Method for preparing spherical cobaltous oxide

A spherical cobaltous oxide technology, which is applied in the field of preparation of cobaltous oxide, can solve the problems of affecting the later discharge performance of the battery, rough particle surface, poor oxidation resistance, etc., so as to avoid errors, smooth particle surface and strong oxidation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

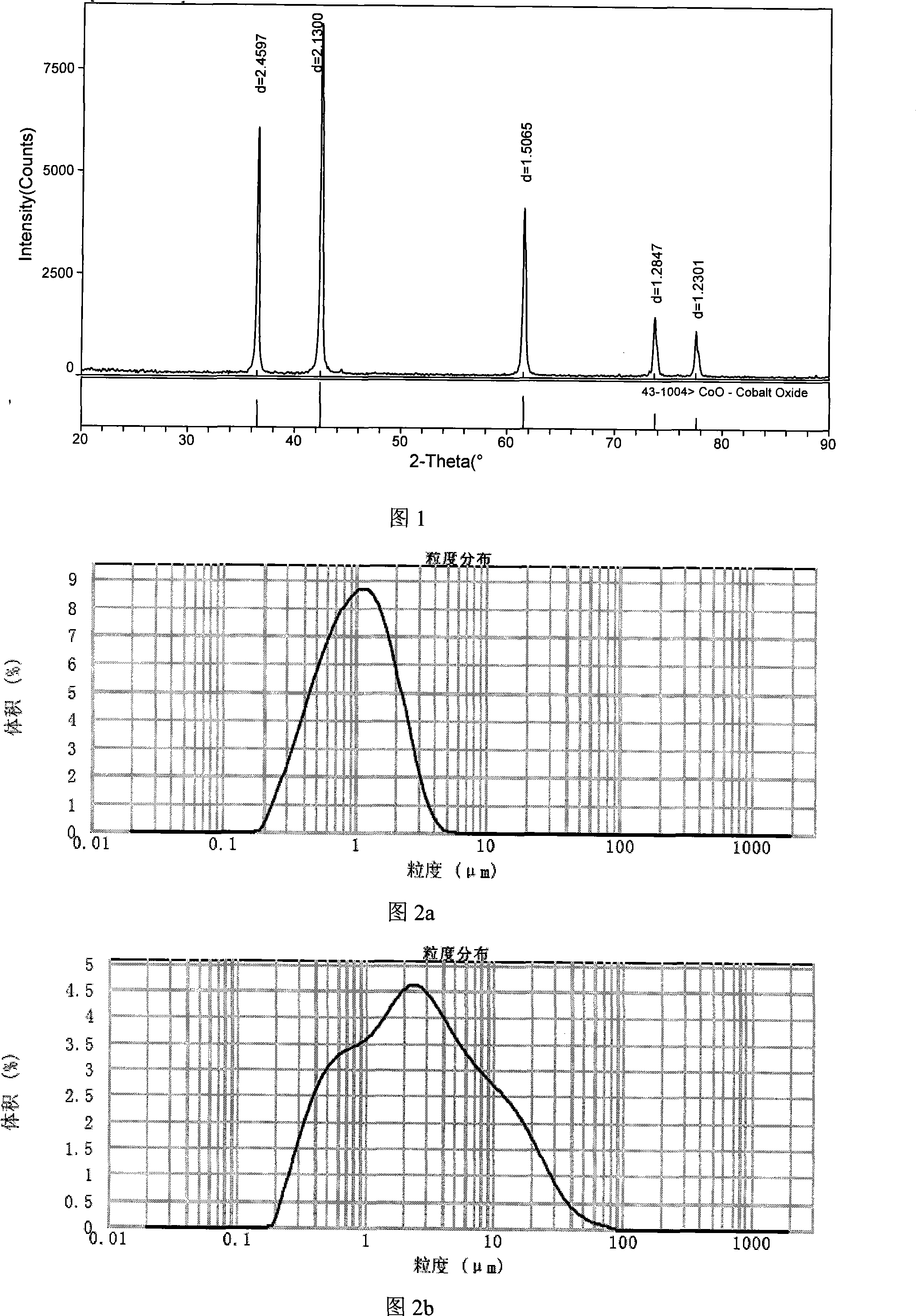

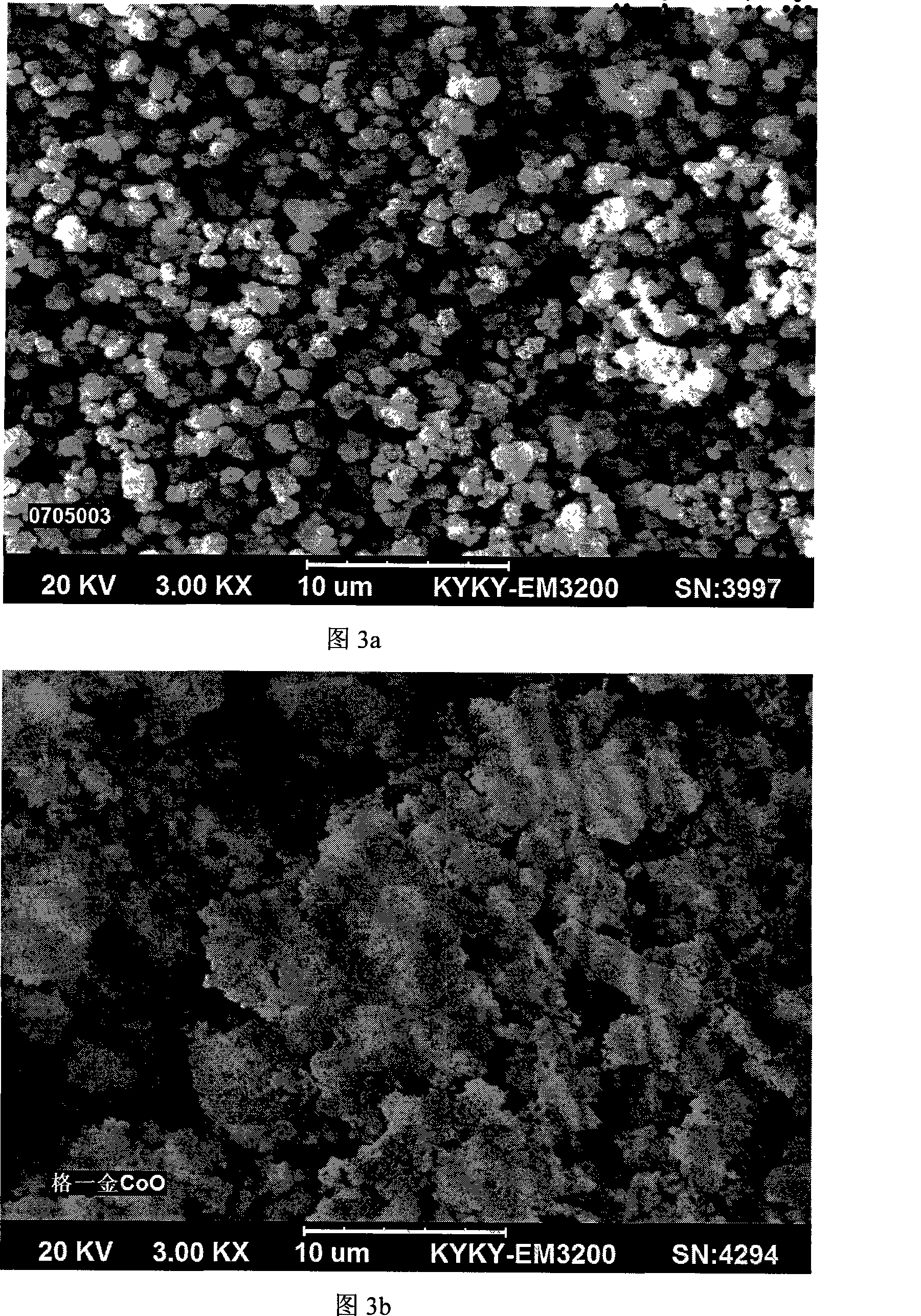

[0030] As shown in Figure 1, a method for preparing spherical cobaltous oxide described in this example uses cobalt-containing ore as a raw material, and after leaching and purification, a high-purity 5g / L-50g / L cobalt liquid is obtained, which is supplied to the above-mentioned Add ammonia water, polyvinylpyrrolidone (PVP), polyvinyl alcohol (PVA), cetyltrimethylammonium bromide (CTAB), polyethylene glycol PEG ( 1000), one or more of water-soluble starch, as a complex cobalt salt solution, select one of ammonium bicarbonate, ammonium carbonate, sodium carbonate or sodium hydroxide as a precipitant, and dissolve and filter to form 10g / L-100g / L precipitant solution; add excess 10%-30% precipitant solution and complex cobalt salt solution to the reactor by co-current feeding method, and control the reaction temperature to 30°C through the DCS distributed control system device -90°C, the reaction pH value is 3.0-9.0, the stirring speed is 400rpm-3000rpm, and the cobalt salt preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com