Wet type permanent magnet vertical ring-adjusted high-gradient high-intensity magnetic separator

A strong magnetic separation and permanent magnet technology, applied in the direction of high-gradient magnetic separators, can solve the problems of small magnetic field strength, small magnetic field gradient, single non-adjustable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

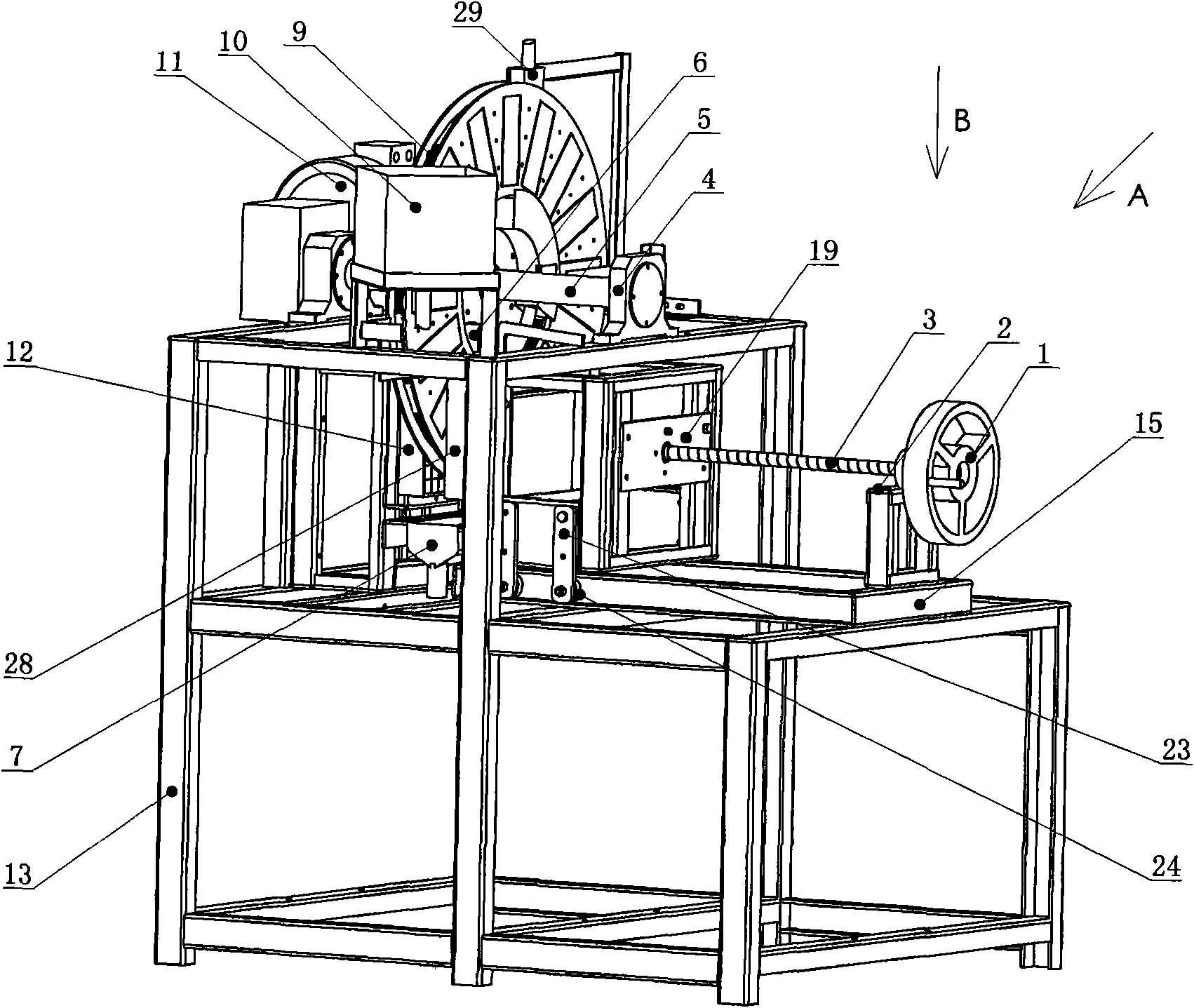

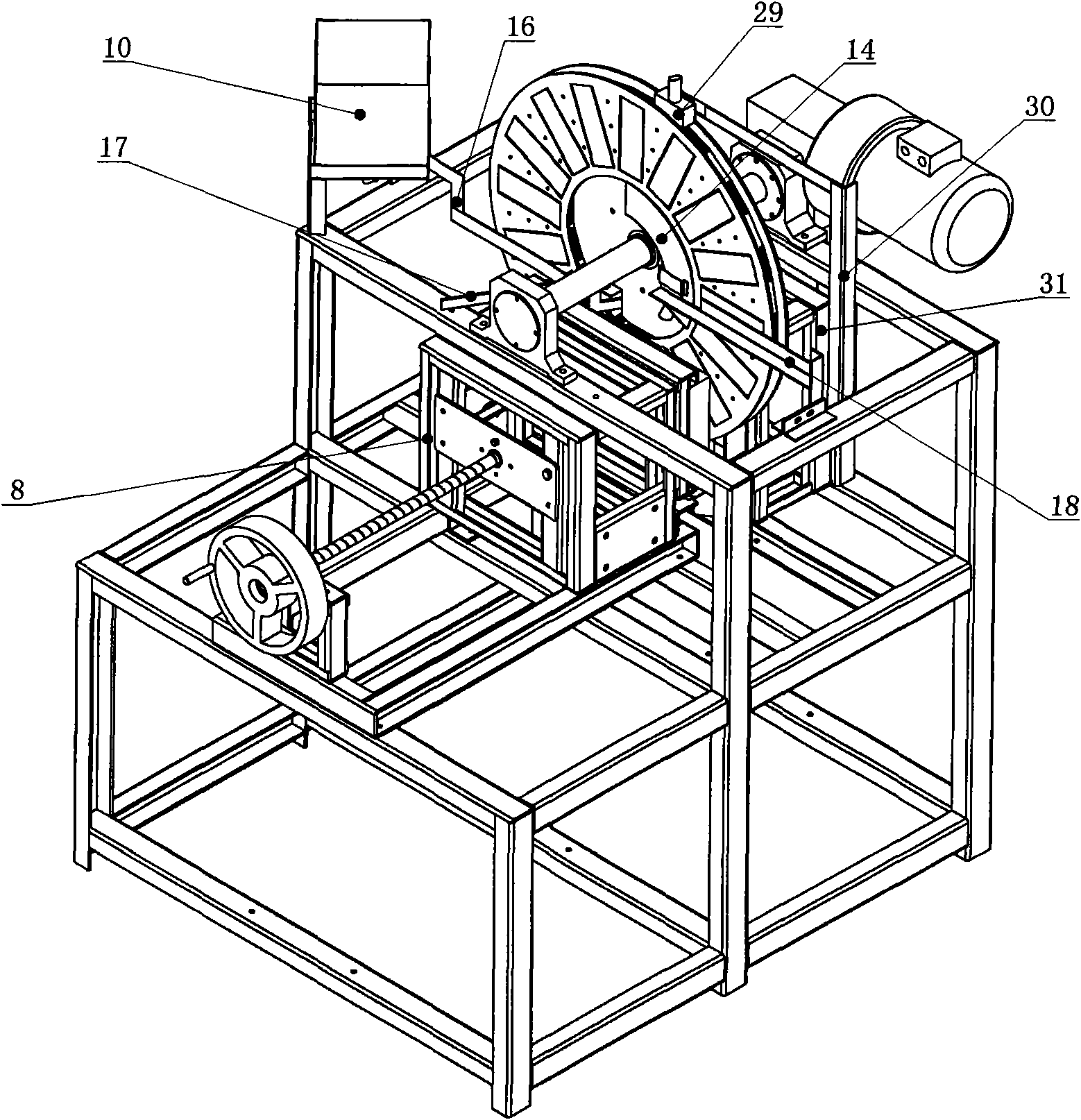

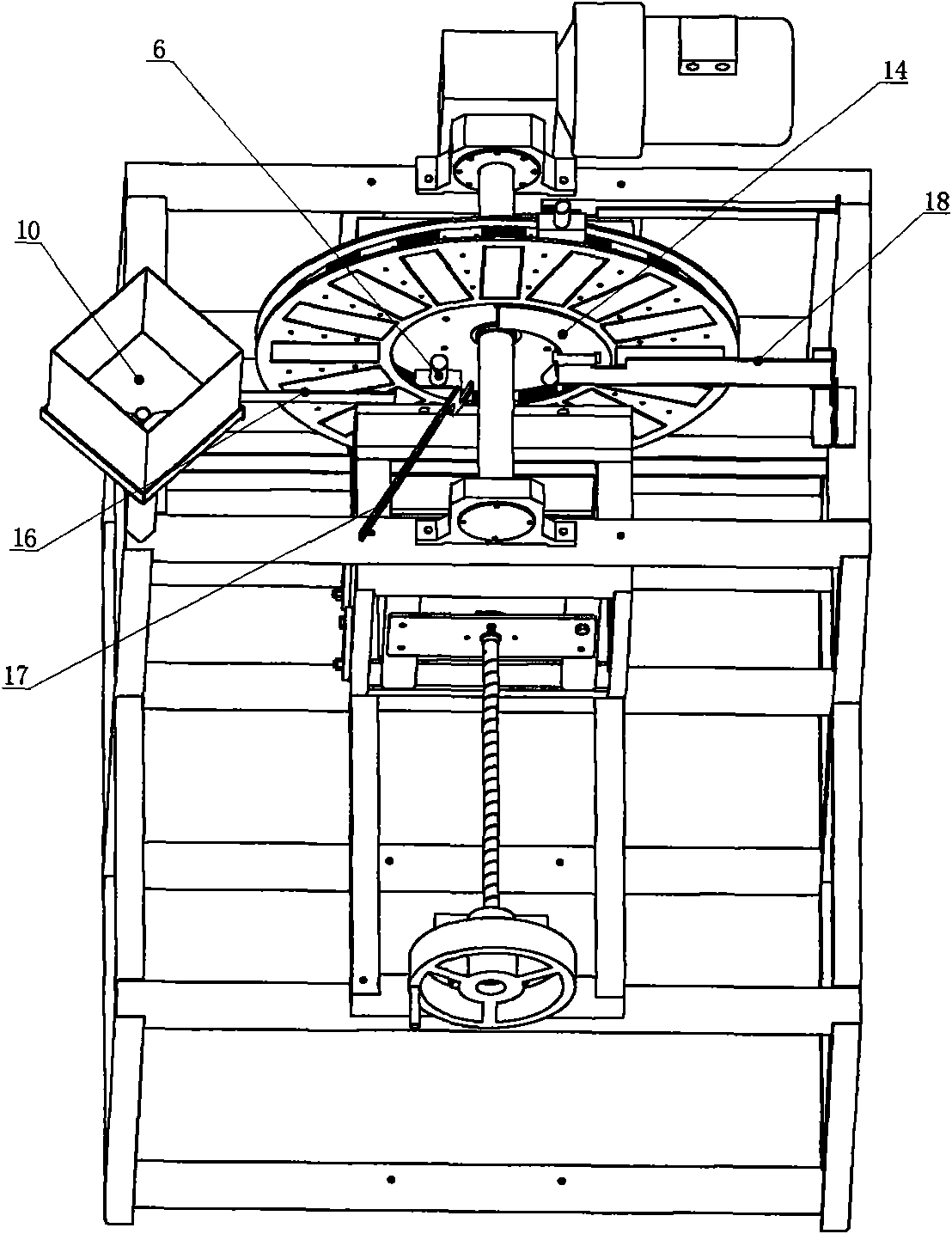

[0021] Such as figure 1 , figure 2 and image 3 As shown, the present invention comprises frame 13, and transmission device 11 and bearing chamber 4 are arranged on frame 13, and main shaft 5 is arranged on transmission device 11, and main shaft 5 is contained on the bearing 4, and the branch assembly of vertical assembly is arranged on described main shaft 5. Select ring 9. Magnetic system I 12 and magnetic system II 28 are arranged on both sides of the sorting ring 9, magnetic system I 12 is arranged on the magnetic system frame I 31, and magnetic system frame I 31 is arranged on the frame 13. The magnetic system II 28 is arranged on the magnetic system frame II 8, the connecting piece 23 is arranged on the magnetic system frame II 8, the lower end of the connecting piece 23 is provided with a pulley 24, the pulley 24 is arranged in the groove of the side wall of the slide rail 15, and the slide rail 15 is arranged on the Rack 13. The handle support 2 is set on the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com