A thickening and dewatering method for tailings and applications thereof

A technology for concentrating and dehydrating tailings, which is applied in the field of concentrating and dehydrating fine-grained tailings and tailings concentrating and dehydrating. It can solve the problems of large land occupation, high power consumption, and large pumping volume, and achieve single equipment and easy operation. , easy to manage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

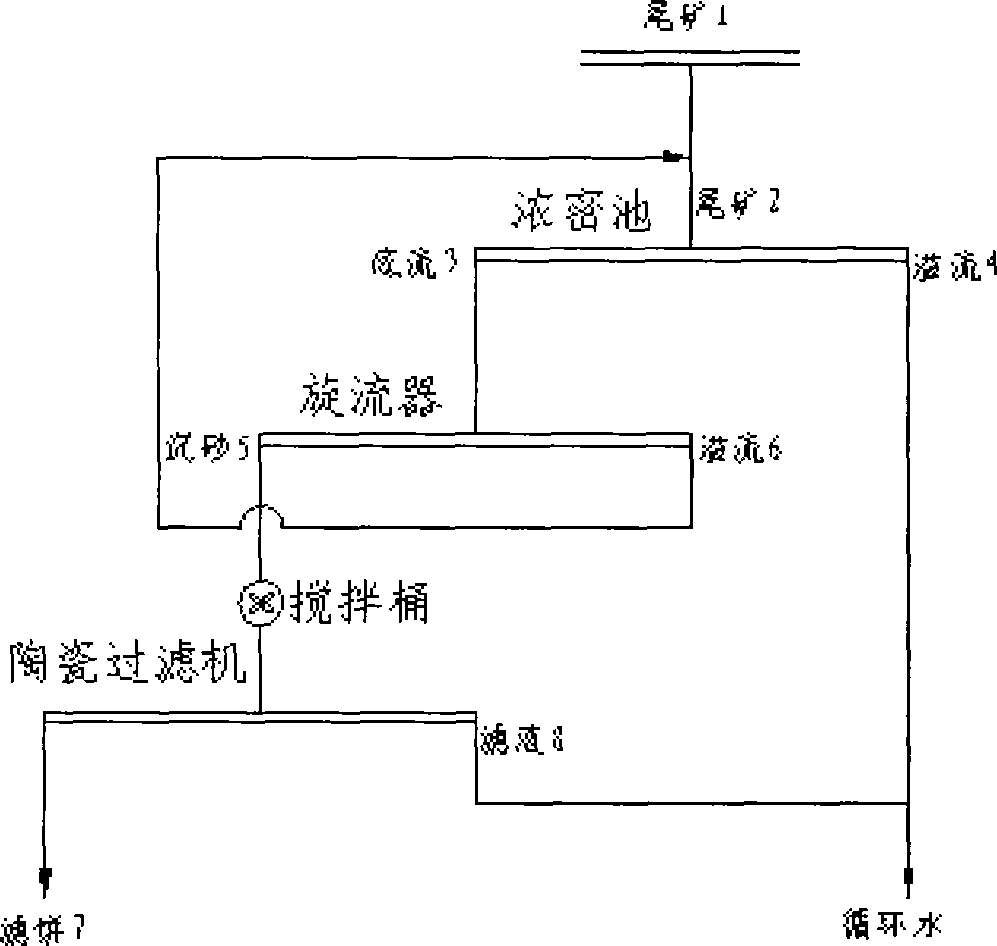

[0019] Referring to Figure 1(A), the comprehensive production capacity of a molybdenum mine is 3000t / d. The ore dressing plant adopts the process of "two and a half stages" closed-circuit crushing and one-stage closed-circuit grinding. To produce molybdenum concentrate, it is required to adopt the tailings treatment plan of dry discharge and dry pile. According to the present invention, the tailings 1 after grinding and flotation are automatically fed into the dense tank after adding flocculant at the tail outlet, and after settling and concentrating, the bottom flow 3 of the dense tank is pumped from the slurry to the dehydration plant through hydrocyclone The overflow 4 of the dense pool flows to the return pool as the mineral processing circulating water; after the concentrated tailings (underflow 3) fed into the hydrocyclone are concentrated for the second time, the sand settling 5 is controlled by the solenoid valve through the mixing tank Feed into the ceramic filter, th...

Embodiment 2

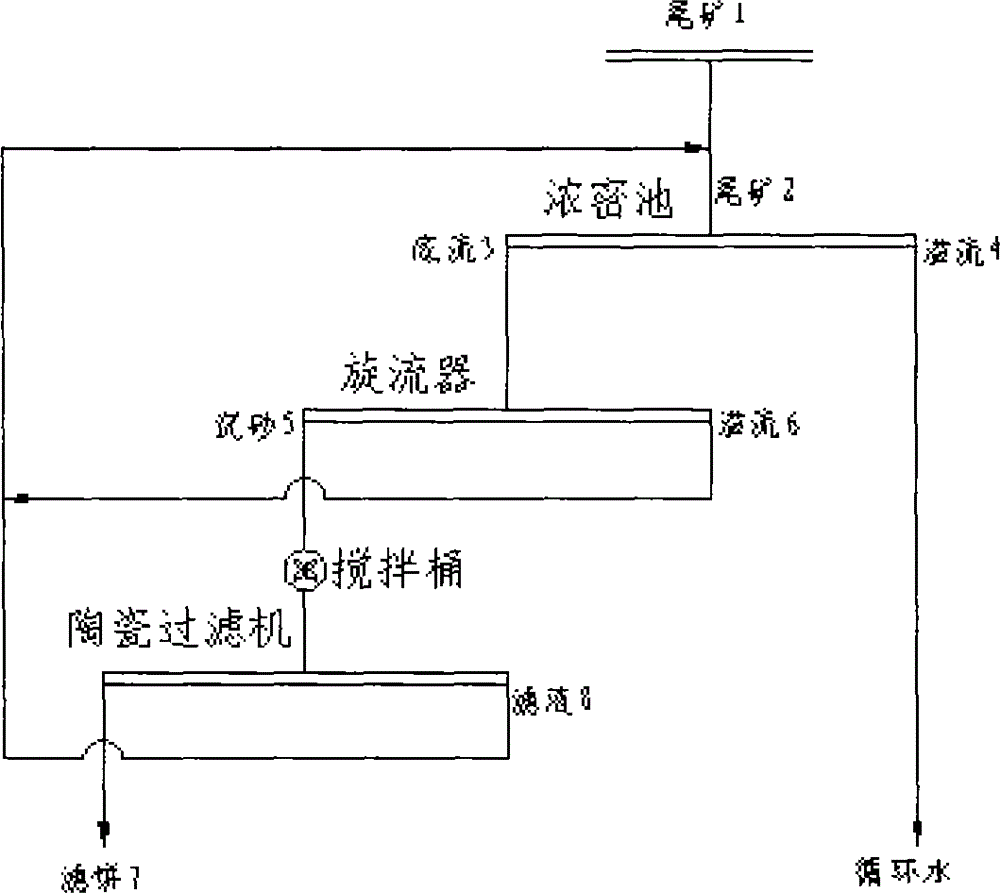

[0021] Referring to Figure 1(B), the comprehensive mining and dressing production capacity of an iron mine is 12,000t / d. The ore dressing plant adopts a two-stage closed-circuit crushing and one-stage closed-circuit grinding process. After desulfurization by flotation and phosphorus reduction by magnetic separation, iron concentrate is obtained. For mineral products, it is required to adopt the tailings treatment plan of dry discharge and dry pile. According to the present invention, the tailings 1 after grinding, flotation, and magnetic separation are fed into the dense pool by adding flocculant at the tailing outlet, and then fed into the dense pool by gravity. The hydrocyclone carries out secondary concentration, and the overflow 4 of the dense pool flows to the return pool; the concentrated tailings (underflow 3) fed into the hydrocyclone undergoes secondary concentration, and the sand settling 5 passes through the mixing tank and is controlled by a solenoid valve. into th...

Embodiment 3

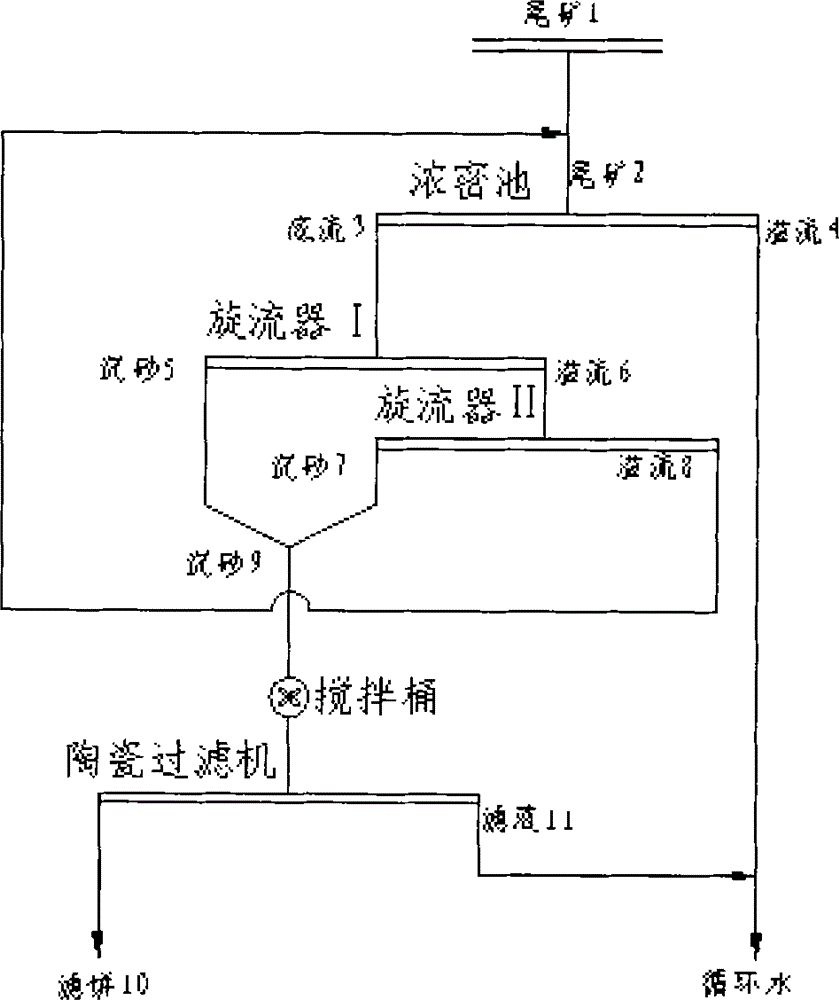

[0023] Referring to Figure 2(A), the comprehensive production capacity of a molybdenum mine is 3000t / d. The ore dressing plant adopts the process of "two and a half stages" closed-circuit crushing and one-stage closed-circuit grinding. To produce molybdenum concentrate, it is required to adopt the tailings treatment plan of dry discharge and dry pile. According to the present invention, the tailings 1 after grinding and flotation are automatically fed into the dense tank after adding flocculant at the tailing outlet, and after settling and concentrating, the bottom flow 3 of the dense tank is pumped from the slurry to the dehydration plant through hydrocyclone The device I carries out secondary concentration, and the overflow 4 of the dense pool flows to the return pool; after the concentrated tailings (underflow 3) fed into the hydrocyclone are concentrated for the second time, the sand settling 5 is fed into the mixing tank, and the overflow 6 is fed into the mixing tank. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com