Biological extract technology for ore of cobalt nickel oxide

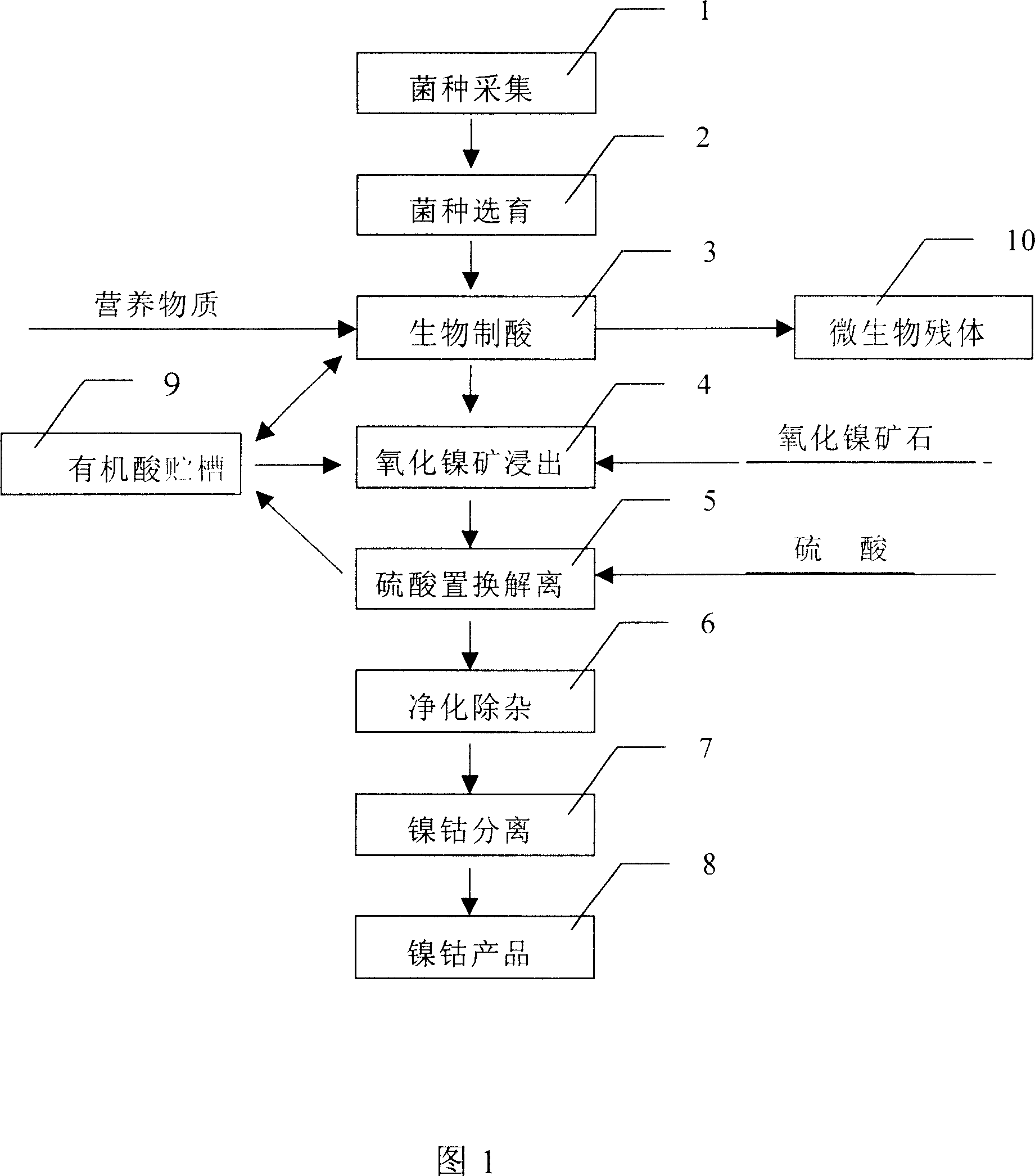

A bioleaching and nickel-cobalt oxide technology, which is applied in the direction of improving process efficiency, can solve the problems of nickel oxide ore having no economic value, heavy environmental pollution, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The new process was applied to a nickel-cobalt oxide ore in Yunnan. The metal minerals in the ore are mainly silicon-magnesium-nickel ore, followed by nickel-containing limonite. Gangue minerals are mainly olivine, serpentine, pyroxene and so on. The contents of nickel and cobalt in the ore are respectively 0.93% nickel, 0.015% cobalt and 7.09% iron.

[0024] (1) Preparation of a variety of biological organic acid mixtures

[0025] Obtaining the original species: the sugar wastewater containing Aspergillus niger was prepared through the preparation of a fungal solid medium (the fixed medium was potato sucrose medium), and the plate was drawn to obtain several bacterial colonies and various fungi. Pick the mycelium that grows black spores and carry out transfer culture.

[0026] Acquisition of exclusive bacteria: Use the improved Zabeck's liquid medium to expand the culture of fungi. The fungus is cultured in a liquid medium for 5-6 days, the culture temperature is 33...

Embodiment 2

[0036] The new process was applied to a nickel-cobalt oxide ore in Yunnan for heap leaching, and the metal minerals in the ore were the same as above.

[0037] (1) Preparation of a variety of biological organic acid mixtures

[0038] With (1) in embodiment 1.

[0039] (2) Nickel and cobalt leaching in ore

[0040] Crush the ore until the particle size is less than 10mm; then build a heap, in order to keep the ore as much as possible to form a porous and well-ventilated natural heap during the heaping process, the height of the heap is 1-3m; use (1) containing a variety of organic acid components The clear liquid is sprayed to leach ore, and the spray speed is 5-10L / m 2 .h.

[0041] (3) Dissociation of organic acid metal complexes under acidic conditions

[0042] Add dilute sulfuric acid to adjust the pH value of the solution to about 0.5-1.7, so that the metal complex of the organic acid is almost completely dissociated. If the cationic resin is too strong, the organic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com