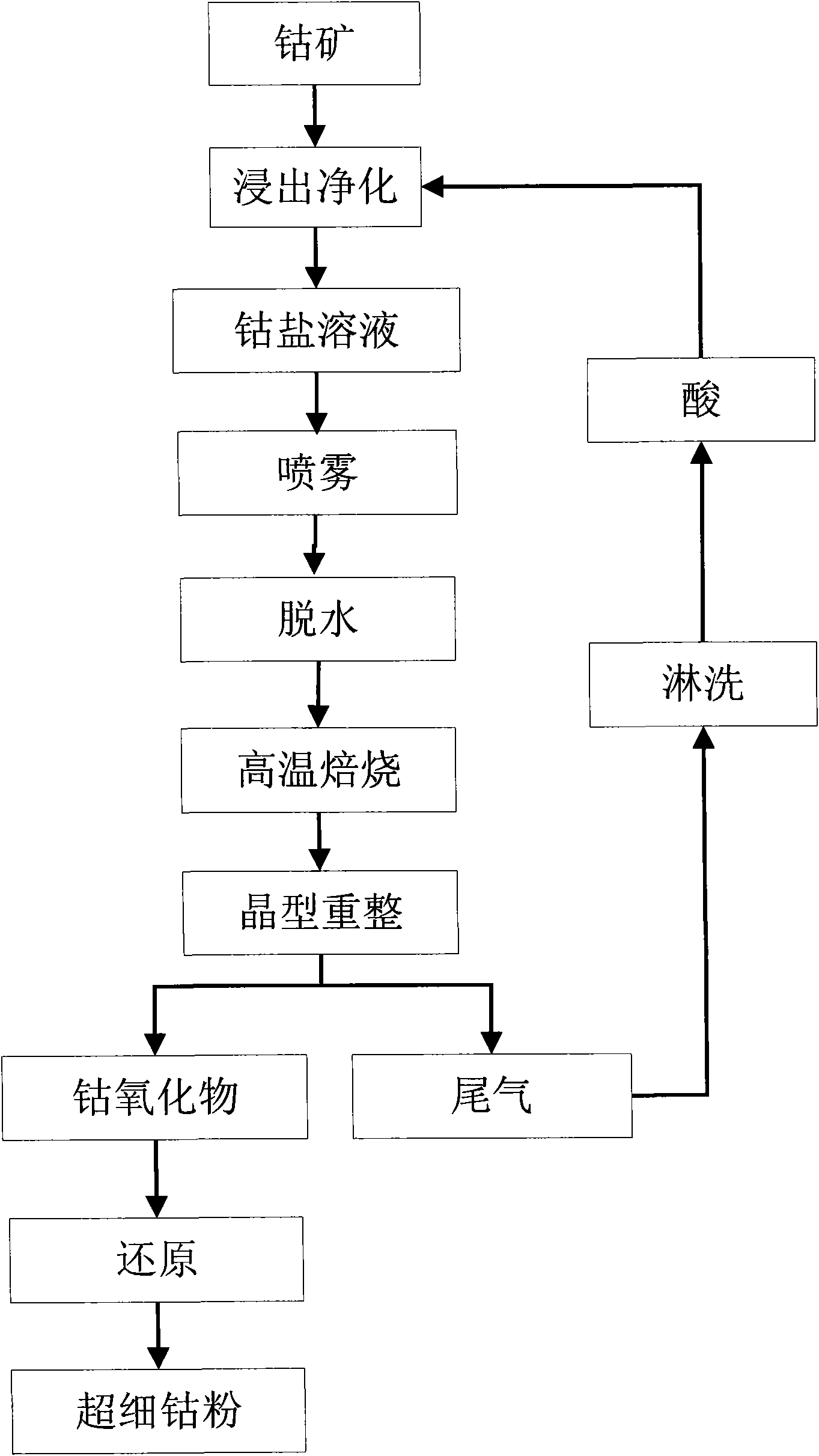

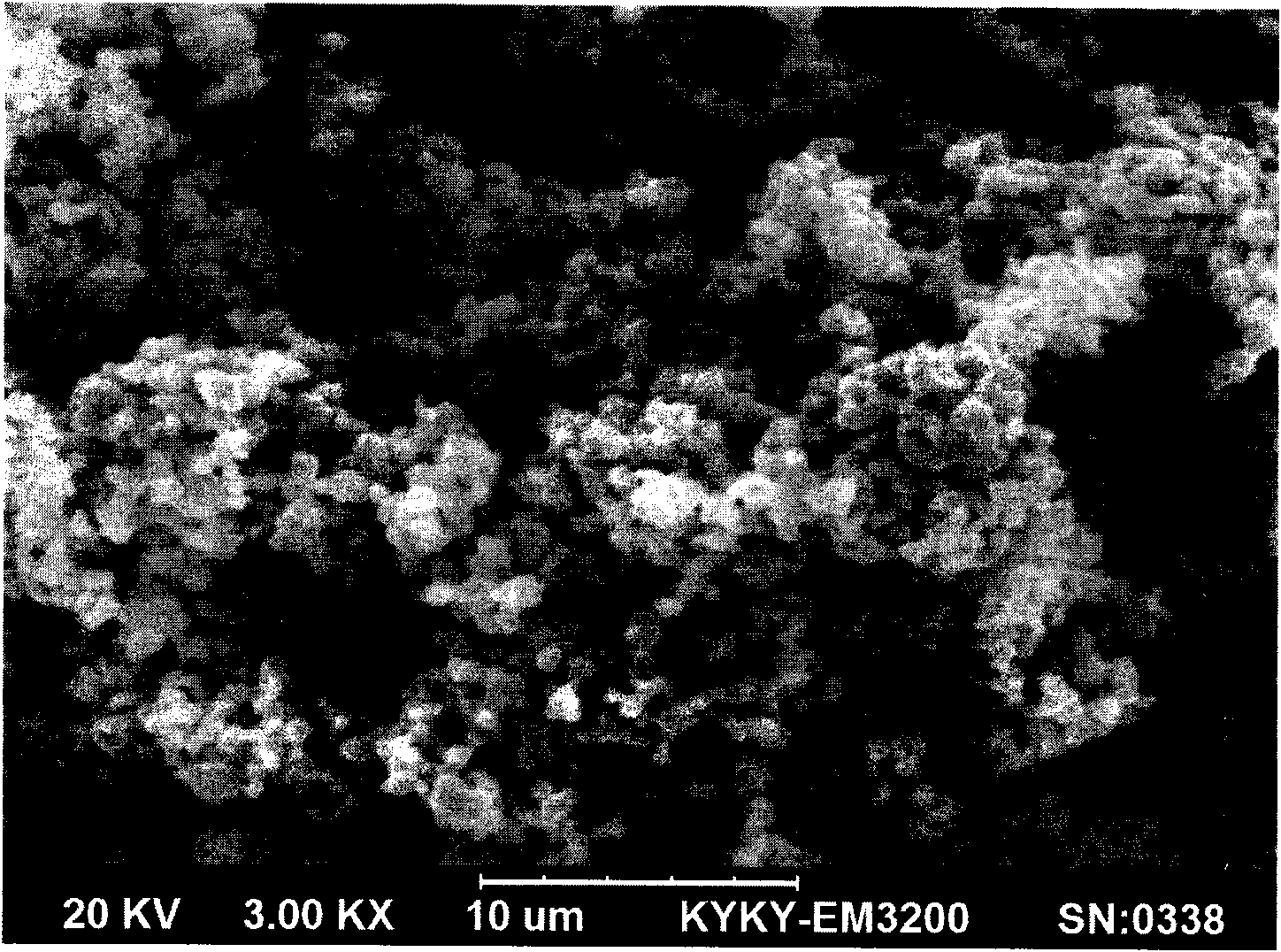

[0035] Embodiment 1 (with reference to figure 1 , 2 )

[0036] The cobalt-containing ore is used as a raw material, and after leaching and purification, a high-purity cobalt-containing 80-150 g / L cobalt chloride solution is obtained. The above cobalt chloride solution is pressure sprayed under the pressure of 0.2-5 MPa to obtain cobalt chloride mist droplets. Dehydrate the mist droplets obtained by spraying at 500-750°C for 10-40 seconds in an air or oxygen atmosphere to remove most of the water in the solution; then at a high temperature of 800-950°C Carry out calcination reaction for 20-80 seconds; then carry out crystal reformation reaction at 700-850°C for 30-100 seconds to obtain cobalt oxide, and release tail gas containing water vapor and acid gas at the same time. The tail gas generated during the high-temperature roasting process is sprayed and absorbed to obtain hydrochloric acid, and then the hydrochloric acid is returned for the leaching and purification process...

Embodiment 2

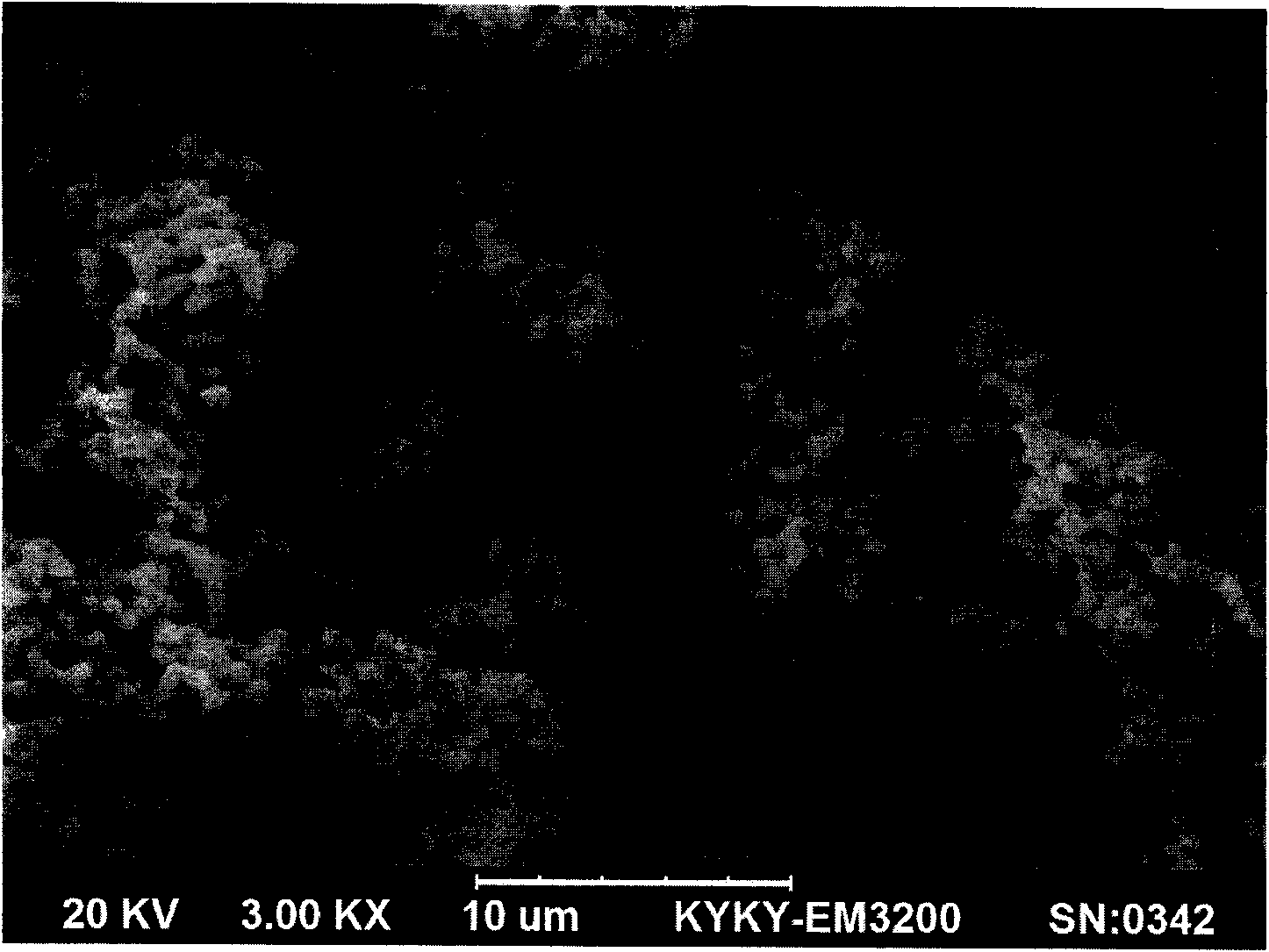

[0043] Embodiment 2 (with reference to figure 1 , 3 )

[0044]The cobalt-containing ore is used as a raw material, and after leaching and purification, a high-purity cobalt-containing cobalt sulfate solution of 80-150 g / L is obtained. The above cobalt sulfate solution is pressure sprayed under a pressure of 0.2-5 MPa to obtain cobalt sulfate mist droplets. Dehydrate the mist droplets obtained by spraying under air or oxygen atmosphere at 600-750°C for 20-40 seconds to remove the water in the solution; -80 seconds roasting reaction; then carry out 30-100 seconds crystal reformation reaction at a high temperature of 700-850 ° C to obtain cobalt oxides, and at the same time release tail gas containing water vapor and acid gas; the tail gas generated during high-temperature roasting, Sulfuric acid is obtained after spray absorption treatment, and then the sulfuric acid is returned for the leaching purification process. Send the prepared cobalt oxide into the reduction furnace,...

Embodiment 3

[0051] Embodiment 3 (with reference to figure 1 , 4 )

[0052] The cobalt-containing ore is used as a raw material, and after leaching and purification, a high-purity cobalt-containing 80-150 g / L cobalt nitrate solution is obtained. The above cobalt chloride solution is pressure sprayed under a pressure of 0.2-5 MPa to obtain cobalt nitrate mist droplets. Dehydrate the mist droplets obtained by spraying under air or oxygen atmosphere at 600-750°C for 20-40 seconds to remove the water in the solution; -80 seconds roasting reaction; then carry out 30-100 seconds crystal reformation reaction at a high temperature of 700-850 ° C to obtain cobalt oxides, and at the same time release tail gas containing water vapor and acid gas; the tail gas generated during high-temperature roasting, Nitric acid is obtained after spray absorption treatment, and then the nitric acid is returned for the leaching purification process. Send the prepared cobalt oxide into the reduction furnace, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com