Production technology of high-grade molybdenum concentrate

A production process, molybdenum concentrate technology, applied in the field of high-grade molybdenum concentrate production process, can solve the problems of high raw ore properties and grade requirements, difficulty in water glass configuration and addition, fine particle size of molybdenum concentrate, etc., to achieve improvement Select operating conditions, reduce pollution and fine mud content, and increase the effect of ore concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

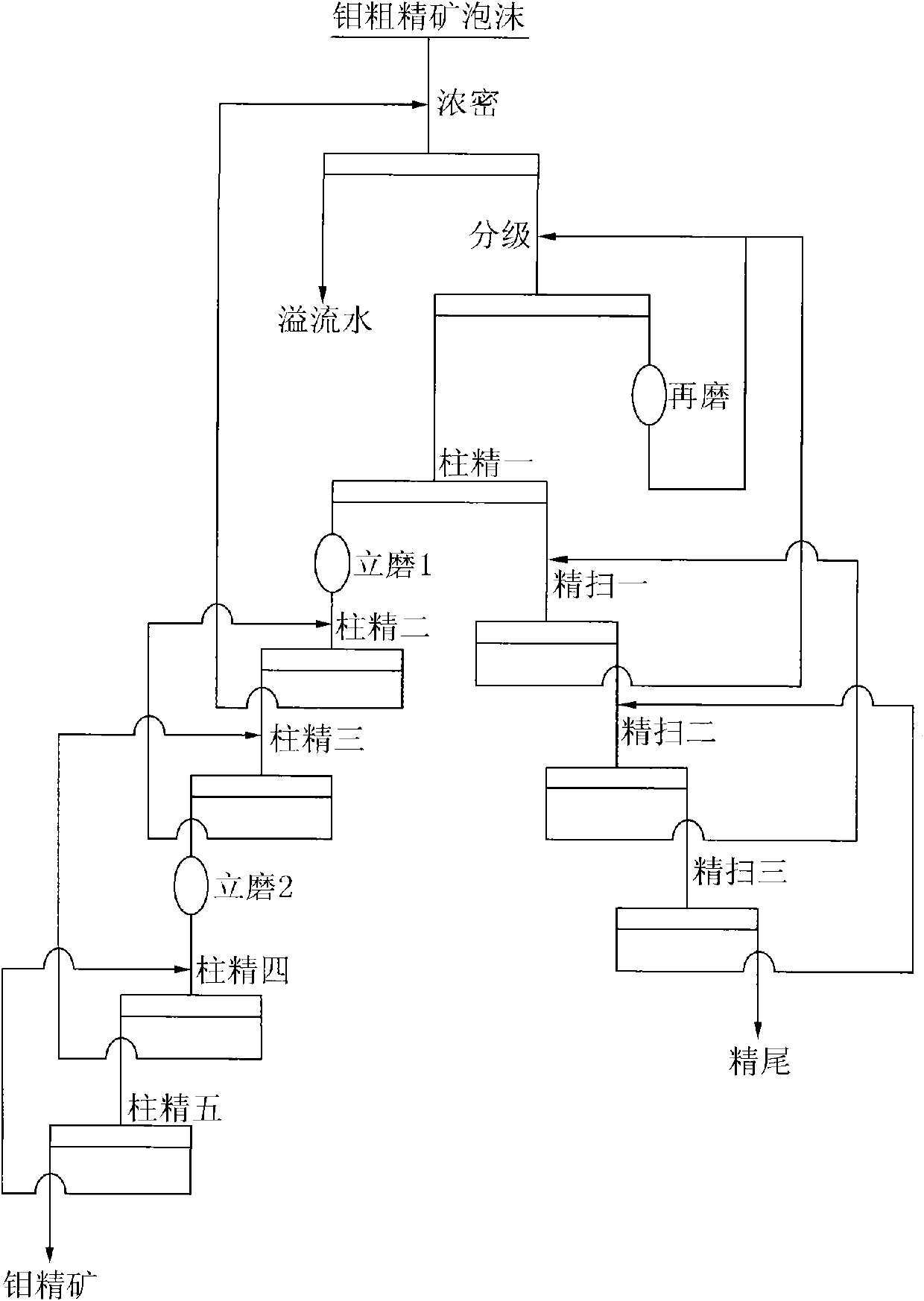

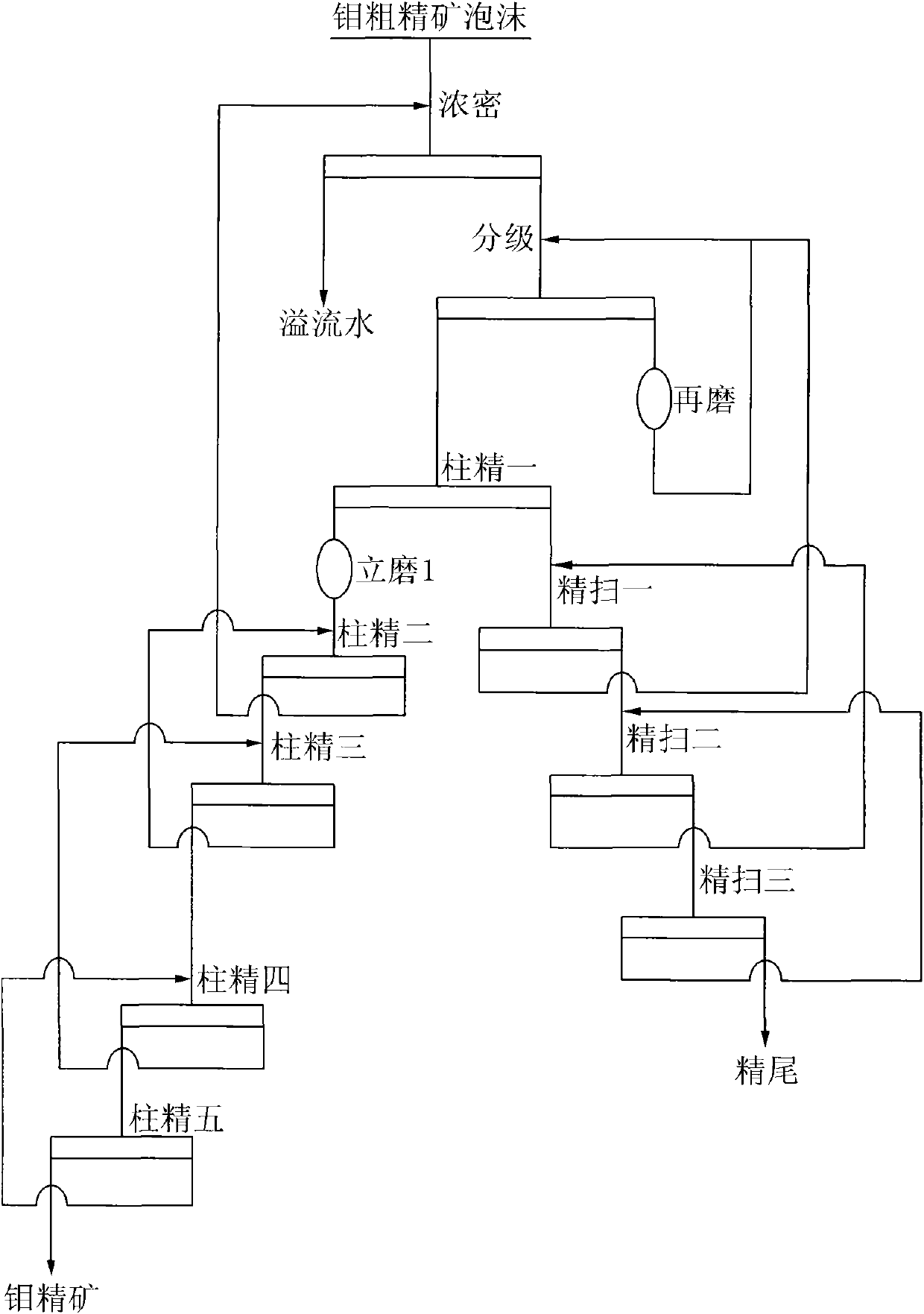

[0019] Such as figure 2 As shown, rough concentrate ore with Mo grade of 15.20% obtained after roughing the raw ore with Mo grade of 0.157% is concentrated and demedicated by the thickener, and the underflow of the thickener enters the hydrocyclone for pre-grading. The overflow enters the primary flotation column for selection, the underflow of the hydrocyclone enters the horizontal ball mill for regrinding, and after regrinding, the ore discharge enters the hydrocyclone for further classification; the primary flotation column selects the concentrate through the vertical grinding machine After a period of scrubbing, it enters the second flotation column and the third flotation column for concentration, and the concentrated ore of the third flotation column directly enters the fourth flotation column and the fifth flotation column for concentration, and obtains a high-quality Mo grade of 57.62% Molybdenum concentrate, the selection recovery rate is 98.37%; the first flotation ...

Embodiment 2

[0021] Such as figure 2 As shown, the raw ore with a Mo grade of 0.142% is roughed to obtain a rough concentrate with a Mo grade of 9.42%. The overflow enters the primary flotation column for selection, the underflow of the hydrocyclone enters the horizontal ball mill for regrinding, and after regrinding, the ore discharge enters the hydrocyclone for further classification; the primary flotation column selects the concentrate through the vertical grinding machine After a period of scrubbing, it enters the second flotation column and the third flotation column for concentration, and the concentrated ore of the third flotation column directly enters the fourth flotation column and the fifth flotation column for concentration, and obtains a high grade of 57.28% Mo grade Molybdenum concentrate, the selection recovery rate is 98.23%; the first flotation column selection tailings are subjected to three fine scavenging by the flotation machine, and the fine tailings after the three ...

Embodiment 3

[0023] Such as figure 2 As shown, rough ore with a Mo grade of 17.28% obtained after roughing the raw ore with a Mo grade of 0.137% is concentrated and demedicated by a thickener, and the underflow of the thickener enters the hydrocyclone for pre-grading. The overflow enters the primary flotation column for selection, the underflow of the hydrocyclone enters the horizontal ball mill for regrinding, and after regrinding, the ore discharge enters the hydrocyclone for further classification; the primary flotation column selects the concentrate through the vertical grinding machine After a period of scrubbing, it enters the second flotation column and the third flotation column for selection, and the concentrated ore of the third flotation column directly enters the fourth flotation column and the fifth flotation column for selection, and obtains a high grade of Mo with a grade of 57.41%. High-quality molybdenum concentrate, the selection recovery rate is 98.25%; the first flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com