Magnetic separation process of fine lean hematite

A hematite and fine-grained technology, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem of low ore concentration of the weak magnetic machine, unsatisfactory sorting effect of the weak magnetic operation, and a large number of weak magnetic machines And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

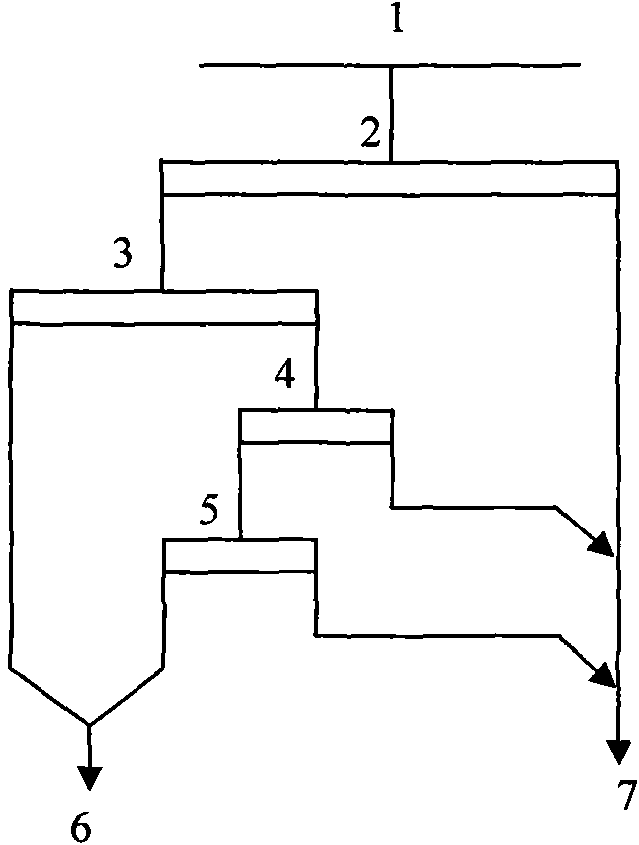

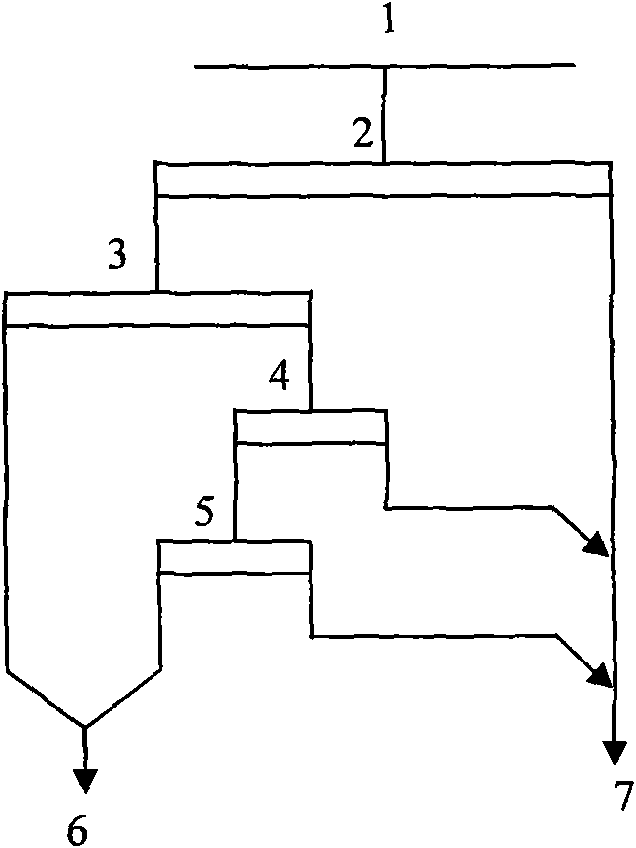

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0016] like figure 1 Shown, a kind of depleted hematite fine-grained magnetic separation process of the present invention comprises the overflow 1 of coarse and fine classification, is characterized in that comprising the following steps (by weight percentage):

[0017] 1) The concentration is <25%, the particle size is -200 mesh, the content is 90-95%, the grade is 22%-24%, and the product of coarse and fine classification overflow 1 is fed into the thickener 2 before the strong magnetic separation,

[0018] 2) The concentration of 35% to 40% of the underflow concentrated by the thickener 2 before the strong magnetic separation is fed into the weak magnetic separator for weak magnetic separation 3, and the overflow of the thickener before the strong magnetic separation is tailings,

[0019] 3) Feed the weak magnetic separation concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com