Patents

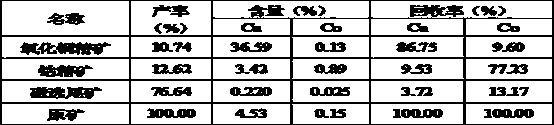

Literature

119 results about "Columbite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

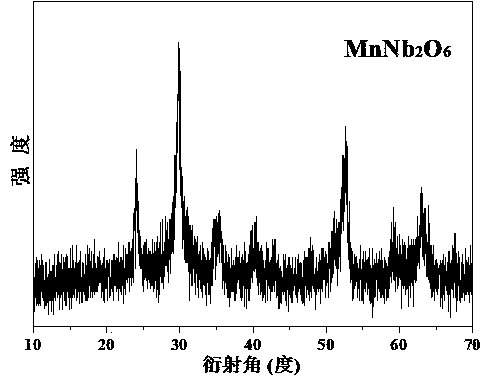

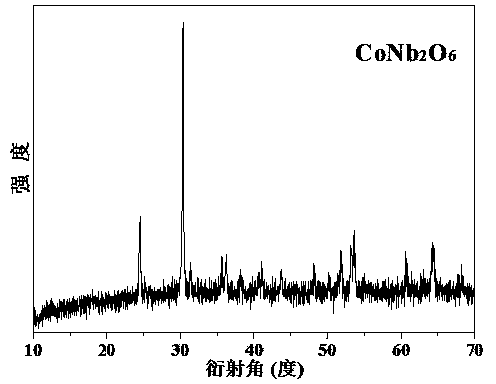

Columbite, also called niobite, niobite-tantalite and columbate [(Fe, Mn)Nb₂O₆], is a black mineral group that is an ore of niobium. It has a submetallic luster and a high density and is a niobate of iron and manganese. This mineral group was first found in Haddam, Connecticut, in the United States. It forms a series with the tantalum-dominant analogue ferrotantalite and one with the manganese-dominant analogue manganocolumbite. The iron-rich member of the columbite group is ferrocolumbite. Some tin and tungsten may be present in the mineral. Yttrocolumbite is the yttrium-rich columbite with the formula (Y,U,Fe)(Nb,Ta)O₄. It is a radioactive mineral found in Mozambique.

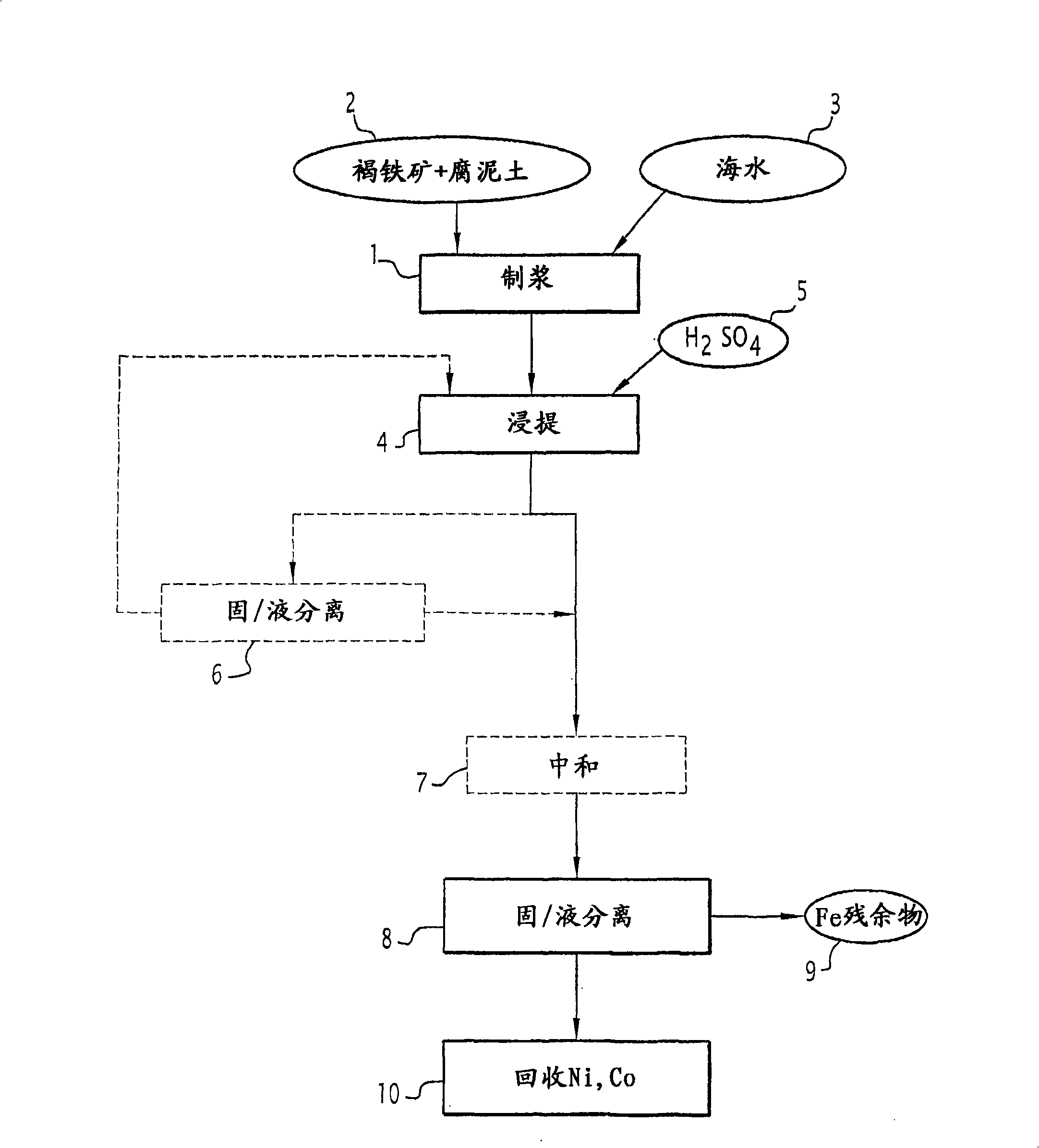

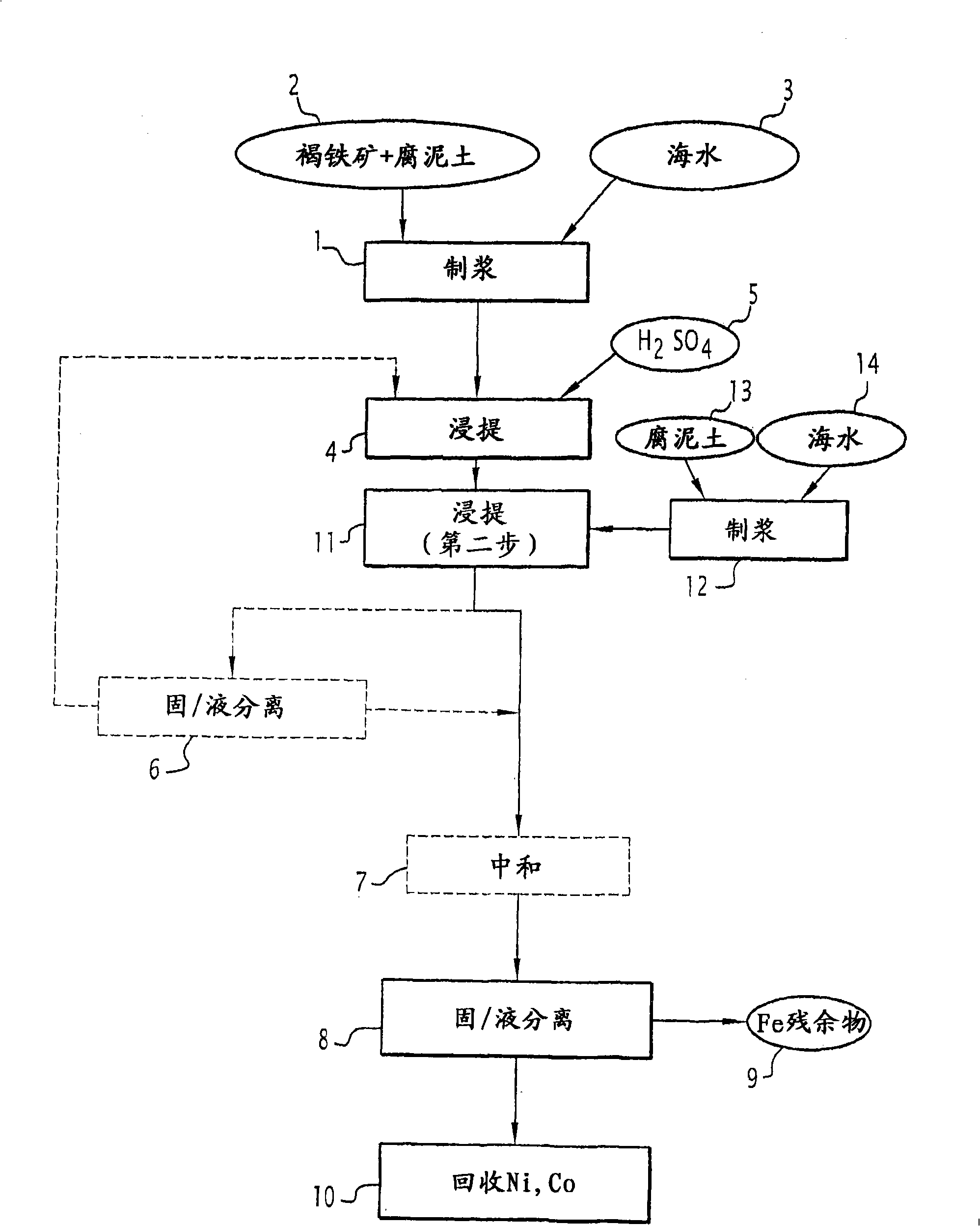

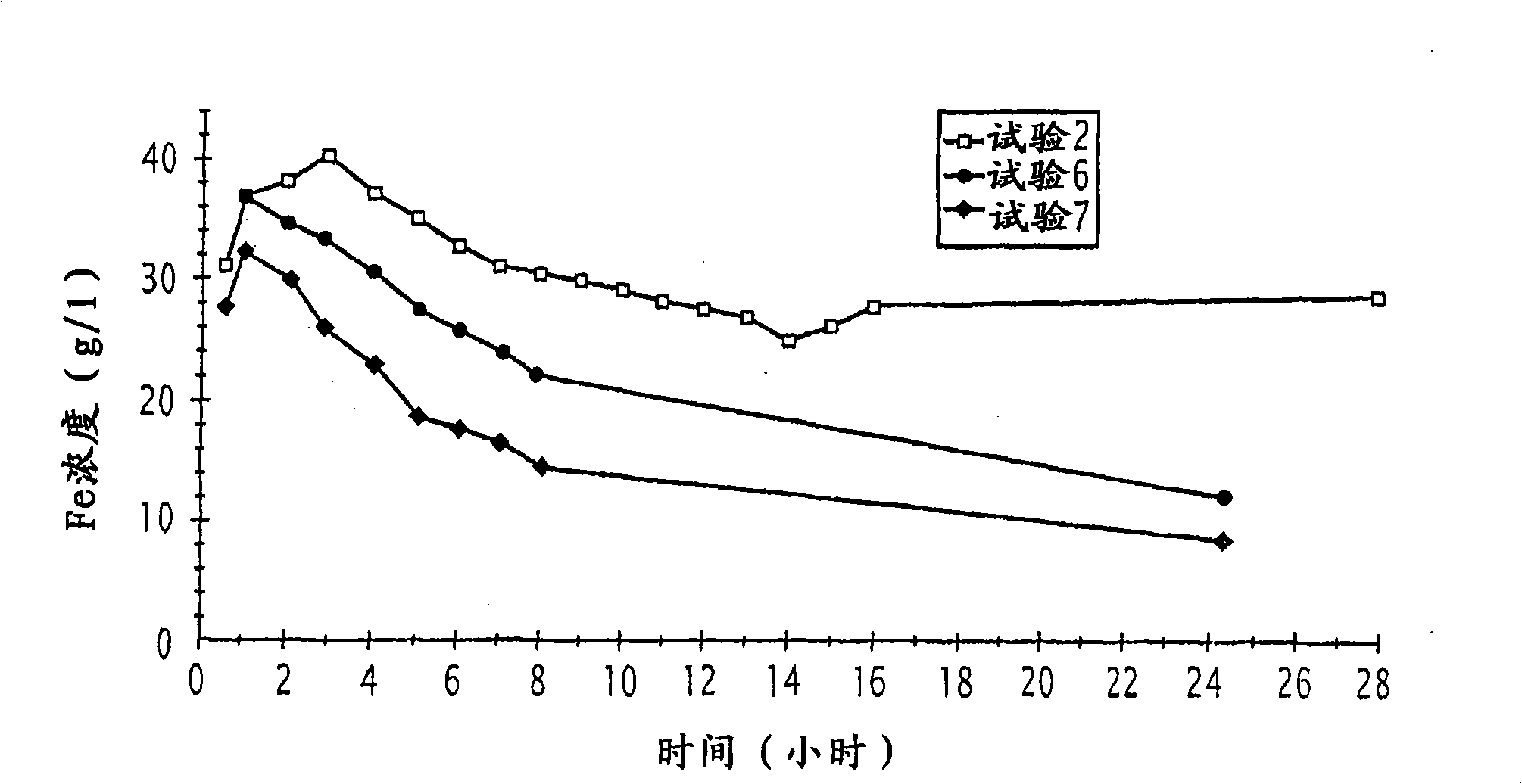

Process for the hydrometallurgical treatment of a lateritic nickel/cobalt ore and process for producing nickel and/or cobalt intermediate concentrates or commercial products using it

ActiveCN101541985ASimple structureShorten the durationProcess efficiency improvementBoiling pointHydrometallurgy

Process for the treatment of a lateritic nickel / cobalt ore consisting of a mixture (2) of limonite and saprolite, characterized in that: the mixture (2) in the presence of an iron-precipitating agent is made into a pulp (1), having a solids content of between 10 and 40% by weight; the pulp undergoes a leaching operation (4) with sulphuric acid (5), at a temperature between 70 DEG C and the boiling point and at atmospheric pressure; and a solid-liquid separation (8) is carried out so as to obtain an iron-containing solid residue (9) and a solution containing nickel and cobalt ions. Process for producing nickel and / or cobalt intermediate concentrates or commercial products using the above process.

Owner:ERAMET

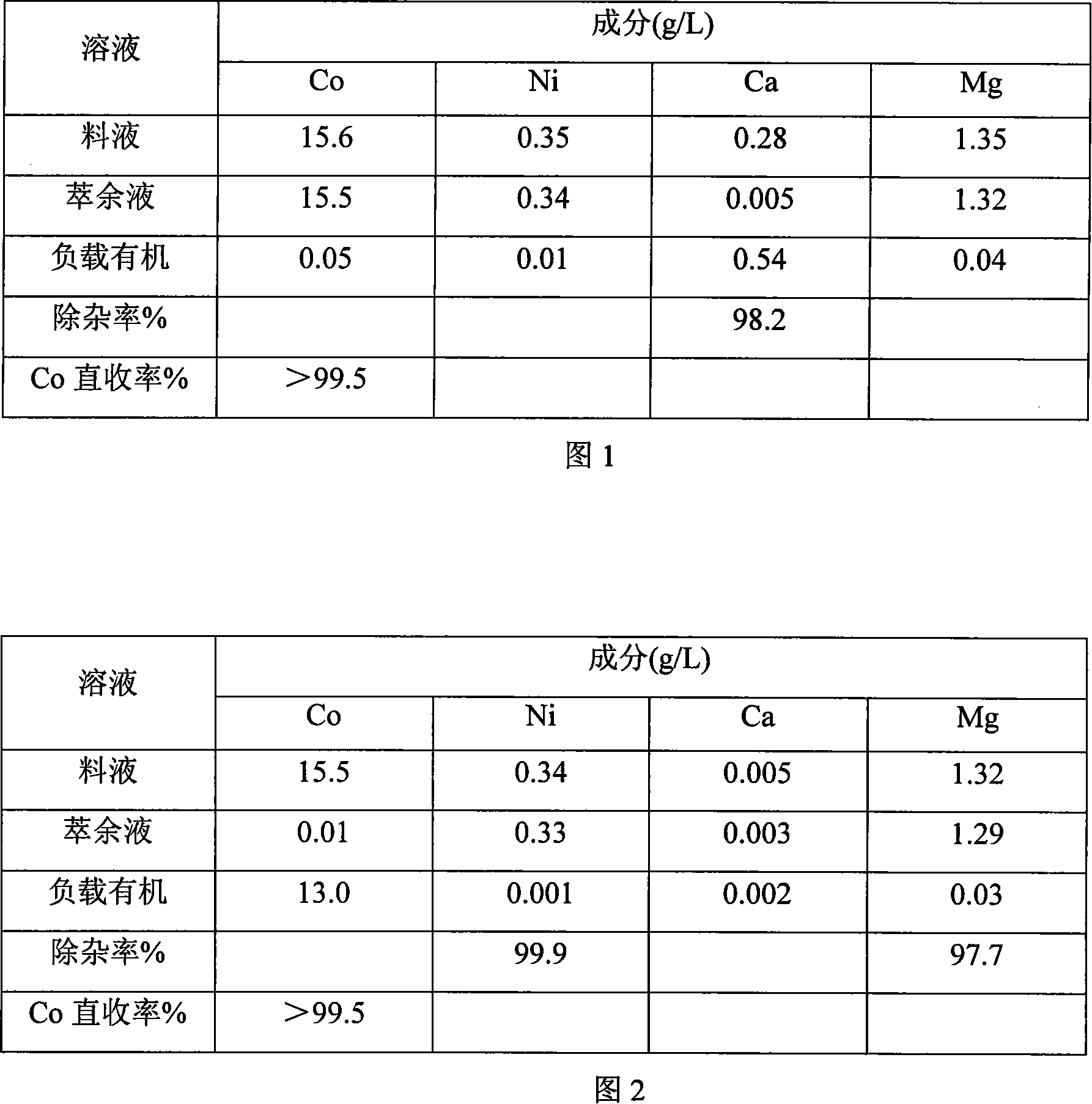

Extraction method for removing calcium and magnesium from copper-cobalt ore leachate

The process of extracting Co and eliminating Ca from copper-cobalt ore includes obtaining mixture leachate with soluble sulfate of Co, Ni, Ca and Mg; and extracting the mixture leachate with organic solvent, which comprises organic matter bis(2-ethyl hexyl) phosphoric acid or ”�2- ethyl hexyl phosphonate ester in 15-25 vol% and kerosene in 75-85 vol%. The organic solvent extracting procedure includes two steps, the first step of transferring Ca into the organic phase while leaving Co, Ni and Mg in the water phase, and the second step of transferring Co to the organic phase while leaving Ni and Mg in the water phase. The process can obtain cobalt sulfate solution with Co content up to 90-100 g / l, Ca ion content lowered to 0.01 g / l, Ni ion content lowered to 0.005 g / l, and Mg ion content lowered to 0.1 g / l and suitable for producing T-cobalt oxide and cobalt salt.

Owner:ZHEJIANG HUAYOU COBALT

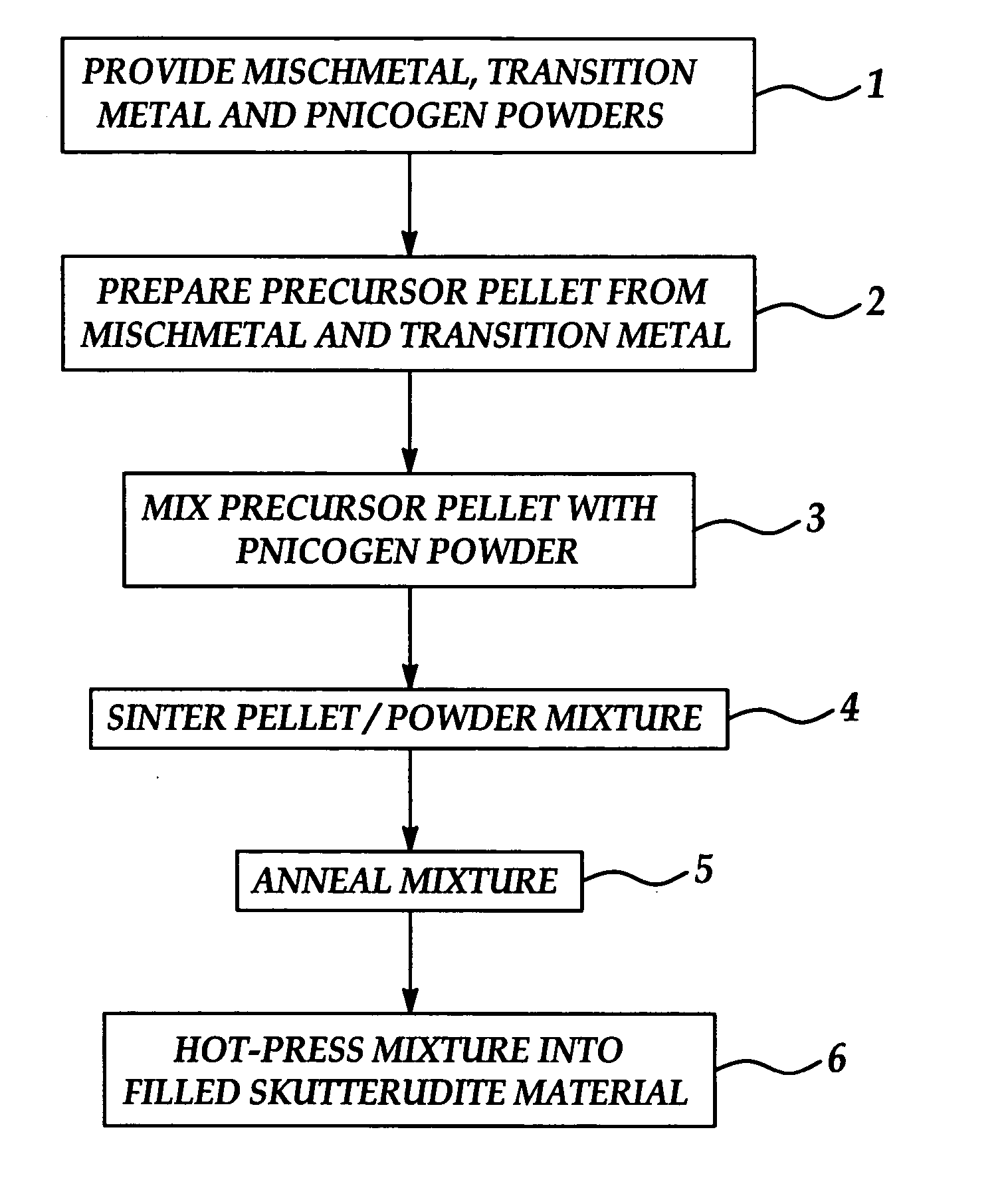

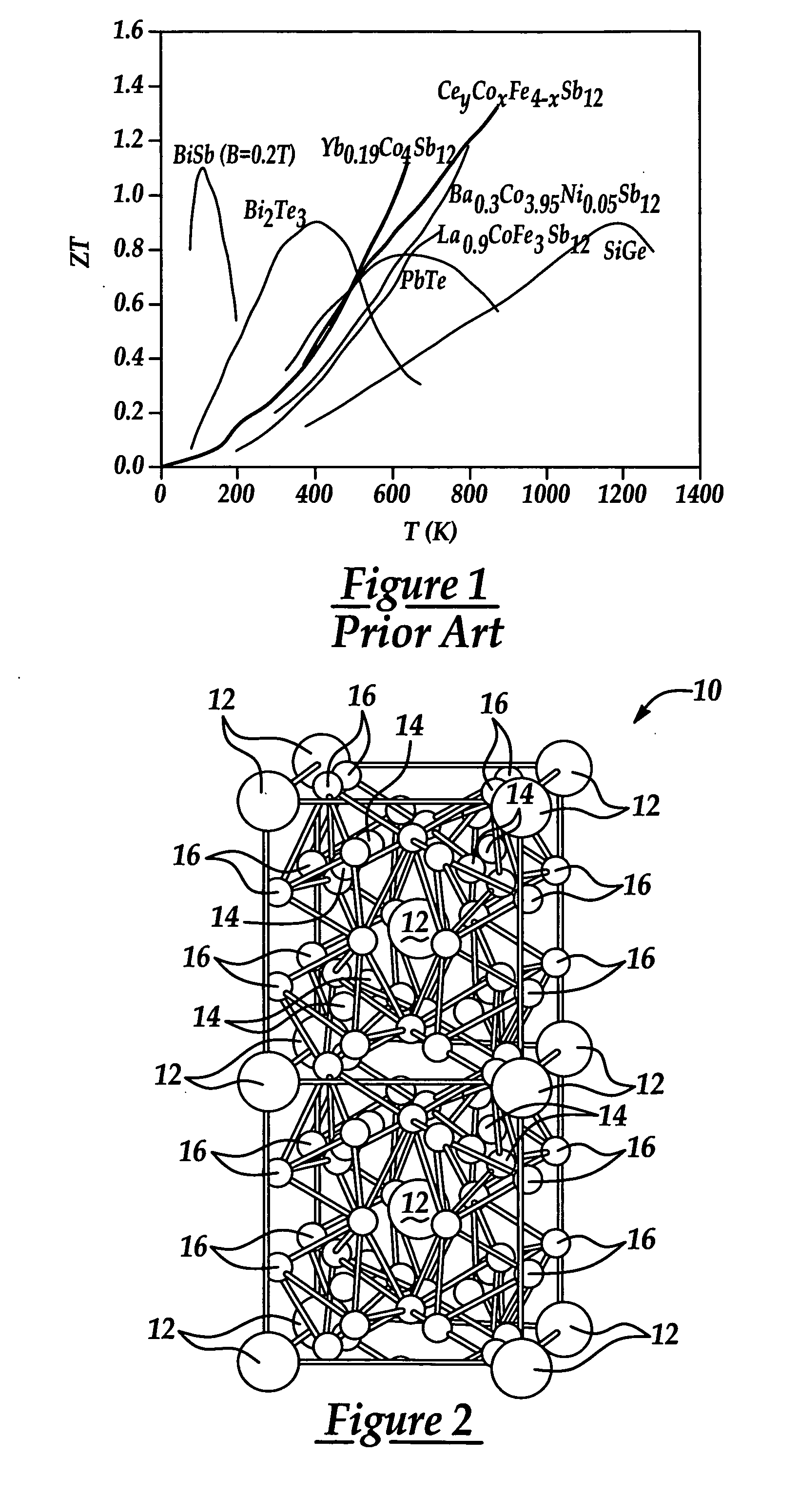

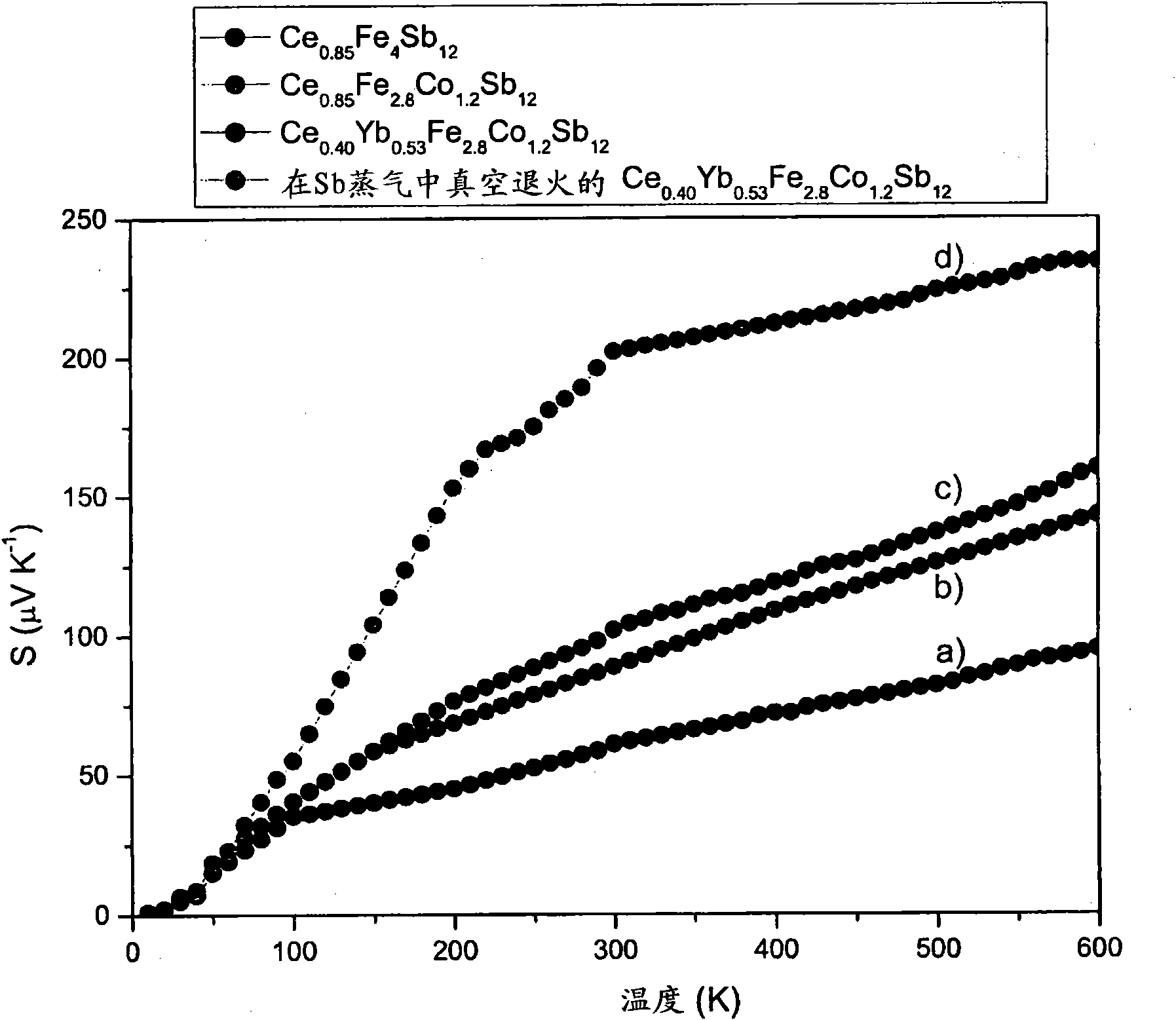

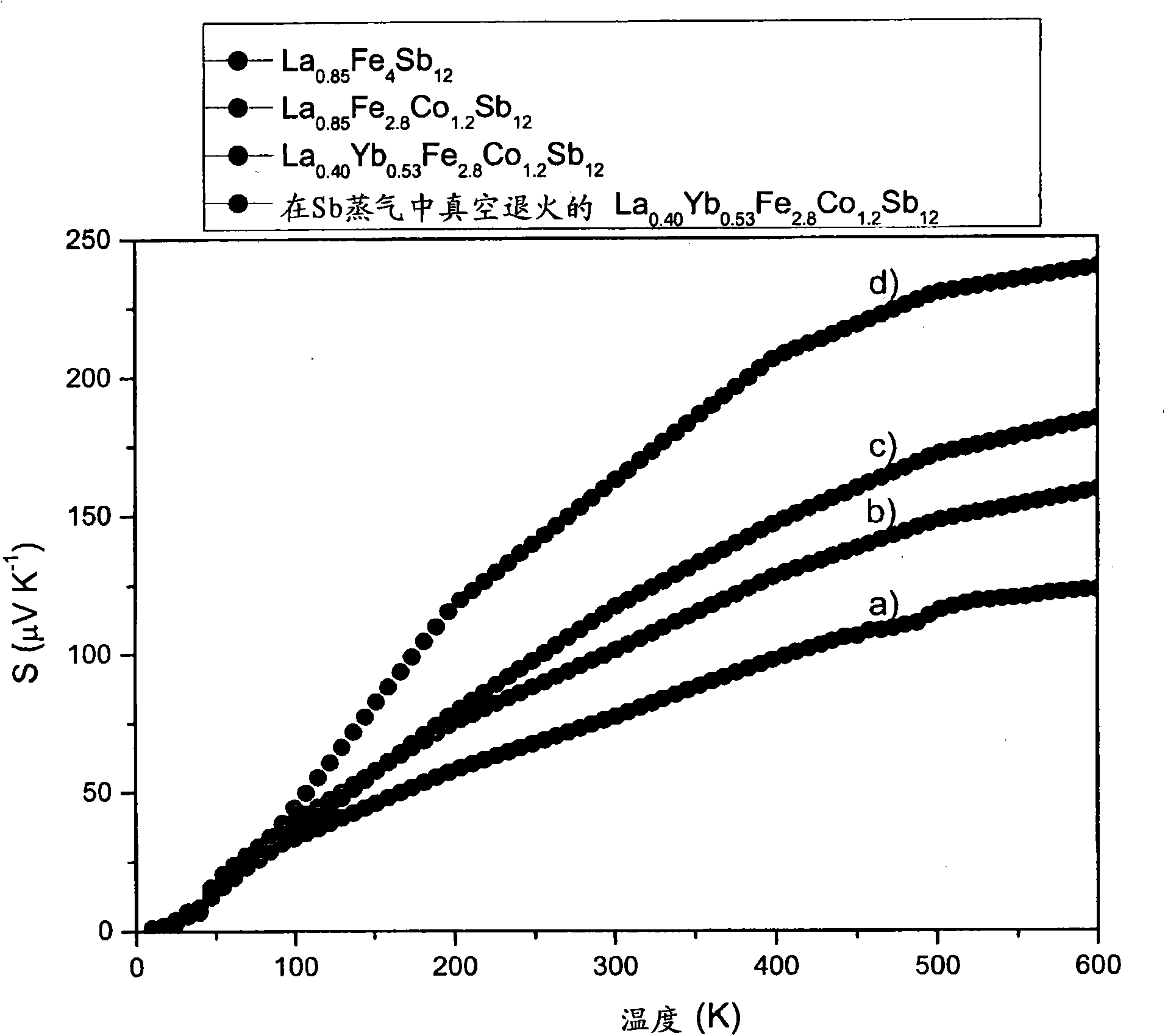

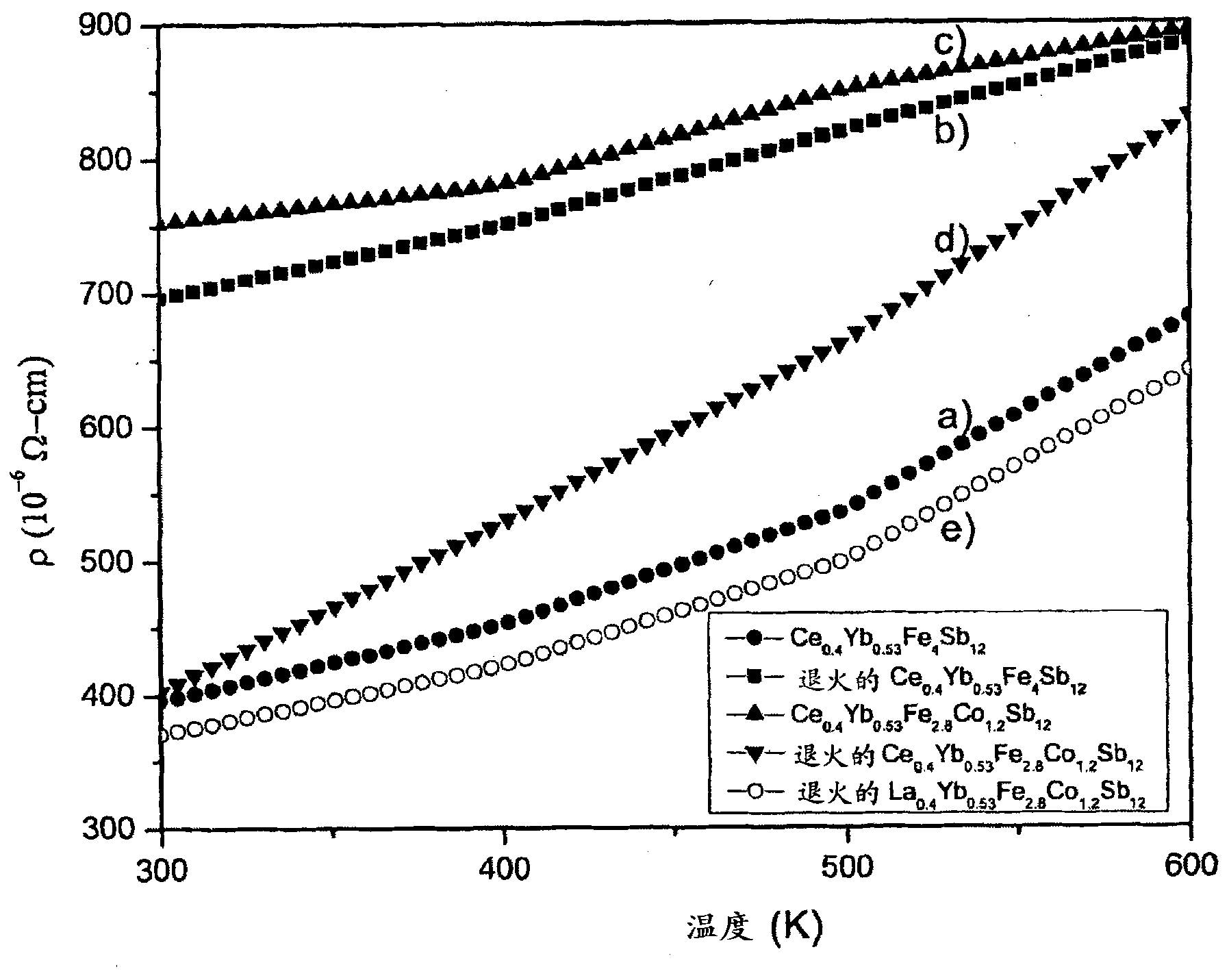

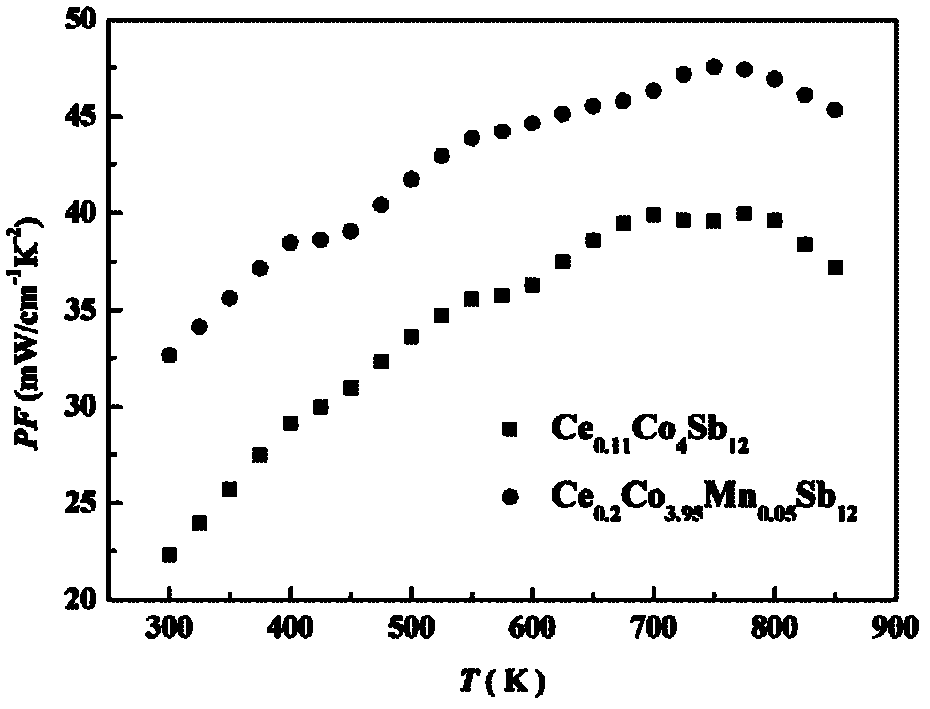

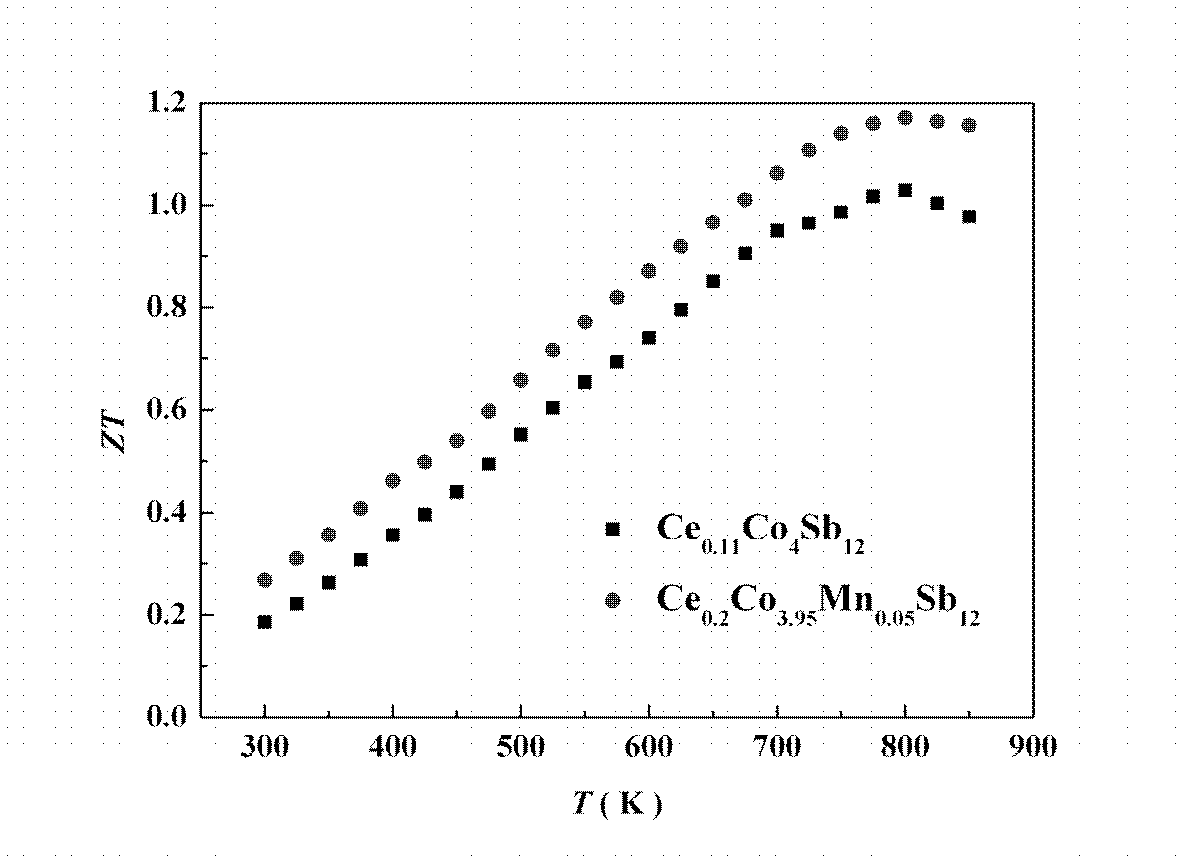

Filled skutterudites for advanced thermoelectric applications

ActiveUS20060016470A1Suitable for useThermoelectric device manufacture/treatmentThermoelectric device junction materialsMischmetalRare-earth element

A low-cost filled skutterudite for advanced thermoelectric applications is disclosed. The filled skutterudite uses the relatively low-cost mischmetal, either alone or in addition to rare earth elements, as a starting material for guest or filler atoms.

Owner:GM GLOBAL TECH OPERATIONS LLC

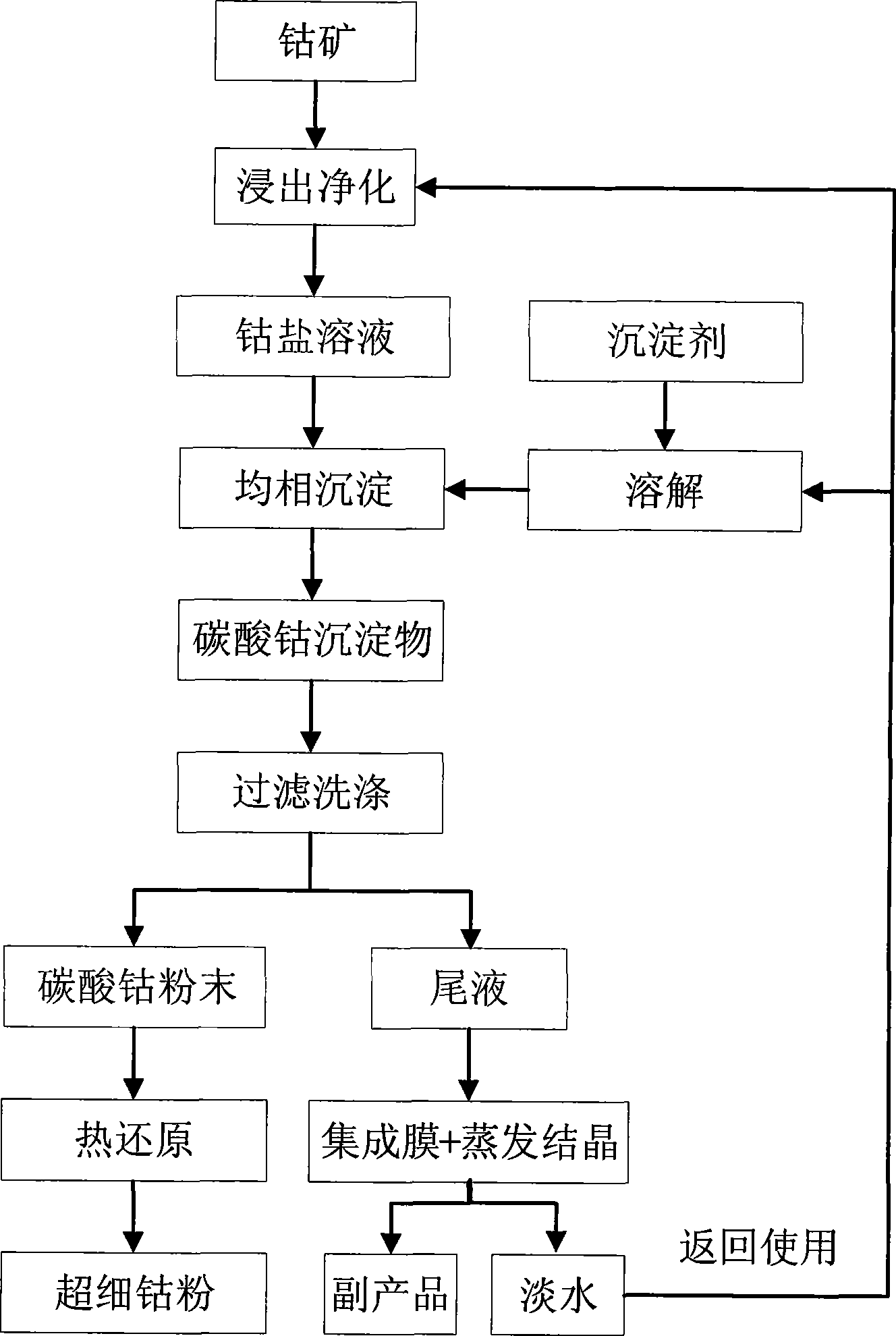

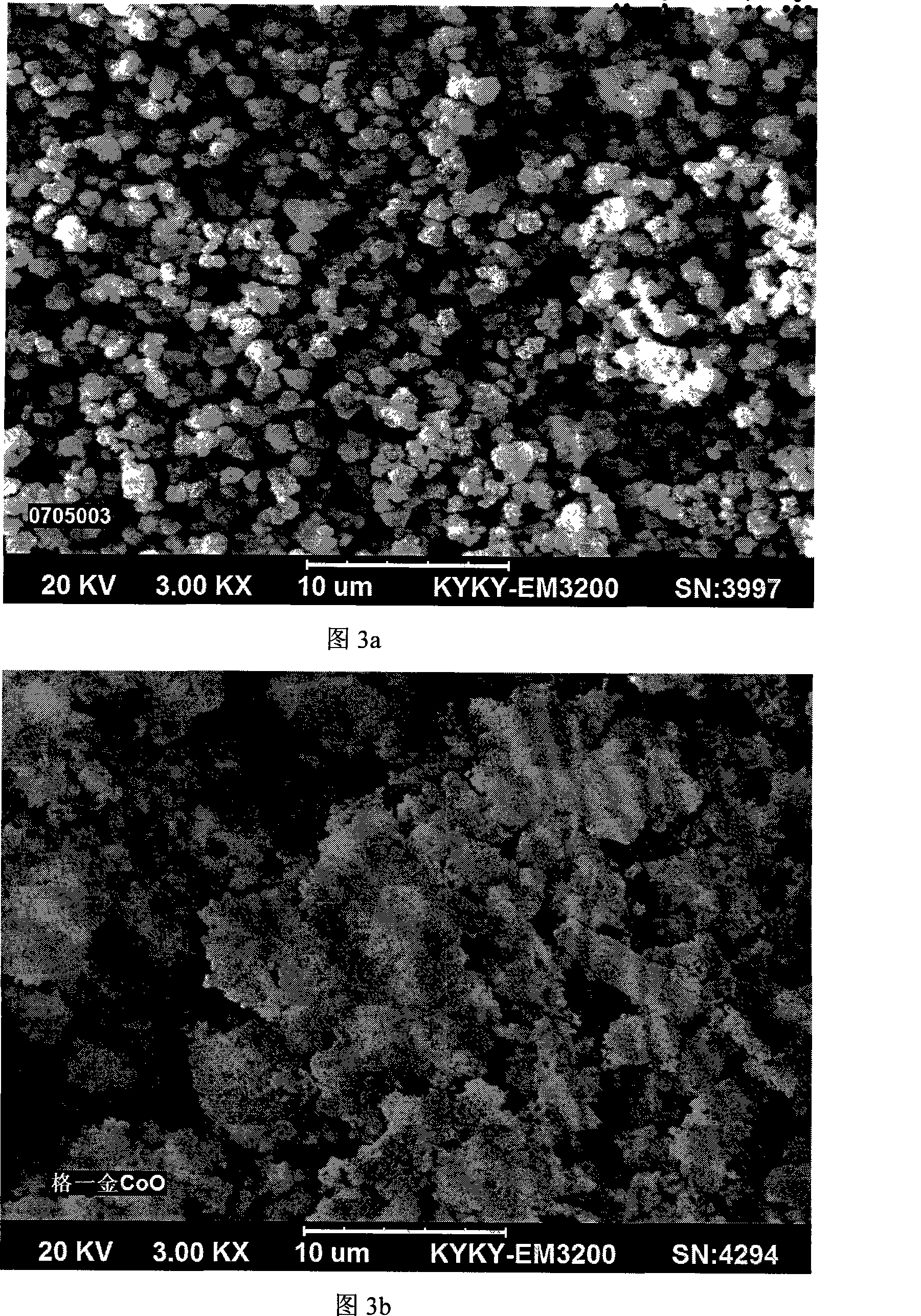

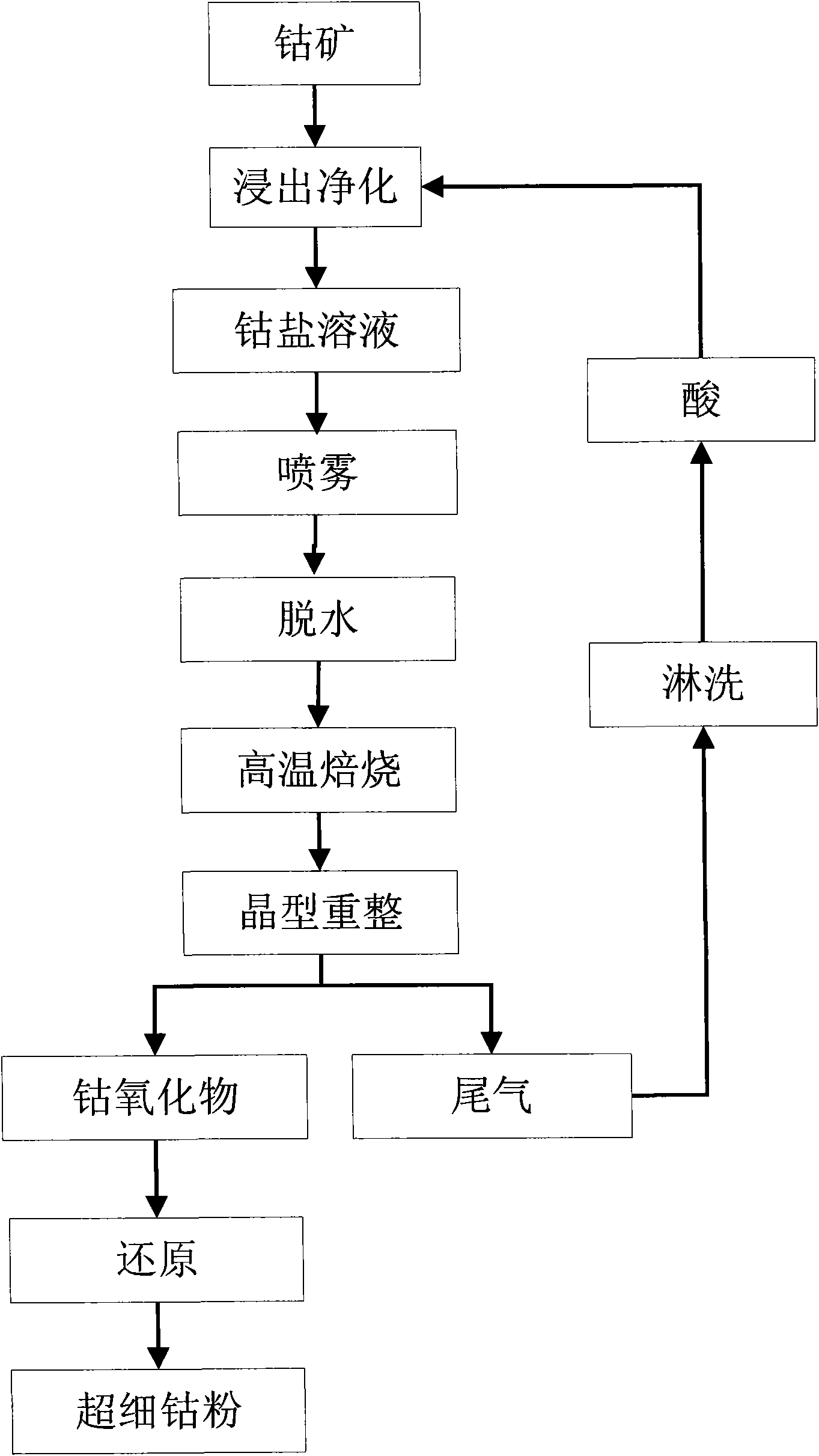

Method for preparing superfine spherical cobalt powder

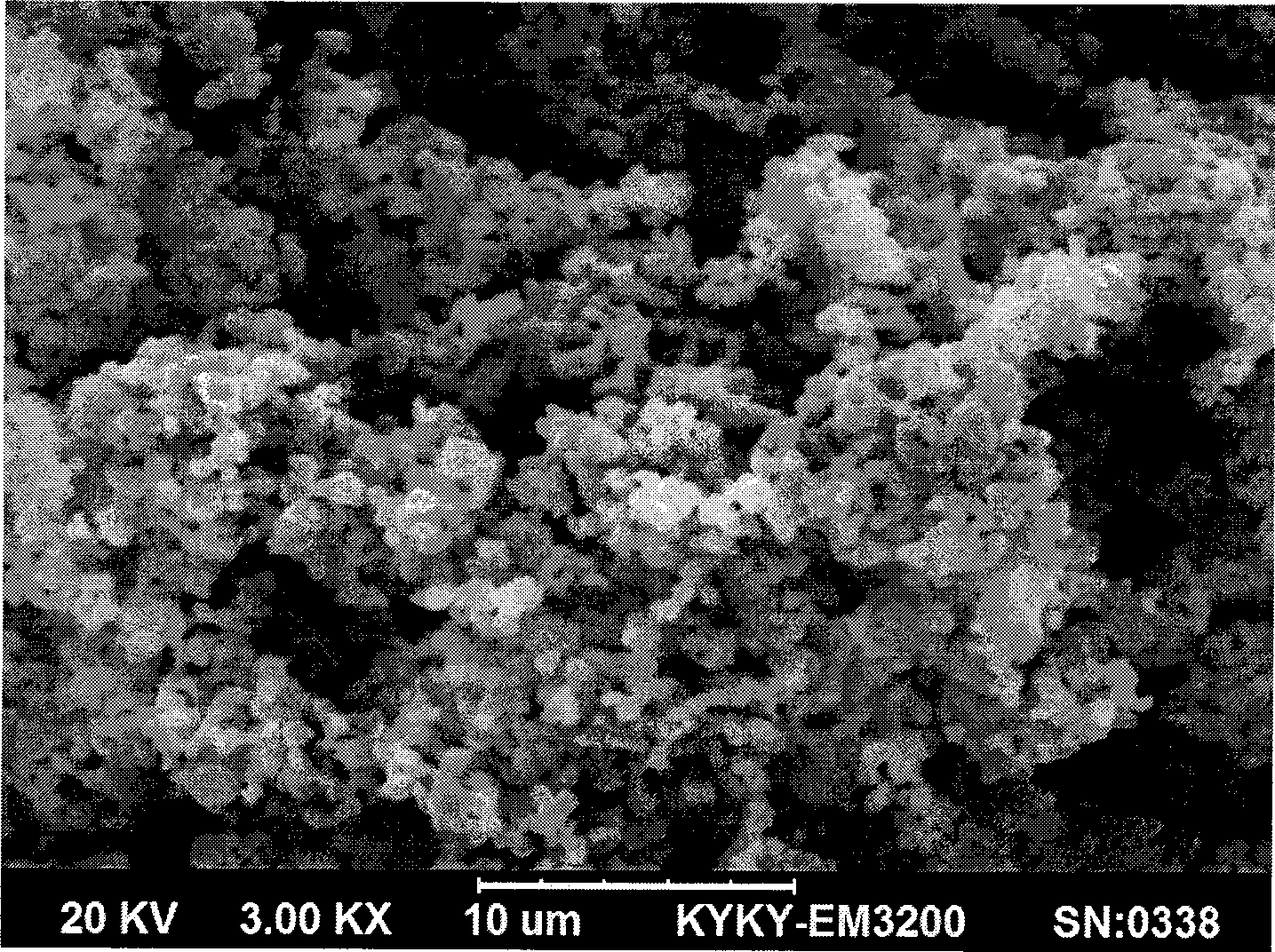

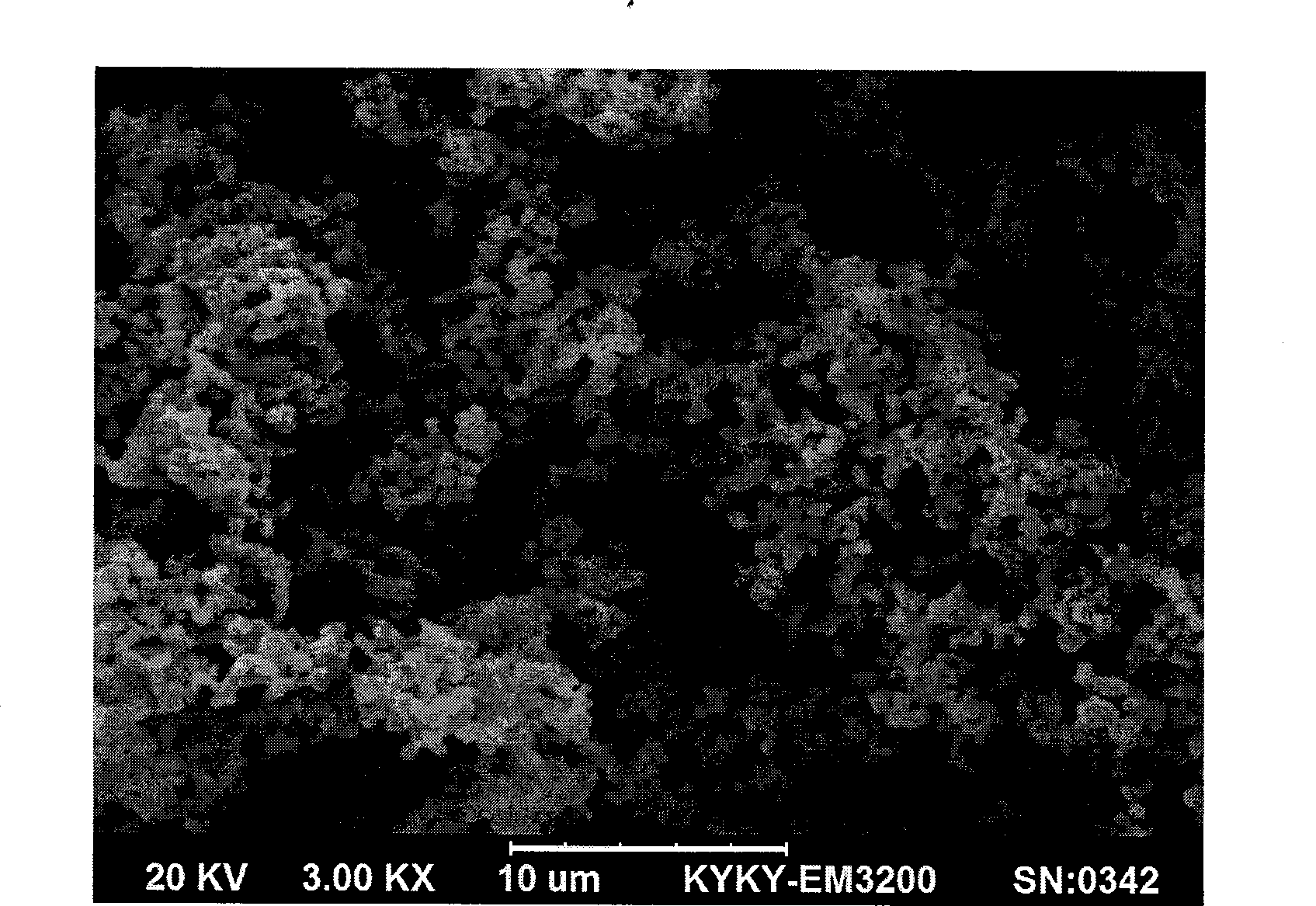

The invention relates to a method for preparing ultrafine spherical cobalt powder. The method adopts the cobalt ore as the raw material and the homogeneous precipitation-thermal reduction method to continuously prepare the mono-disperse ultra-fine spherical cobalt powder, processes the tail liquid generated during the synthesis process, and returns the tail liquid to the production system for recycling, thereby reducing the wastewater discharge, saving the production water supply and realizing the environment-friendly industrialized mass production of the ultrafine spherical cobalt powder. The prepared product of the ultrafine cobalt powder is in the shape of spherical particle with uniform particle size and intensive distribution. The method has the advantages of simple process, low production cost, high production efficiency, no environmental pollution and suitability for industrialized mass production.

Owner:ZHEJIANG HUAYOU COBALT

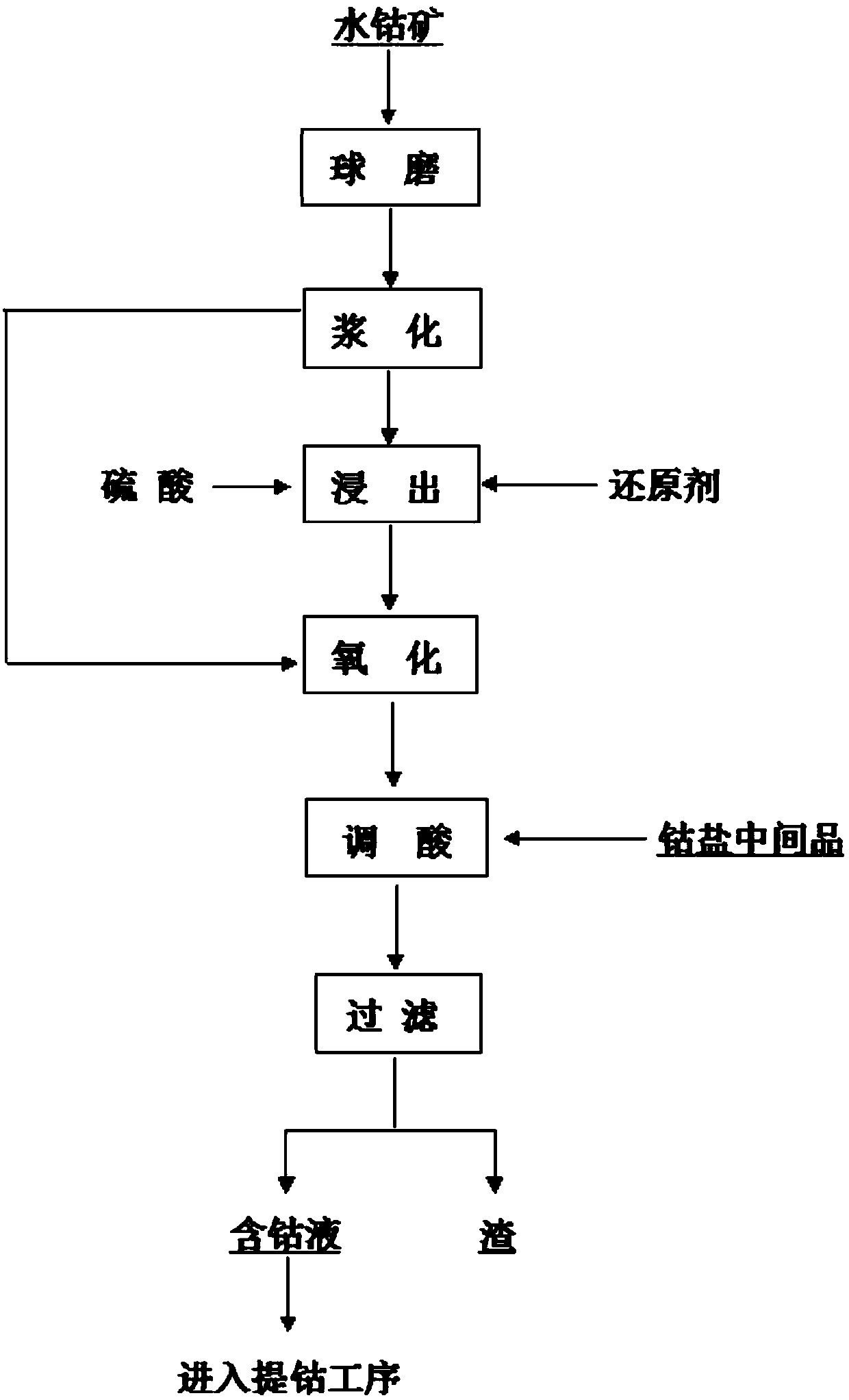

Method for selective solvent extraction of heterogenite with full-wet-process

InactiveCN101509069ATake advantage ofProcess efficiency improvementFerric hydroxideReaction temperature

The invention relates to a method for selectively leaching heterogenite, which is based on the whole wet method and characterized in that the method comprises the following steps: ball-milling and pulping heterogenite minerals until the requirement that the particle size is smaller than 150 meshes is met; putting the heterogenite minerals into concentrated sulfuric acid, concentrated hydrochloric acid or a mixed solution of both the concentrated sulfuric acid and the concentrated hydrochloric acid; adding a reducing agent containing ferrous ions to carry out reduction reaction for 5 to 9 hours under the conditions that the pH value of the solution is 1.0 to 2.0 and the reaction temperature is 60 to 90 DEG C; sampling and detecting, and stopping adding the reducing agent when the content of Cobalt in the residue is lower than 0.5% and the content of the ferrous ions in the solution is lower than 2.0g / L; adding sodium chlorate or hydrogen peroxide as an oxidizing agent, or pumping air into the solution, to oxidize the residue ferrous iron into ferric iron; adding sodium carbonate to the solution to adjust the pH value of the solution to 2.5 to 4.5; reacting for 2 to 3 hours, to precipitate the ferric iron in the form of ferric hydroxide; and leaching the waste residue after the reaction. The invention has the advantages of low production cost and low environmental pollution level.

Owner:南通新玮镍钴科技发展有限公司

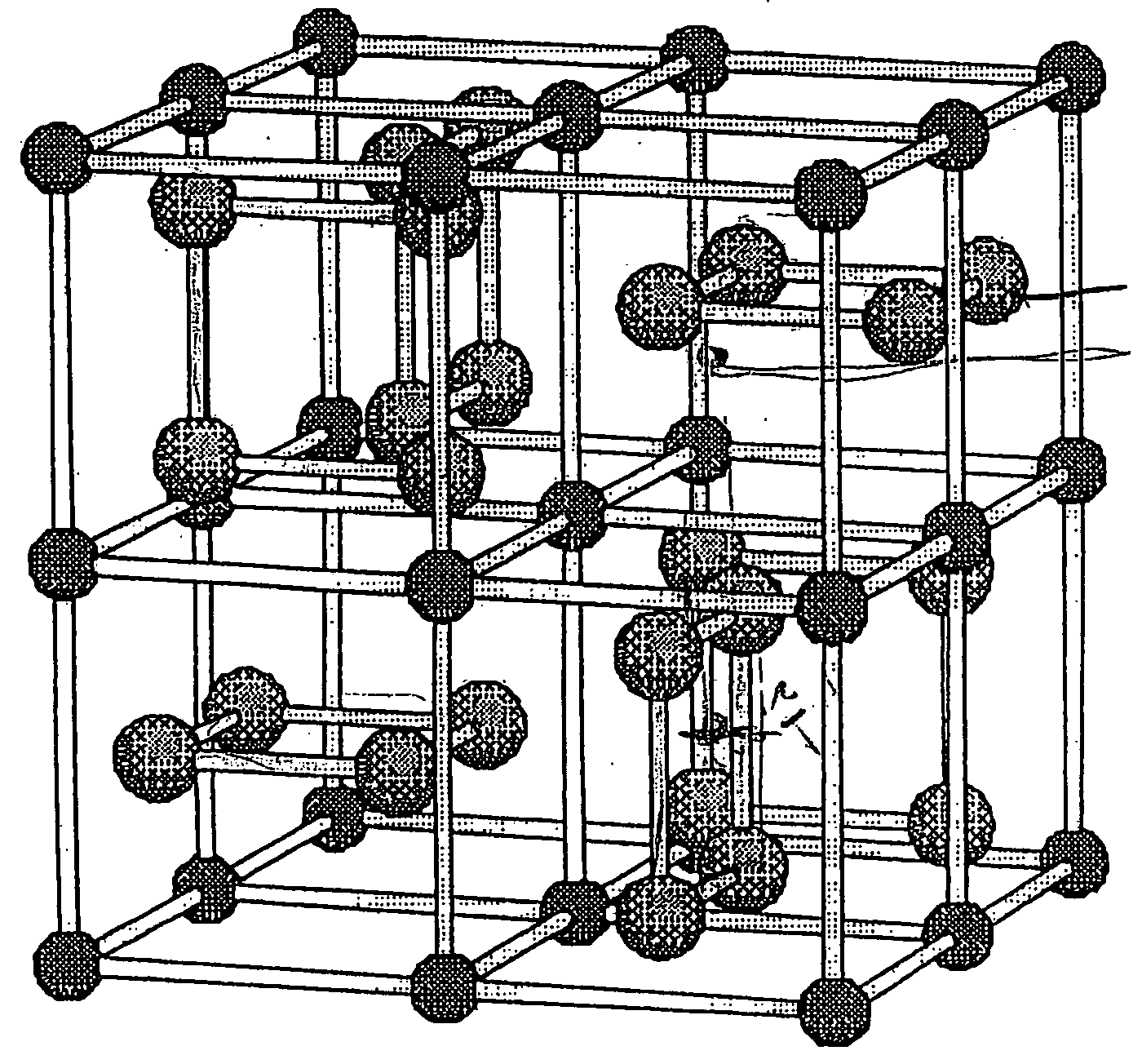

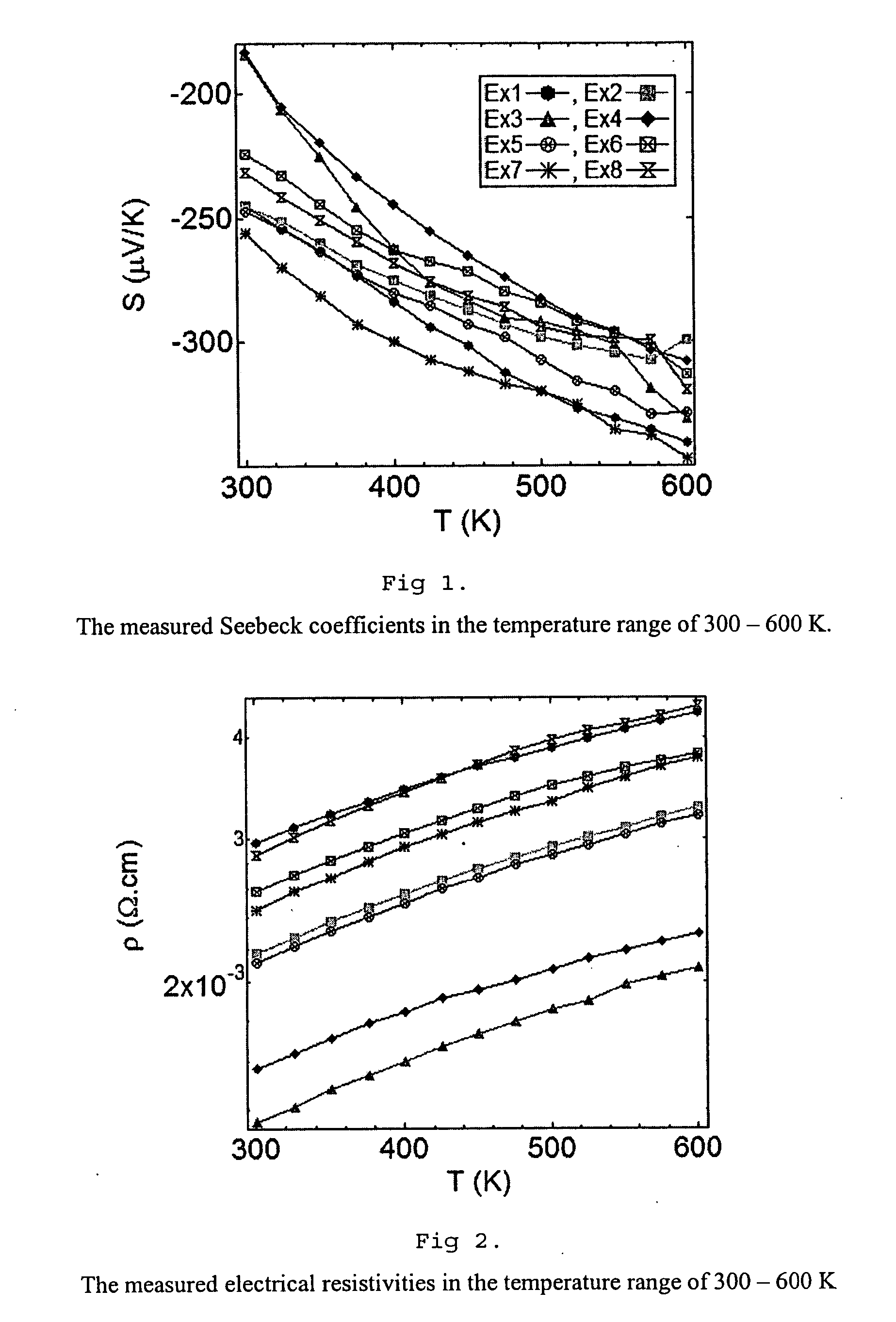

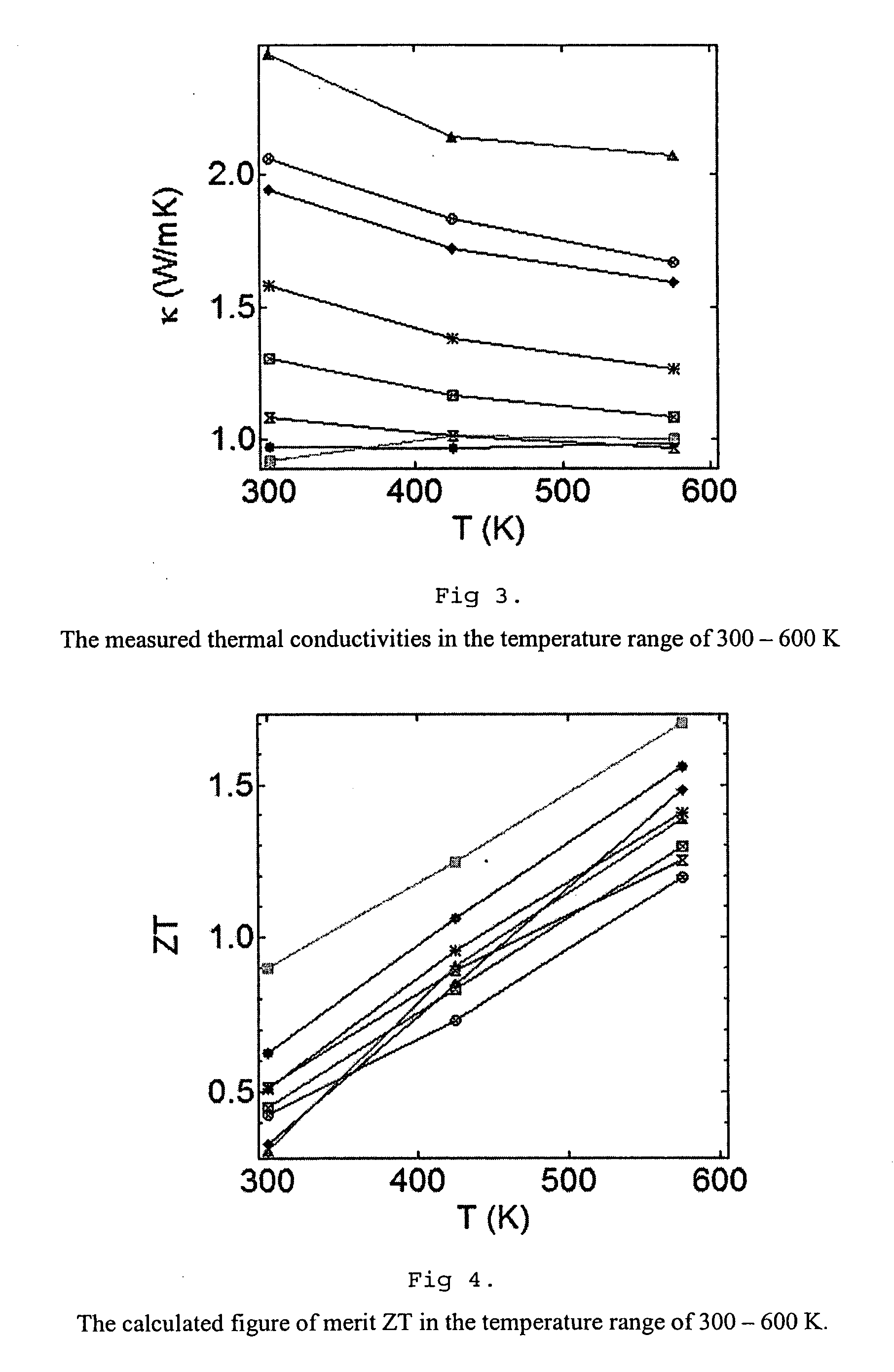

High performance thermoelectric materials and their method of preparation

InactiveUS20050229963A1High quality factorCobalt compoundsMetal/metal-oxides/metal-hydroxide catalystsIndiumSkutterudite

The present invention provides an indium-doped CO4Sb12 skutterudite composition in which some Co on the cubic lattice structure may be replaced with one or more members of the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt; some Sb on the planar rings may be replaced by one or more members of the group consisting of Si, Ga, Ge and Sn; and a second dopant atom is selected from a member of the group consisting of Ca, Sc, Zn, Sr, Y, Pd, Ag, Cd, Ba, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu. The composition is useful as a thermoelectric material. In preferred embodiments, the composition has a figure of merit greater than 1.0. The present invention also provides a process for the production of the composition, and thermoelectric devices using the composition.

Owner:EI DU PONT DE NEMOURS & CO

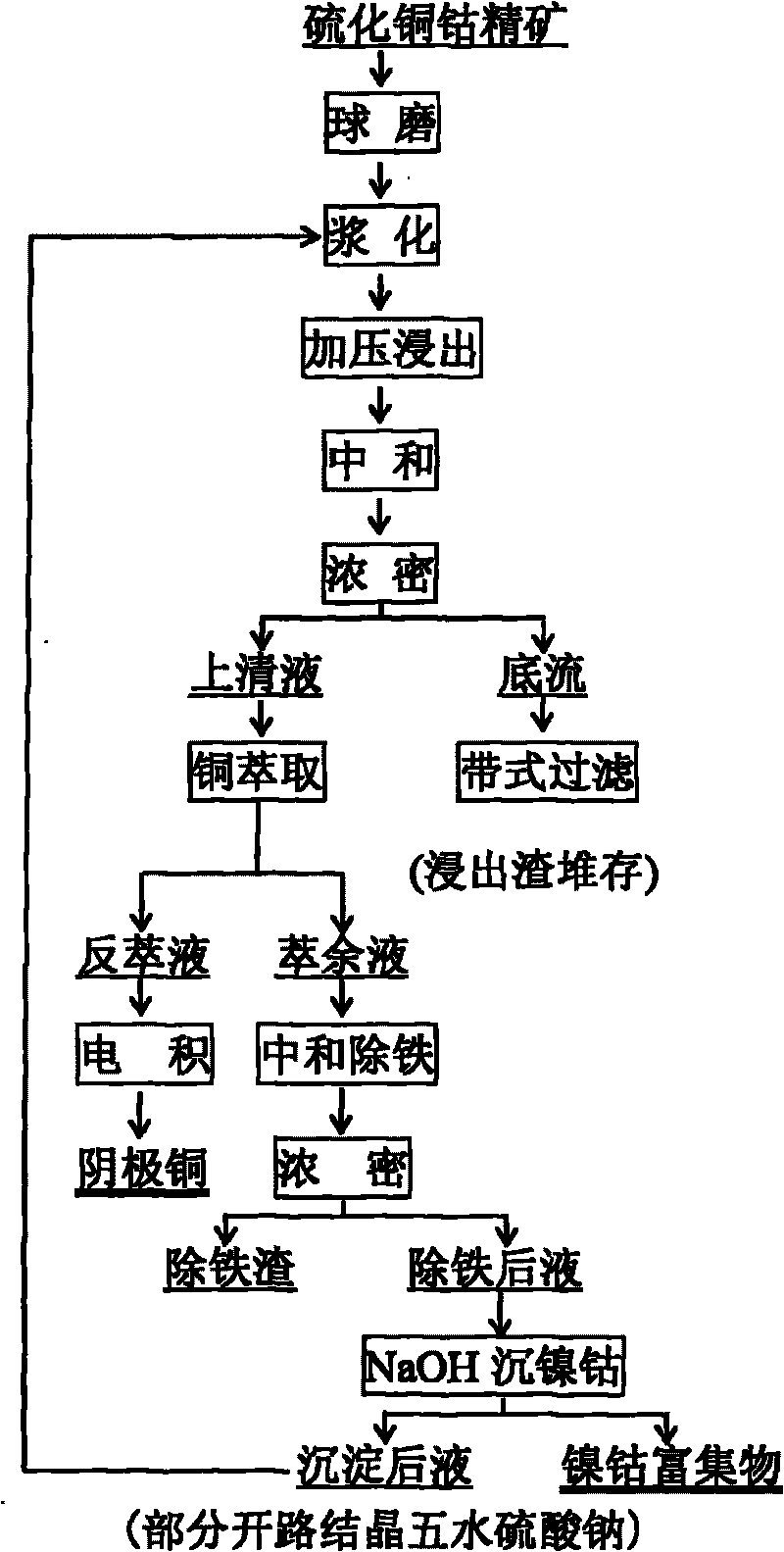

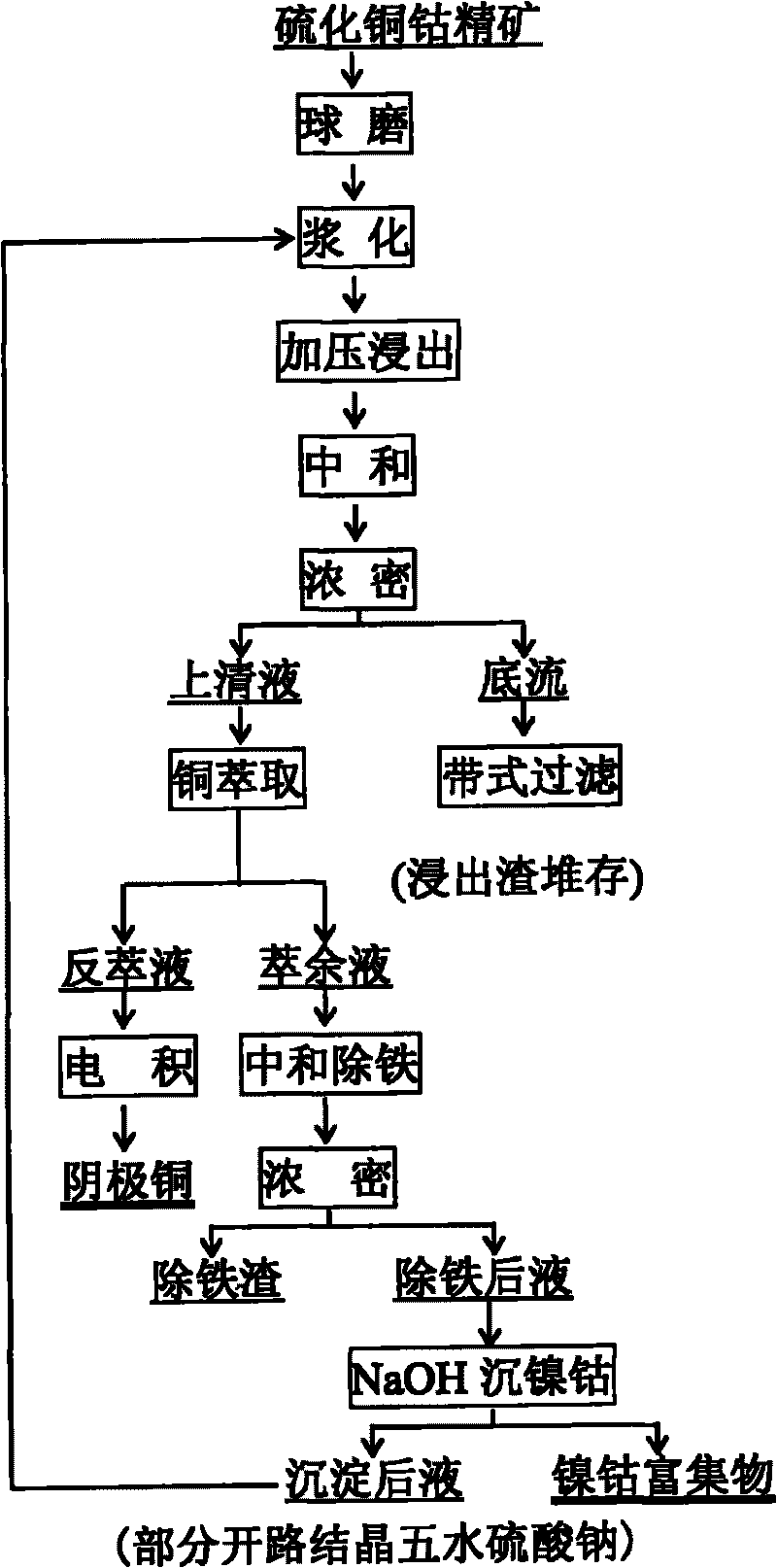

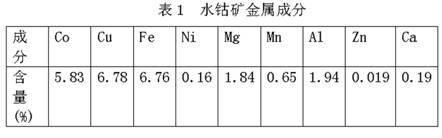

Method for extracting cobalt in copper cobalt sulfide ore

ActiveCN101705371AAchieve recyclingRealize self-heatingPhotography auxillary processesProcess efficiency improvementRaffinateSulfur containing

The invention provides a method for extracting cobalt in a copper cobalt sulfide ore, and relates to a method for extracting the cobalt in a copper cobalt ore which is in low grade and hard to treat and contains cobalt mineral raw materials. The method is characterized by comprising the following steps: (1) crushing and grinding low sulfur containing copper cobalt ore; (2) adding water into the grinded ore material for autoclave leaching; (3) neutralizing and filtering the leached ore pulp, and sending leaching residue into tailing; (4) carrying out copper extraction, extract stripping and strip liquor electrodeposition on the filtered solution to prepare cathode copper; (5) neutralizing copper extracting raffinate to remove iron and aluminum, filter-pressing and separating the neutralized ore pulp, and performing the neutralizing step after the filter-pressed and separated residue is returned to the step (3) for leaching; (6) precipitating cobalt and nickel in filter-pressed and separated solution by adopting sodium hydroxide, wherein the separated precipitate is cobalt nickel hydroxide concentrate; and (7) returning separated after-precipitating solution to the step (2) for the leaching process. The method has simple technical process and less equipment corrosion, and realizes comprehensive reclamation and utilization of valuable metals in the low sulfur containing copper cobalt concentrate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Process for selectively extracting copper and cobalt from heterogenite

InactiveCN101994003AAchieve separationRealize produceProcess efficiency improvementSulfite saltCobalt

The invention provides a process for selectively extracting copper and cobalt from heterogenite, which comprises the following steps of: performing selective reduction and acid leaching on the copper and the cobalt by using sulfuric acid and a reducing agent, namely sodium sulfite; filtering to separate leachate, and performing rotational flow electrodeposition on the leachate to extract the copper; performing rotational flow electrodeposition on liquid from which the copper is extracted to extract the cobalt; and returning liquid from which the cobalt is extracted for acid leaching. Valuable metals such as the copper, the cobalt and the like are selectively leached and immersed into solution, the leaching rates of the copper and the cobalt are over 95 percent, and 99.5 percent of iron is left in leaching residues, so that the copper and the cobalt are separated from the iron in the leaching process; the rotational flow electrodeposition method is adopted, and other impurity removal processes are not needed, so that the process is short, and equipment is simple; and wastewater is not generated and discharged, so that the closed cycle of the solution is realized, and the process is environmental-friendly and suitable for mass production.

Owner:CENT SOUTH UNIV

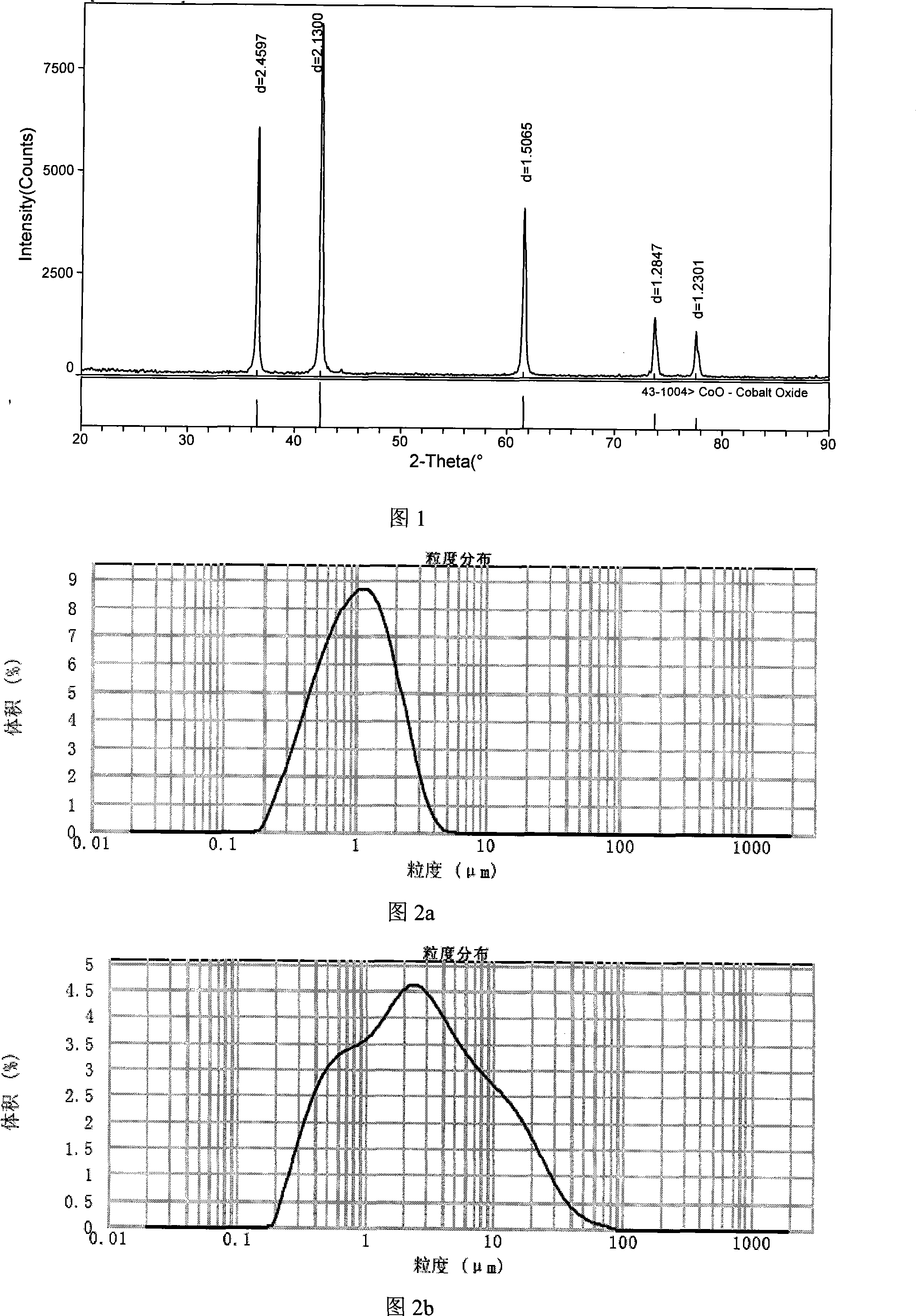

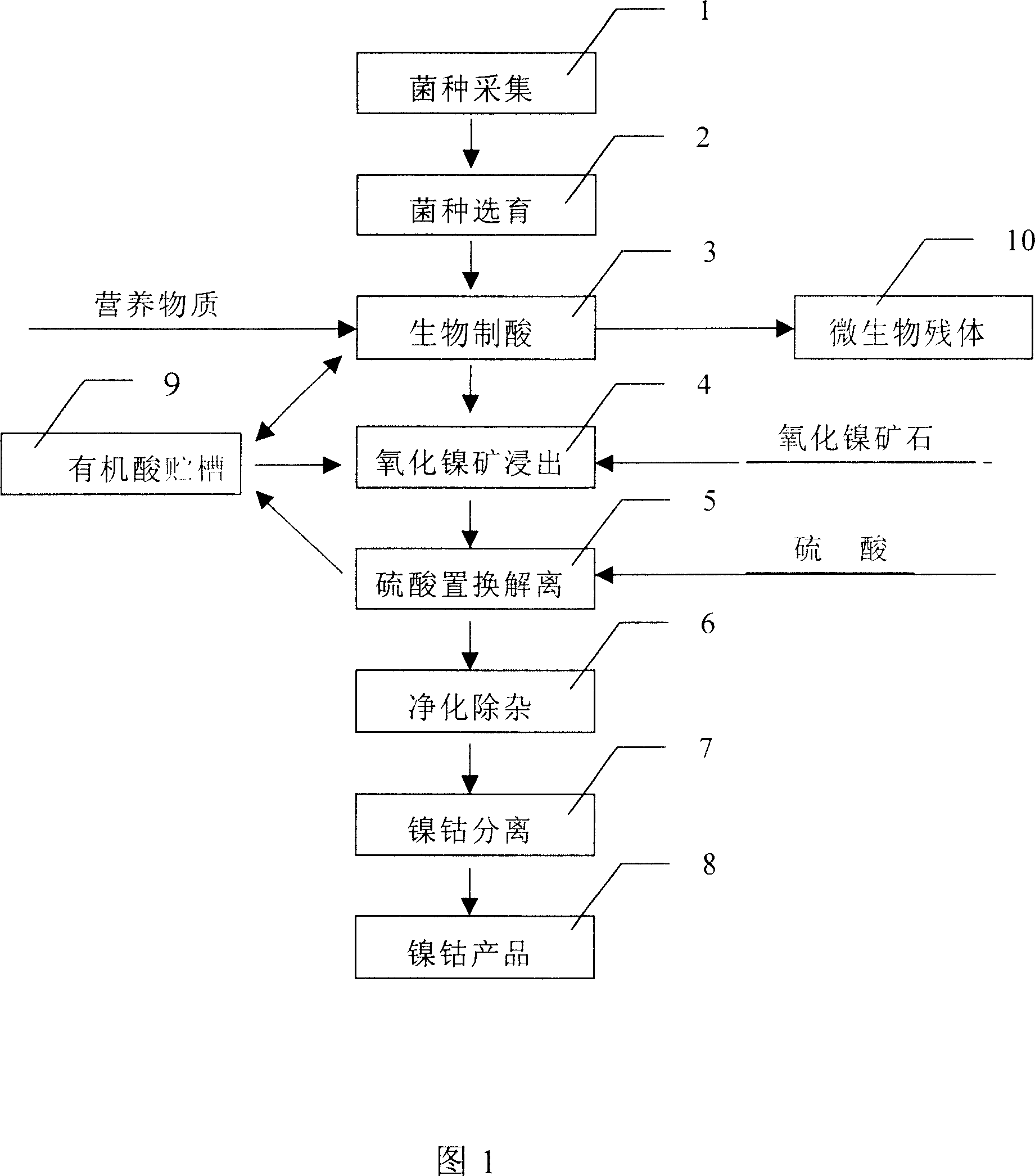

Method for preparing spherical cobaltous oxide

ActiveCN101182043AHigh activityHigh purityCell electrodesCobalt oxides/hydroxidesCobalt saltHigh activity

The invention discloses a preparation method of spherical cobaltous oxide, and relates to cobalt solution which is obtained by the leaching and purification of cobalt ore that is used as cobalt raw material. The invention is characterized in that a precursor is prepared by a complexing-homogeneous precipitation method, that is the cobalt solution is made into complexing cobalt salt solution whichis then added with precipitator solution, thereby, the precipitate precursor is formed by controlling the synthesis of the precursor; the spherical cobaltous oxide is obtained by the thermal decomposition of the precursor at 300 to 550 degrees under inert or slight reducing gas atmosphere; and then spherical cobaltous oxide of the invention is formed through the associated passivation of the obtained spherical cobaltous oxide by using gas passivator and liquid passivator, and heat seal packing. The cobaltous oxide powder which is obtained by adopting the method of the invention has the advantages of high activity, high purity, uniform particle size, centralized distribution, smooth surface of particles and strong inoxidability, etc. The invention has easy technology flow, stable production quality, low cost, high automation, thereby being applicable to the large-scale industrialized production.

Owner:ZHEJIANG HUAYOU COBALT

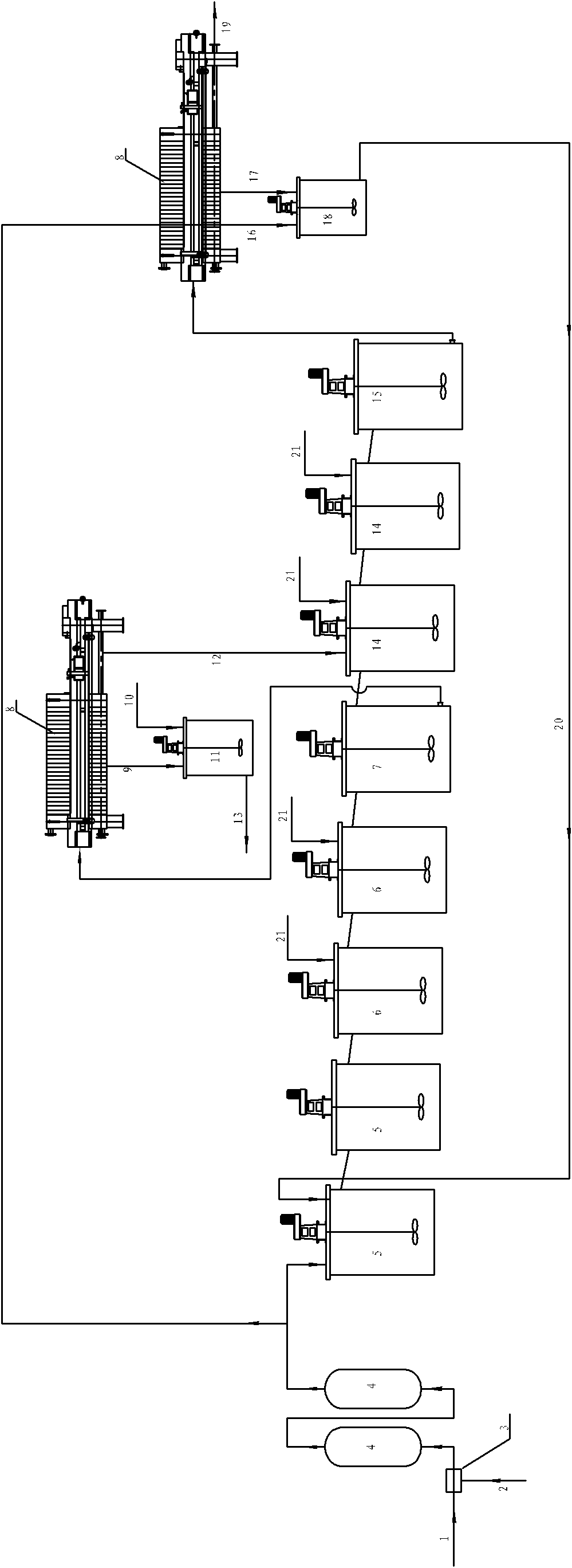

Biological extract technology for ore of cobalt nickel oxide

InactiveCN1958815AImprove leaching effectReduce heavy ironProcess efficiency improvementLower gradeLow graded

This invention relates to a biological method for leaching ores of nickel oxide and cobalt oxide. The method comprises: leaching ores of nickel oxide and cobalt oxide by using leaching organism derived organic acid, dissociating the leaching solution containing nickel and cobalt, passing through a separation resin, and separating nickel and cobalt from the eluate by a resin to obtain nickel sulfate and cobalt sulfate products. The method has such advantages as short process, simple equipment, low investment, low cost, no pollution and high recovery rate. The method can treat low-grade ores of nickel oxide and cobalt oxide that cannot be treated by traditional separation process, thus expanding the utility range of resources and increase the recovery rate of nickel and cobalt.

Owner:有研资源环境技术研究院(北京)有限公司

Ceramic material based on bismuth niobate substituted with zinc

The invention relates to ceramic materials based on bismuth niobate substituted with zinc and can be used for producing multilayer high frequency thermostable ceramic condensers provided with electrodes based on an alloy which comprises Ag and Pd, and also for producing multilayer microwave films. The aim of the invention is to develop a ceramic material having a low sintering temperature sufficient for using silver-palladium electrodes having a silver content of up to 90%. Said material has an optimum dielectric permittivity and thermostability which are sufficient for producing a wide range of items based on said material. Zinc niobate ZnNb2O6 having a structure of columbite with a quantity ranging from 7.0 to 99.0, expressed in mass %, is added into a ceramic material based on the bismuth niobate substituted with zinc having a crystal-chemical formula (Bi⅔[ ]⅓)2(Zn<2+>⅓Nd⅔)2O6[ ]1,[ ] being a vacancy with a pyrochlore structure. Glass having the following component ratio, in mass %, can be added into the material: PbO ranging from 26 to 33, Bi2 ranging from 14 to 24, B2O3 ranging from 4 to 10, TiO2 ranging from 15 to 21, ZnO ranging from 21 to 28.

Owner:NENASHEVA ELIZAVETA ARKADIEVNA +1

Iron removal process for copper cobalt ore leach liquor

ActiveCN101921914AIncreased Fe contentLow viscosityProcess efficiency improvementSlagMetal impurities

The invention relates to an iron removal process for copper cobalt ore leach liquor, belonging to the cobalt wet smelting industry. At present, the goethite method and the precipitate neutralization iron removal method are combined to remove iron, although the total quantity of iron slag can be reduced, the total quantity of the iron slag is still great because the precipitate neutralization method with high pH value is used for removing iron at a later stage. The process is characterized by comprising the following steps of: firstly, oxidizing the liquor before iron removal to oxidize ferrous iron in the liquor into ferric iron; then, removing most of iron impurities in the oxidized liquor before iron removal by using the goethite method in an iron removal tank, and removing the rest iron and other metal impurities in the liquor by the precipitate neutralization iron removal method; and filter pressing the obtained ore pulp by using a filter press to obtain filter liquor as liquor after iron removal. Under the premise of ensuring the iron removal effect, the iron content in the iron slag is increased by changing the slag form of scrap iron slag, and thus, the total quantity of the iron slag is reduced.

Owner:ZHEJIANG HUAYOU COBALT

Process for producing cobaltic-cobaltous oxide

The invention relates to a process for producing cobaltosic oxide. The process steps comprise that: boodtite powder is crushed and selectively leached out valuable metals such as cobalt and the like under the acid condition, after removing impurities and recovering the valuable metals such as copper, nickel, manganese, a solution of cobalt salt, of which the cobalt concentration is more than 100g / L, is obtained; and the solution of cobalt salt is diluted by deionized water to be between 88 and 92g / L, and the solution of cobalt salt and a solution of sodium hydroxide are continuously added in a reaction kettle at the same time, the pH value is controlled to be between 10 and 11, the compressed air is pumped in, the obtained suspension of cobaltous hydroxide is overflowed from the reaction kettle, filtered and washed by deionized water, and the washed cobaltous hydroxide is dried or placed in a calcinator with adjustable gas atmosphere, calcined at a temperature of between 400 and 1,300 DEG C for 6 to 20 hours, and crushed and graded to obtain the cobaltosic oxide. The process has the advantages of short flow and low consumption, and the reducer used in the reductive leaching process of the boodtite is a byproduct of ferrous salt generated in the whole technological process, thereby saving a large amount of sodium sulfite.

Owner:南通新玮镍钴科技发展有限公司

Process for leaching cobalt from heterogenite by virtue of cobalt salt intermediate

The invention discloses a process for leaching cobalt from heterogenite by virtue of cobalt salt intermediate. According to the process, heterogenite is used for oxidizing Fe<2+> in leach liquor, andthe cobalt salt intermediate is used for adjusting the solution, so that the amount of oxidant and alkali liquor added is reduced, the spare acidity of the leach liquor is made full use of, the consumption of reagents is reduced, the production cost is low, and the pollution to the environment is small.

Owner:上海格派镍钴材料股份有限公司

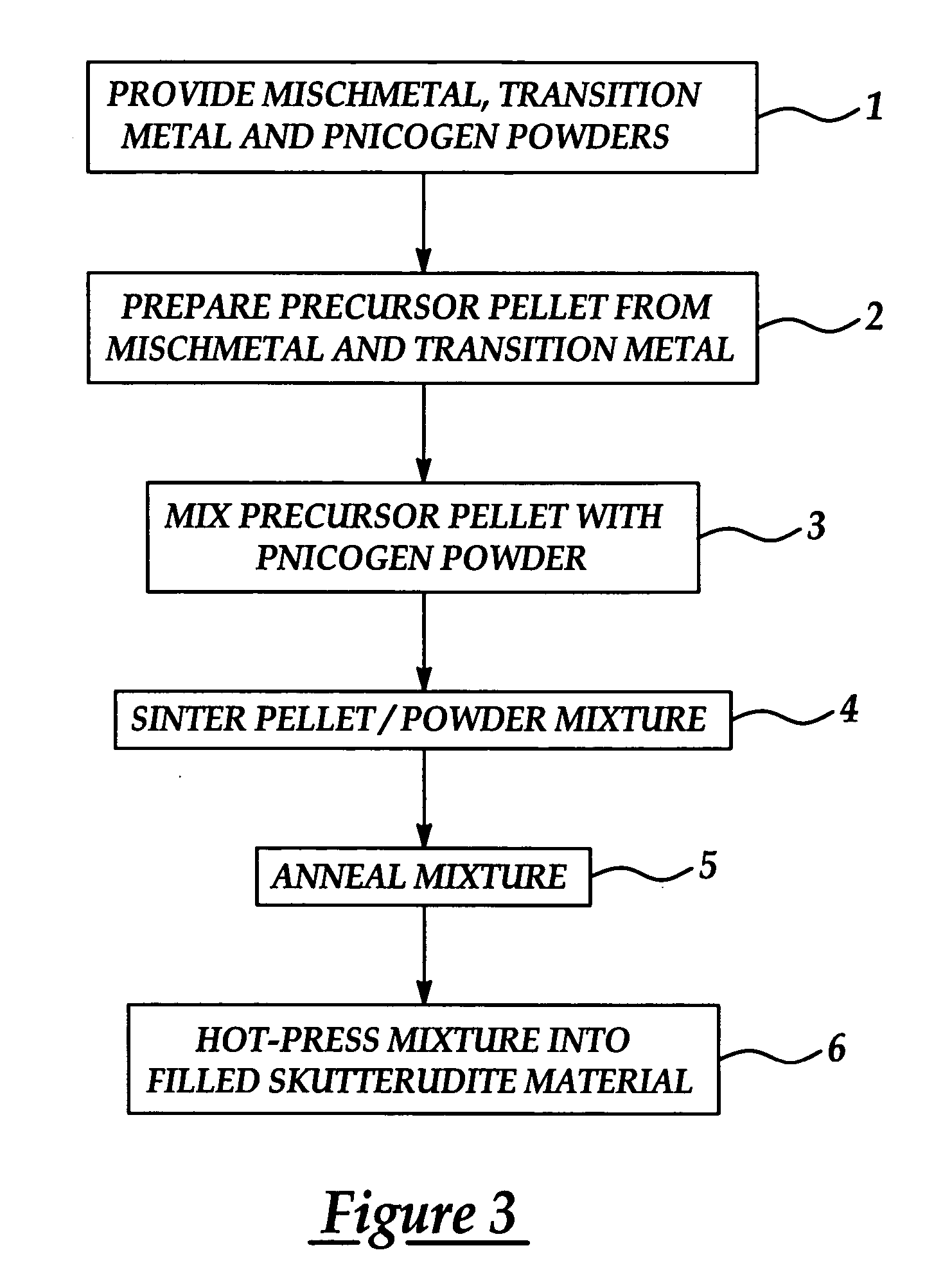

Method for producing a thermoelectric intermetallic compound

InactiveCN101952466AImprove figure of meritThermoelectric device junction materialsCompound aPhase formation

A method for producing an intermetallic compound, the method comprising: (1) providing components A, B and X; and forming by solid state reaction of components A, B and X an intermetallic compound having a filled skutterudite structure and formula of AaBbXc; (2) melting the intermetallic compound having a filled skutterudite structure produced in step (1) in the presence of additional X; and (3) annealing the intermetallic compound of step (2) in the presence of additional X at a temperature equal to, or greater than the phase formation temperature of the intermetallic compound.

Owner:BIOMETRIC TECH SOLUTIONS

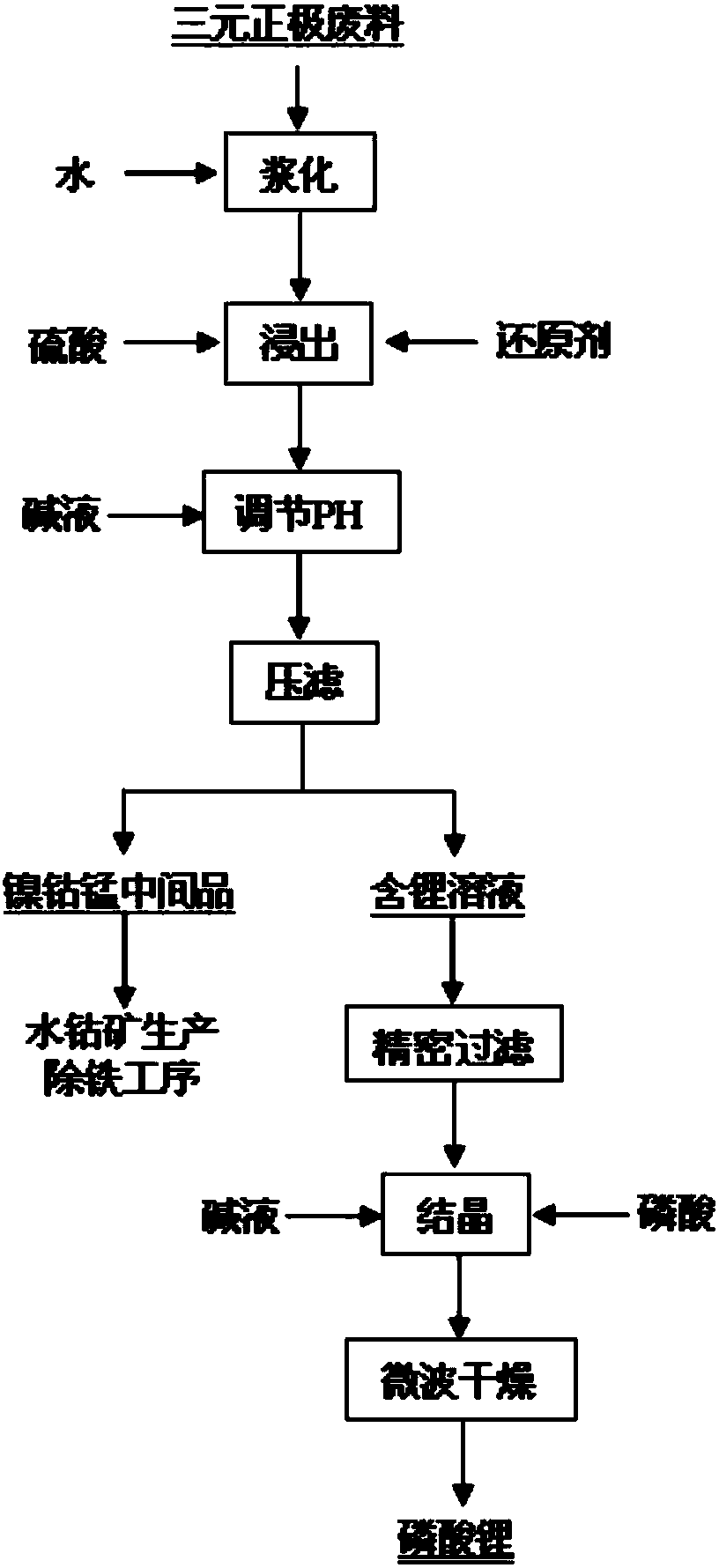

Nickel cobalt lithium manganate ternary polymer battery anode waste material recovery method

InactiveCN108172925ASimple processWide range of recyclingWaste accumulators reclaimingProcess efficiency improvementRecovery methodLithium hydroxide

The invention discloses a nickel cobalt lithium manganate ternary polymer battery anode waste material recovery method. A recovered nickel cobalt lithium manganate battery anode waste material is slurried, is subjected to reduction leaching under acidic condition, alkali lye is used for adjusting a pH value to deposit nickel cobalt manganese, press filtration is carried out to obtain a nickel cobalt manganese intermediate, the intermediate is used for adjusting the pH value during an iron removal process in a heterogenite production process, which can substitute addition of sodium carbonate during the iron removal process; a filtered lithium hydroxide solution is subjected to further purifying through a high-molecular PE microporous membrane, a phosphoric acid solution is slowly added, thealkali lye is used for controlling the pH value of the solution, and a reaction product is subjected to aging, centrifugation filtering, washing with pure water and microwave drying to obtain the micron-level lithium phosphate.

Owner:浙江格派钴业新材料有限公司

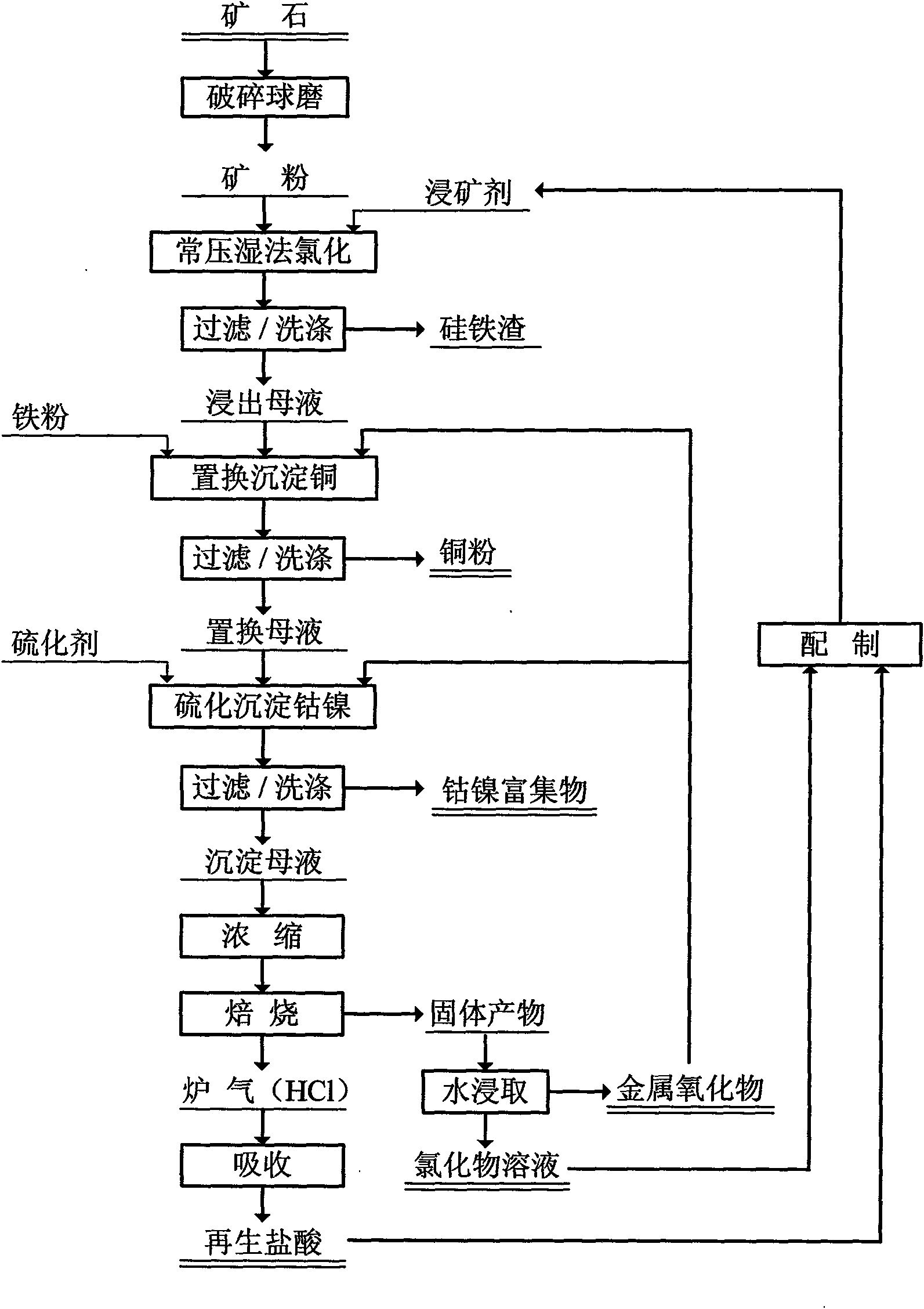

Method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore

ActiveCN101575673AImprove leaching ratePromote circulationProcess efficiency improvementSlurrySulfide

The invention provides a method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore, which uses low-grade complex mixed copper-cobalt ore (sulfide and oxide) as a raw material to extract an intermediate product of the copper and cobalt-nickel by adopting process flows of crushing and grinding ore into slurry, leaching the slurry with acidic villaumite by a wet method, extracting copper powder by reduction and replacement, vulcanizing and depositing nickel (cobalt), concentrating, drying, baking and hydrolyzing deposited mother solution at low temperature and the like. The method comprises main technical points that metallic elements in the mixed copper-cobalt ore are dissolved and leached by the acidic villaumite under normal pressure; copper in leaching liquor is reduced and deposited by a reducing agent; the cobalt and nickel are deposited by a vulcanizing agent to obtain the intermediate product; the mother solution is concentrated, dried, baked and hydrolyzed at low temperature after cobalt-nickel deposition to obtain metal oxide, metal oxychloride and hydrogen chloride containing iron, magnesium and the like; hydrogen chloride is reclaimed to obtain hydrochloric acid, and baked solid is leached into water to obtain chloride solution; and the hydrochloric acid and the chloride solution are used for leaching of ore slurry. The method comprehensively reclaims the copper, the cobalt-nickel and the like, and has the characteristics of high leaching rate of the copper and the cobalt-nickel, less energy consumption, low cost, closed circulation of chlorine (hydrochloric acid), less investment of project engineering and the like. The whole process is concise, clean and environment-friendly. The method is particularly applicable to large-scale industrial production.

Owner:福建常青新能源科技有限公司

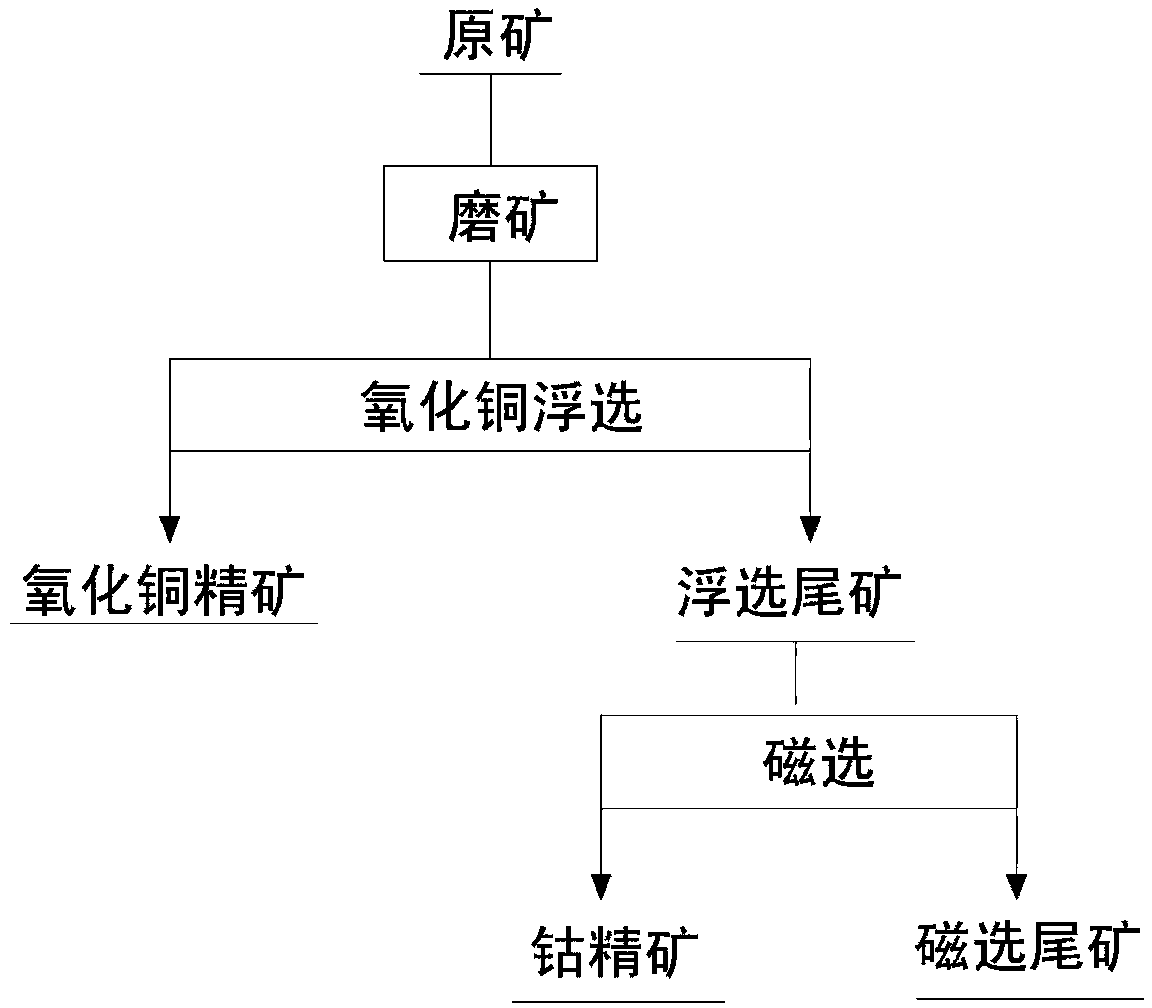

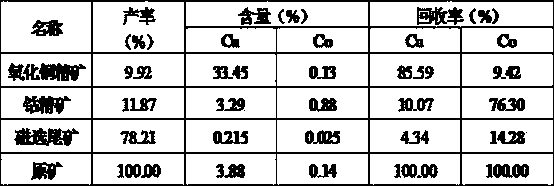

Beneficiation method for copper oxide cobalt ores

The invention relates to a beneficiation method for copper oxide cobalt ores. The beneficiation method is characterized by comprising the following steps of 1, ore grinding, i.e. crushing and grinding raw ores; 2, copper oxide flotation, i.e. adding sodium sulfide, a collecting agent butyl xanthate and a foaming agent terpenic oil in the primary roughing process, adding sodium sulfide, butyl xanthate and terpenic oil in the primary scavenging process, adding sodium sulfide, butyl xanthate and terpenic oil in the secondary scavenging process and carrying out secondary blank concentration to obtain copper oxide concentrates and flotation tailings; and 3, magnetic separation, i.e. carrying out primary roughing magnetic separation on the flotation tailings to obtain cobalt rough concentrates and magnetic separation tailings and carrying out secondary concentration magnetic separation on the cobalt rough concentrates to obtain cobalt concentrates and magnetic separation tailings. The invention provides the beneficiation method for the copper oxide cobalt ores, which reduces cost and pollution. The method disclosed by the invention is suitable for the copper oxide cobalt ores comprising copper oxide ores, copper oxide cobalt ores and cobaltous oxide minerals.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

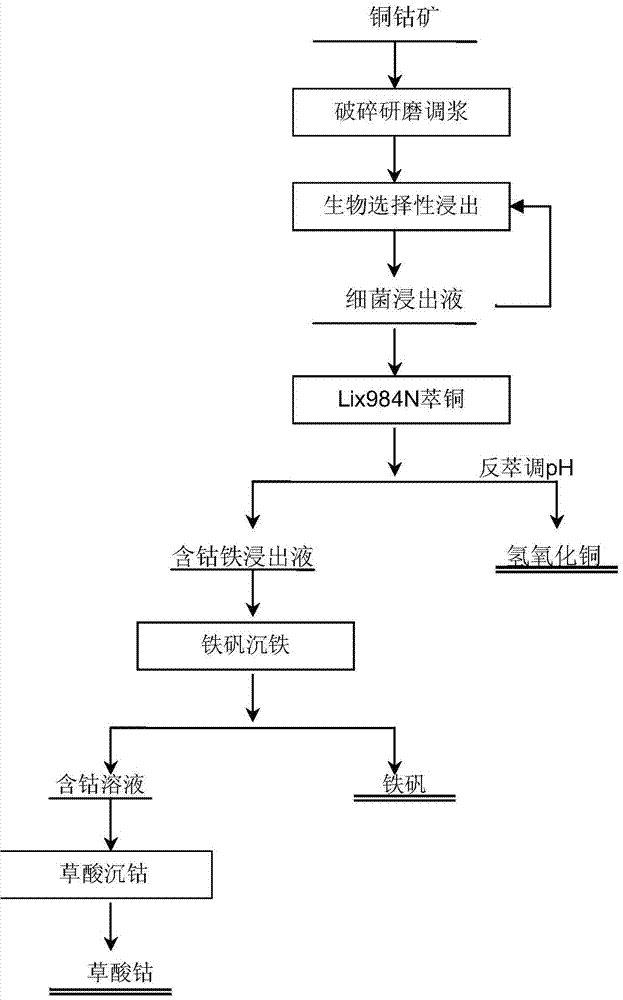

Biological selectivity leaching method of low-grade copper-cobalt ore

ActiveCN103572050AAchieve separationEfficient recyclingProcess efficiency improvementThiobacillus ferrooxidansCobalt

The invention discloses a biological selectivity leaching method of low-grade copper-cobalt ore, and belongs to the field of microbial metallurgy. The biological selectivity leaching method comprises the following steps: the copper-cobalt ore is crushed and grinded; a mixed bacterium liquid containing ferrous oxide micro spirilla, acidophilic thiobacillus ferrooxidans and acidophilic thiobacillus thiooxidans is introduced to a 9 K of culture medium for cultivating to obtain a bacterium culture solution. The copper-cobalt ore is added to the bacterium culture solution to conduct bacterium leaching on the cobalt concentrate; when the leaching rate of cobalt in the bacterium leaching liquid reaches above 97%, the leaching liquid containing valuable metal ions such as cobalt and copper is separated from the leaching residue; then Lix984N extraction agent is adopted to extract copper to obtain a copper product; the raffinate from which the copper is extracted is subjected to precipitation and iron removing treatment by a jarosite process to obtain an iron product; cobalt-containing liquid after being subjected to iron removal is crystallized to obtain a cobalt oxalate product. The biological selectivity leaching method has the advantages of short technique flow, easy operation, simple equipment, low energy consumption, no high-temperature smelting, no emission of pollutant smoke and poisonous gas, and quick achievement of separation and efficient recovery of cobalt and other valuable metals.

Owner:NORTHEASTERN UNIV

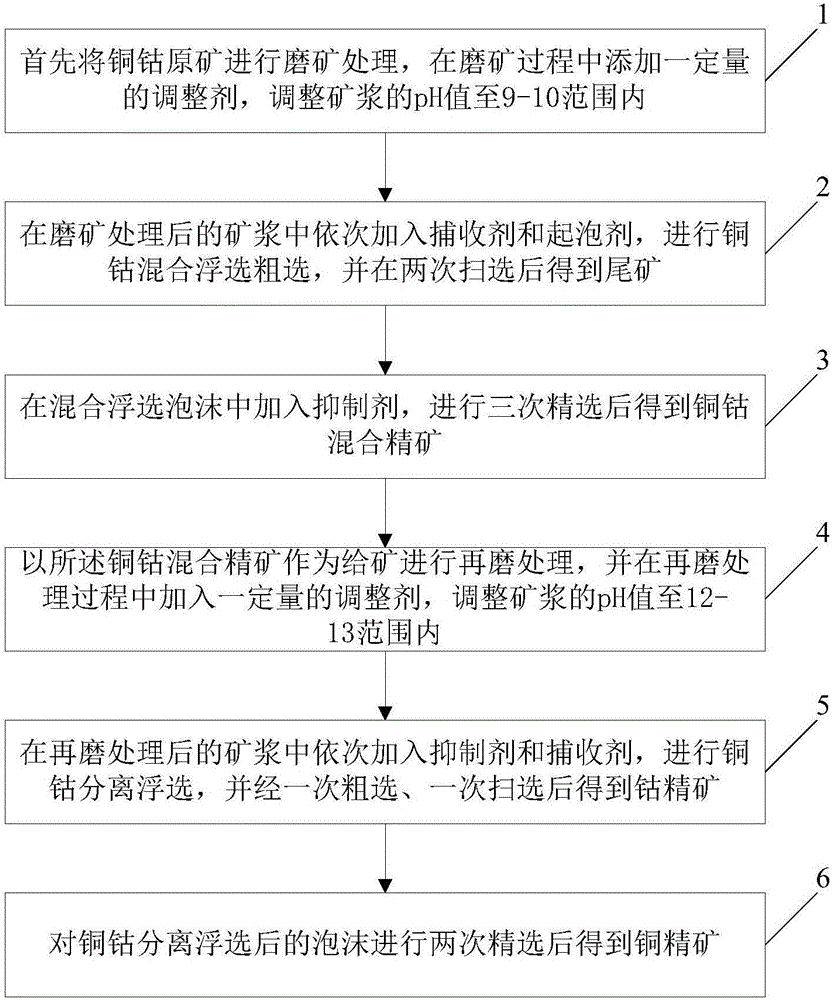

Ore dressing method of copper-cobalt ores

The invention discloses an ore dressing method of copper-cobalt ores. The ore dressing method comprises the following steps: first, carrying out ore grinding treatment on copper-cobalt raw ores, adding a certain quantity of regulator in an ore grinding process, and regulating the pH value of ore slurry within a 9-10 range; sequentially adding a collector and a foaming agent into the ore slurry which is treated by ore grinding, carrying out copper-cobalt bulk flotation rough concentration, and after scavenging twice, obtaining tailings; adding an inhibitor into bulk flotation foams, and after carrying out fine concentration for three times, obtaining copper-cobalt bulk concentrates; using the copper-cobalt bulk concentrates as fed ores, carrying out regrinding treatment, adding a certain quantity of regulator in a regrinding treatment process, and regulating the pH value of the ore slurry within a 12-13 range; sequentially adding an inhibitor and a collector into the ore slurry which is treated by regrinding, carrying out copper-cobalt separating flotation, and obtaining cobalt concentrates after one rough concentration and one scavenging; and after carrying out fine concentration twice on the foams which are subjected to copper-cobalt separating flotation, obtaining copper concentrates. The method can effectively separate the copper-cobalt ores and obtain high-quality copper and cobalt concentrates.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

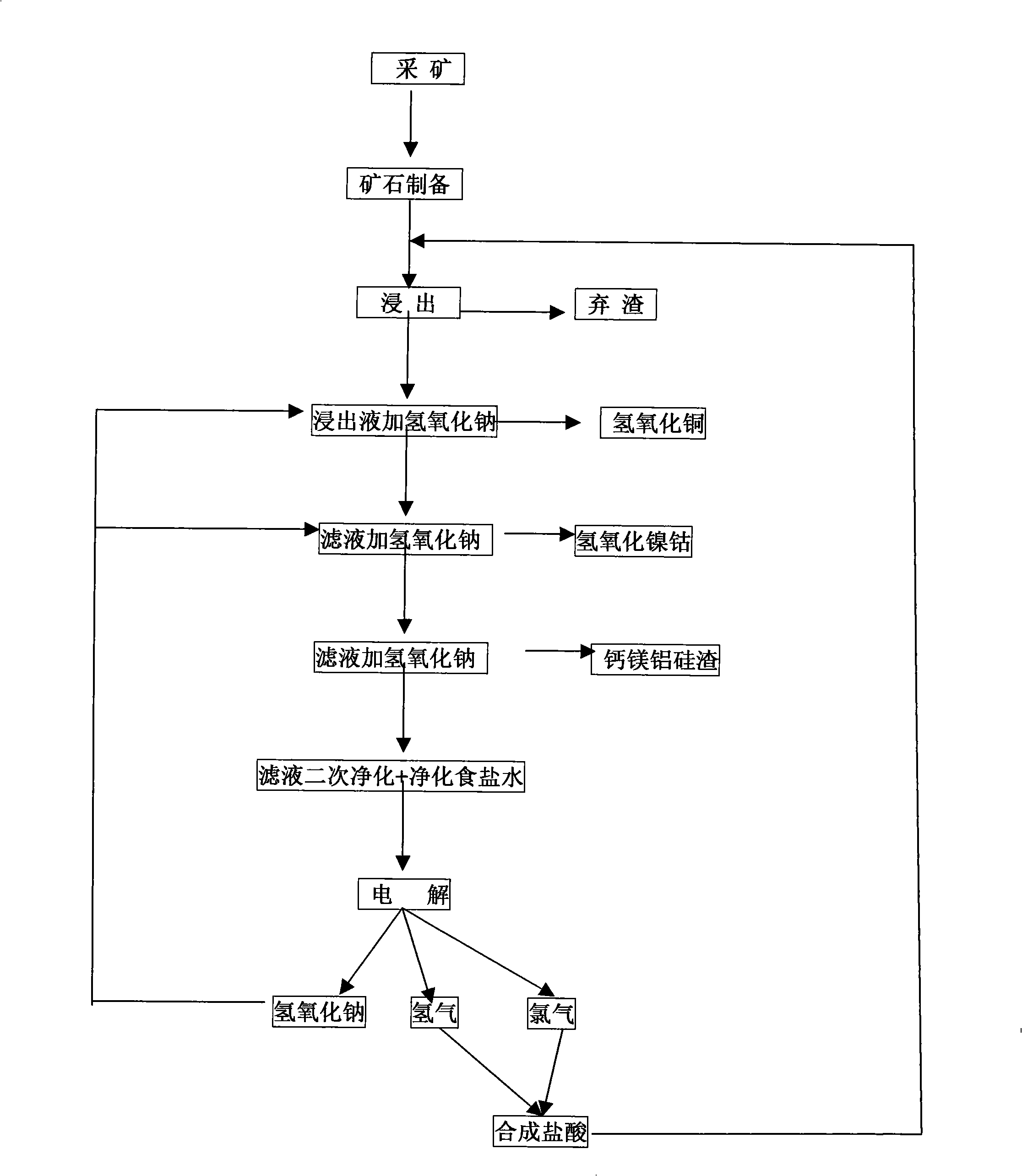

Method for extracting copper, cobalt and nickel from cupric oxide cobalt ore

InactiveCN101328538AHigh recovery rateImprove leaching rateElectrolysis componentsProcess efficiency improvementCopper oxideImpurity

The invention provides a method for extracting copper, cobalt and nickel from copper oxide and cobalt oxide ores by a hydrochloric acid method. The method takes the copper oxide and cobalt oxide ores as raw materials, and comprises the steps of mining, ore preparation, ore leaching, separation, washing of leaching dregs, precipitation of copper in leaching liquid, precipitation of cobalt and nickel in the leaching liquid, purification of the leaching liquid, reclaiming of regeneration hydrochloric acid(caustic soda), utilization; and intermediate products of copper and nickel are extracted, the hydrochloric acid and the caustic soda are reclaimed and regenerated for cyclic utilization, and simultaneously washing water is reclaimed for cyclic utilization, no waste is discharged, so that the environmental pollution is not existed. The method has the advantages of fast leaching, strong impurity removal capability, high leaching ratio of the copper, the cobalt and the nickel, high recovery, wide application range of resources, the formation of a closed cycle not discharging to the outside and maximal environmental protection; under the condition of low unit metal investment, the process, the technology and the equipment of the invention can completely meet the requirements of mass production and industrial production; moreover, the technological process also has the advantages of simpleness, low energy consumption, little material consumption, low cost and relatively high comprehensive utilization rate of ores, and the economic benefits and the environmental protection benefits of the invention are much better compared with the prior art.

Owner:YUNNAN JIAMING TECH IND

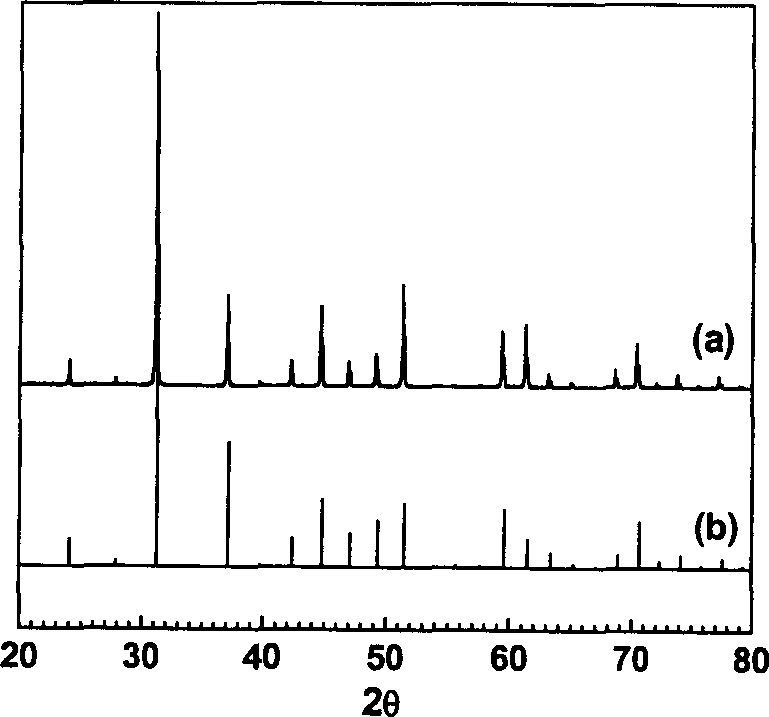

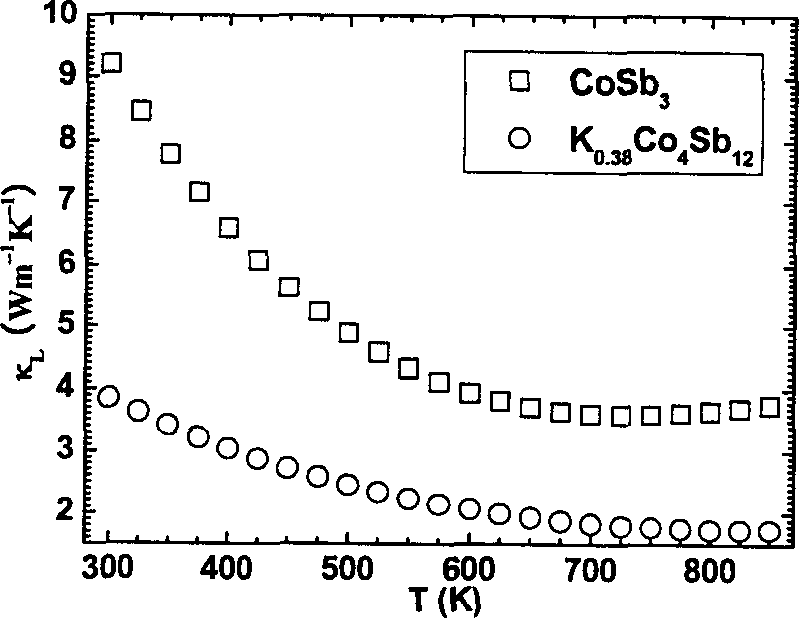

Filling in thermoelectric material of cobalt stibide based skutterudite by alkali-metal atom, and preparation method

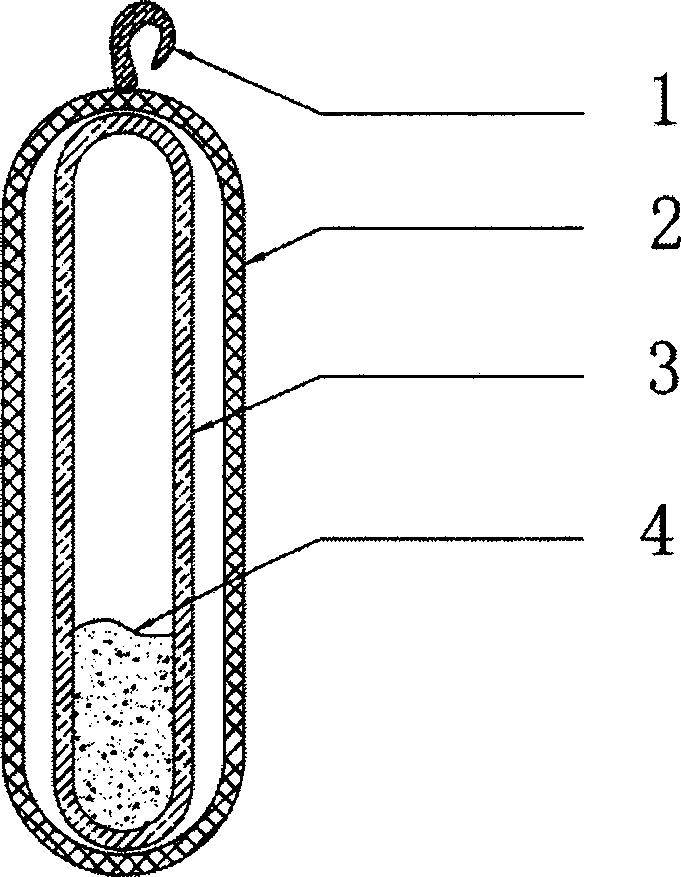

ActiveCN1916211ASolve preparation difficultiesSolve the problem of strong corrosionThermoelectric device junction materialsMolten stateCobalt

This invention relates to a method for preparing alkali-metal-filled cobalt-antimonide-based thermoelectric material having high filling amount and excellent thermoelectric property. The thermoelectric material has a general chemical formula of AyCo4Sb12, wherein y is within 0-1, and A is at least one of Li, Na, K and Rb. The method comprises: (1) preparing metal raw materials with purities higher than 99% according to a stoichiometric ratio of Ay+y'Co4Sb12, wherein y' is within 0-0.5y and y within 0-1; (2) mixing and filling into a carbon-coated quartz tube in vacuum or inert atmosphere; (3) heating to 950-1200 deg.C for melting, and reacting completely; (4) quenching in air or quenching liquid oil (oil or water) to obtain AyCo4Sb12 crystal rod; (5) grinding into powder, mixing uniformly and tableting; (6) performing thermal treatment in inert atmosphere, grinding into powder, placing into a graphite mold, and rapidly sintering by plasma-discharging sintering to obtain compact block. The method has such advantages as simple process and low cost, and the obtained alkali-metal-filled cobalt-antimonide-based thermoelectric material has excellent thermoelectric properties.

Owner:中科西卡思(苏州)科技发展有限公司

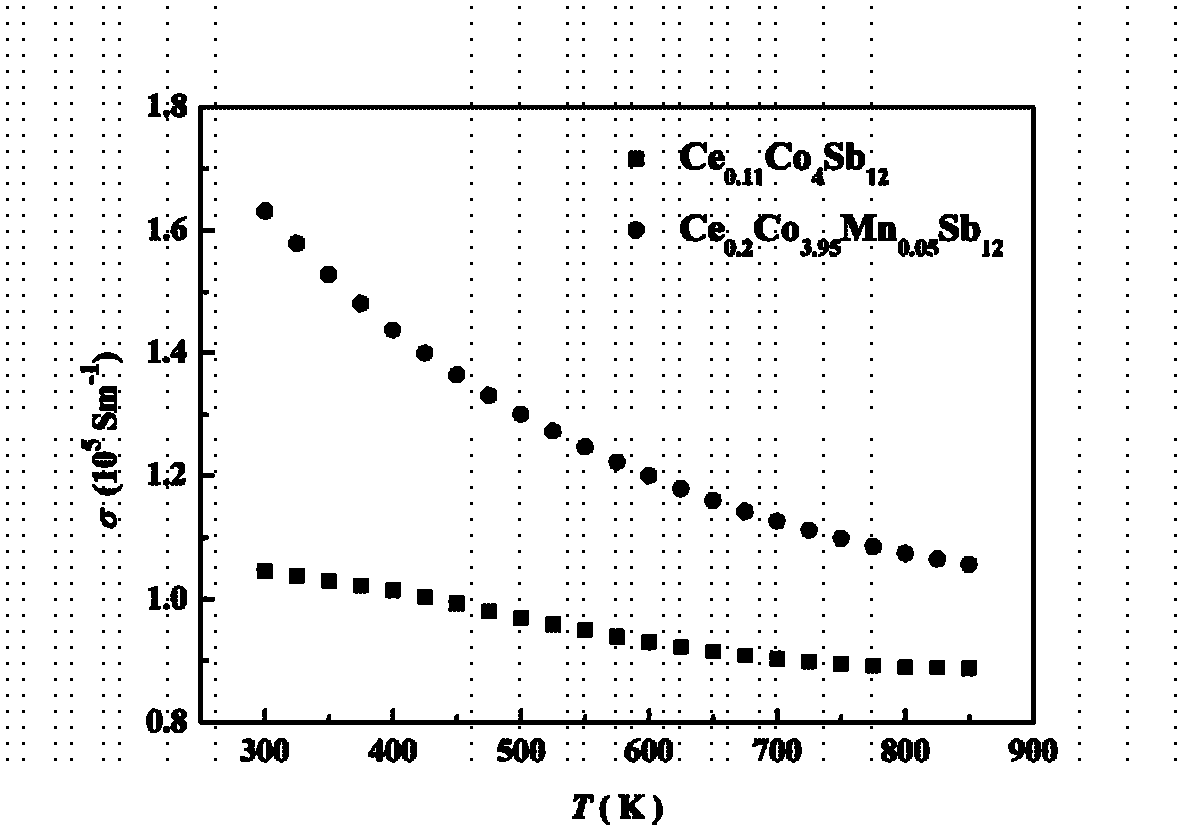

Hole compensation type skutterudite thermoelectric material and preparation method therefore

ActiveCN102881814AIncrease filling volumeHigh conductanceIron compoundsCobalt compoundsSkutteruditeElectron number

The invention relates to a hole compensation type skutterrudite thermoelectric material and a preparation method of the hole compensation type skutterudite thermoelectric material. The hole compensation type skutterudite thermoelectric material is shown in the following description: RyA(4-x)BxSb12 / z NC, wherein x is equal to or greater than 0.01 and equal to or less than 0.5, y is equal to or greater than 0.01 and equal to or less than 1 and z is equal to or greater than 0% and equal to or less than 10%; R is selected from at least one of the following group of elements: Ca, Ba, La, Ce, Pr, Nd and Yb; A is selected from at least one of the following group of elements: Fe, Co and Ni; B is selected from at least one of the following group of transition metal elements: Ti, V, Cr, Mn, Fe, Nb, Mo, Tc and Ru, and electron number of the element B is less than that of the element A; and NC is in phase II, wherein z is mole% in the phase II of the thermoelectric material. The invention also provides the preparation method of the hole compensation type skutterrudite thermoelectric material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

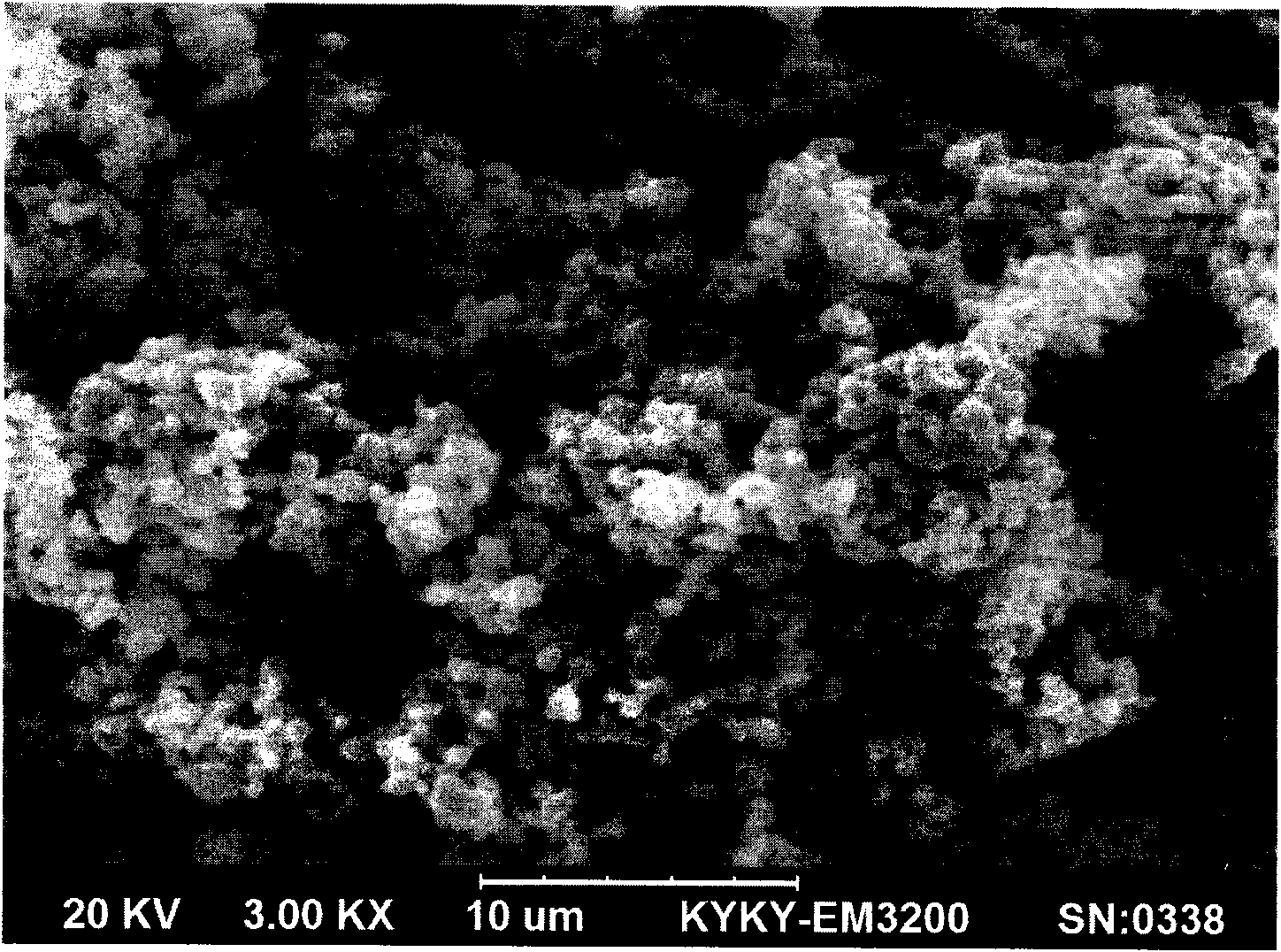

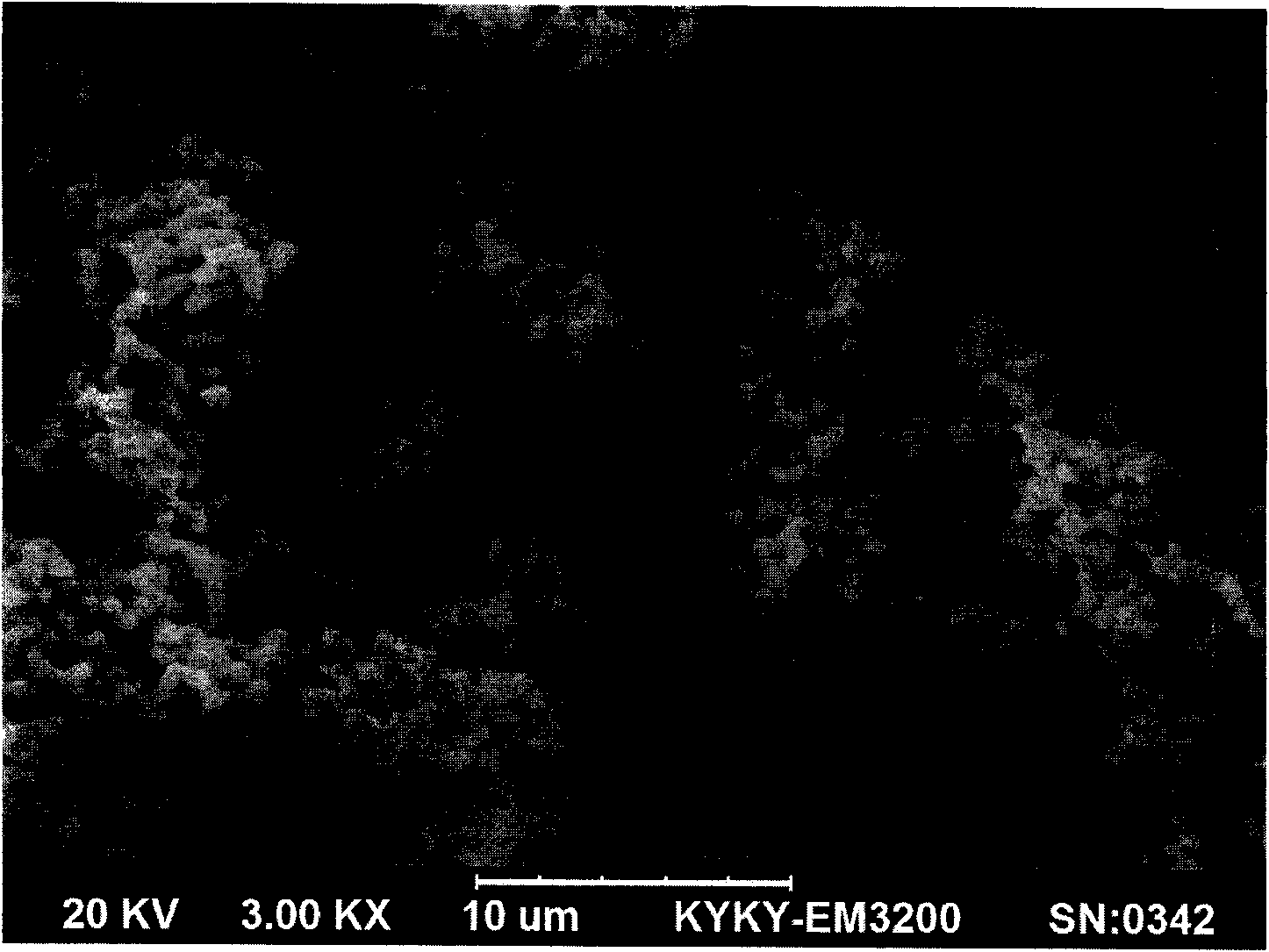

Method for preparing nano structure of columbite-type metal niobate

InactiveCN103964505AMix well and evenlyUniversalMaterial nanotechnologyNiobium compoundsNano structuringPotassium hydroxide

The invention discloses a method for preparing nano structure of columbite-type metal niobate. The method is characterized by comprising the following steps: conducting reaction of niobium pentoxide and melted potassium hydroxide, performing recrystallization in a water solution to prepare a precursor of six potassium niobate, and performing hydrothermal reaction of six potassium niobate and soluble metal salt. The technical method disclosed by the invention has the following obvious advantages: 1, the adopted hydrothermal method is simple in technology, convenient to operate, low in manufacturing cost, and environment-friendly; 2, the synthesis technology can be carried out in a relatively low reaction temperature; 3, the whole reaction is carried out in a liquid phase, so that the precursor is fully and uniformly mixed; 4, the method has obvious applicability to the preparation of metal niobate series.

Owner:NANCHANG UNIV

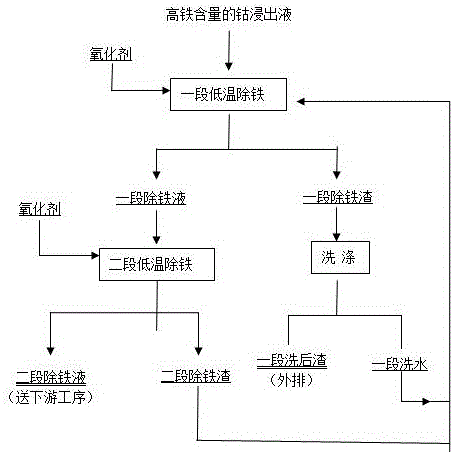

Two-step low-temperature iron removing method for copper-cobalt ore leachate

InactiveCN106756022AHigh recovery rateLow recovery rateProcess efficiency improvementSocial benefitsSlag

The invention provides a two-step low-temperature iron removing method for copper-cobalt ore leachate. The process that iron is removed in a two-step neutralization-hydrolysis mode, the final pH of first-step low-temperature iron removal is controlled to be 2.5-3.0, and the final pH of second-step low-temperature iron removal is controlled to be 3.5-4.5 is adopted. An open loop is formed through iron slag after first-step washing, the entrainment rate of valuable metal in the first-step iron slag is as low as being smaller than 0.1%, and the recovery rate of the valuable metal is increased; and the iron content of liquid subjected to second-step iron-removal is smaller than 0.01 g / L, the iron removing depth is high, and the solution purification iron-removing effect is good. Meanwhile, deep iron-removal can be conducted even at a low temperature, the energy consumption is low, accordingly the production cost is lowered, and the economic benefits are high. The method is simple, technical conditions are easy to control, the content of the valuable metal in the open-loop slag is low, and the metal recovery rate is high; the liquid subjected to low-temperate iron-removal is low in iron content and good in solution purification iron-removing effect; and meanwhile, raw materials provided for the method are low in price, low-temperature operation is achieved, the energy consumption is low, scale production is easy to achieve, and the economic benefits and the social benefits are good.

Owner:JINCHUAN GROUP LIMITED

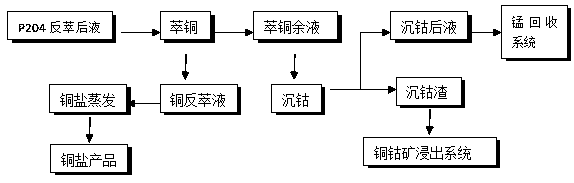

Method for separating and recovering cobalt and copper from P204 reverse extraction liquid in cobalt and copper mine wet method smelting process

PendingCN109487083AHigh recovery rateSolve complexityProcess efficiency improvementCopper sulfatesKeroseneSmelting process

The invention provides a method for separating and recovering cobalt and copper from P204 reverse extraction liquid in a cobalt and copper mine wet method smelting process. The method for separating and recovering the cobalt and the copper from the P204 reverse extraction liquid in the cobalt and copper mine wet method smelting process comprises the following steps that a copper extraction agent and sulfonated kerosene are added into the P204 reverse extraction liquid for extraction, a PH value is controlled between 1.5 and 2.0 in the process, and extracted copper residual liquid and extractedcopper organic load are obtained; sulfuric acid is added into the extracted copper organic load for reverse extraction to form a copper sulphate solution, and the copper sulphate solution is fed intoa copper salt vaporization system for vaporization to obtain a copper salt product; and the extracted copper residual liquid is heated to 30-60 DEG C, a precipitating agent is added for precipitation, a final PH value is controlled between 3.0 and 4.0, filter pressing and solid-liquid separation are carried out finally to obtain cobalt slag and precipitating cobalt liquid, the cobalt slag is fedto a copper and cobalt leaching system, and the cobalt and the copper are effectively separated. According to the method for separating and recovering the cobalt and the copper from the P204 reverse extraction liquid in the cobalt and copper mine wet method smelting process, the operation process is simple, the production cost is low, the production efficiency is high, and the metal recovery rateis effectively improved.

Owner:江苏雄风科技有限公司

Combined high-pressure acid leaching method for cobalt alloy and oxide cobalt minerals

InactiveCN105568001AImprove reliabilityReduce riskProcess efficiency improvementDecompositionHigh pressure

The invention discloses a combined high-pressure acid leaching method for cobalt alloy and oxide cobalt minerals. The method comprises the following steps that 1, after the cobalt alloy is subjected to ball milling, normal-pressure pre-leaching is carried out in a sulfuric acid system; 2, the oxide cobalt minerals obtained after ball milling and cobalt alloy normal-pressure pre-leaching residues obtained in the step 1 are mixed for size mixing; and 3, the materials are added into an autoclave after size mixing, and the autoclave is controlled to carry out pressure acid leaching for preset time at certain stirring speed at the preset temperature and pressure to obtain leachate and leaching residues. According to the method, based on the strong oxidizing property of the oxide cobalt minerals and the reducing property of the cobalt alloy, a dual-mineral method is adopted for combined leaching, a reducing agent needed for reduction decomposition of the oxide cobalt minerals can be met, and an oxidizing agent needed for oxidative decomposition of the cobalt alloy can also be met; comprehensive utilization of resources is achieved, and then production cost is greatly reduced; and meanwhile, the cobalt alloy and the oxide cobalt minerals are controlled to be in a proper ratio, so that simultaneous and efficient leaching of valuable metal in the two kinds of minerals is achieved, the reliability of the operation of operating personnel is improved, and the risks for the operating personnel in the production process are reduced.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD

Method for extracting copper, nickel and cobalt intermediate products from copper and cobalt ore at low cost

InactiveCN102560109AImprove leaching rateNo pollutionProcess efficiency improvementIron(II) oxideCrusher

The invention relates to a method for extracting copper, nickel and cobalt intermediate products from copper and cobalt ore at low cost. The method comprises the following steps of: crushing copper and cobalt ore by using a crusher, grinding by using an ore gridding machine into powder with the particle size of less than or equal to 100 meshes; placing the ore powder with the particle size of less than or equal to 100 meshes in a reaction kettle, performing agitation leach by using hydrochloric acid at normal temperature and normal pressure, and allowing copper, nickel, cobalt, iron, magnesium, and calcium in a form of chloride in the ore to enter lixivium; adjusting the pH value to be 0.5 to 1.5, and adding iron powder in an amount which is not less than 1.5 times that of the copper in the solution and replacing to remove copper; dropwise adding ammonia water and hydrogen peroxide simultaneously at the temperature of 90DEG C with continuous stirring to adjust the pH and ferrous oxide ions to generate goethite and remove iron; and extracting nickel and cobalt by using an organic extracting agent P204. The method is low in investment, energy consumption and production cost, and simple and reasonable; and leaching rate is high.

Owner:JIANGXI UNIV OF SCI & TECH

Combined high-pressure acid leaching method for cobalt containing sulfide and heterogenite

InactiveCN105568000AAvoid joiningAvoid accessProcess efficiency improvementPregnant leach solutionSulfide

The invention discloses a combined high-pressure acid leaching method for cobalt containing sulfide and heterogenite. The method comprises the following steps that 1, copper sulfide cobalt ore and the heterogenite obtained after ball milling are mixed for size mixing; and 2, the materials are added to an autoclave after size mixing, and stirring, pressurizing and acid leaching are carried out to obtain leachate and leaching residues. According to the method, the copper sulfide cobalt ore is subjected to oxidizing leaching through the heterogenite, so that a reducing agent is prevented from being added in the heterogenite leaching process, and meanwhile introduction of oxygen in the copper sulfide cobalt ore leaching process is omitted; and then production cost is greatly reduced, the reliability of the operation of operating personnel is improved, and the risks for the operating personnel in the production process are reduced.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD

Preparation method of ultrafine cobalt powder

The invention discloses a preparation method of ultrafine cobalt powder. Some prior methods have the disadvantages of higher cost, or existence of discharge problems of ammonia-nitrogen waste water, or coarser cobalt powder particles or difficult acquisition of high-purity products, and the like; and the prior methods are not suitable for large-scale industrialized production. In the invention, the cobalt ore is used as raw material, a spraying and roasting-reducing method is used for preparing ultrafine spherical cobalt powder, and meanwhile, the tail gas generated in the spraying and roasting processes is absorbed, treated and returns to a production system for recycling, thereby shortening the technological processes, reducing the discharge of the waste water and achieving the purposesof environmental protection and large-scale industrialized production of ultrafine spherical cobalt powder.

Owner:ZHEJIANG HUAYOU COBALT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com