Extraction method for removing calcium and magnesium from copper-cobalt ore leachate

A leaching solution and extraction technology, which is applied in the field of cobalt extraction, can solve the problems of low cobalt yield, low solubility of sodium fluoride, and large reaction energy consumption, etc., and achieve low purification costs, good removal effect, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

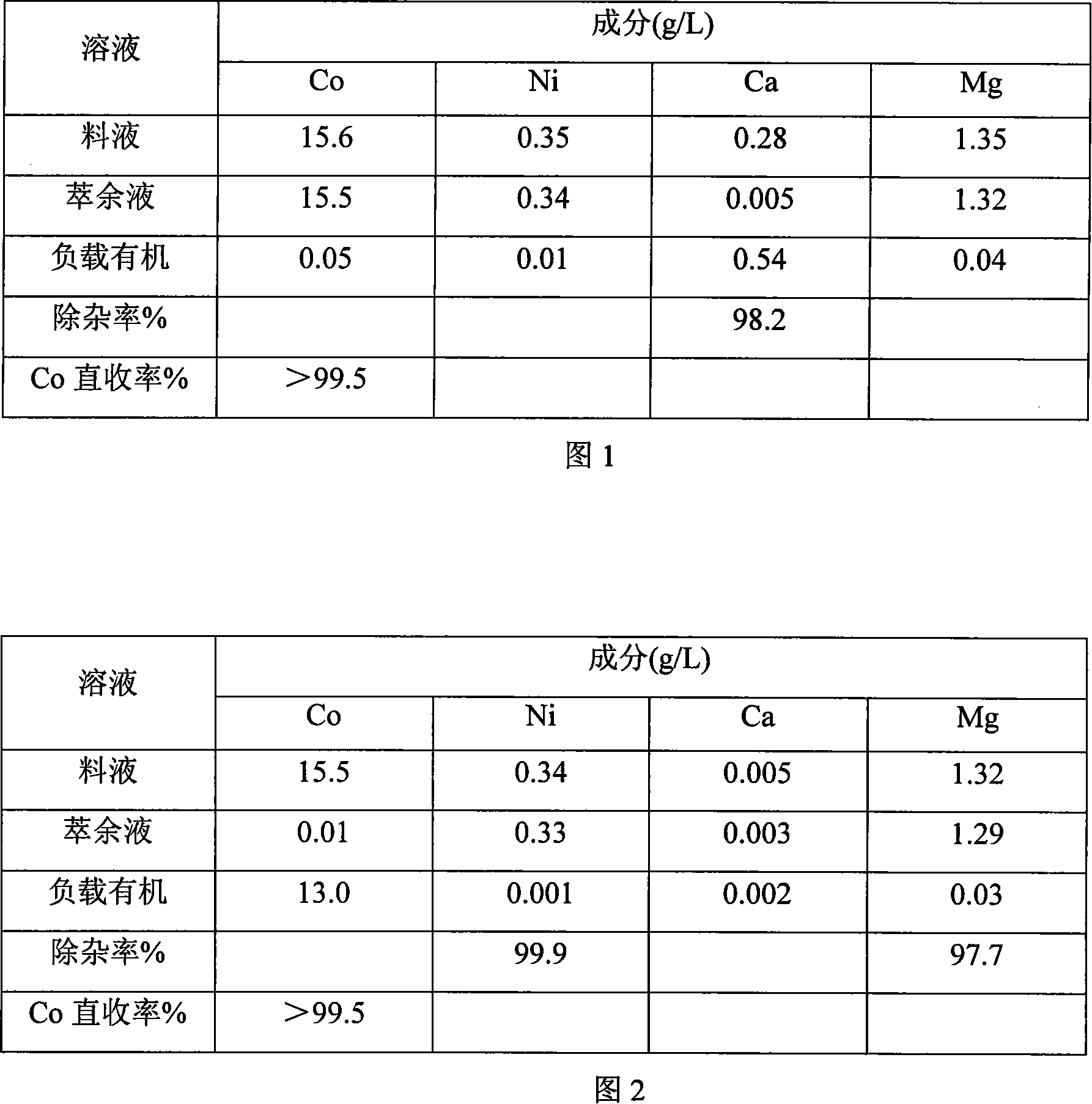

[0016] A method for extracting calcium and magnesium from the copper-cobalt ore leaching solution provided in this embodiment is to adjust the pH value of the sulfuric acid leaching solution of the copper-cobalt ore after iron removal from 3.5 to 4.0 with sodium hydroxide, and the organic phase is made of P204 and kerosene as diluent constitute, wherein the volume ratio of P204 is 15%, kerosene is 85%, saponification rate is 68%, flow ratio O / A=1: 2-3, after 9 stages of contact extraction, make calcium conversion into the organic phase and cobalt, nickel, and magnesium are stored in the water phase, and then the loaded organic phase is washed with 1.2N concentration of dilute sulfuric acid for 7 stages, so that the cobalt, nickel, and magnesium enter the water phase, and the loaded organic phase is washed with 3N concentration 5-stage hydrochloric acid back-extraction, the calcium in the organic phase is back-extracted, and finally the remaining iron in the organic phase is bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com