Patents

Literature

60 results about "High-intensity magnetic separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the recent past the problem of removing the deleterious iron particles from a process stream had a few alternatives. Magnetic separation was typically limited and moderately effective. Magnetic separators that used permanent magnets could generate fields of low intensity only. These worked well in removing ferrous tramp but not fine paramagnetic particles. Thus high-intensity magnetic separators that were effective in collecting paramagnetic particles came into existence. These focus on the separation of very fine particles that are paramagnetic.

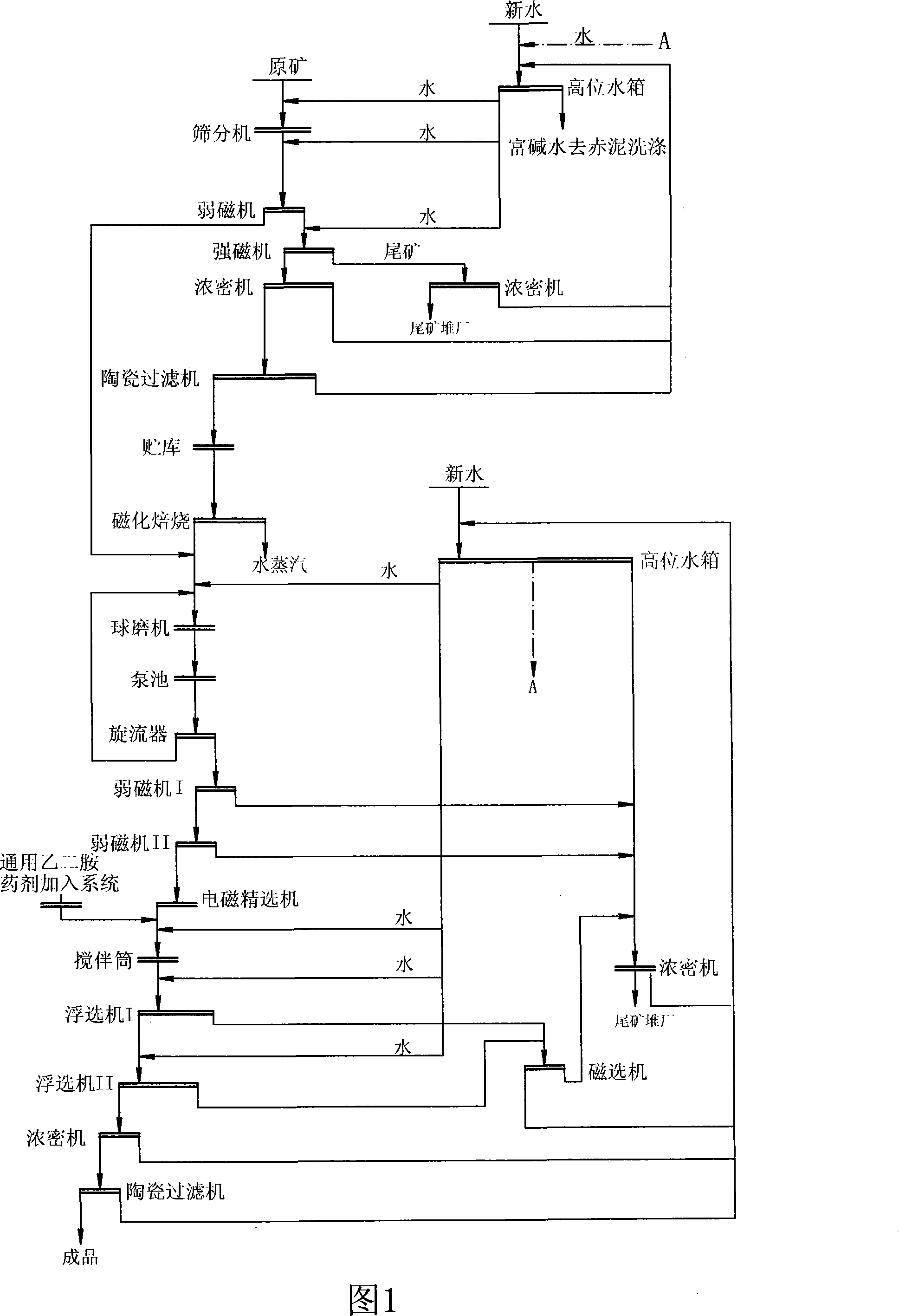

Method of refining iron ore from alkaline red mud and making gangue neutral

The invention relates to a method to select refined iron ore from alkaline red mud and neutralize mine tailings. The method consists of red mud pretreatment and technological process of preparing refined iron ore. The red mud pretreatment is that water is added into the red mud slurry discharged from aluminum factory; the red mud slurry is diluted to the solid concentration of 30 to 40 percent and then is screened and put into a low intensity magnetic separator for selecting ferromagnetic substance. The ferromagnetic substance is dehydrated and directly selected as the product. The remaining red mud is watered down to 30 percent solid concentration and put into a high intensity magnetic separator for magnetic separation and desliming. The obtained coarse ore is washed to a coarse ore settling tank or a thickener to be concentrated while the undercurrent is sent into a vacuum ceramic filter and a filter cake is roasted in a suspended magnetic roasting furnace. The roasted materials are crushed into a ball mill and then are milled. The water is overflown until 95 percent of the solid material granularities are less than 75m and then is treated by the third stage magnetic separation and the second flotation. The undercurrent is filtered by the ceramic filter, and then the refined iron ore with a purity of 58 to 65 percent is obtained. The refined iron ore is recycled from the red mud by the invention so as to fully employ aluminum ore, save resources and energy consumption and neutralize the whole red mud. The invention reduces environmental pollution and has good economic and social benefits.

Owner:SHENYANG XINBO IND TECH

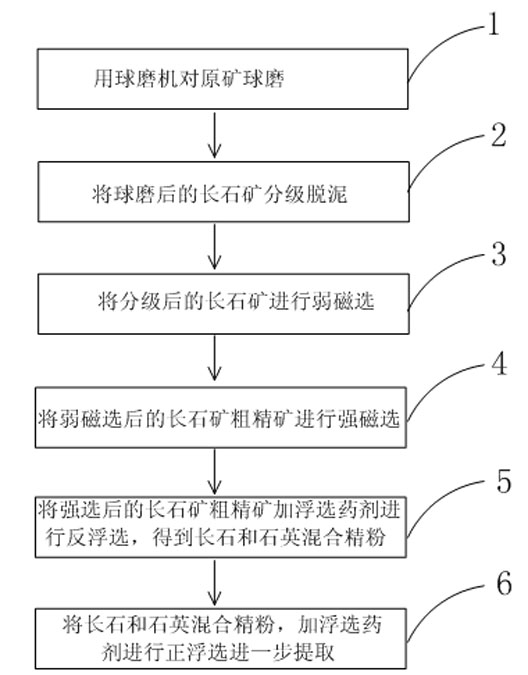

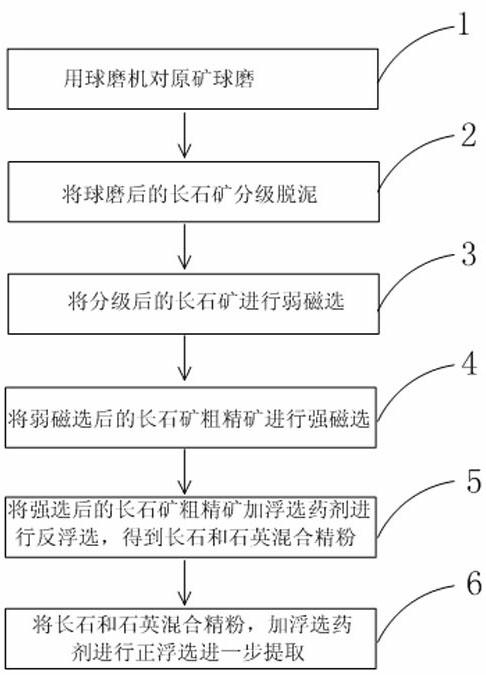

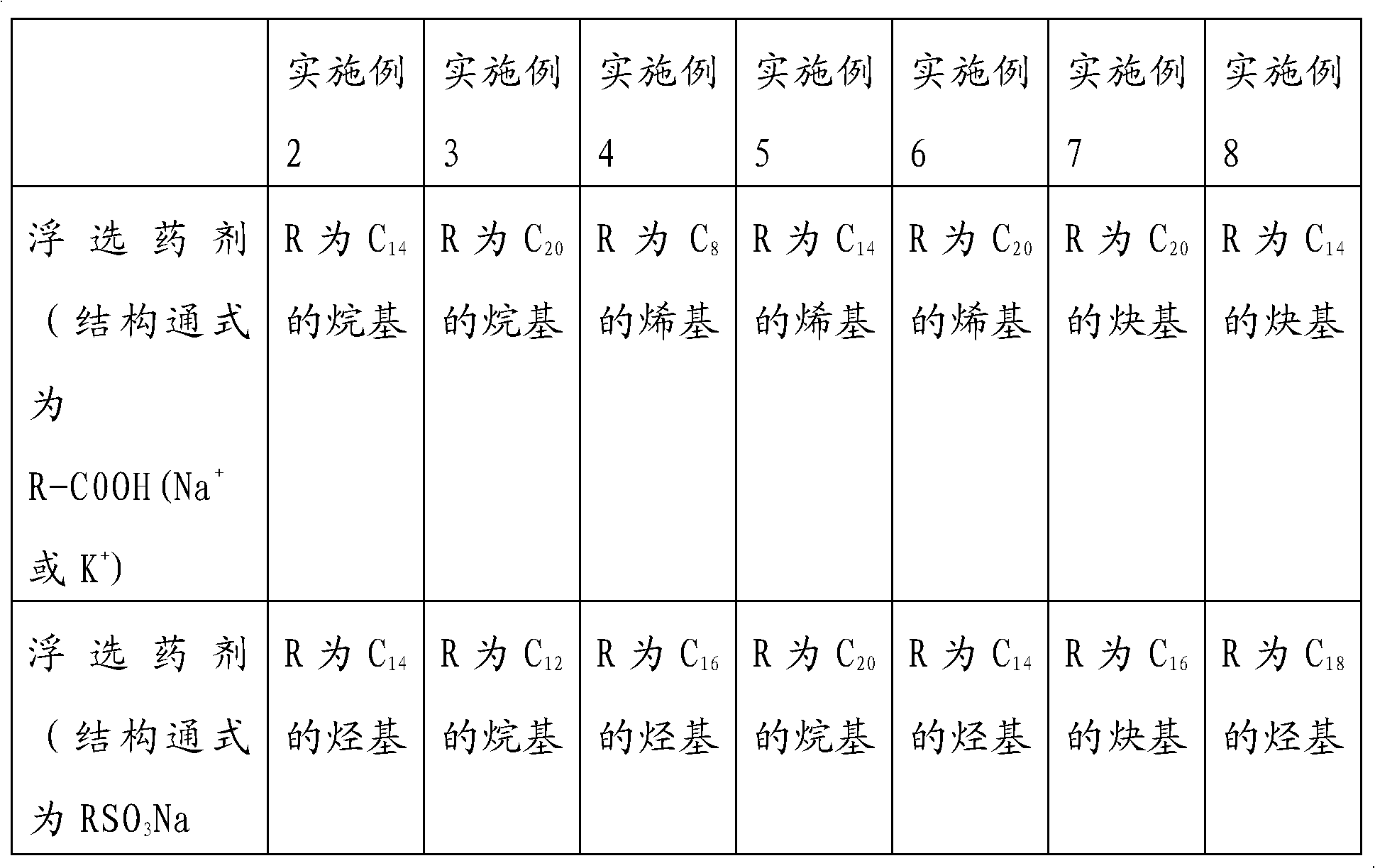

Method for separating and extracting feldspar ore with complex impurity components

InactiveCN102069033AEfficient removalImprove burnt board whitenessWet separationHigh intensityReverse flotation

The invention relates to a method for separating and extracting feldspar ore with complex impurity components, which comprises the following steps of: 1) performing ball milling on the feldspar ore with complex impurity components through a ball mill; 2) performing classification and de-sliming on the milled feldspar ore by using an improved hydraulic classifier; 3) performing low-intensity magnetic separation on the classified feldspar ore through a low-intensity magnetic separator to obtain high-intensity magnetic substances and rough feldspar concentrate for high-intensity magnetic separation; 4) performing high-intensity magnetic separation on the rough feldspar concentrate obtained by the low-intensity magnetic separation through a high-intensity magnetic separator to obtain low-intensity magnetic substances and rough feldspar concentrate for flotation; and 5) performing size mixing and segmentation on the rough feldspar concentrate obtained by the high-intensity magnetic separation, adding a flotation agent, and performing reverse flotation, impurity removal and dehydration through a flotation machine to remove impurities and obtain fine feldspar and quartz mixed powder and flotation water.

Owner:烟台宜陶矿业有限公司

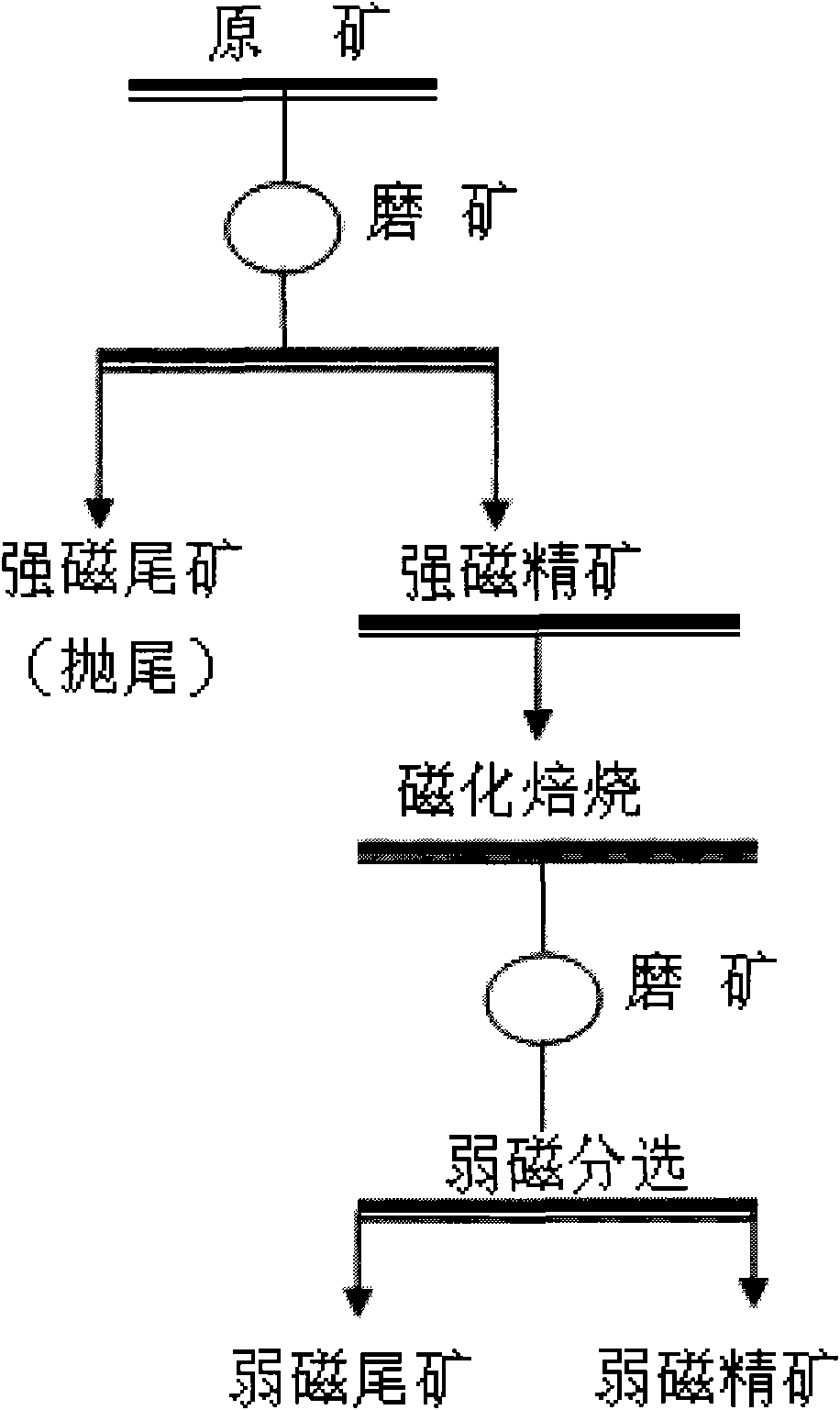

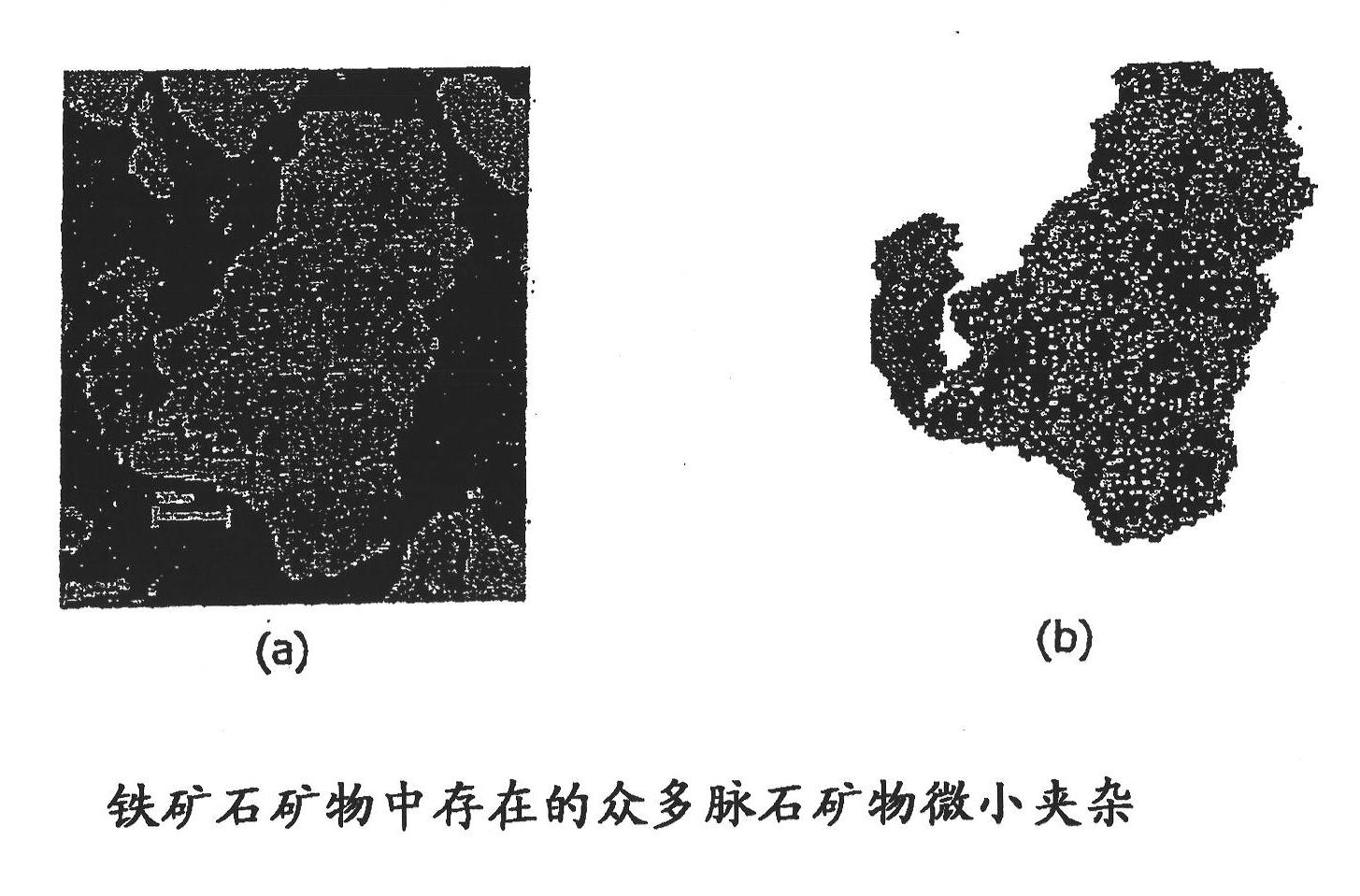

Separation-smelting combined method for producing iron ore concentrate from oolitic lean hematite

InactiveCN101862703ASimple processGood technical and economic indicatorsMagnetic separationCombined methodSlurry

The invention relates to a separation-smelting combined method for producing iron ore concentrate from oolitic lean hematite. The technical scheme first comminutes oolitic lean hematite containing 30 to 40 percent of iron, the comminuted mineral slurry enters a high-intensity magnetic separator and preseparated, weak-magnetic mineral is turned into strong-magnetic concentrate, and tailings are removed in advance; the strong-magnetic concentrate is mixed with pulverized coal, the weight of which accounts for 10 to 30 percent of the weight of the concentrate, and the mixture is heated to 900 DEG C to 1100 DEG C in a muffle furnace, and is magnetically roasted as the temperature is kept for 1 to 3 hours; after being cooled, the magnetically roasted mineral sample is wet-milled, and is then fed into a low-intensity magnetic separator and separated under low-intensity magnetism, magnetic mineral is turned into weak-magnetic concentrate, and thereby high-quality iron concentrate is produced. The grade of the obtained iron concentrate is higher than 64 percent, the phosphor content is less than 0.15 percent, and the sulfur content is less than 0.10 percent. The invention is characterized by simple process flow, good technical and economic indexes and high product quality.

Owner:KUNMING UNIV OF SCI & TECH

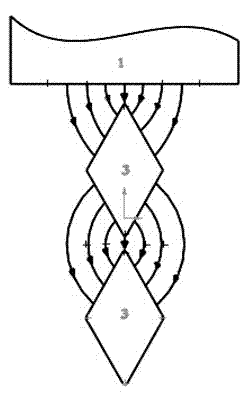

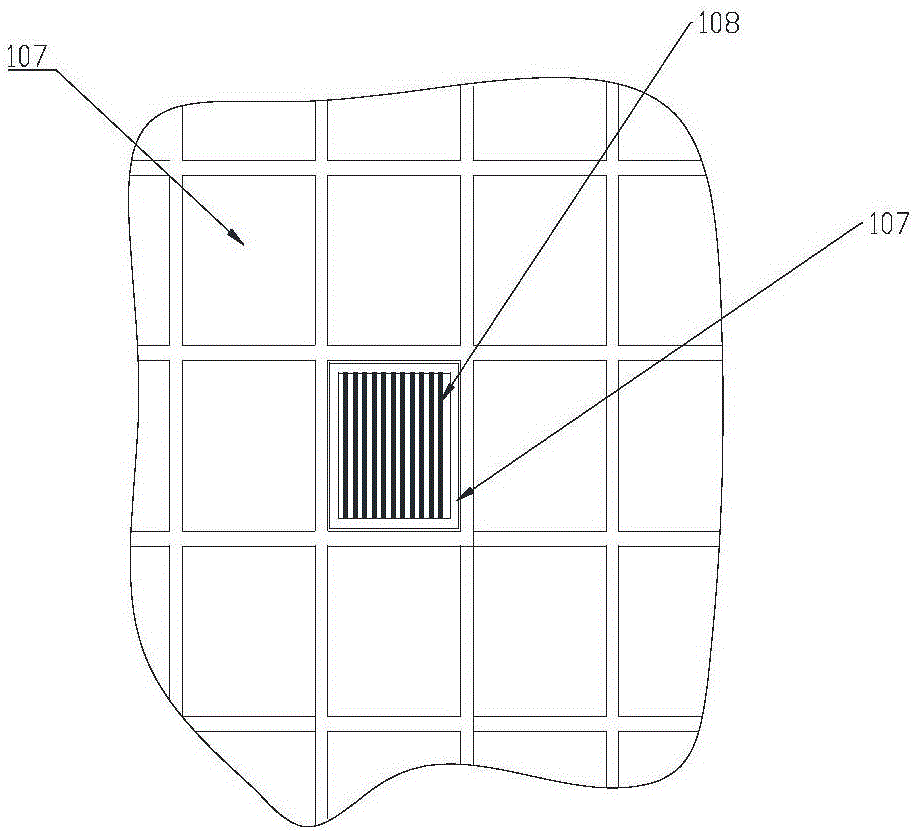

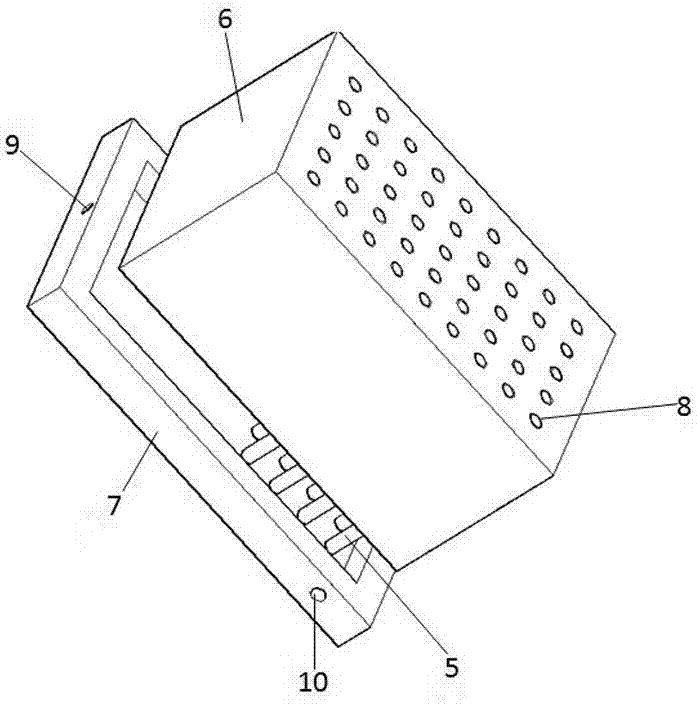

High-gradient magnetic flux converging medium for high intensity magnetic separator

InactiveCN102335638AHigh recovery rateRaise the magnetic field gradientHigh gradient magnetic separatorsMagnetic field gradientLower limit

The invention discloses a novel high-gradient magnetic flux converging medium for a high intensity magnetic separator. The high-gradient magnetic flux converging medium comprises non-magnetic conducting metal plates and a magnetic conducting medium rod, wherein a cross section of the magnetic conducting medium rod has a shape of equilateral rhombus; the rhombic magnetic conducting medium rod is fixed between the two non-magnetic conducting metal plates, thereby forming a separating medium box; the two non-magnetic conducting metal plates are embedded into a separating space of the magnetic separator in a parallel mode and are in suitable size; and two long-end vertex angles (acute angles) of the equilateral rhombic magnetic conducting medium rod are subjected to chamfering treatment. The high-gradient magnetic flux converging medium provided by the invention has the advantages that a gradient of a magnetic field in a magnetic path is high, magnetic resistance is small and energy consumption is saved; the high-gradient magnetic flux converging medium has the advantages of being free from 'magnetic short circuit' phenomenon and being difficult to block during an ore grain recycling process; and the high-gradient magnetic flux converging medium is specially suitable for recycling fine weak-magnetic ore grains and an effective grain level recycling lower limit can reach 5 microns.

Owner:KUNMING UNIV OF SCI & TECH

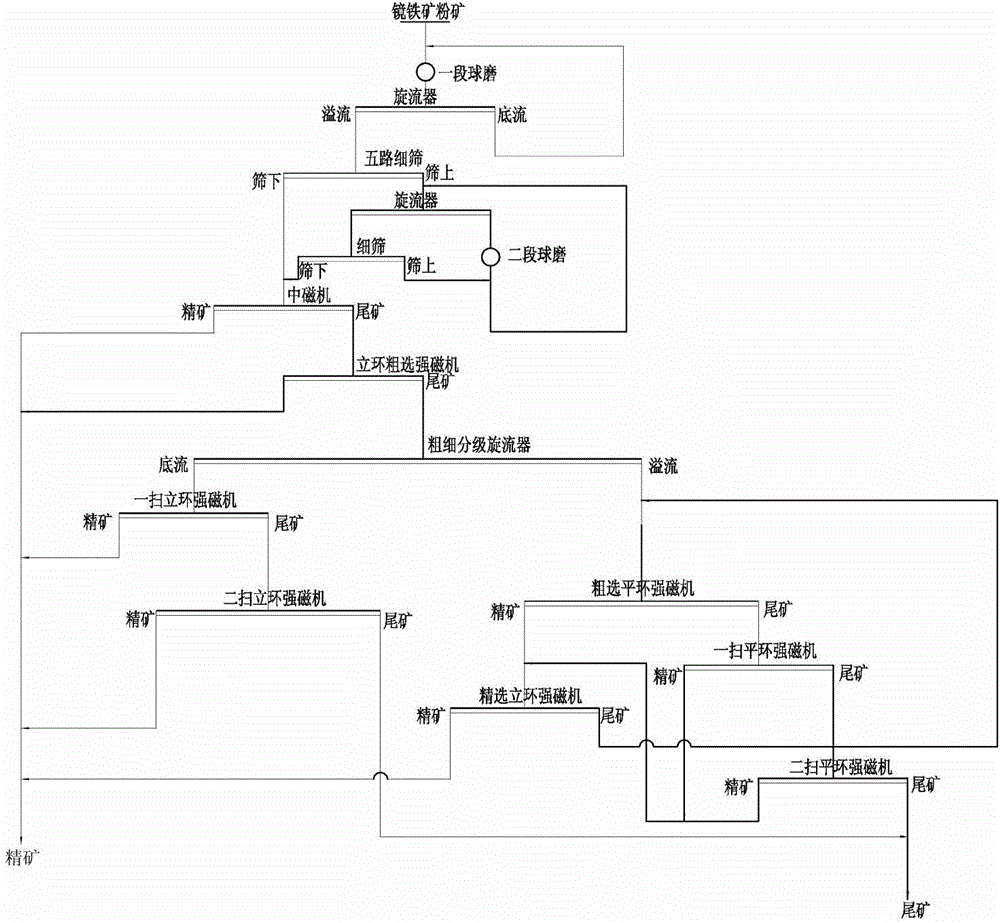

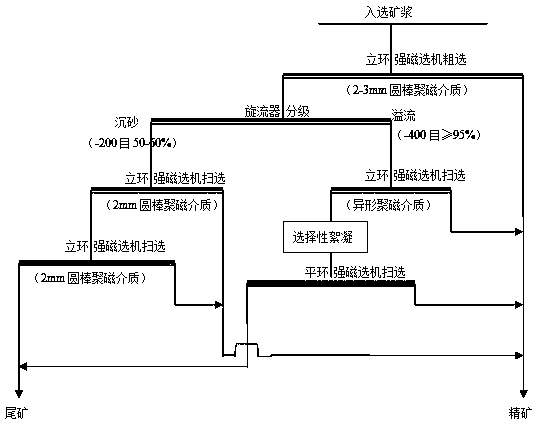

Specularite dust ore dressing technology

The invention belongs to the technical field of ore dressing and particularly relates to a specularite dust ore dressing technology. The specularite dust ore dressing technology is characterized by comprising an ore grinding and grading system and a magnetic separation and dressing system. The grade of input raw ore is 33%, and the granularity is 0-15 mm. The specularite dust ore dressing technology comprises specific steps that firstly, specularite dust ore passes through two segments of continuous closed circuits for grinding until specularite is dissociated from gangue monomers, wherein the ball mill-cyclone-fine screen closed circuit is adopted for each segment of ore grinding; the products of which the grading size is 0.074 mm, the grade is 33% and the productivity is 100% in the two segments of closed circuits for grinding are fed into a medium-intensity magnetic separator, a roughing vertical-ring high-intensity magnetic separator, a concentration vertical-ring high-intensity magnetic separator, a roughing flat-ring high-intensity magnetic separator, a concentration vertical-ring high-intensity magnetic separator and two segments of scavenging flat-ring high-intensity magnetic separators for magnetic separation. The grade of final iron ore concentrate can be improved to 50%-52%, and the recovery rate can be increased to 70%-72%. Accordingly, economic benefits of a dressing plant are greatly increased, and the loss of iron resources is lowered.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

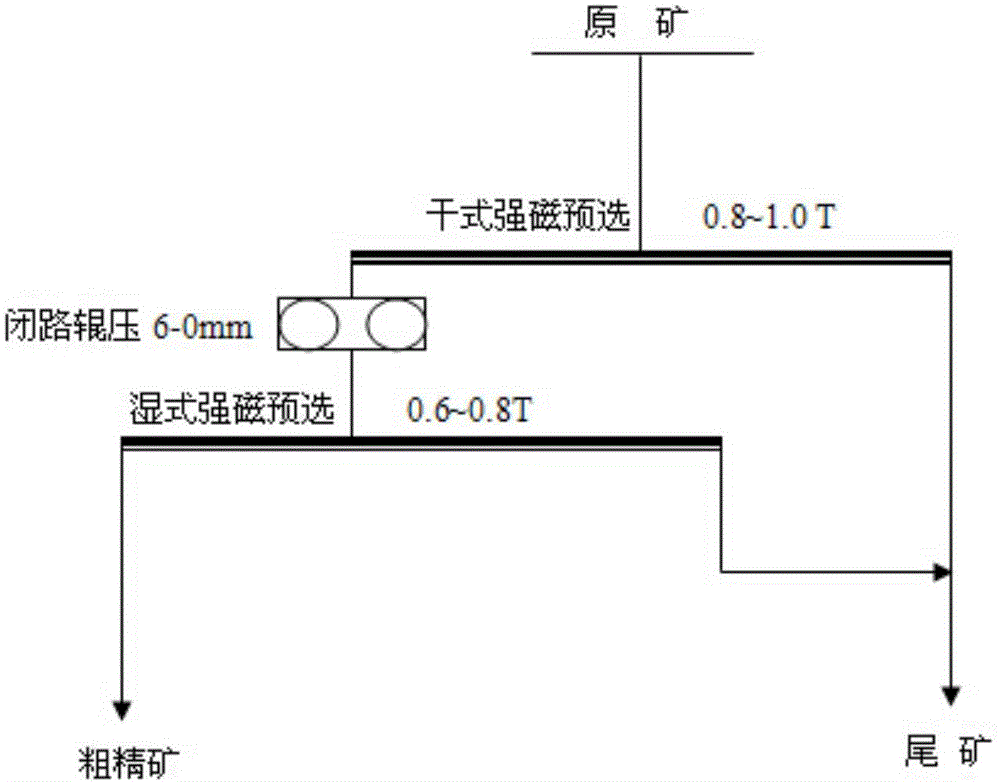

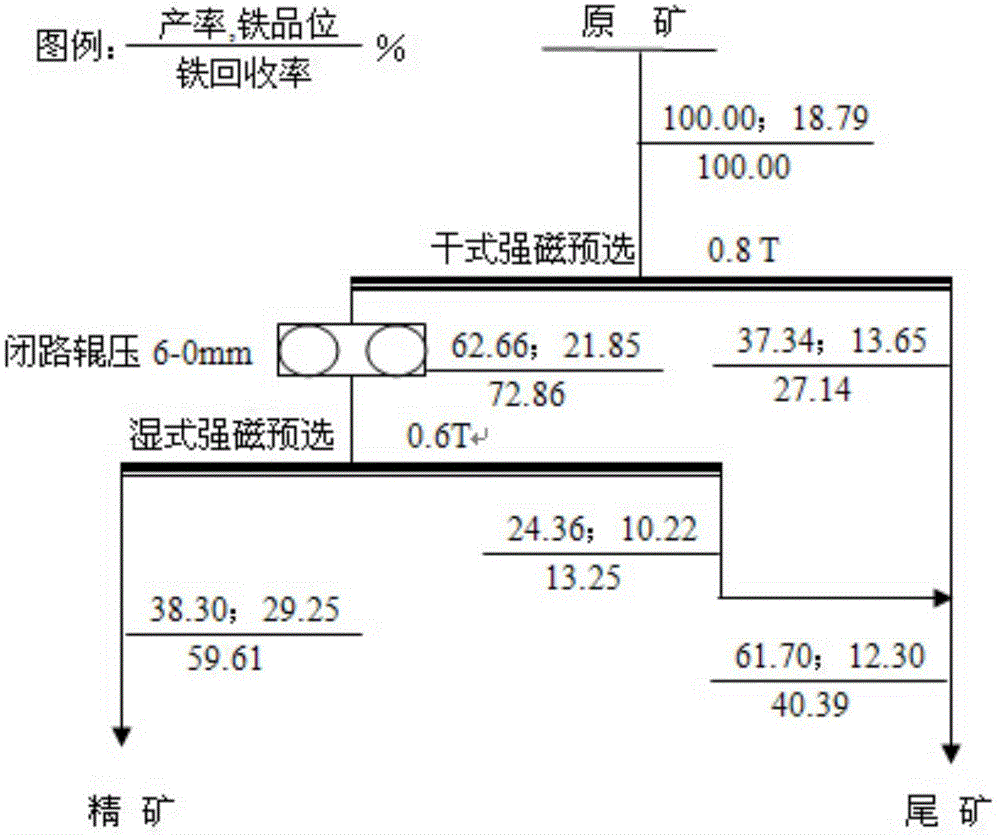

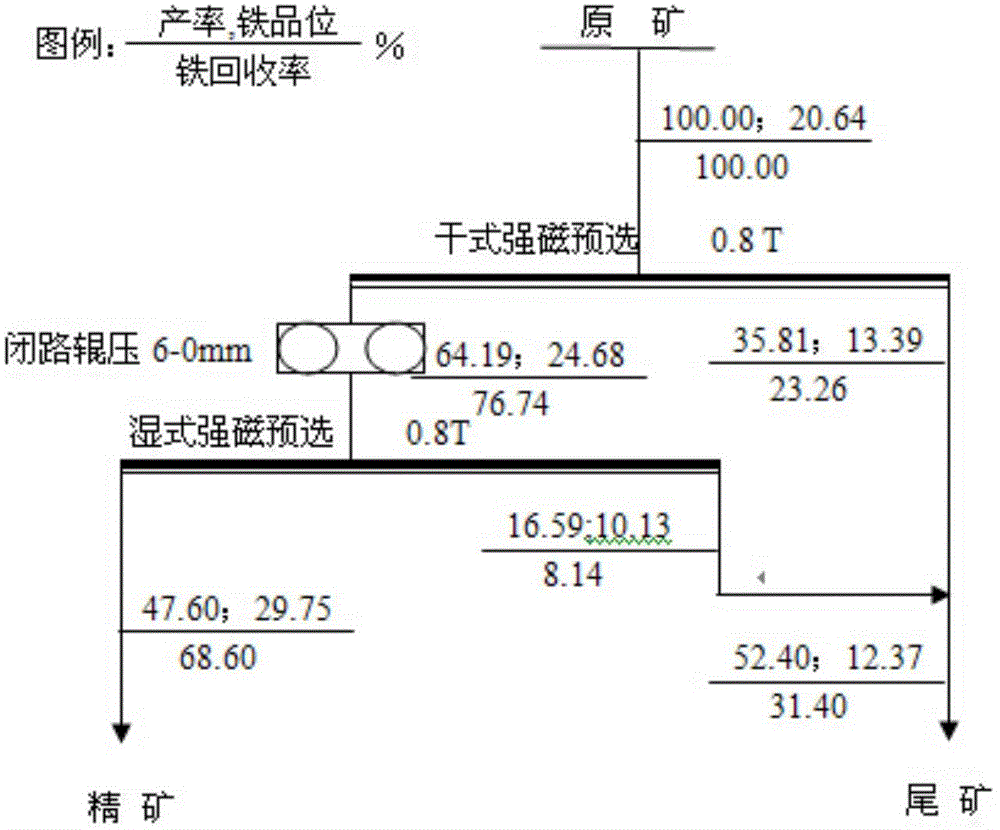

Pre-selection method for low-grade hematite-containing waste rock

ActiveCN104399578AEmission reductionExtended service lifeMagnetic separationHigh pressureLayer thickness

The invention discloses a pre-selection method for low-grade hematite-containing waste rock. The pre-selection method comprises: fragmenting low-grade hematite-containing waste rock raw ore with the iron grade of 18-23% to 40-0 mm through coarse crushing and intermediate crushing work, employing a permanent-magnet dry type high-intensity magnetic separator to perform pre-selection, controlling the cylinder surface magnetic field intensity of the permanent-magnet dry type high-intensity magnetic separator to be 0.8-1.0 T, controlling the cylinder surface linear velocity, the separation baffle plate distance and the material layer thickness, and throwing out coarse-grain tailings with the iron grade less than 14.0%; grinding the rough concentrate obtained through permanent-magnet dry type high-intensity magnetic separation to 10-0 mm through a high-pressure roller, then preselecting by an electromagnetic pulsation high-gradient coarse-grain wet-type high-intensity magnetic separator, and then throwing out fine-grain tailings with the iron grade of 11% or less, so as to obtain rough concentrate which is sent to a main workshop for grading through a grinding selection technology. According to the method, a large amount of tailings are thrown out through magnetic pre-selection before ore grinding, the ball milling amount of the ore is reduced, the ball milling grade is improved, the ore grinding energy consumption is reduced, the method has the advantages of simple structure, short flow, low energy consumption, strong adaptability and high ore selection technology index, is widely applicable to hematite selection factories, and is especially suitable for pre-selection of low-grade hematite-containing waste rock.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

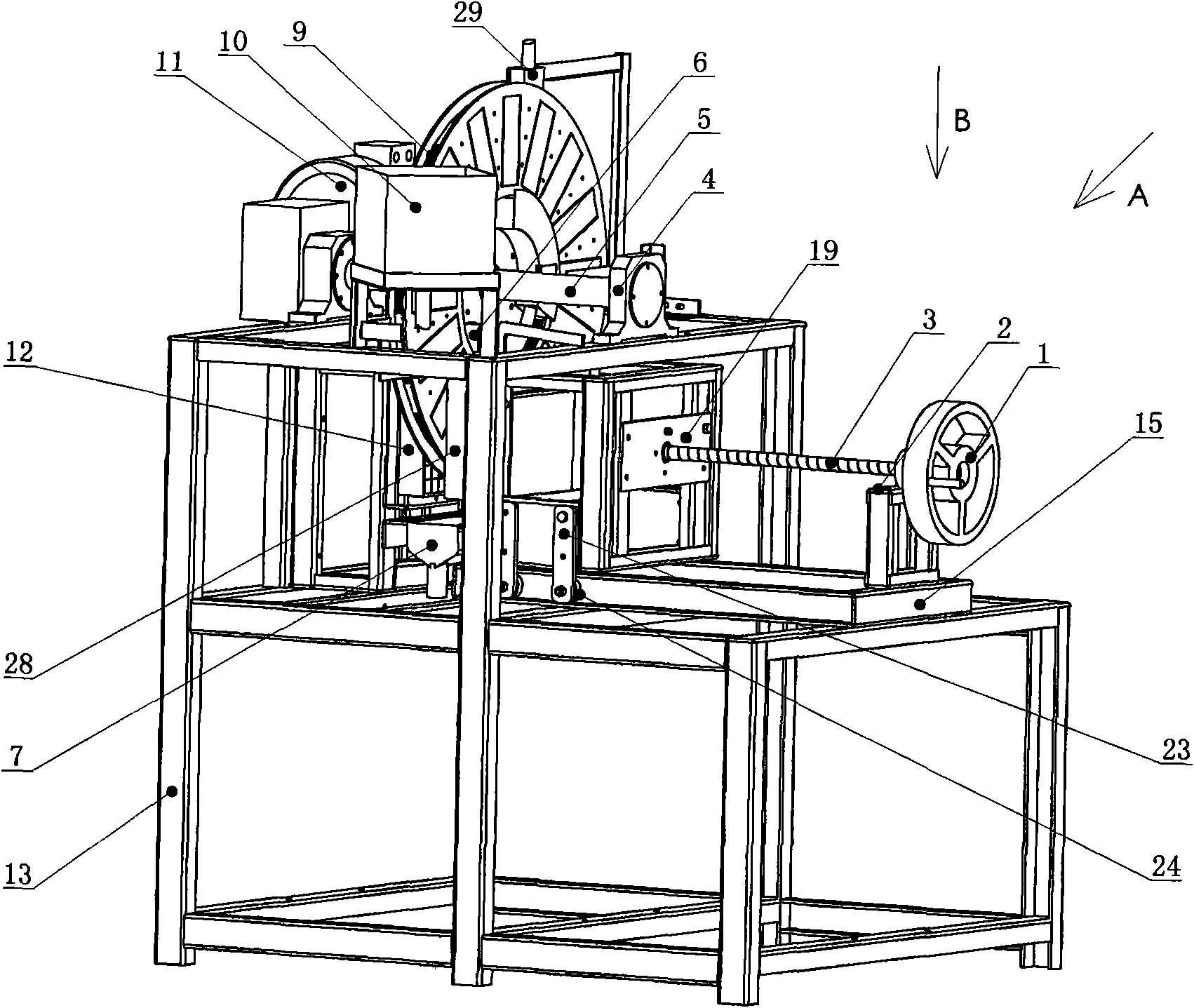

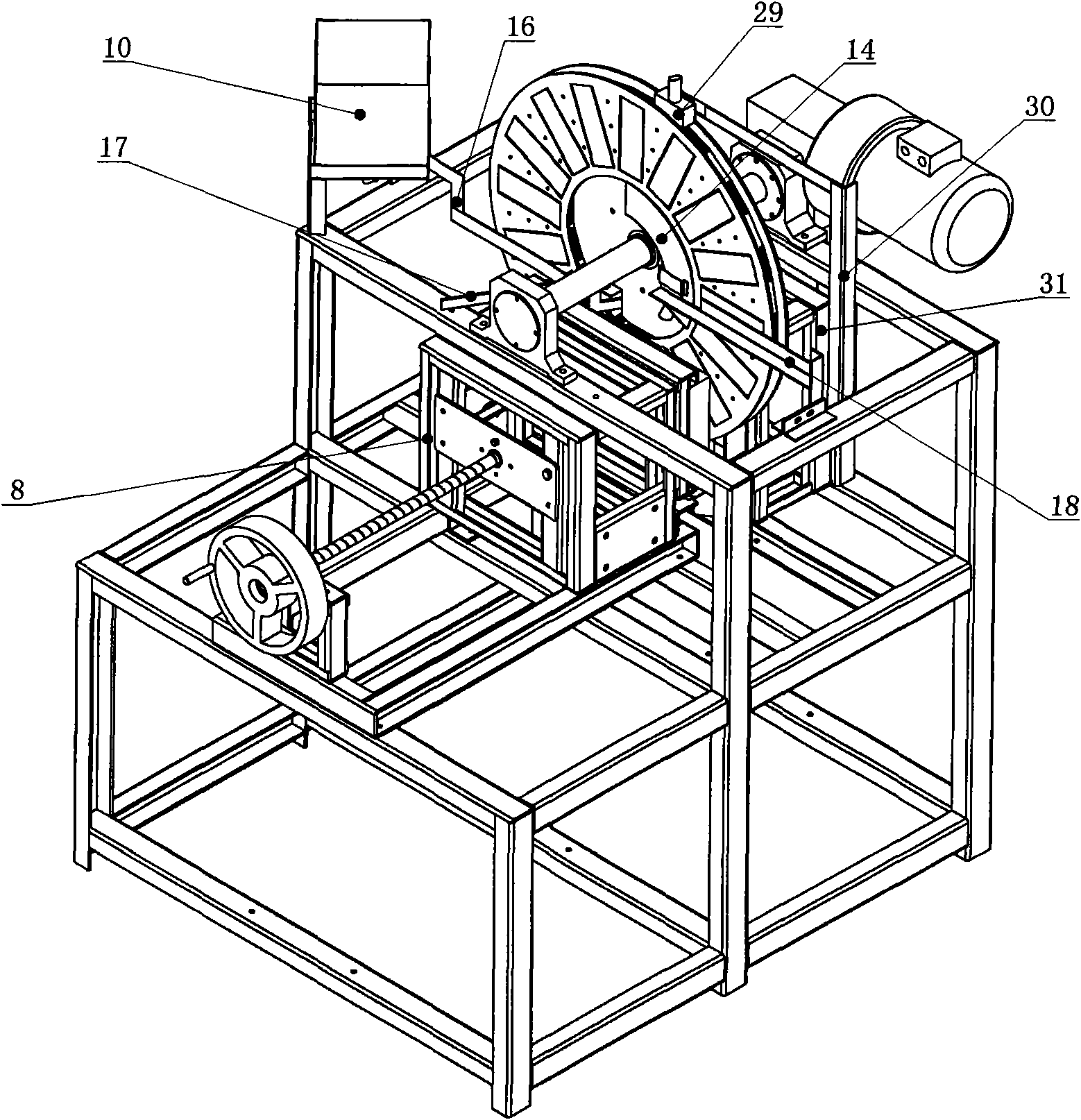

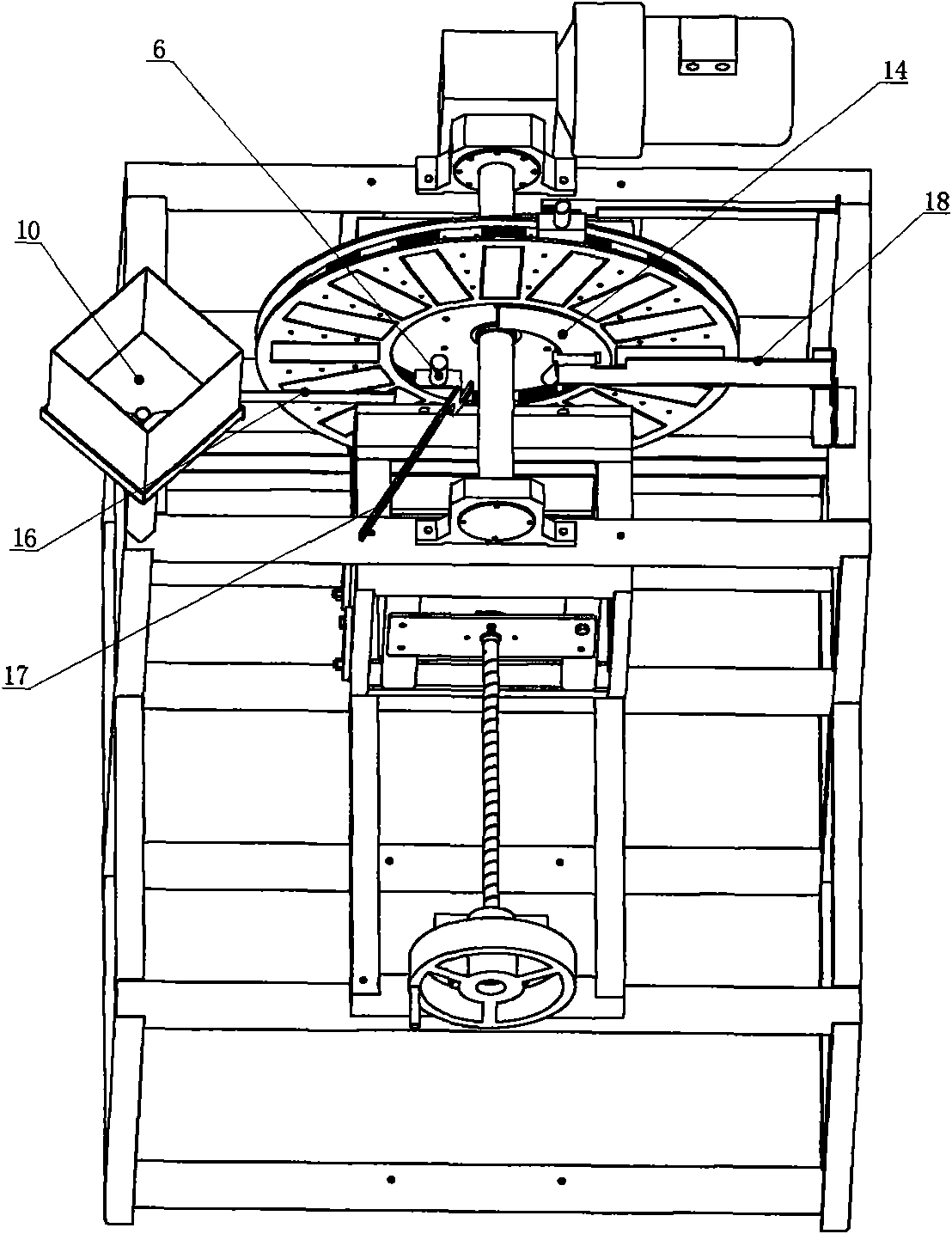

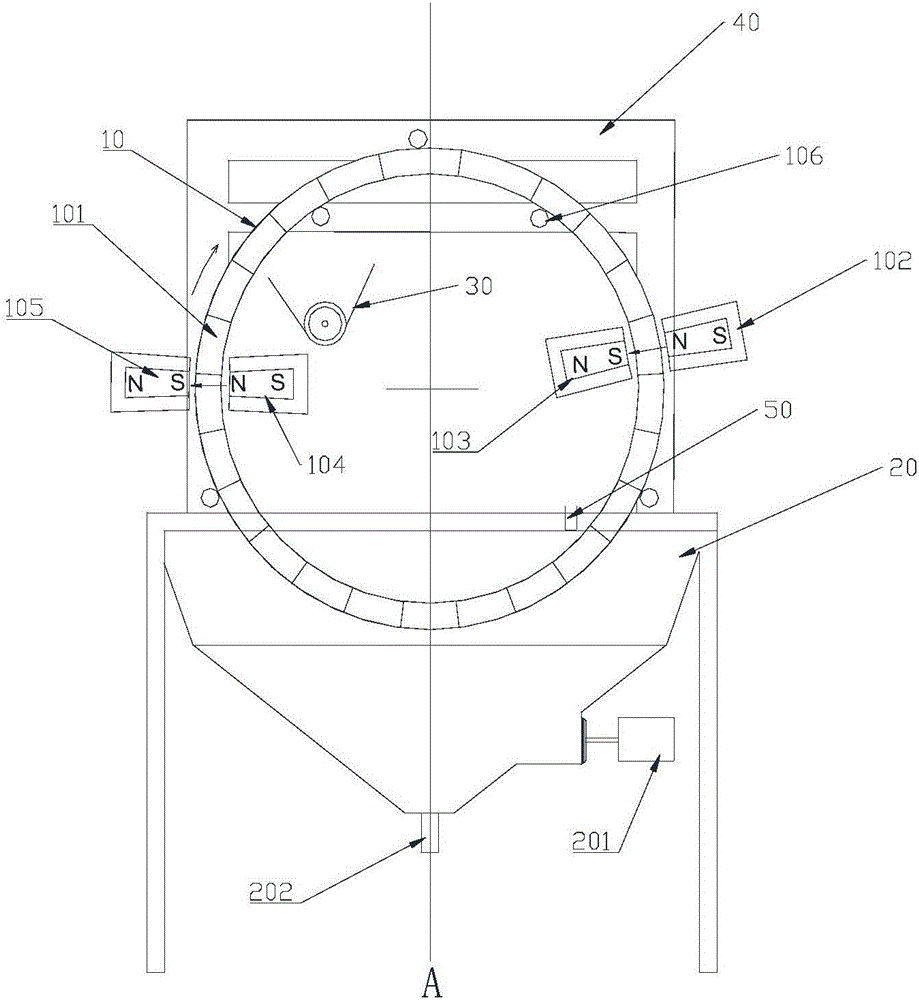

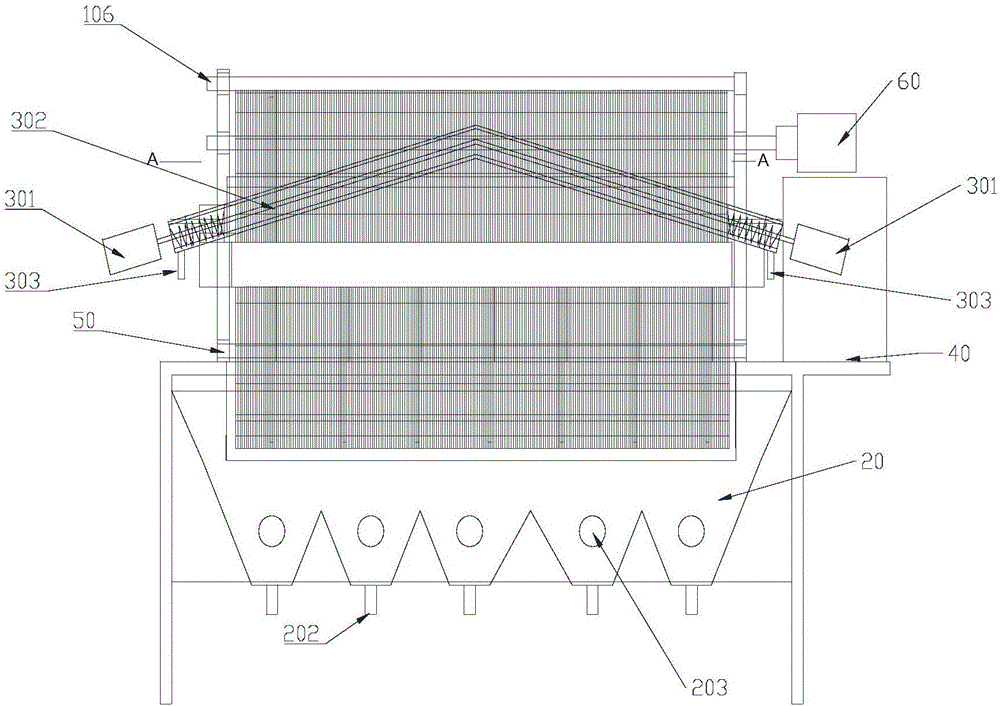

Wet type permanent magnet vertical ring-adjusted high-gradient high-intensity magnetic separator

InactiveCN101884952AAdjustable magnetic field gradientHigh gradient magnetic separatorsMagnetic field gradientEngineering

The invention discloses a wet type permanent magnet vertical ring-adjusted high-gradient high-intensity magnetic separator, and relates to the field of metallic or non-metallic ore weakly-magnetic mineral separation. The magnetic separator comprises a machine frame provided with a transmission device and a bearing room, the transmission device is provided with a main shaft arranged on a bearing, and the main shaft is provided with a separation ring vertically arranged. A. Both sides of the separation ring are provided with a magnetic system I and a magnetic system II, the magnetic system I is arranged on a magnetic system frame I arranged on the machine frame, the magnetic system II is arranged on a magnetic system frame II, and the magnetic system frame II is in moving connection with a sliding rail arranged on the machine frame; B. the sliding rail is provided with a handle support provided with an adjusting screw rod, one end of the adjusting screw rod is provided with a magnetic system adjusting handle, and the other end of the adjusting screw rod is provided with a fixing plate arranged on the side of the magnetic system II. The magnetic field gradient on the magnetic matrix is high, and the distribution of magnetic fields between the magnetic systems can be changed by turning the adjusting handle, so that different weakly-magnetic materials can be separated.

Owner:河南长实矿业科技有限公司

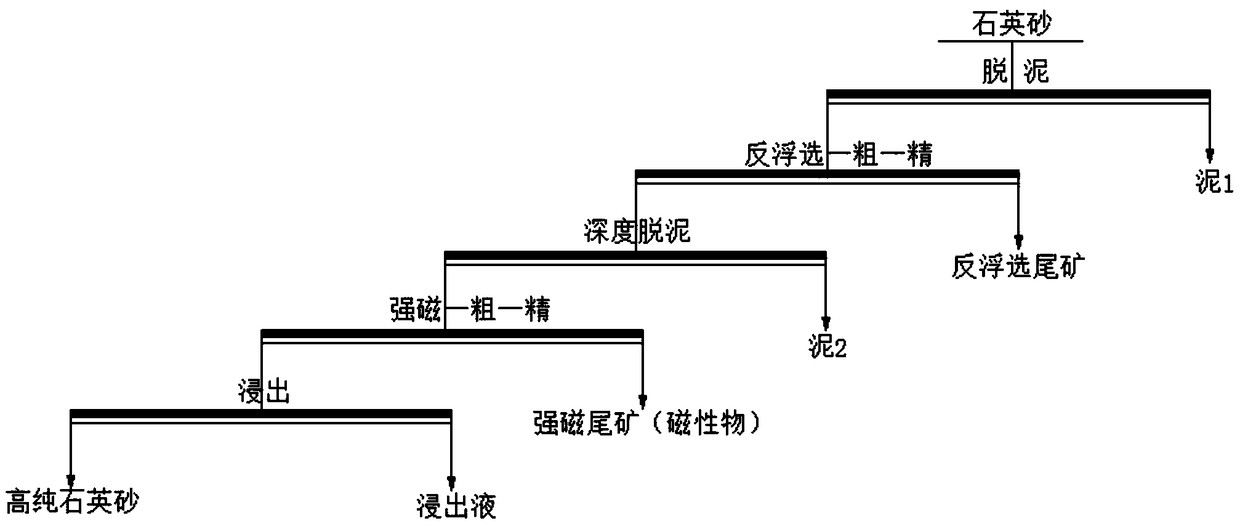

Ore dressing purifying method for high-purity quartz sand

InactiveCN109111101AReduce Fe <sub>2</sub> o <sub>3</sub> content Raise the gradeFlotationHigh intensityReverse flotation

The invention discloses an ore dressing purifying method for high-purity quartz sand. The method comprises the following processes and steps: feeding raw material quartz sand with particle size less than or equal to 0.3mm and SiO2 content more than or equal to 98.0% into a desliming process; feeding the produced desliming sand into a flotation machine for reverse flotation; feeding the produced reverse flotation concentrate into a deep desliming operation; feeding the produced desliming concentrate into a high-intensity magnetic separator for high-intensity magnetic separation impurity-removing operation; concentrating the produced magnetic concentrate; feeding into a leaching tank containing an acidic solution, stirring and removing acid-soluble impurity elements from the magnetic concentrate; cleaning, grading, filtering and drying, thereby obtaining the high-purity quartz sand with SiO2 grade more than or equal to 99.95%. The ore dressing purifying method has the advantages of simple technological process, low production cost, capability of obtaining high purity of quartz sand products, and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

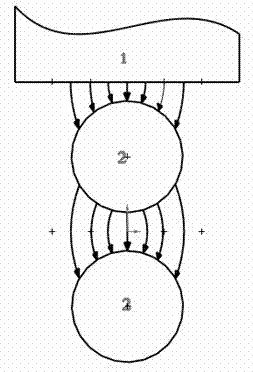

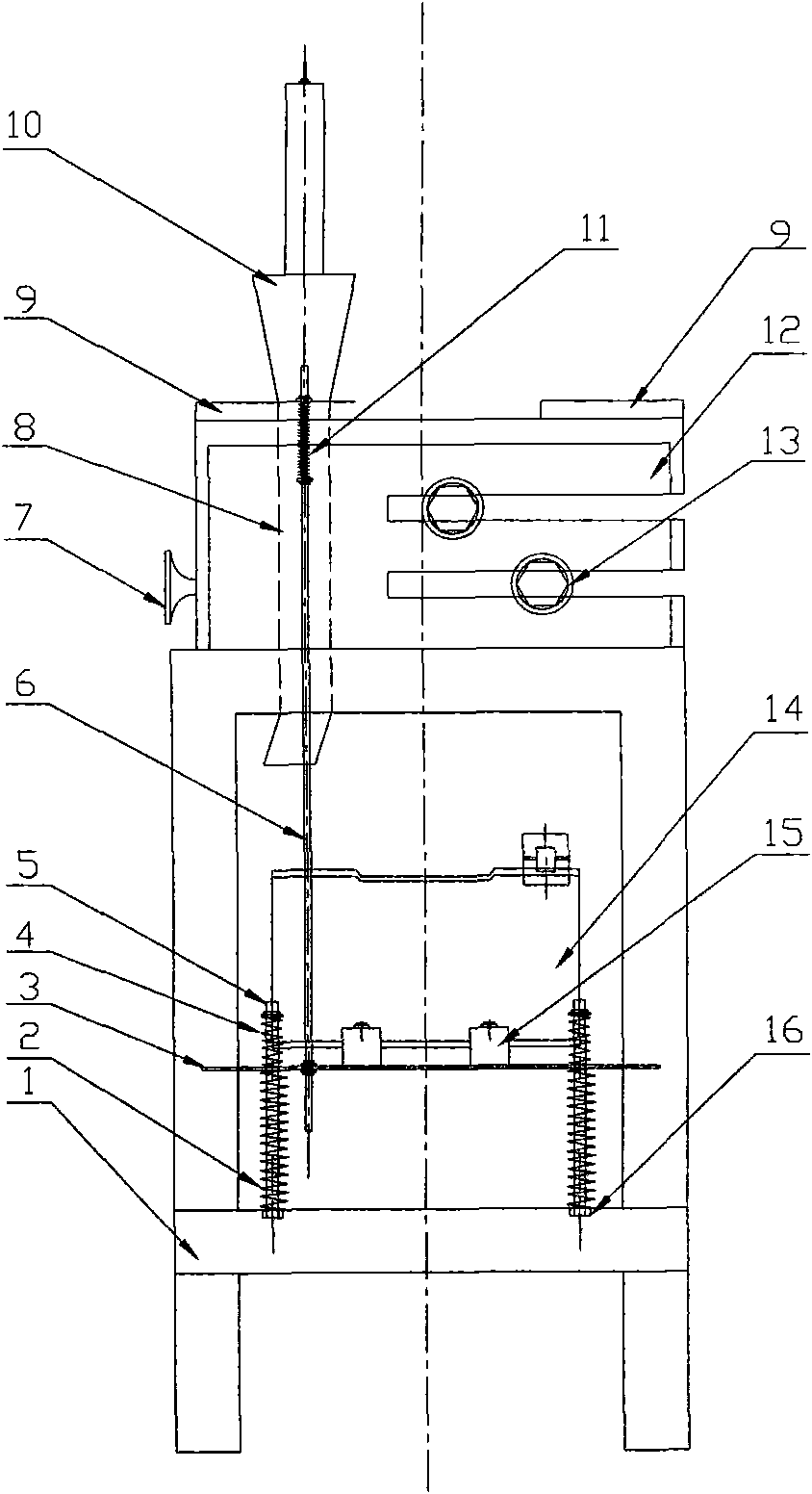

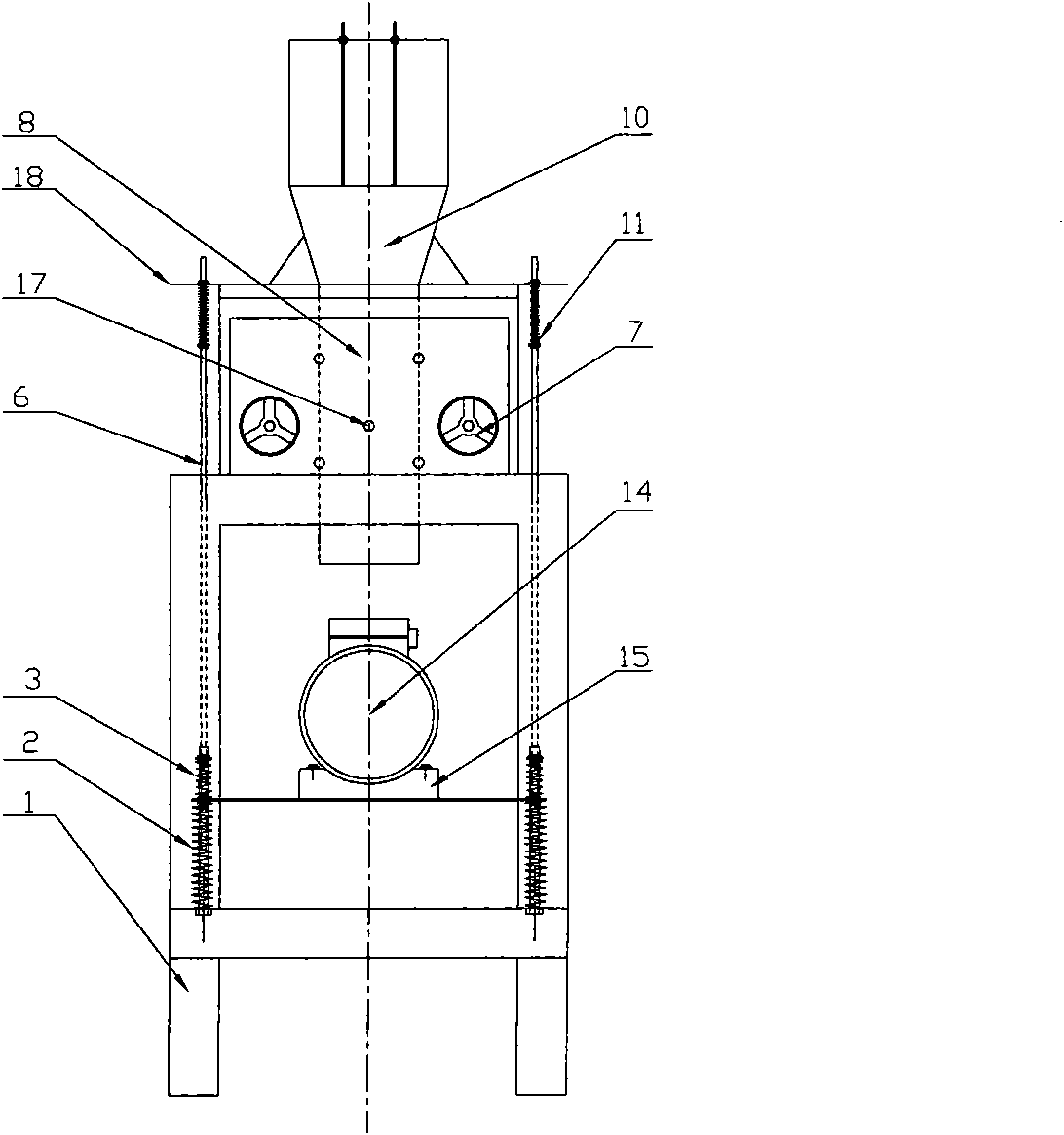

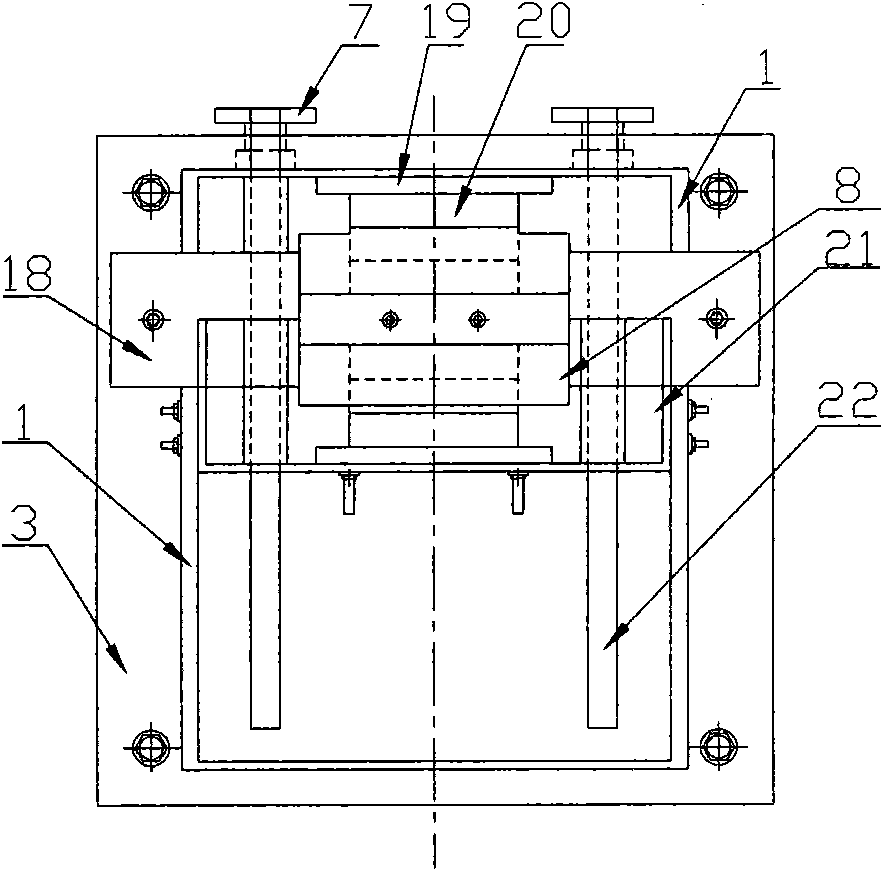

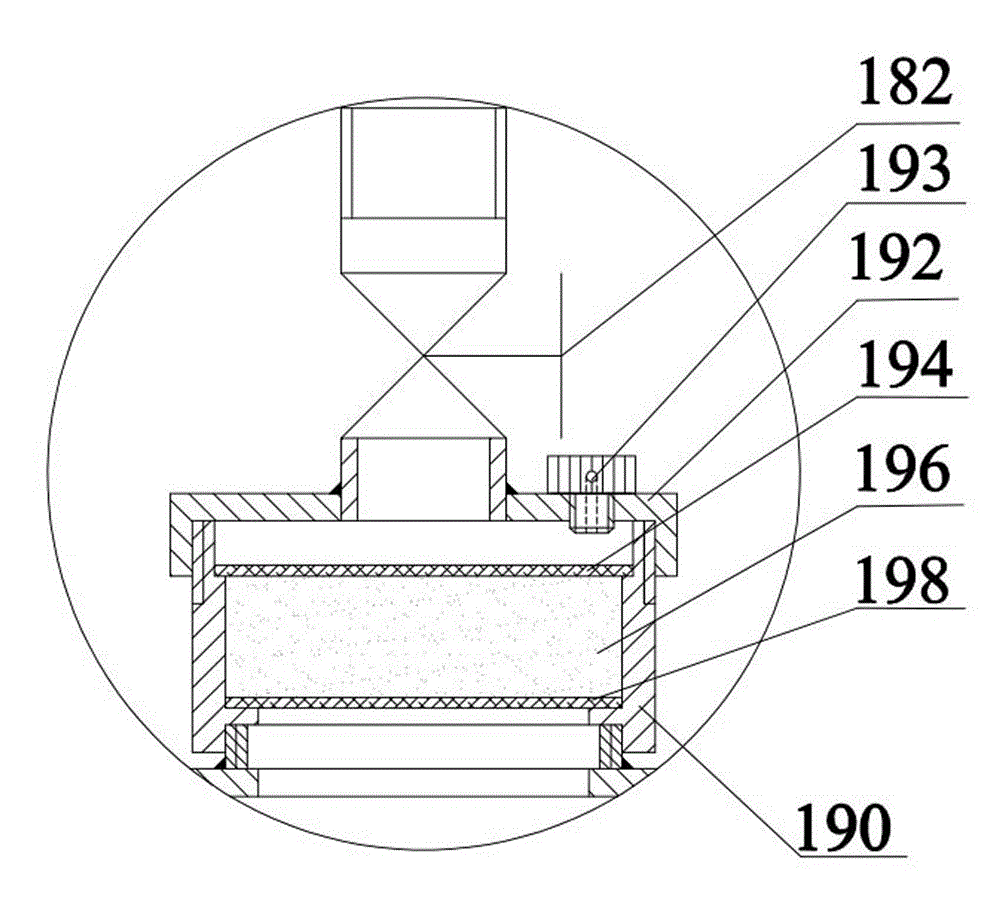

Anti-podal permanent magnetic high-intensity magnetic separator

InactiveCN101554614AFully adsorbedReasonable structureMagnetic separationElectricityElectrical polarity

An anti-podal permanent magnetic high-intensity magnetic separator is characterized in that the magnetic separator comprises a frame (1), a power vibration mechanism arranged at the middle part of the frame, a permanent magnetic system arranged at the top of the frame, and a vibration supporting frame (18) which is arranged above the permanent magnetic system and is used for installing a feeding funnel (10) and a magnetism-collecting medium box (8); the vibration supporting frame is combined with the power vibration mechanism by a connecting and supporting rod (6); the permanent magnetic system is characterized in that a plurality of axial permanent magnetic alnicos (20) with the same specification are superposed by an extrusion way in two groups and arranged at two sides of the magnetism-collecting medium box (8) in the horizontal direction, the polarity arrangement of each group is N-S-N-S-N-S or S-N-S-N-S-N, the external surfaces of the permanent magnetic alnicos form an antipodal magnetic separation space and a closed magnetic circuit, and the internal surface of each group of the permanent magnetic alnico is clamped between two bakelite boards (19) after being extruded, assembled and positioned precisely; and the Bakelite boards (19) are fixedly arranged on a chute vibration board (12) and a sliding plate (21) by a connecting bolt.

Owner:HENAN POLYTECHNIC UNIV

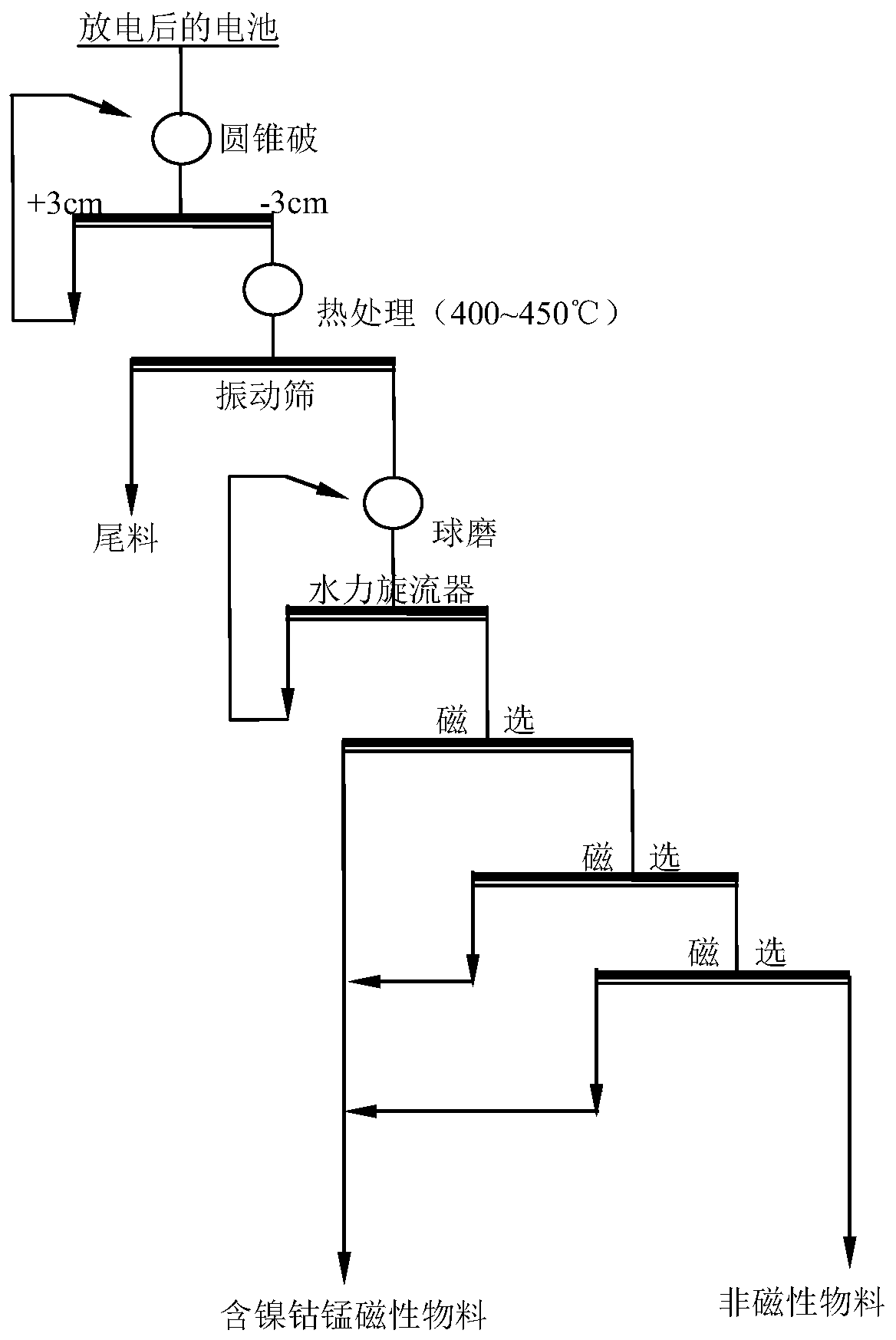

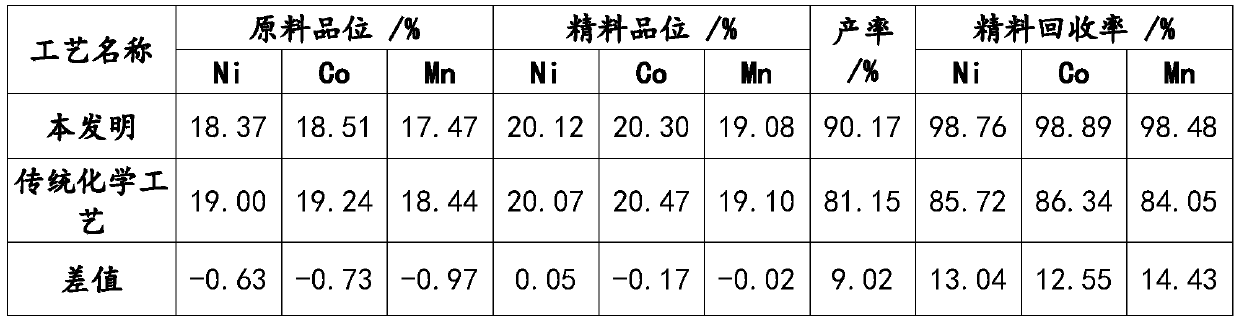

Method for green and efficient recycling of nickel, cobalt and manganese in waste lithium batteries

InactiveCN110479478AHigh recovery rateHigh purityWaste accumulators reclaimingBattery recyclingManganeseLithium-ion battery

The invention discloses a method for green and efficient recycling of nickel, cobalt and manganese in waste lithium batteries, and aims at solving the problems of environmental pollution and low recycling rate of nickel, cobalt and manganese during the recycling of the waste lithium batteries. The method comprises the following steps: performing single-stage crushing and single-stage grinding, sothat the processing capacity is greatly increased and the unit energy consumption is reduced; performing pre-discharging, pre-treatment, milling and sieving to physically separate a positive electrodematerial from other materials; and performing combined magnetic separation on the positive electrode material powder by a three-stage high intensity magnetic separator to recycle nickel, cobalt, manganese and other valuable metal element materials, so that the comprehensive recycling rate of nickel, cobalt, manganese magnetic materials is greatly improved. The method has simple process, large production scale, low power consumption, and high purification efficiency. The produced nickel-cobalt-manganese-containing valuable metal element materials have stable performance and a good beneficiation environment, the entire production process belongs to physical beneficiation and does not cause the environment pollution, and at the same time, the method can also be used for large-scale production of positive electrode raw materials for lithium ion batteries.

Owner:赣州金环磁选科技装备股份有限公司

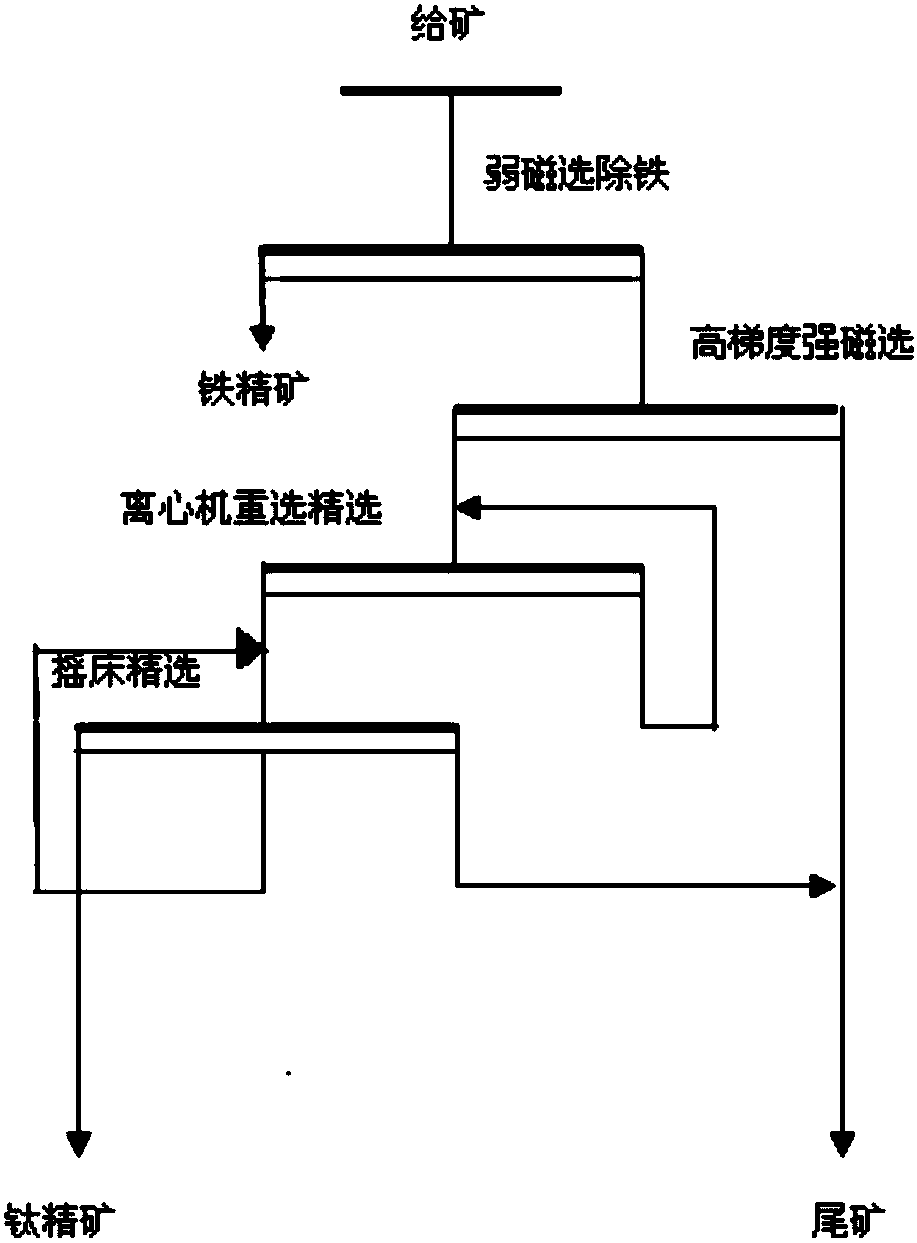

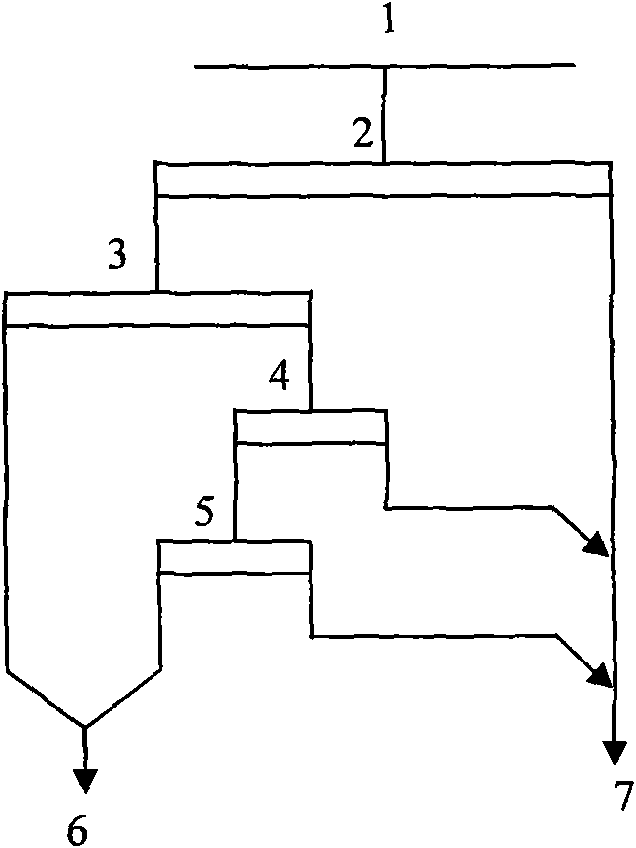

Method and system for recovering low-grade fine-fraction ilmenite

The invention provides a system for recovering low-grade fine-fraction ilmenite. The system comprises a low-intensity magnetic separator, a high-intensity magnetic separator with an inlet connected with a tailing outlet of the low-intensity magnetic separator, a centrifugal separator with an inlet connected with an ilmenite concentrate outlet of the high-intensity magnetic separator as well as a shaking table with an inlet connected with an ilmenite concentrate outlet of the centrifugal separator. The system for recovering the low-grade fine-fraction ilmenite performs high-intensity magnetic separation, centrifugal gravity separation and tabling sequentially, particularly, the low-grade fine-fraction ilmenite is recovered by the centrifugal separator and the shaking table, the technological process of recovery is simplified, production cost is low, metal recovery rate is higher, and environmental pollution is low. The invention further provides a method for recovering the low-grade fine-fraction ilmenite.

Owner:PANGANG GRP MINING

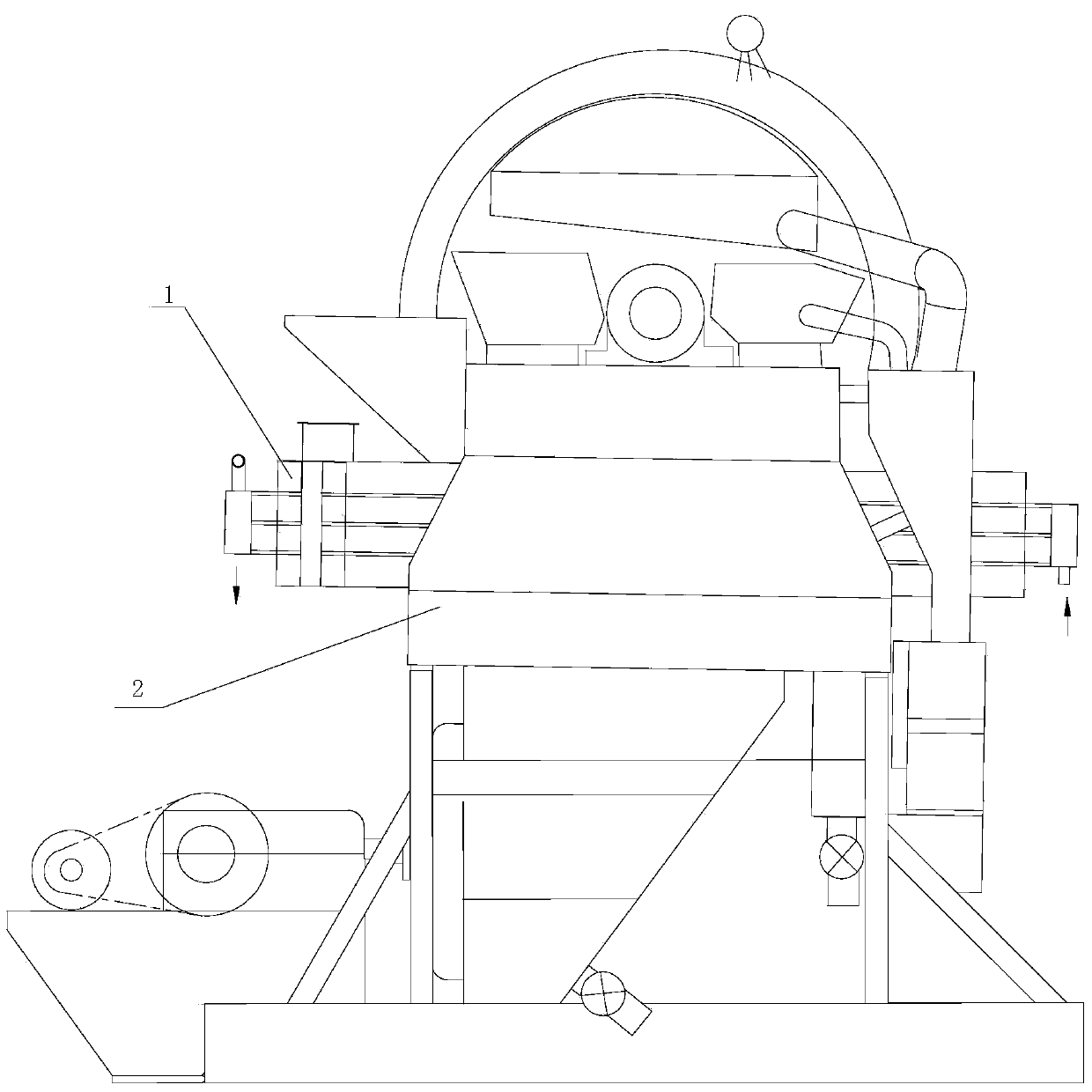

Energy-saving, high-gradient and high-intensity magnetic separator

InactiveCN106824519ASimple structureIncrease throughputMagnetic separationEngineeringEnergy consumption

The invention relates to an energy-saving, high-gradient and high-intensity magnetic separator. The energy-saving, high-gradient and high-intensity magnetic separator comprises a magnetic separation device, a conveying device, a feeding device and a sorting box, wherein the magnetic separation device comprises a magnetic separation drum, a magnetizing system, a demagnetizing system and a driving device of the magnetic separation drum, and the magnetic separation drum consists of medium rod filler and a framework thereof; the feeding device is mounted at the lower end of an inner space of the magnetic separation drum and conveys to-be-separated ore granules to the inner side of the magnetic separation drum; the sorting box is located at the lower part of the magnetic separation drum, receives ore granules left by the magnetic separation drum and keeps the drum being immersed in ore pulp. The medium rod is not required to always finish adsorption of the ore granules in a magnetic field after being made from a hard magnetic material, the air gap space of the required magnetic system is substantially narrowed, the energy consumption and the cost are reduced, and the ore treatment amount is increased.

Owner:攀枝花市焱乾富慧科技有限公司

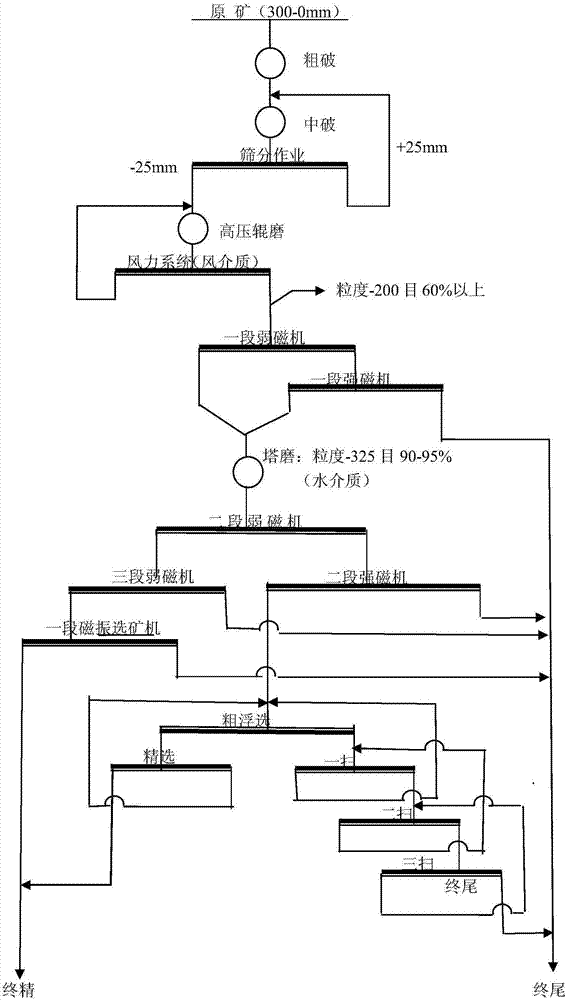

Mixed ore high pressure roll milling dual-media magnetic separation-hematite ore sorting process

InactiveCN107029868AReduce the amount of oreReduce consumptionWet separationHigh pressureMaterials science

The invention relates to a mixed ore high pressure roll milling dual-media magnetic separation-hematite ore sorting process. The process is characterized by comprising the following steps that raw ore is subject to coarse breaking and medium breaking two-section breaking and screening until the content of products with the granularity reaching -25 mm being 90% or above, then the material is fed into a high pressure roll milling-wind hierarchy system, and the content of products with the granularity being -200 meshes is 60%-65%; and the material is fed into a first-section low-intensity magnetic separator and a first-section high intensity magnetic separator for sorting, first-section low intensity magnetic separation concentrate and first-section high intensity magnetic ore are fed into a tower mill to be milled until the content of products with the granularity being -325 meshes is 90% or above, the products are fed into a second-section low-intensity magnetic separator, a third-section low-intensity magnetic separator, a first-section magnetic vibrating concentrator and an anion reverse flotation operation, concentrate with the grade being 67%-67.5% is obtained, and first-section high intensity magnetic separation tailing, second-section low intensity magnetic separation tailing, third-section low intensity magnetic separation tailing, second-section high intensity magnetic separation tailing and first-section magnetic vibrating concentrator tailing are combined into final tailing. According to the mixed ore high pressure roll milling dual-media magnetic-hematite ore grading process, fine breaking operation and two-section ore grinding operation are reduced, the fine screening operation is eliminated, the flow structure is simplified, and dual-media and short-flow grading is achieved, and the mineral separation cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

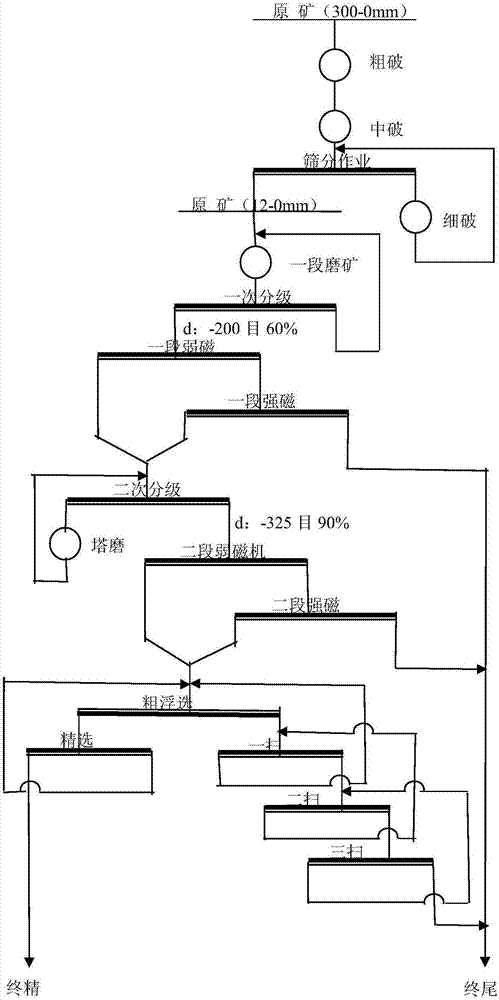

Magnetic separation process of fine lean hematite

The invention belongs to the technical field of separation of hematite in ferrous metals and in particular provides a magnetic separation process of fine lean hematite. The process comprises coarse and fine classified overflow and is characterized by comprising the following steps: feeding the coarse and fine classified overflow with concentration being less than 25% into a concentrator before high-intensity magnetic separation, feeding the bottom flow with concentration being 35-40%, which is concentrated by the concentrator before high-intensity magnetic separation into a low-intensity magnetic separator for low-intensity magnetic separation, wherein the overflow in the concentrator before high-intensity magnetic separation is tailing, feeding the concentrates after low-intensity magnetic separation into concentration operation before floatation, feeding the tailing after low-intensity magnetic separation into a slag remover to remove the slag, feeding the concentrates after the slag remover removes the slag into a high-intensity magnetic separator for high-intensity magnetic separation, feeding the high-intensity magnetic concentrates separated by the high-intensity magnetic separator into concentration before floatation and combining the concentrated tailing before high-intensity magnetic separation, the slag removed tailing and the tailing after high-intensity magnetic separation into the final tailings. The process improves the feeding conditions during low-intensity magnetic operation, reduces the number of the low-intensity magnetic separators needing to be operated and reduces the low-intensity magnetic operation and the final tailings grade.

Owner:ANSTEEL GRP MINING CO LTD

Magnetic separation method of pyrite roasting slag

InactiveCN105597925AImprove overall recoveryImprove concentrate gradeMagnetic separationSlagBall mill

The invention discloses a magnetic separation method of pyrite roasting slag, which comprises following steps: feeding the roasting slag into a ball mill and adding water to grind into ore pulp, wherein first grade magnetic separating adopts a high intensity magnetic separator with a magnetic field intensity of 2600Gs, the ore pulp is conveyed into the first grade magnetic separator by using a slurry pump for primary separating, residue after magnetic separating is conveyed into a tailings pond for settling, and a magnetically separated material flows to the second grade magnetic separating, second grade magnetic separating adopts a medium intensity magnetic separator with a magnetic field intensity of 1200-1400Gs, first fine selecting is performed, a magnetically separated material flows to a third grade magnetic separating and the residue after magnetic separating returns back to a pulp pool, third grade magnetic separating adopts a low intensity magnetic separator with a magnetic field intensity of 800-1200Gs, second fine selecting is performed, the magnetically separated material flows to a concentrate pool and is settled as iron concentrate, and the residue after magnetic separating returns back to the pulp pool. A total recycle rate of iron element of the method is high and a concentrate grade is high.

Owner:GUIZHOU DAFANG RUNFENG CHEM CO LTD

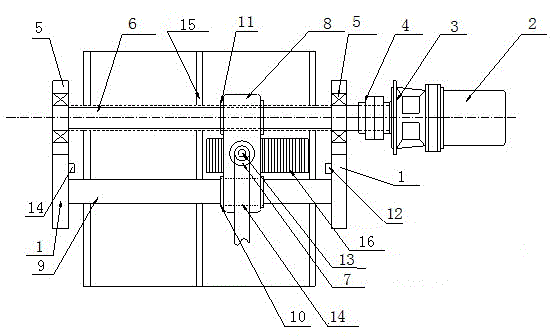

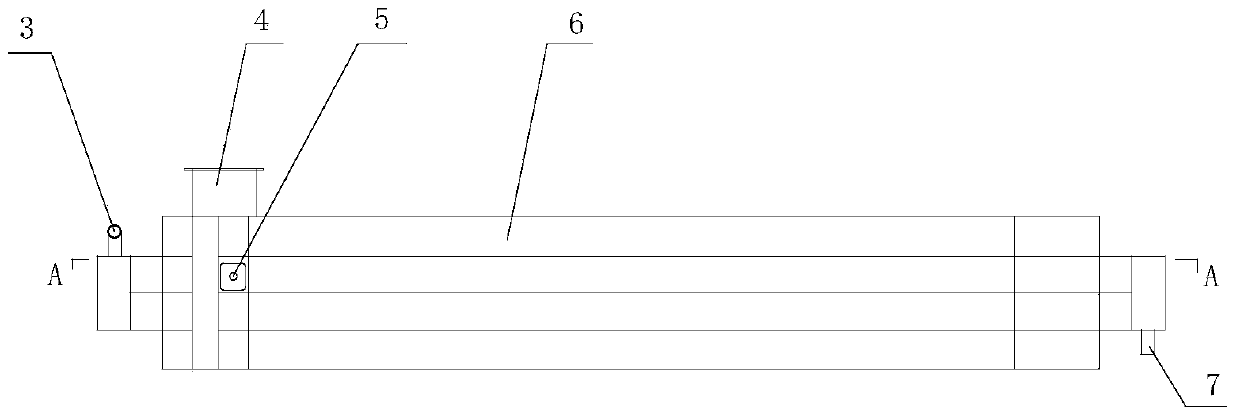

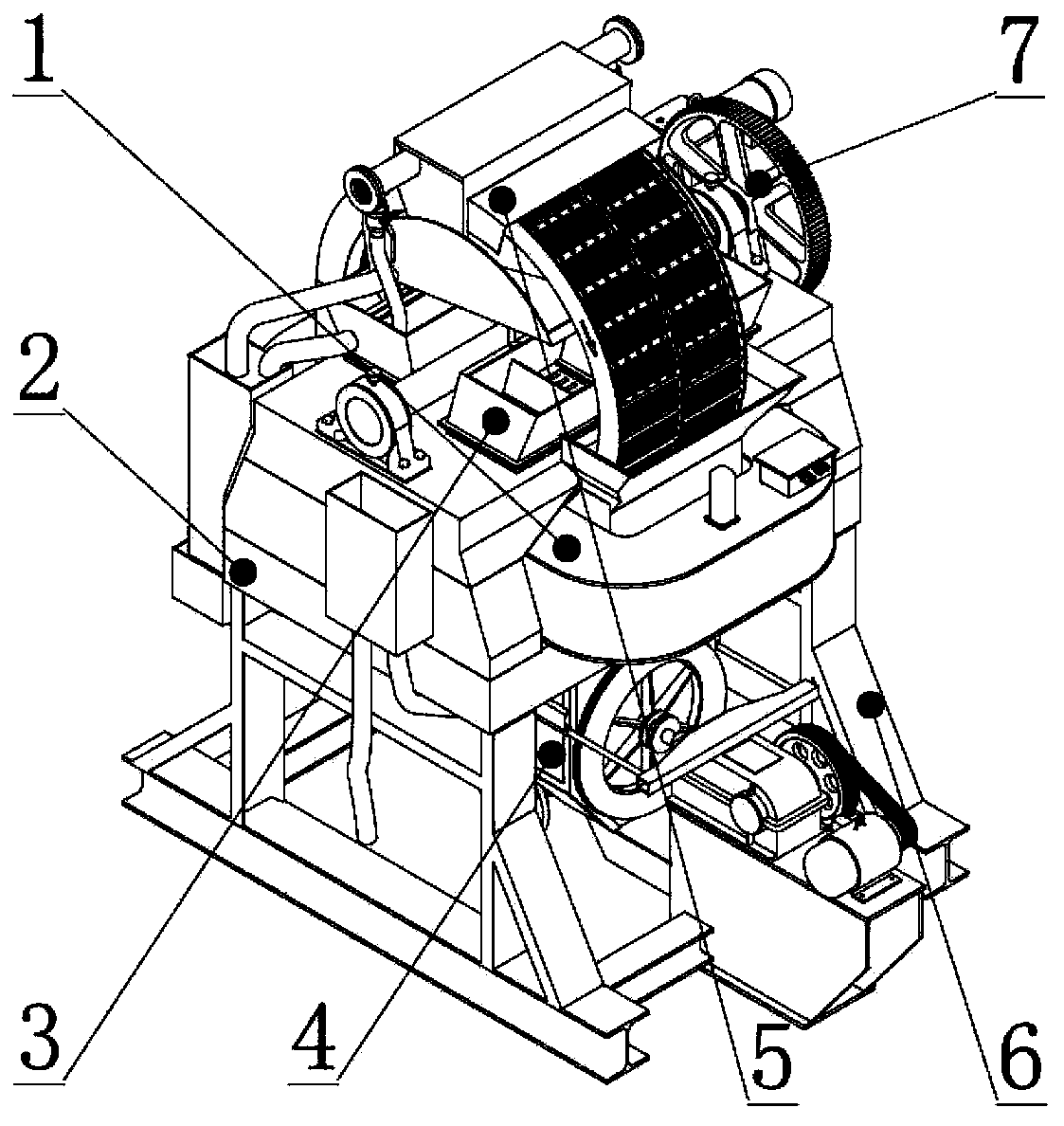

Online cleaning machine for high intensity magnetic separator medium box

InactiveCN103949342ASimple structureEasy to installHigh gradient magnetic separatorsElectric machineryReducer

The present invention relates to an online cleaning machine for a high intensity magnetic separator medium box. The online cleaning machine comprises a rack, an electric drive device and a high pressure water gun device, wherein the electric drive device comprises a motor, a speed reducer, a connection hand, a bearing pedestal and a drive screw, the high pressure water gun device comprises a high pressure water gun, a water gun walking frame, a water gun stabilizing rod, a stabilizing snapping ring and a drive screw nut, the machine further comprises two reversing switches, and the reversing switches are respectively fixed on both sides of the rack. By installing the online cleaning machine, the problems of poor sorting effect, metal loss and the like due to clogging of the high intensity magnetic separator medium box are effectively solved.

Owner:NANJING MEISHAN METALLURGY DEV +1

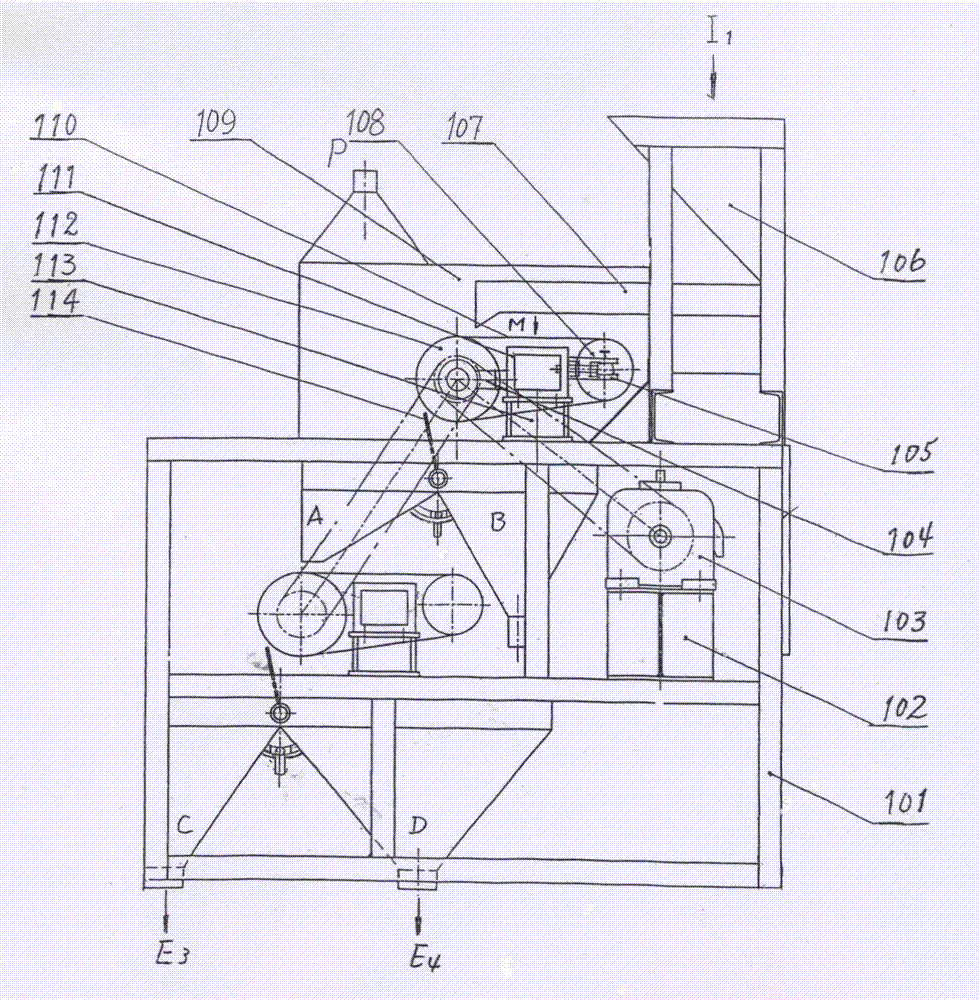

Chromium ore recovering system

InactiveCN102764733AHigh recovery rateHigh puritySievingGas current separationIron removalMagnetic poles

The invention discloses a chromium ore recovering system which is characterized by comprising a general machine frame; a high intensity magnetic separator is mounted at the top of the general machine frame; a vibrating feeder and a gravity separator are mounted under the high intensity magnetic separator; an iron remover is mounted on the side surface of the gravity separator; a material bin is mounted at the upper part of a machine frame I of the high intensity magnetic separator; a vibrating conveyor is mounted under the material bin; a conveyor belt tensioned by a magnetic roller and a redirection roller is mounted under the vibrating conveyor; an air cleaner, a blower and a blast tank are mounted on the vibrating feeder and the under frame of a machine frame II of the gravity separator; a vibrating case is mounted on the machine frame II; a gravity separating sieve is mounted in the vibrating case; a vibrating sieve is mounted at the front end of the gravity separating sieve; a wind distributing board is mounted under the gravity separating sieve; a reducer is mounted on a machine frame III of the iron remover; an output worm gear of the reducer is inserted in a shaft end of a rotary drum; and a magnetic pole seat is mounted in the inner cavity of the rotary drum. The chromium ore recovering system can sort out valuable weakly-magnetic chromium ore particles in mixed particles from other non-magnetic particles, is high in recovery rate, is good in purity, and has significant economic effects.

Owner:杭州太阳铸造工程技术有限公司

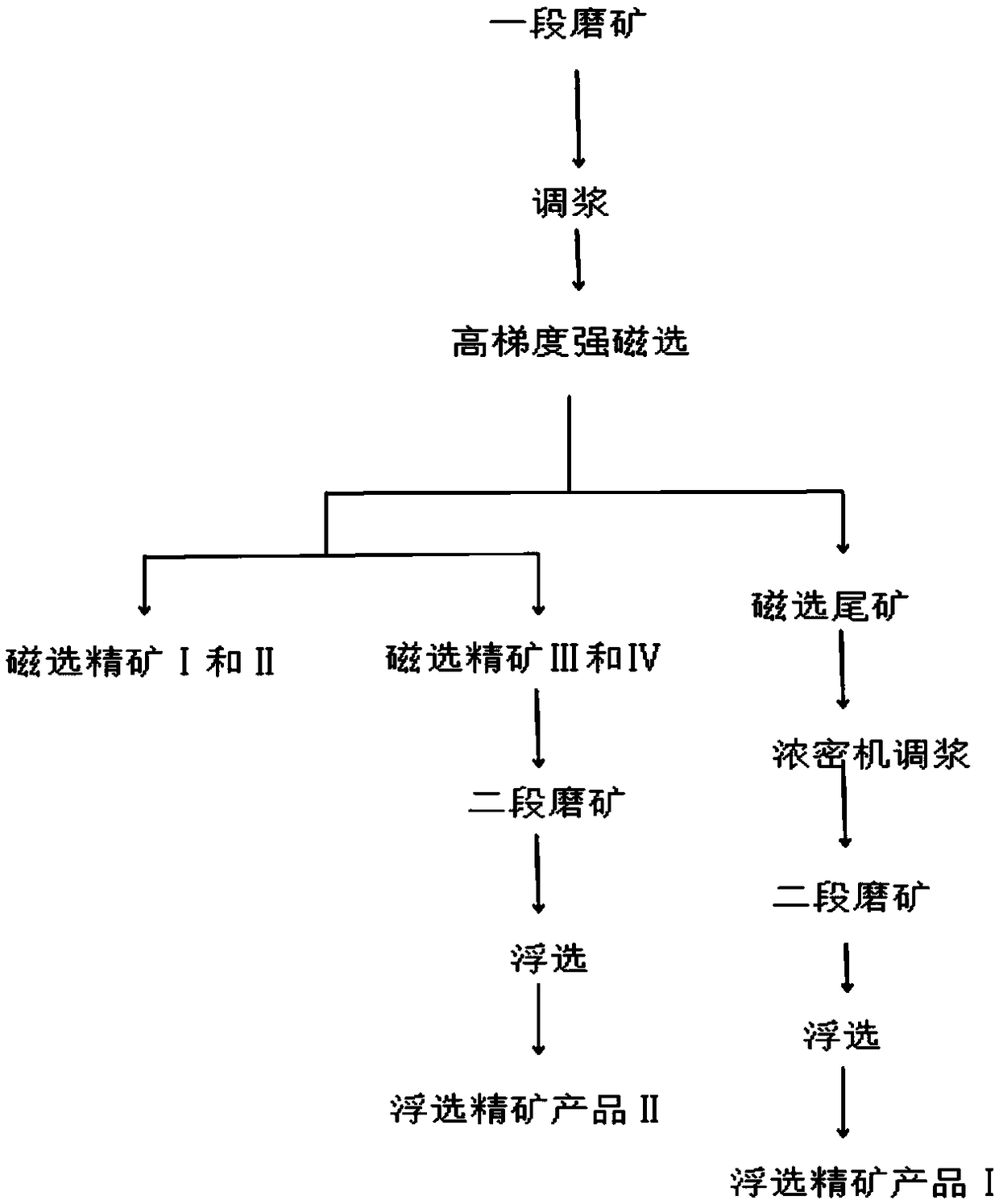

Magnetic levitation combined beneficiation method for biotite type ore containing rubidium

ActiveCN108816499AAvoid damageEasy to recycleHigh gradient magnetic separationFlotationRubidium oxideRubidium

The invention discloses a magnetic levitation combined beneficiation method for biotite type ore containing rubidium. According to the method, the biotite type ore containing rubidium is subjected toprimary ore grinding and size mixing, obtained ore pulp is subjected to four times of magnetic separation through a high-gradient wet type high-intensity magnetic separator, magnetic concentrate I-IVis sequentially obtained, and remaining ore is magnetic separation tailings; and after the magnetic separation tailings and the magnetic concentrate III-IV are correspondingly subjected to secondary ore grinding and size mixing, then floatation separating is performed, and flotation concentrate products are obtained. According to the method, due to strong magnetic separation and combined flotation, rubidium in the biotite type ore containing rubidium is recycled step by step, efficient enriching of rubidium is achieved, the comprehensive recycling efficiency of rubidium is improved, the gradeof rubidium oxide in the concentrate is improved to 0.22%-0.28%, the total recycling rate of rubidium reaches 75.5%-84.22%, and economic benefits are remarkably improved.

Owner:CENT SOUTH UNIV

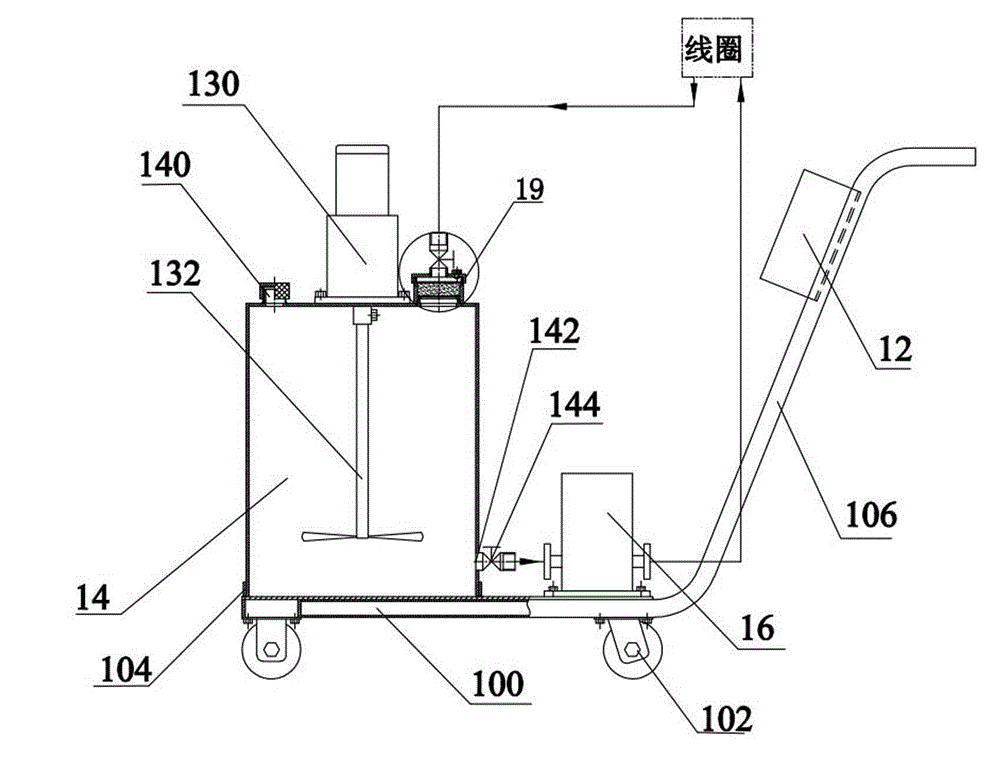

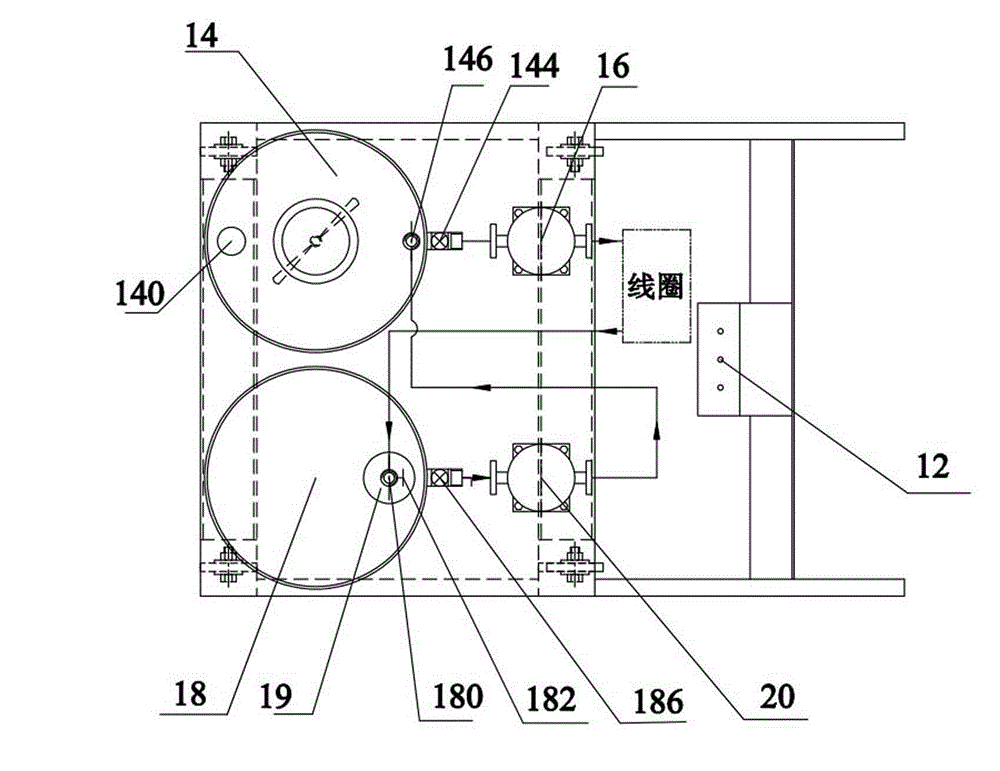

System for cleaning high-intensity magnetic separator coils

ActiveCN104874571AFlexible and easy to operateImprove cleaning efficiencyHollow article cleaningCleaning using liquidsEngineeringChemical cleaning

The invention provides a system for cleaning high-intensity magnetic separator coils. The system comprises a mobile trolley as well as an electronic control box, a storage tank and a cleaning fluid delivery pump which are arranged on the mobile trolley, wherein a cleaning fluid inlet is formed in the storage tank; a cleaning fluid outlet is formed in one end close to the bottom of the storage tank; a cleaning fluid outlet valve is arranged at the cleaning fluid outlet; one end of the cleaning fluid delivery pump is connected with the cleaning fluid outlet, and the other end is connected with the high-intensity magnetic separator coils, and the cleaning fluid delivery pump is used for delivering a cleaning fluid in the storage tank to the high-intensity magnetic separator coils for cleaning. According to the system for cleaning the high-intensity magnetic separator coils, the cleaning fluid is stored in the storage tank and delivered by the cleaning fluid delivery pump to the high-intensity magnetic separator coils for chemical cleaning, so that the cleaning efficiency is high, and the equipment damage is little.

Owner:岳阳大力神电磁机械有限公司

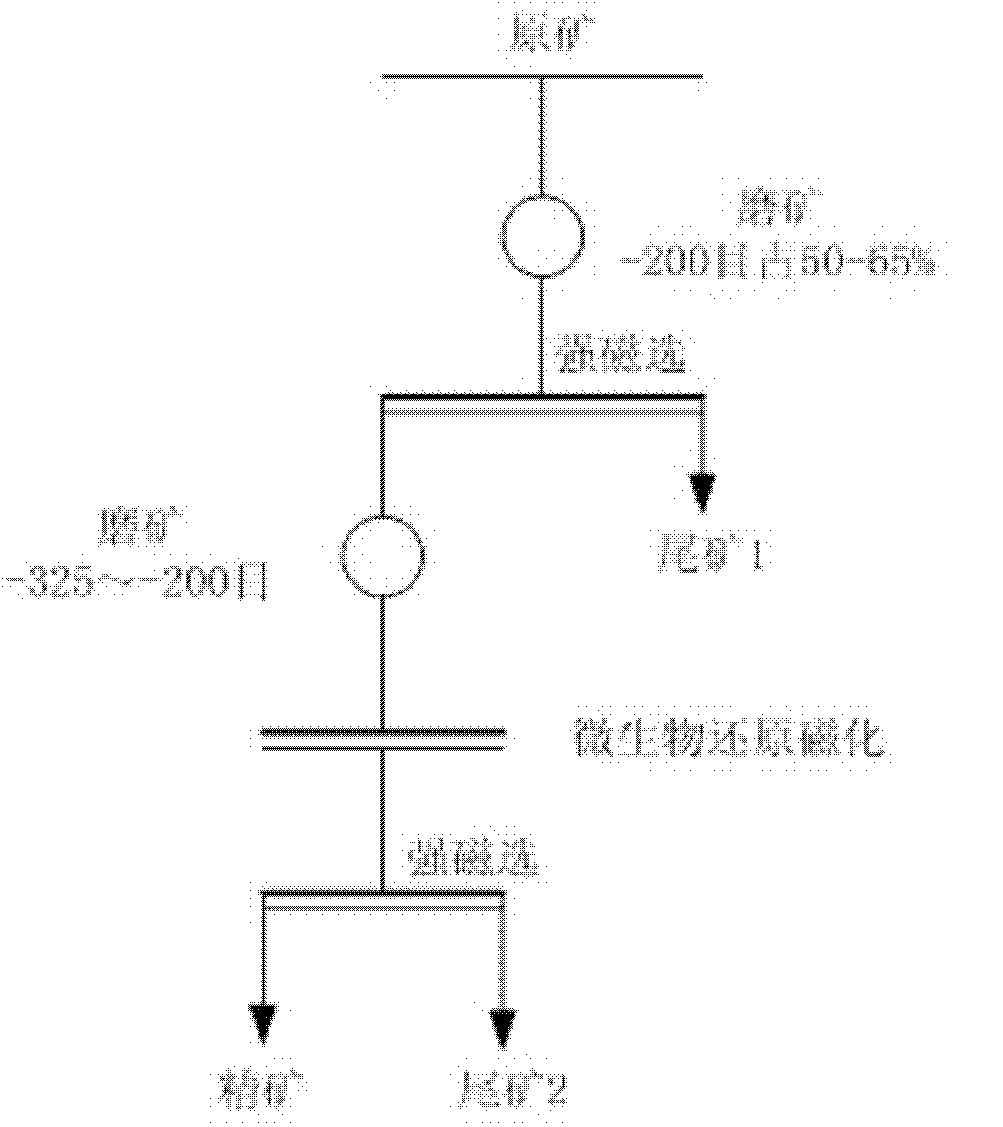

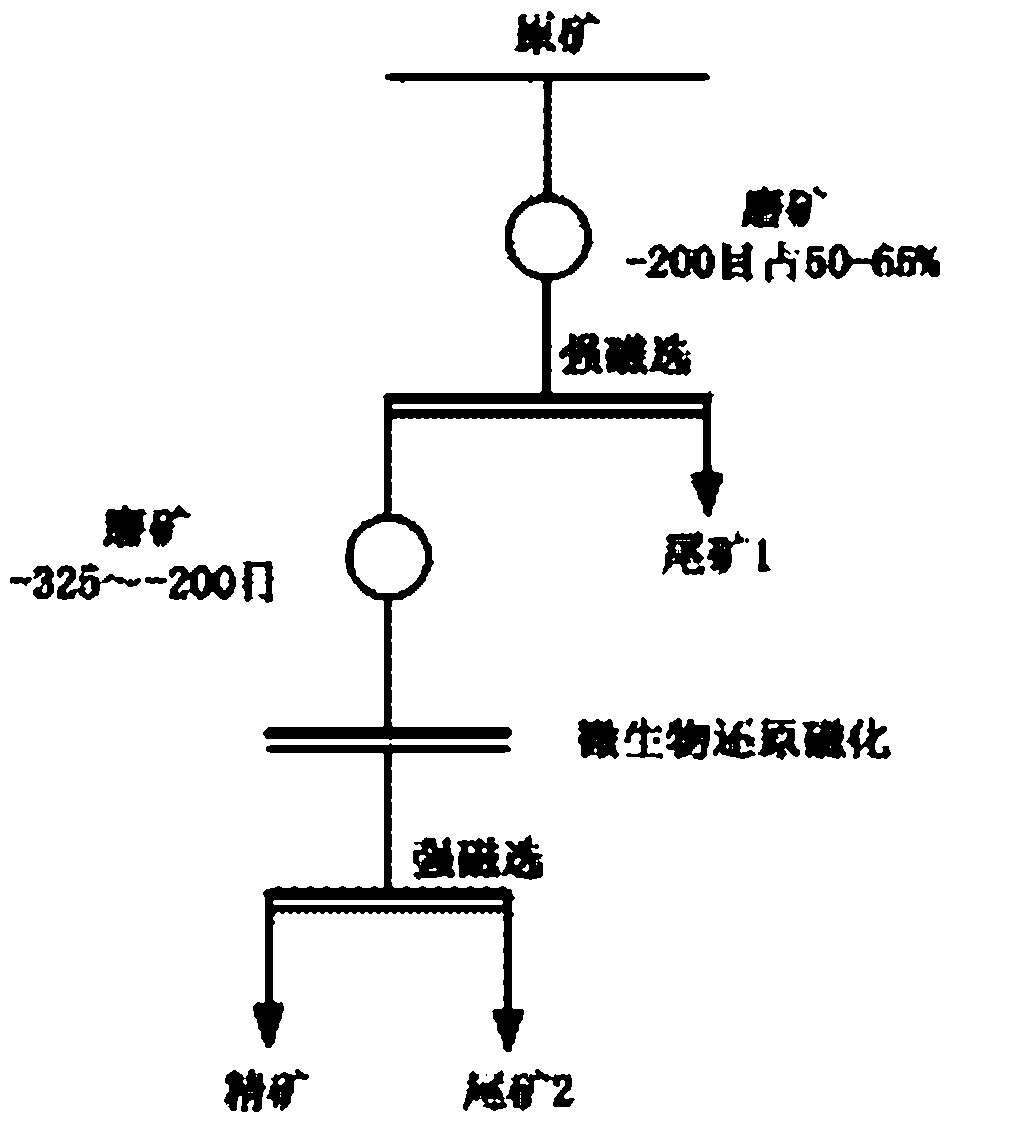

Method for raising grade of hematite by biologically reducing and magnetizing and dressing

The invention belongs to the field of dressing of black metals, and relates to a method for raising the grade of complex hematite which is difficult for dressing by reducing and magnetizing with microorganisms and dressing. A major process comprises ore grinding, forced magnetic dressing, reducing and magnetizing with microorganisms, and the like. The method is characterized by comprising the following steps of: feeding hematite of which the granularity is 0-4 millimeters into an ore mill for milling till hematite of -200 meshes accounts for 50-65 percent of all hematite; grading a ground ore sample with a high-gradient high intensity magnetic separator; feeding selected ore concentrate into the ore mill for milling to ore of less than -200 meshes; reducing and magnetizing with microorganisms by taking organic waste water as a culture medium; and selecting final ore concentration by performing high intensity magnetic separation, wherein the iron grade can be up to 55-70 percent, the recovery rate is over 70 percent, and the COD (Chemical Oxygen Demand) of the organic waste water is lowered remarkably. According to the method, complex hematite which is difficult for dressing can be fully recycled, and the product grade and the recovery rate are remarkably increased in comparison to those in the conventional high intensity magnetic separation process; and moreover, the energy consumption is low, and the method is environmentally-friendly.

Owner:UNIV OF SCI & TECH BEIJING

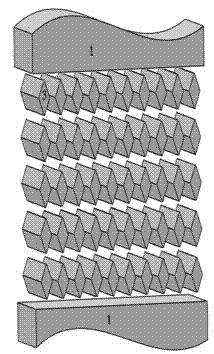

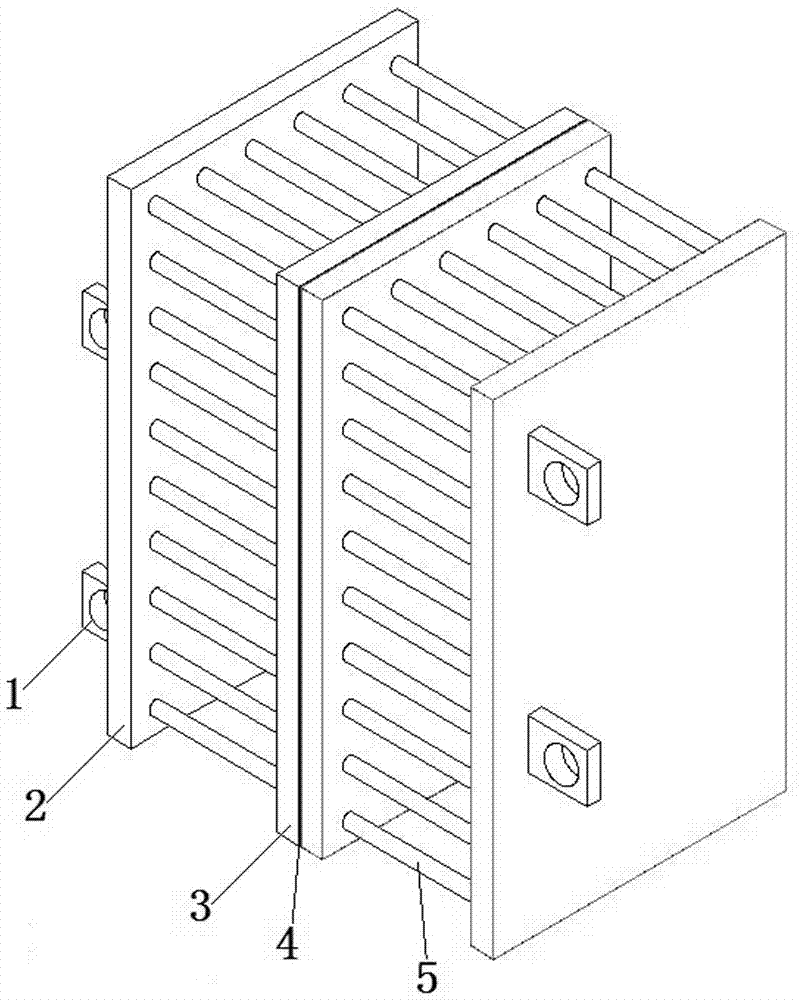

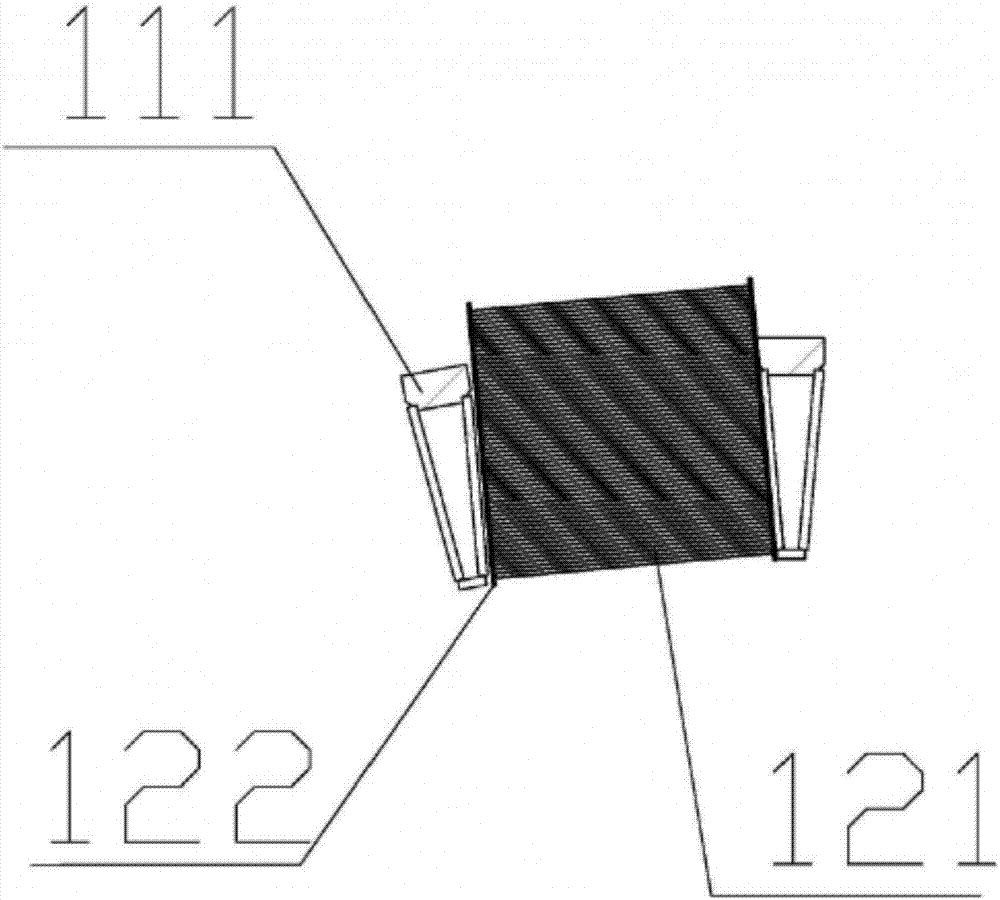

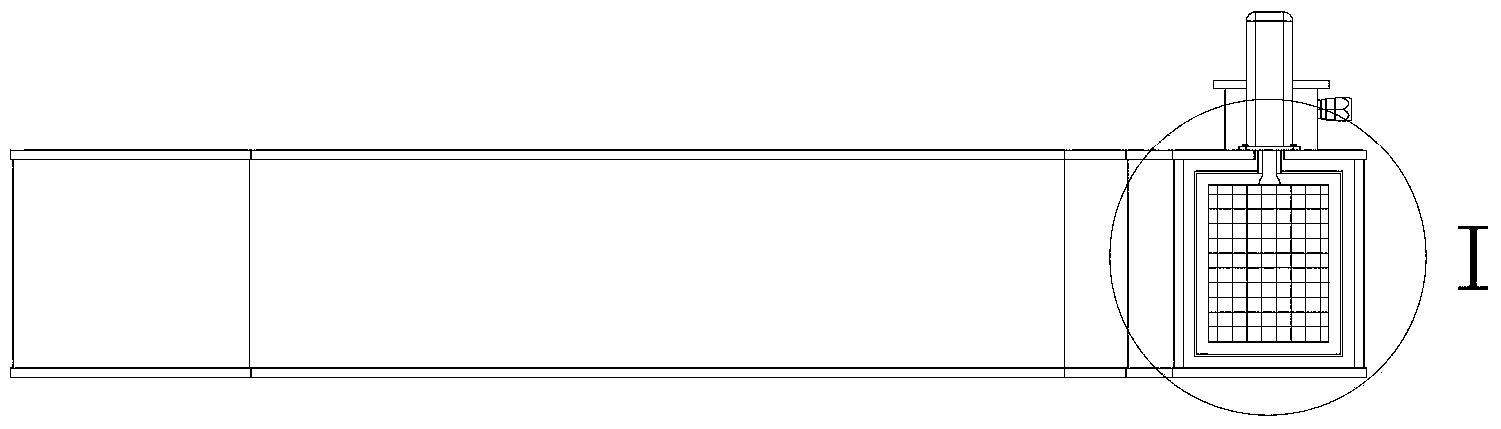

Manufacturing method of magnetic matrix box for vertical ring high-intensity magnetic separator

ActiveCN107225226ASimple processIncrease productivityHigh gradient magnetic separatorsEngineeringUltimate tensile strength

The invention discloses a manufacturing method of a magnetic matrix box for a vertical ring high-intensity magnetic separator. The magnetic matrix box comprises more than two matrix sub-boxes; each of the matrix sub-boxes comprises lifting lugs, panels with the lifting lugs, a panel without lifting lug and magnetic matrix filaments; and the manufacturing method is characterized in that thousands of the magnetic matrix filaments are fixed together with the panels with the lifting lugs and the panels without lifting lugs by adopting the casting method. According to the manufacturing method of the magnetic matrix box for the vertical ring high-intensity magnetic separator, the processing efficiency of the magnetic matrix box for the vertical ring high-intensity magnetic separator is improved, the labor intensity is reduced, the corrosion resistance of the panels is improved, and the service life of the high-intensity magnetic separator is prolonged.

Owner:嘉峪关天源新材料有限责任公司

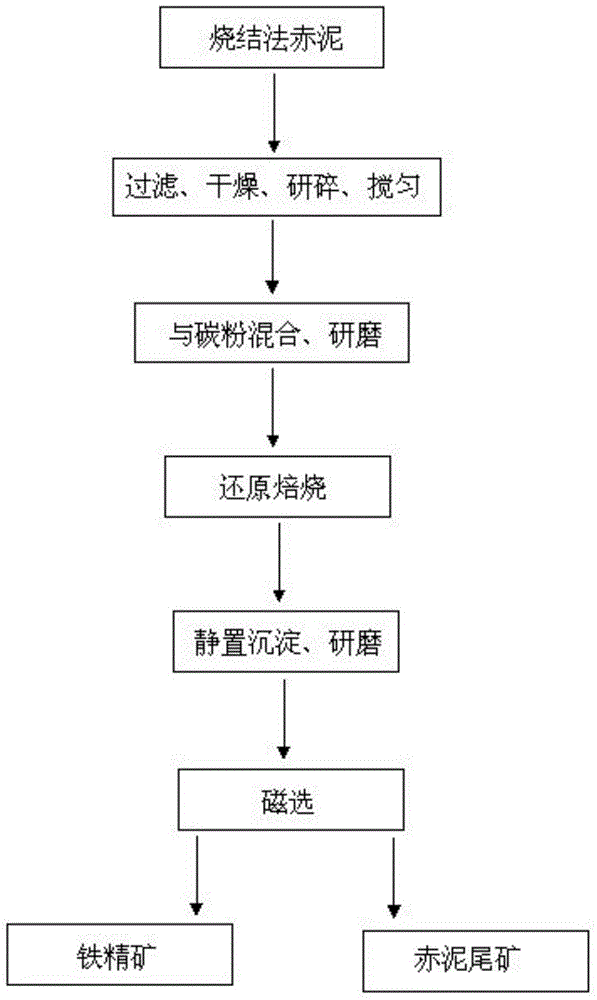

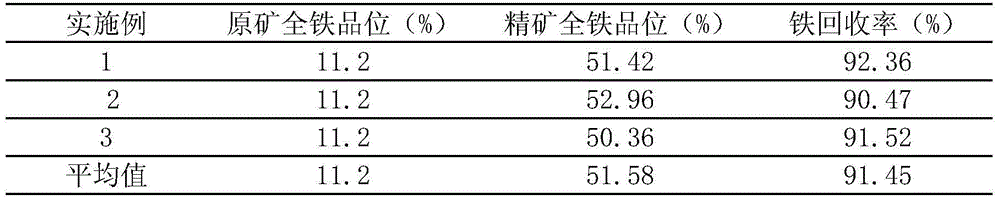

Treatment method for recovering iron from sintered red mud

The invention belongs to the technical field of comprehensive utilization of solid waste discharged during alumina production by sintering and particularly relates to a treatment method for recovering iron from sintered red mud. The treatment method comprises the concrete steps that firstly, the sintered red mud is filtered, dried, pulverized and stirred to be even, so that well mixed sintered red mud is obtained; afterwards, carbon powder and the well mixed sintered red mud are sequentially subjected to mixing, grinding, roasting, water quenching and static settlement, so that a deposit is obtained; finally, the deposit is ground, water is added to the deposit, ore pulp is obtained through preparation, and the ore pulp is separated through a high-intensity magnetic separator, so that iron ore concentrate and red mud tailings slag are obtained. The treatment method has the advantages that the technology process is simple, energy consumption is low, there is no special requirement for equipment, and industrialization is easy to implement, thereby having important significance for utilization of the solid waste and environmental protection.

Owner:CHANGAN UNIV

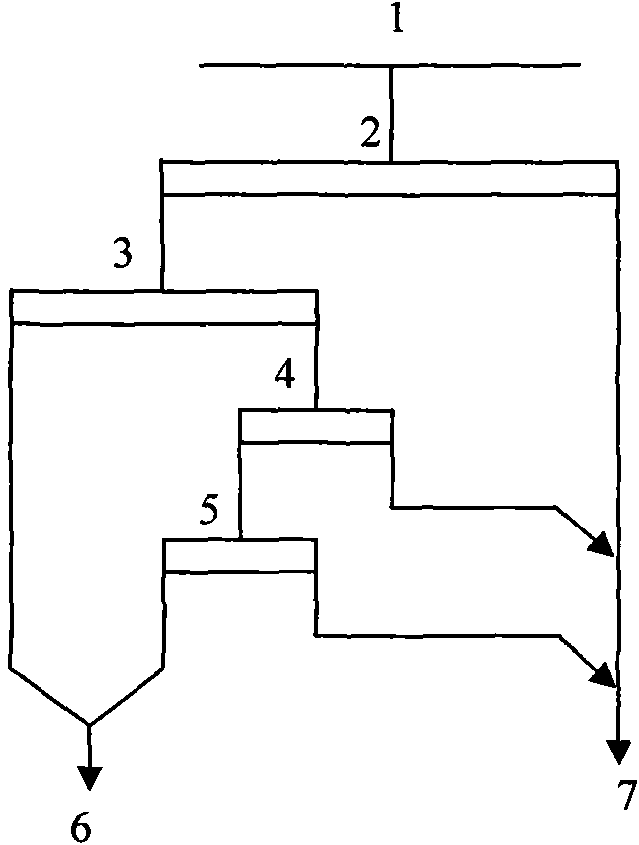

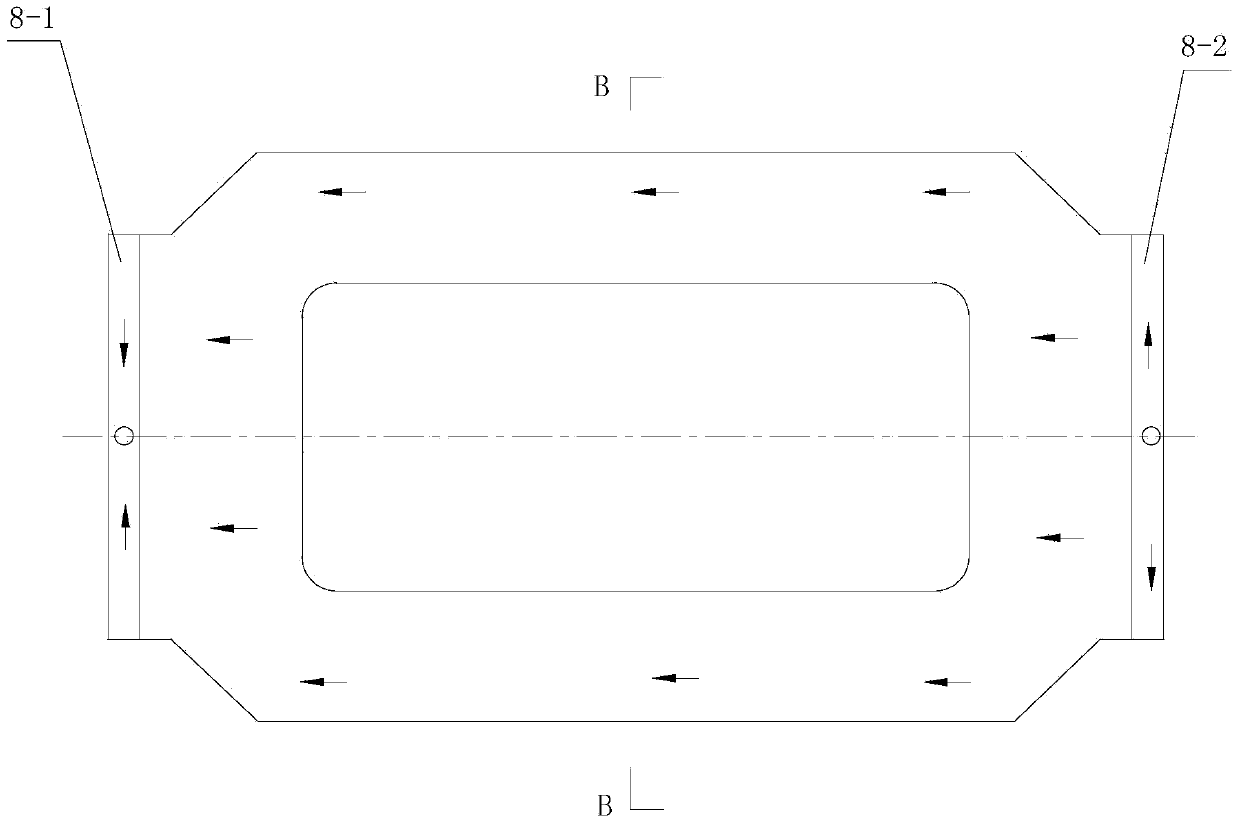

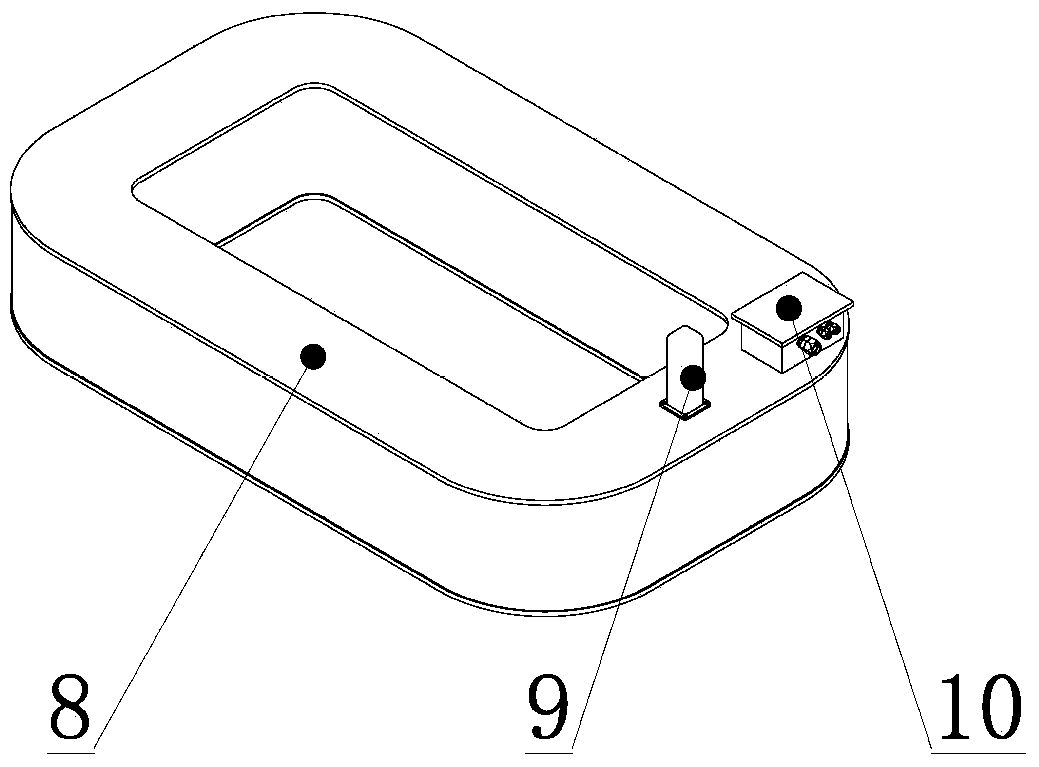

Vertical revolving ring induction type wet-process high-intensity magnetic separator coil

ActiveCN103433133AIncrease the number of turnsWon't blockMagnetic separationCoilsWater channelCoil structure

The invention discloses a vertical revolving ring induction type wet-process high-intensity magnetic separator coil which is of a multi-layer coil structure and comprises a water outlet (3), a wiring part (4), single disc coils (6), a water inlet (7), a first-end water distribution cavity (8-1), a second-end water distribution cavity (8-2), cooling water channels (11) and water channel retainer rings (12). The vertical revolving ring induction type wet-process high-intensity magnetic separator coil is characterized in that the multiple layers of single disc coils (6) are sequentially arranged from top to bottom along the outer edges and the inner edges of the single disc coils (6) and are welded together; each water channel retainer ring (12) is arranged between the corresponding two adjacent layers of single disc coils (6) to form a gap through which cooling water passes, and is welded on the outer edges and the inner edges of the corresponding two adjacent layers of single disc coils (6), each two adjacent layers of single disc coils (6) are connected to form one body, and the gaps, through which cooling water passes, are taken as the cooling water channels (11). The cooling mode with a large water channel section and a short water channel flow path of the magnet exciting coil can be used for solving the problem of poor heat dissipation of a conventional coil, and the coil can work at low temperature due to strong heat dissipation potential, so that a high-intensity magnetic separator can have a high magnetic field, and the economic benefit and the working efficiency are improved.

Owner:LONGI MAGNET CO LTD

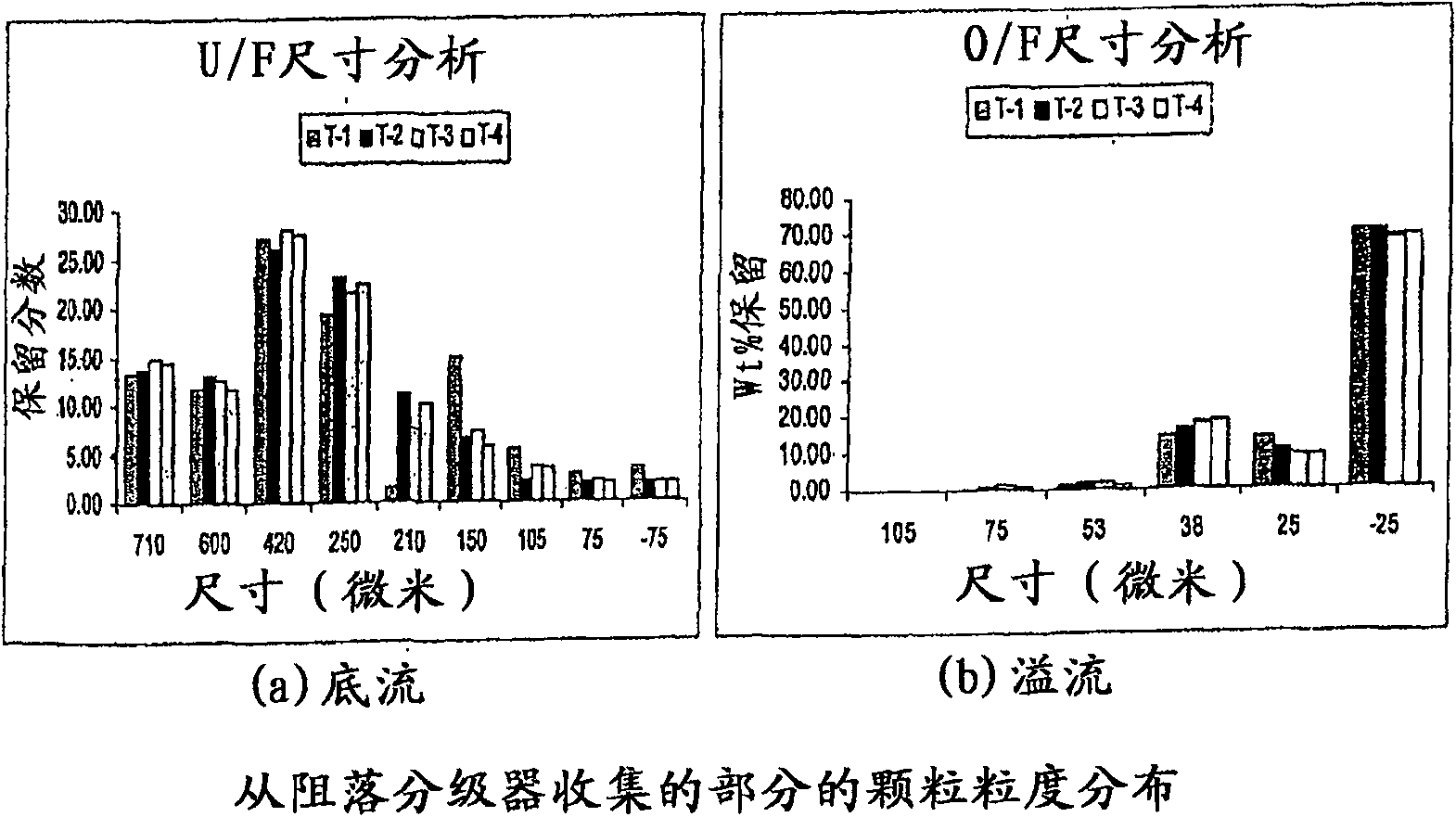

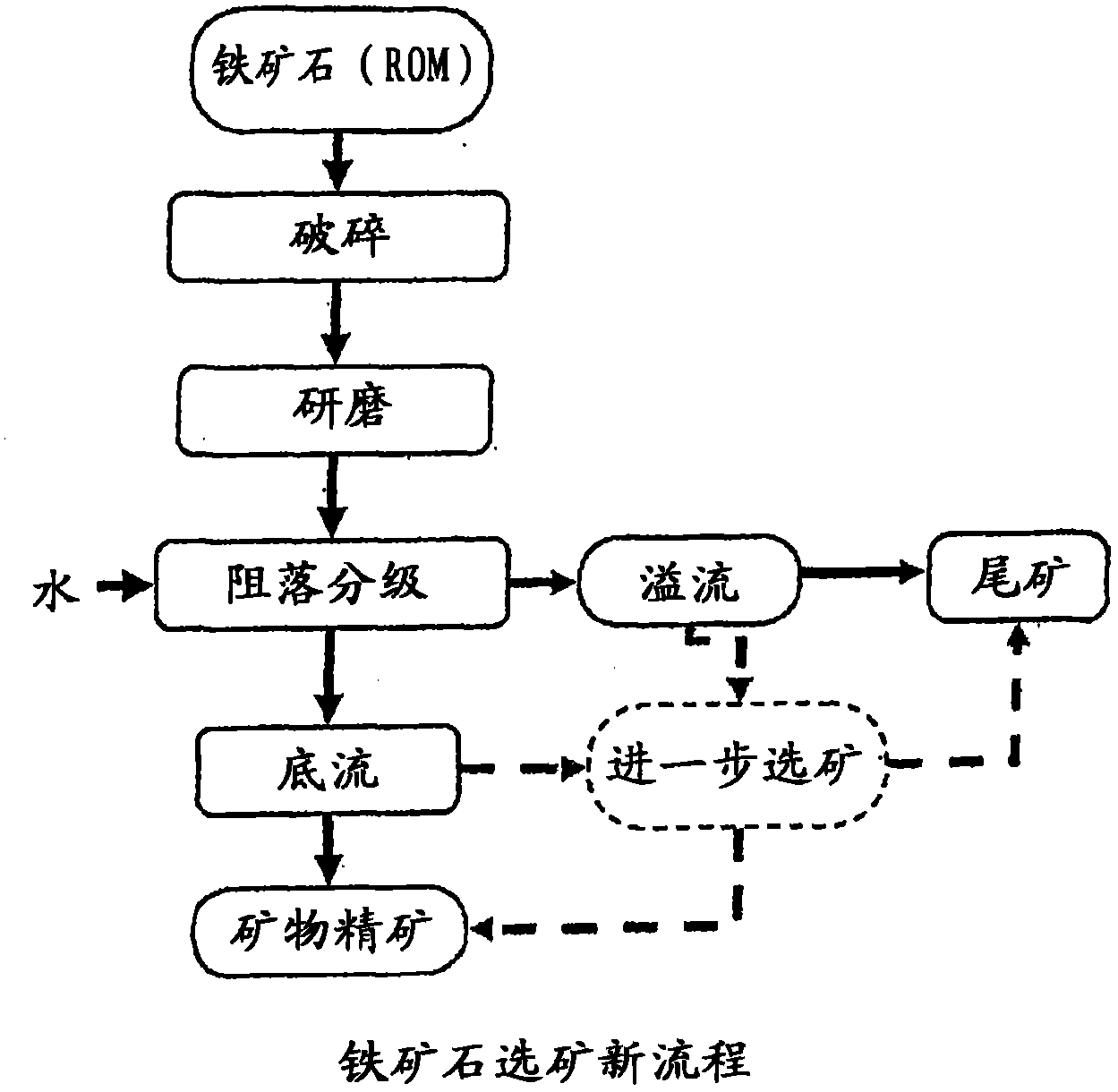

A novel method for production of iron ore concentrates suitable for iron and steel making processes

A method for production of iron ore concentrates comprising the steps of: crushing low grade ore, slimes and other deposits to produce iron ore particle of the size less than 1.5 mm; subjecting the said particles to the step of selective separation to isolate iron ore mineral from gangue minerals; and obtaining enriched ore with high iron content from (60% to 67%) using low intensity magnetic separator (LIMS) and high intensity magnetic separator (HIMS).

Owner:TATA STEEL

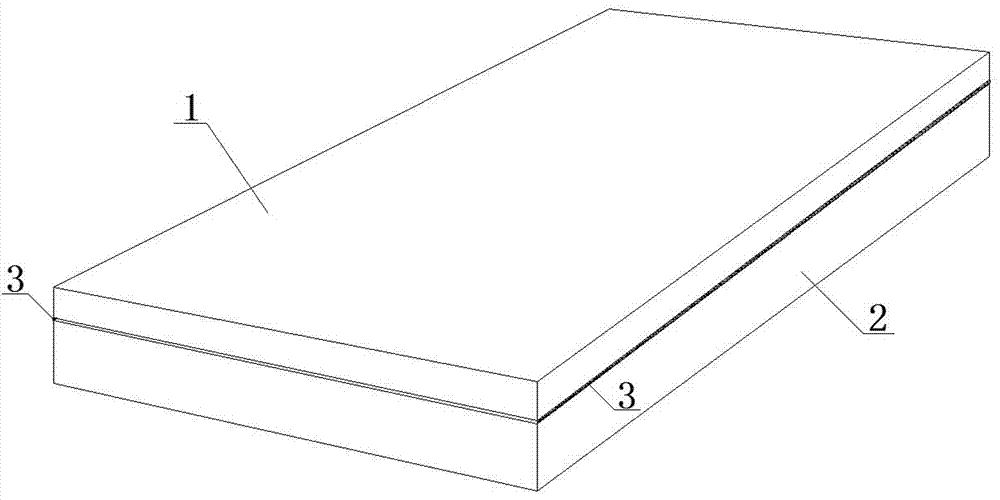

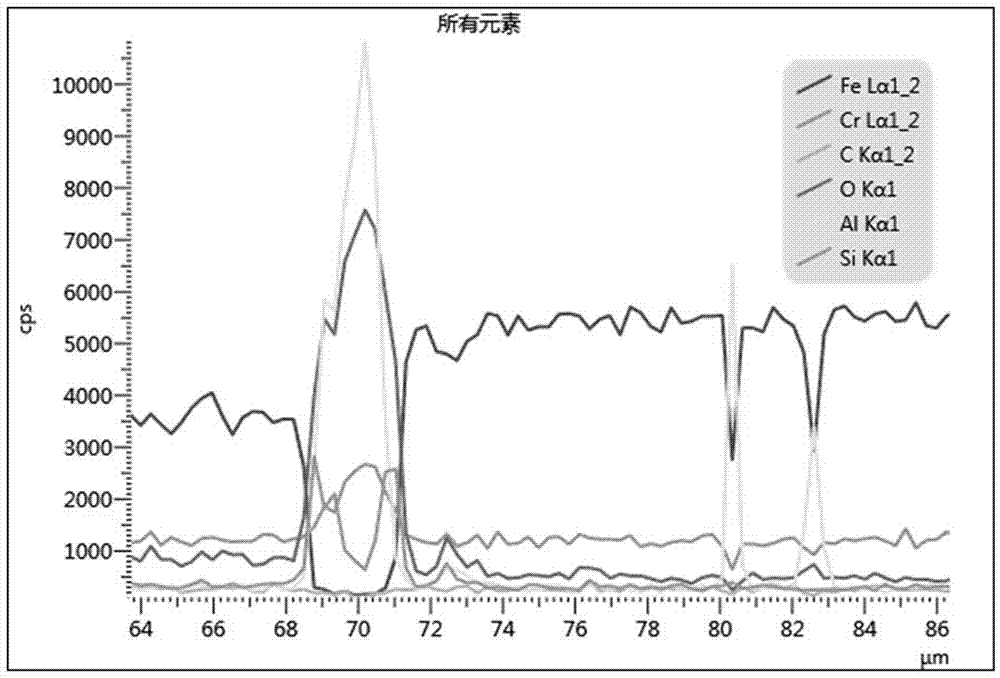

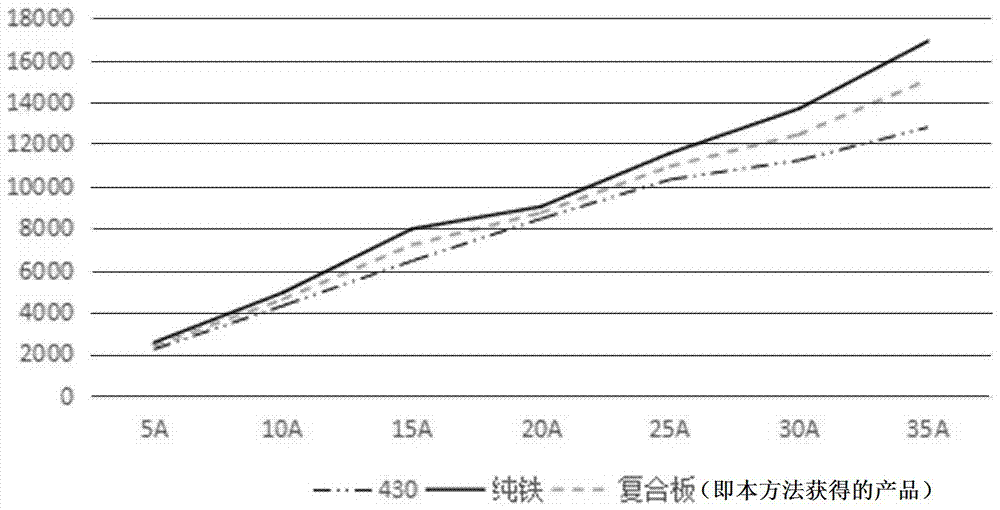

Preparing method of composite magnetism-gathering medium for horizontal ring type high-gradient high intensity magnetic separator

ActiveCN107186436AReduce manufacturing costRaise the magnetic field gradientMagnetic field gradientHigh intensity

The invention discloses a preparation method of a composite magnetism-gathering medium for a horizontal ring type high-gradient high intensity magnetic separator. The composite magnetism-gathering medium is formed by compounding ultra-pure ferritic stainless steel and industrial pure iron, wherein the composite material is subjected to surfacing degreasing, welding, rolling and cooling to prepare the high intensity magnetic separation magnetism-gathering medium. The tooth-shaped magnetism-gathering medium prepared by the composite material has the advantages of being low in preparing cost, high in magnetic field gradient, long in service life and the like, and is capable of increasing the metal recovery rate and reducing the discharging amount of the tailings in the high intensity magnetic separation process.

Owner:嘉峪关天源新材料有限责任公司

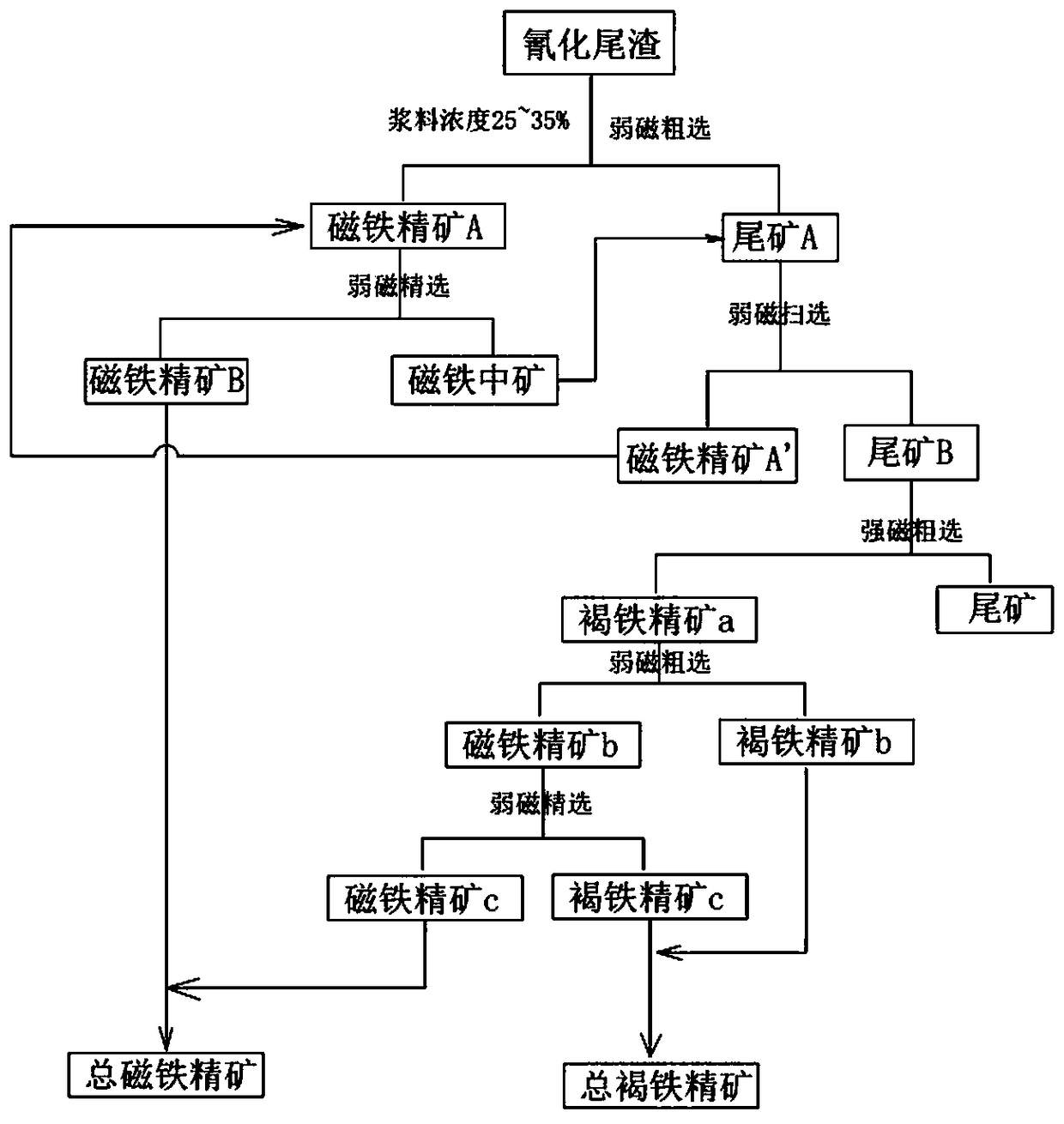

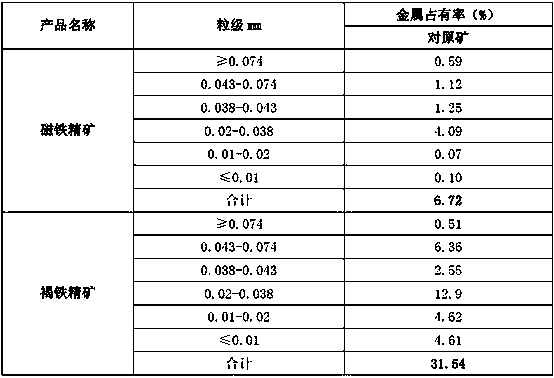

Method for recovering magnetite in brown iron ore concentrate

InactiveCN109201324AEasy to handleImprove recycling efficiencyHigh gradient magnetic separatorsMagnetiteUltimate tensile strength

The invention belongs to the technical field of magnetite recovery, and particularly relates to a method for recovering magnetite in a brown iron ore concentrate. After a magnetic separation operationcombination of a plurality of times of roughing and concentration, a semi-countercurrent low-intensity magnetic separator with the corresponding magnetic field intensity is used for roughing, a resulting magnetite concentrate is further selected by a wet-type semi-countercurrent drum magnetic separator with the corresponding magnetic field intensity, and the recovery efficiency is improved. In order to solve the problem that the magnetite recovery rate of the magnetic separation operation is low, firstly magnetic separation is performed by a high-intensity magnetic separator, and then low-intensity magnetic separation is performed to recover the magnetite in the brown iron ore concentrate to improve the recovery rate of the magnetite and increase the benefits of an enterprise.

Owner:鹤庆北衙矿业有限公司

Anti-corrosion magnetic medium box used for vertical ring high-intensity magnetic separator

ActiveCN103464279AReduce pollutionSimple structureHigh gradient magnetic separatorsElectricityGalvanic anode

The invention discloses an anti-corrosion magnetic medium box used for a vertical ring high-intensity magnetic separator. The anti-corrosion magnetic medium box comprises galvanic anodes (1), a magnetic medium box body (2) and an electroplated layer (3). According to the anti-corrosion magnetic medium box used for the vertical ring high-intensity magnetic separator, the magnetic medium box body is used as a framework, the galvanic anodes are embedded or welded to the anti-corrosion magnetic medium box body, the galvanic anodes are electrically communicated with the magnetic medium box body, and the electroplated layer (3) is electroplated on the surface of the magnetic medium box body (2). The anti-corrosion magnetic medium box is simple and clear in structure, reasonable in design and wide in application range. Compared with a medium box in the prior art, the anti-corrosion magnetic medium box has the advantages of being longer in service life, easy to operate and maintain, little in environment pollution and the like and is the ideal anti-corrosion magnetic medium box used for the vertical ring high-intensity magnetic separator at present.

Owner:LONGI MAGNET CO LTD

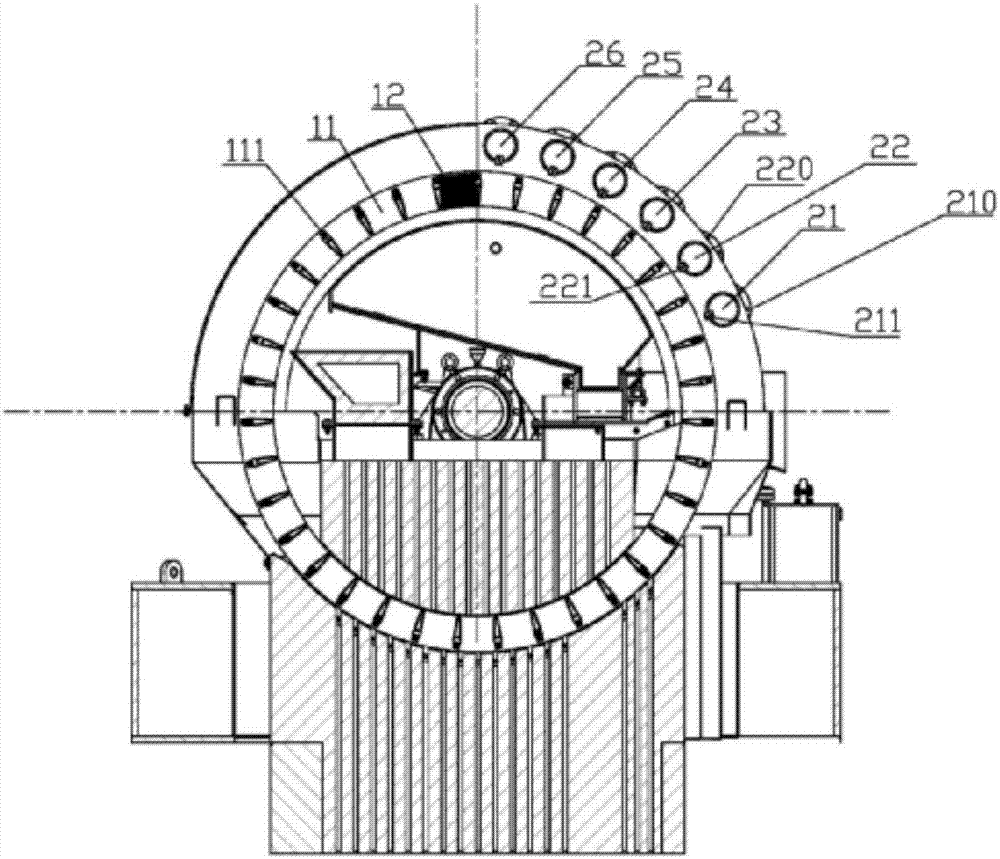

Vertical ring high intensity magnetic separator and method for improving ore discharge efficiency of vertical ring high intensity magnetic separator

PendingCN107470019ASpeed up circulationReduce dosageHigh gradient magnetic separatorsHigh concentrationEngineering

The invention discloses a vertical ring high intensity magnetic separator and a method for improving the ore discharge efficiency of the vertical ring high intensity magnetic separator. The method comprises the following step of sequentially arranging N (larger than or equal to 2) groups of air channels and water channels which are not connected with one another circumferentially in a region from the position above the medial axis horizontal line of a swivel to the perpendicular bisector of the diameter of the swivel. A material is repeatedly treated by N groups of a great quantity of high-pressure air and a small quantity of ore discharge water sequentially and alternately, so that the purpose of improving the ore discharge efficiency is realized. By adopting the vertical ring high intensity magnetic separator and the method, high-pressure air assistance is added for many times, and the dosage of the ore discharge water is lowered on the basis of increasing the ore discharge pressure and keeping the ore discharge effect unchanged, so that the concentration of high-concentration ores cannot be lowered, the working efficiency of subsequent ore dressing is improved, waste of water resources is also reduced, the ore discharge efficiency is effectively improved by 20 percent or above at the same time, the ore dressing handing capacity is promoted to be remarkably increased, and the service life of equipment is prolonged.

Owner:LONGI MAGNET CO LTD

Method for increasing recovery rate of complex refractory iron oxide ores

The invention discloses a method for increasing the recovery rate of complex refractory iron oxide ores. The method comprises the steps that firstly, the complex refractory iron oxide ores are pretreated, then selected slurry is prepared and subjected to rough concentration operation to obtain concentrate pulp and tailings pulp, the concentrate pulp is pumped into a concentrate concentration largewell, the tailings pulp is graded into a fine fraction part and a coarse fraction part, the fine fraction part and the coarse fraction part are sorted separately, the sorting process parameters are set individually, inclusions are reduced, and the recovery effect is good; a vertical ring high intensity magnetic separator with a special-shaped poly magnetic medium is used for primary scavenging operation of the fine fraction part after coarse and fine grading, and the recovery effect of the micro-size fraction is reinforced; and a horizontal ring high intensity magnetic separator is utilized to conduct secondary scavenging operation on the fine fraction part after coarse and fine grading, a selective flocculation process is conducted before secondary scavenging, and thus the interference of vertical ring pulse jig frequency on selective flocculation is avoided. According to the method, the metal recovery rate is effectively increased, the application range is wide, industrial production is easy to achieve, operability is high, and the effect of increasing the recovery rate of fine fraction mineral separation is remarkable.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

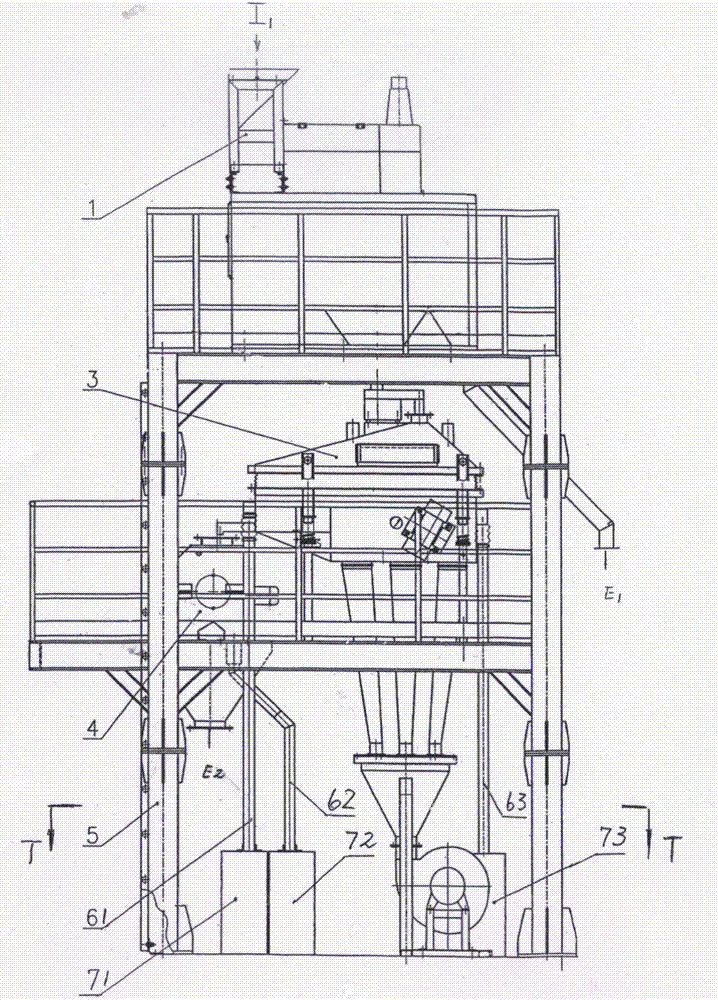

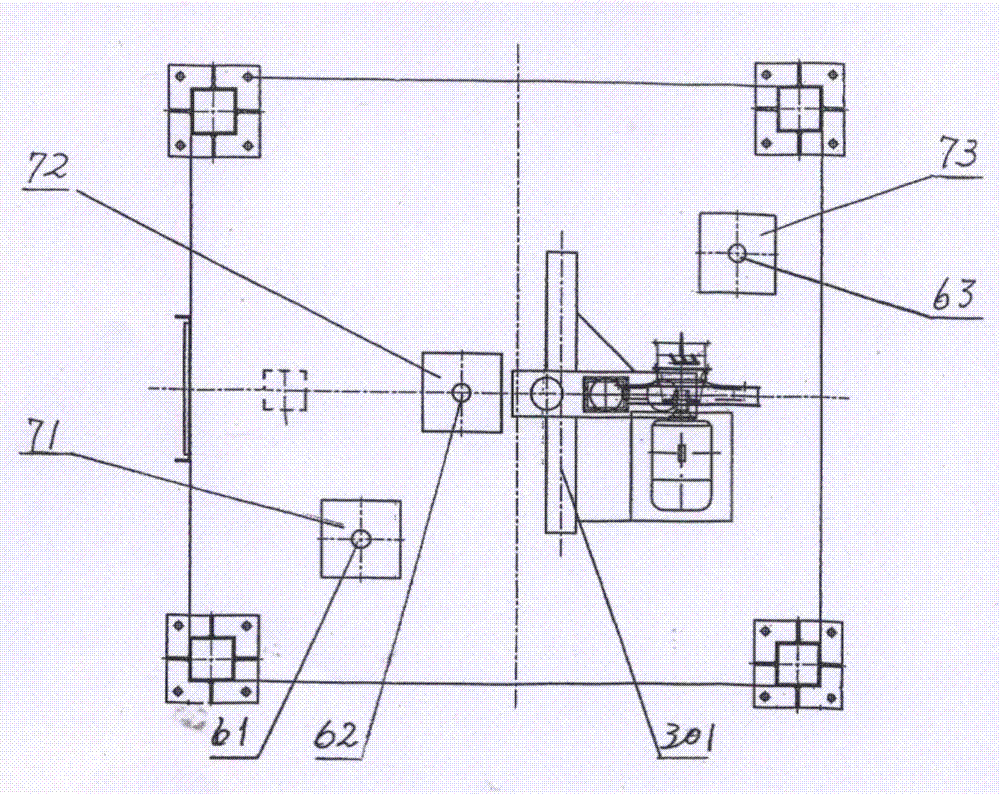

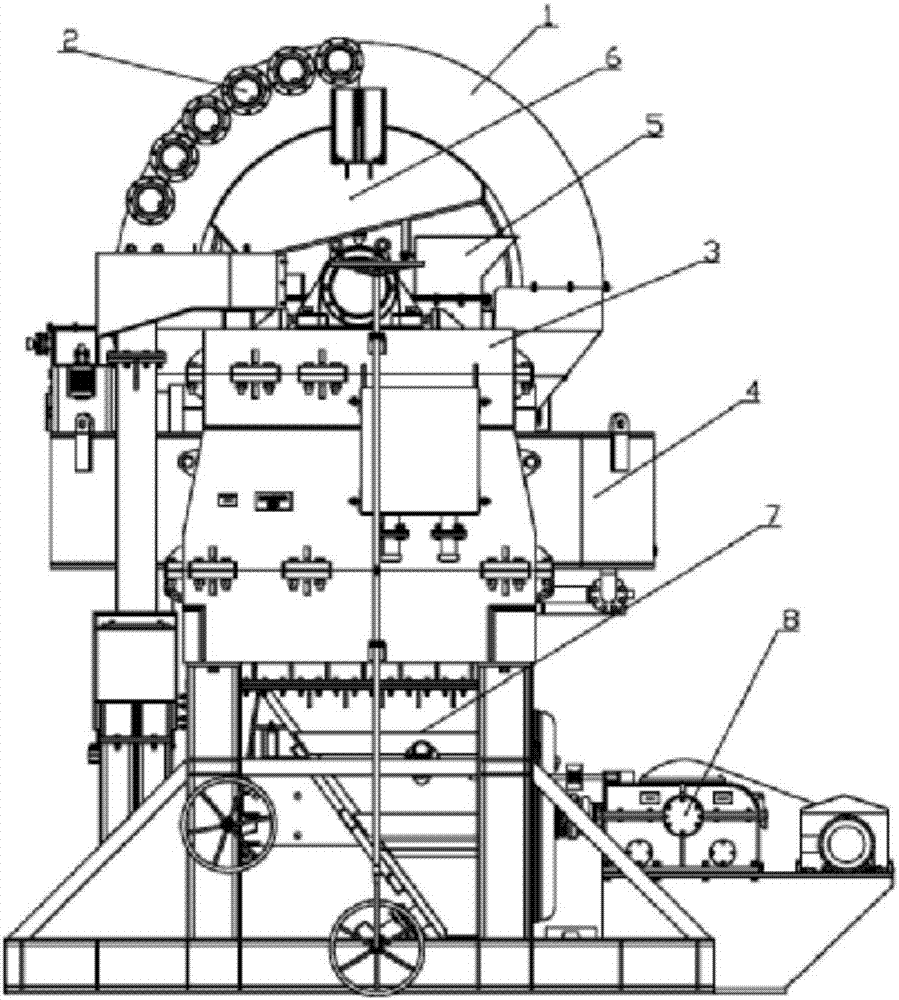

Vertical-loop high-intensity magnetic separator with superconductivity magnet exciting coil

ActiveCN103433134ASimple structureReasonable designHigh gradient magnetic separatorsSuperconducting magnets/coilsSuperconductivityEnergy consumption

The invention provides a vertical-loop high-intensity magnetic separator with a superconductivity magnet exciting coil. The vertical-loop high-intensity magnetic separator comprises seven parts, namely, the superconductivity magnet exciting coil (1), a high-intensity magnetic separator magnet yoke (2), an upper high-intensity magnetic separator hopper (3), a lower high-intensity magnetic separator hopper (4), a high-intensity magnetic separator hood (5), a high-intensity magnetic separator bracket (6), a high-intensity magnetic separator swivel, a swivel driving part (7), and the like. According to the vertical-loop high-intensity magnetic separator provided by the invention, as a superconductivity wire is used as a carrier of current in the whole excitation process, and the superconductivity wire is always in an environment with extremely low temperature and is in the superconductivity state constantly when working, excitation energy consumption of equipment is avoided in the while process, and the effect of reducing the energy consumption is achieved.

Owner:LONGI MAGNET CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com