Chromium ore recovering system

A recovery system, chromium ore technology, applied in the direction of magnetic separation, solid separation, filter and sieve, etc., can solve the problem of not being able to continue to use, and achieve the effect of saving foreign exchange, significant economic benefits, and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

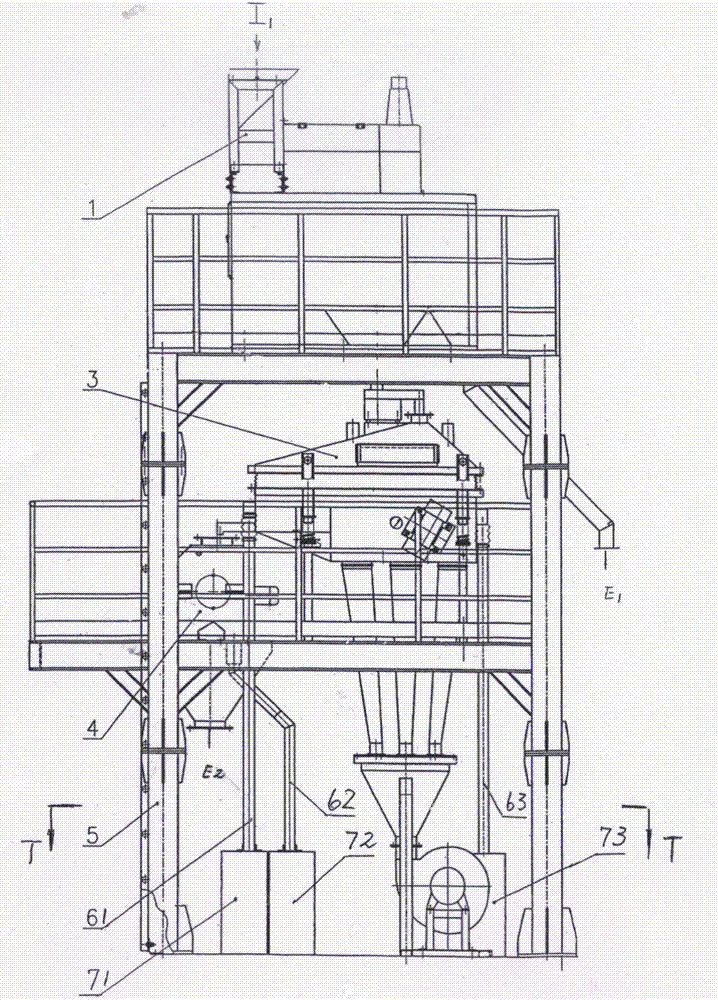

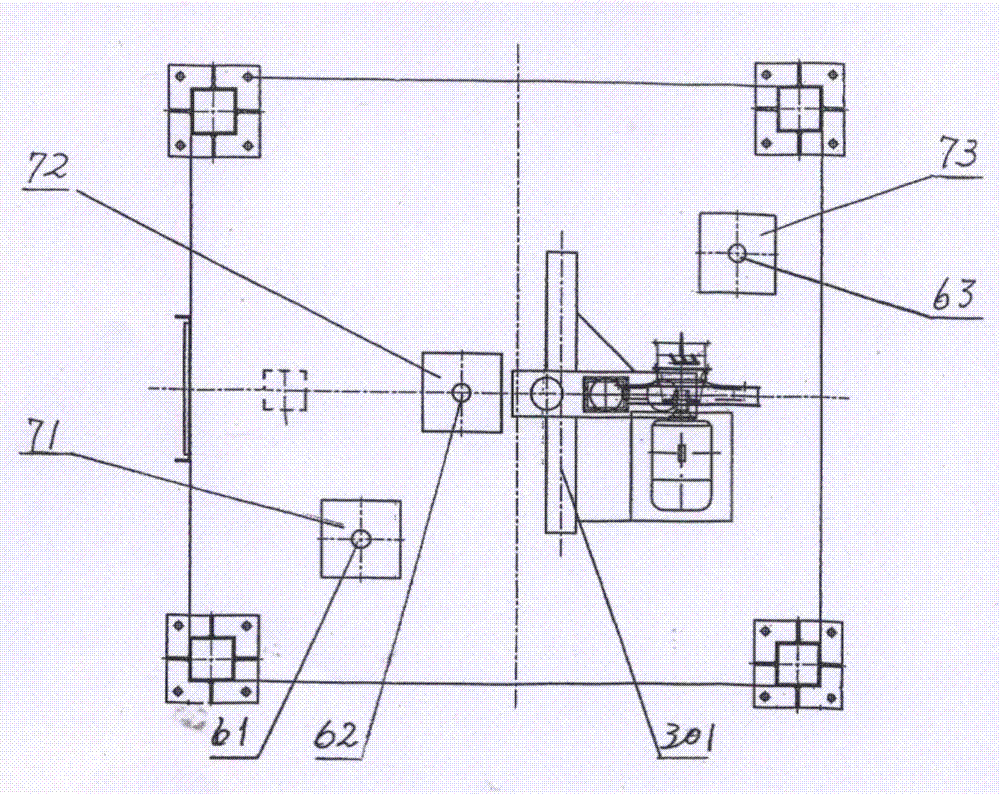

[0049] The present invention includes a main frame 5, on which a strong magnetic separator 1, a gravity separator 3, a vibrating screen 316, and an iron remover 4 are vertically installed in sequence in sequence. Composition of chrome ore recovery system.

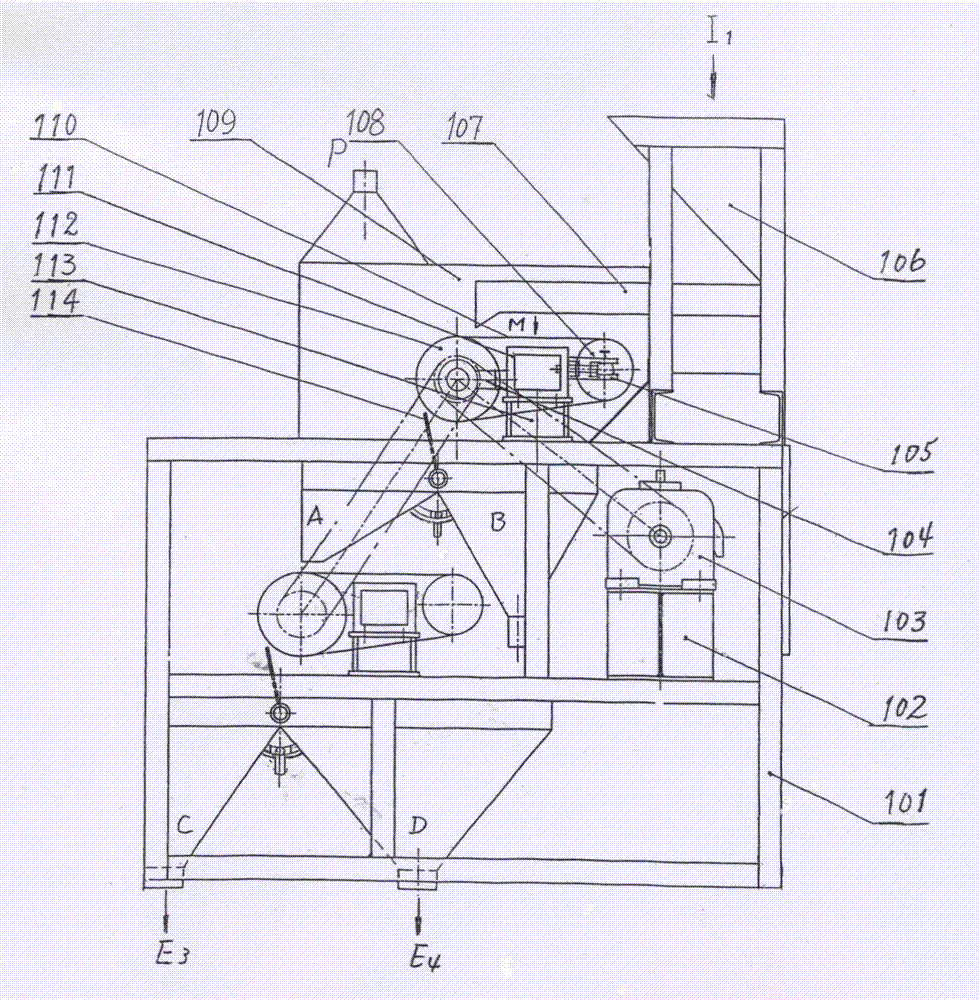

[0050] Strong magnetic separator:

[0051] This machine uses the weak magnetic properties of chrome ore to separate chrome ore and some magnetized particles and ferromagnetic particles from the mixed sand. Although the recovery rate of chrome ore after secondary magnetic separation is >90%, there are still Contains a large proportion of silica sand and magnetic impurities.

[0052] Strong magnetic separator 1 is made up of frame one 101, vibrating conveyor 107, magnetic roller 112, reversing roller 108, beam 111, conveyer belt 110, material distribution plate 114, frequency conversion speed regulating motor 103 and transmission mechanism, in order To improve the recovery rate, two-stage magnetic separation is adopted.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com