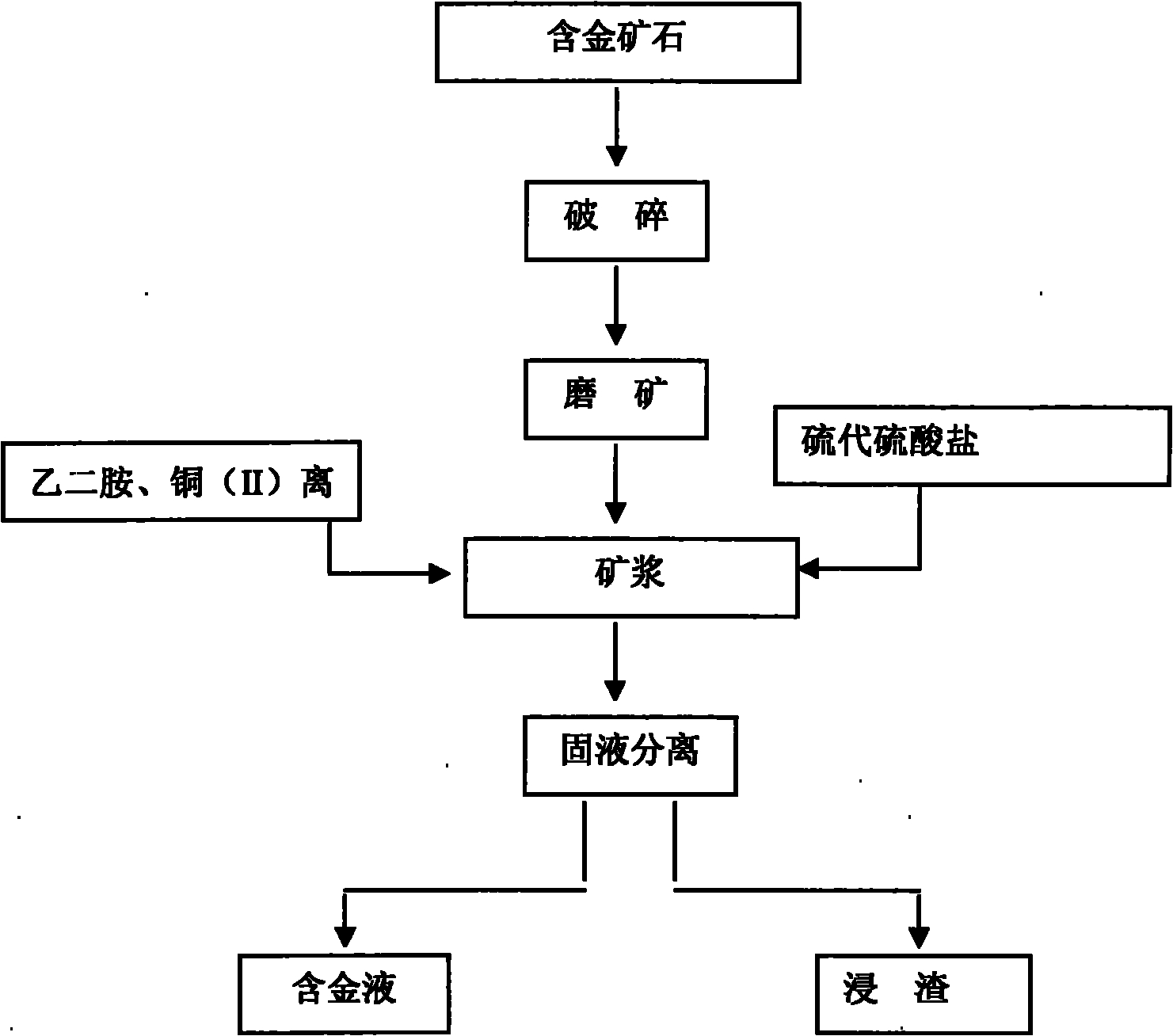

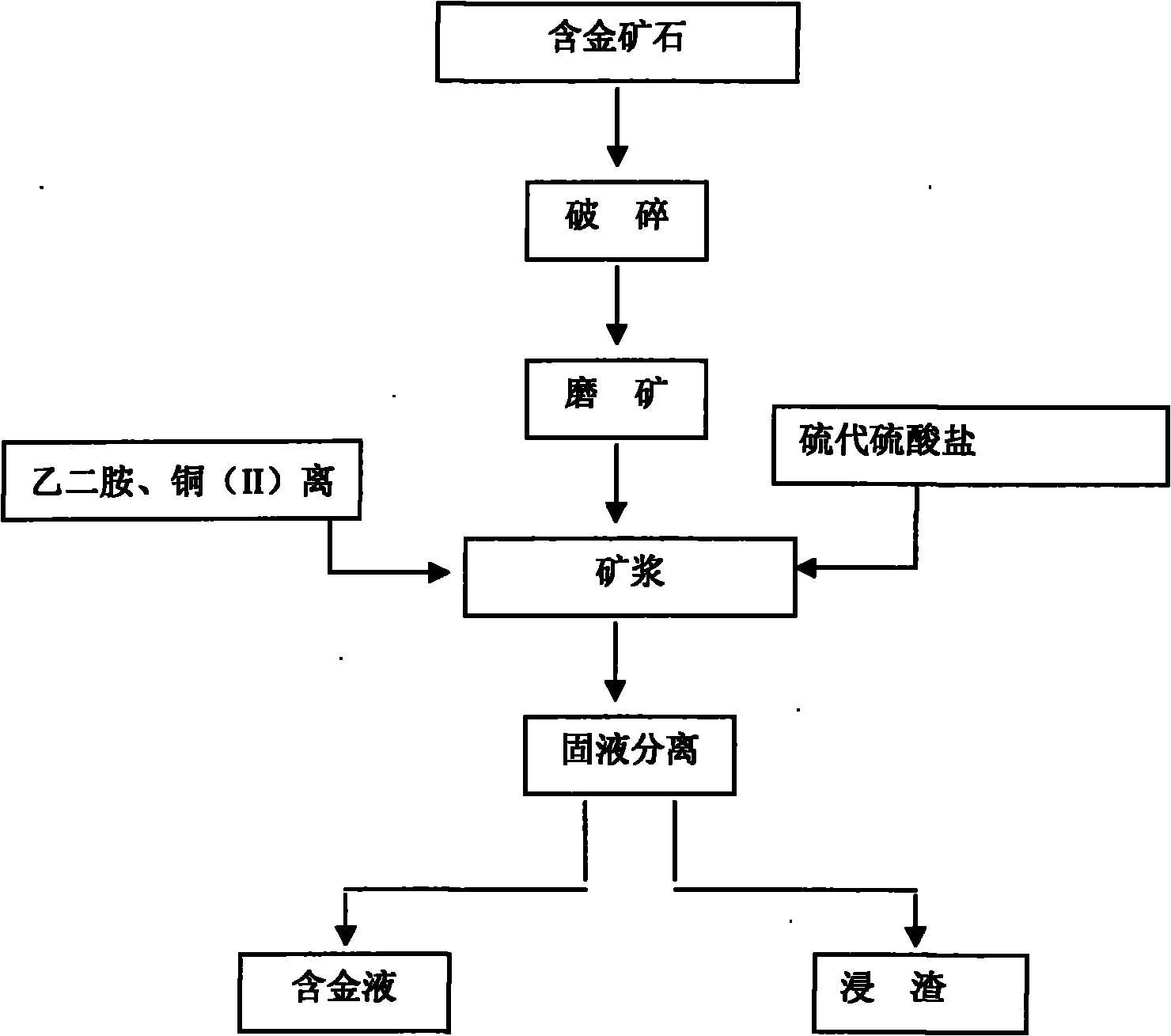

Method for extracting gold from thiosulfate adopting ethanediamine as additive

A technology of thiosulfate and ethylenediamine, which is applied in the field of hydrometallurgy, can solve the problems of large consumption of reagents and complex leaching system, and achieve the effects of low consumption of reagents, high gold leaching rate and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A gold mine contains 2.78g / t gold and 0.18% copper. The ore is crushed and wet-milled to a fineness of -200 mesh, accounting for 95%, and the mass concentration of the pulp is adjusted to 40% (solid phase 40%, liquid phase 60%) with water, and sodium thiosulfate is added to the pulp to 0.03mol according to the water volume / dm 3 , then add ethylenediamine to 0.003mol / dm 3 and CuSO 4 5H 2 O to copper (II) ions: 0.0015mol / dm 3 , forming ethylenediamine copper complex ion additive, adjusting the pH to 11 according to the routine, stirring and leaching for 6 hours to obtain a gold-containing leachate, and recovering the gold in the leachate according to the routine. The gold leaching rate is up to 87.3%, and the consumption of sodium thiosulfate is 3.5kg / t ore (when cuproammonia is used as additive, the consumption of sodium thiosulfate is 21.5kg / t ore).

Embodiment 2

[0016] A flotation gold concentrate contains 198.2g / t of gold and 23.1% of copper. The ore is crushed and wet-milled to a fineness of -200 mesh, accounting for 95%, and the mass concentration of the pulp is adjusted to 40% with water. According to the water volume, sodium thiosulfate is added to the pulp to 3mol / dm 3 , then add ethylenediamine to 0.09mol / dm 3 and CuSO 4 5H 2 O to copper (II) ion is 0.03mol / dm 3 , form ethylenediamine copper complex ion additive, adjust the pH to 12 according to the routine, and stir and leach for 24 hours to obtain a gold-containing leachate, and recover the gold in the leachate according to the routine. The gold leaching rate reaches 88.4%, and the consumption of sodium thiosulfate is 4.92kg / t of ore (when cuproammonia is used as an additive, the consumption of sodium thiosulfate is 29.6kg / t of ore).

Embodiment 3

[0018] A gold concentrate contains 49.4g / t of gold and 2.4% of copper. Crush and wet-grind the ore to a fineness of -200 mesh, accounting for 95%, adjust the mass concentration of the pulp to 40% with water, and add sodium thiosulfate to the pulp to 0.3mol / dm in terms of water volume 3 , then add ethylenediamine to 0.03mol / dm 3 and CuCl 2 Up to 0.015mol / dm of copper (II) ions 3 , form ethylenediamine copper complex ion additive, adjust the pH to 10 according to the routine, and stir and leach for 12 hours to obtain a gold-containing leachate, and recover the gold in the leachate according to the routine. The gold leaching rate reaches 87.3%, and the consumption of sodium thiosulfate is 4.75kg / t of ore (when cuproammonia is used as an additive, the consumption of sodium thiosulfate is 27.3kg / t of ore).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com