Treatment method for recovering iron from sintered red mud

A treatment method and technology of sintering method are applied in the treatment field of iron recovery from red mud by sintering method, which can solve the problems of high consumption of chemical reagents such as acid and alkali, high requirements on equipment quality, easy corrosion and damage of equipment by chemical reagents, etc. Recovery rate and concentrate grade, simple preparation process, improved ferromagnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

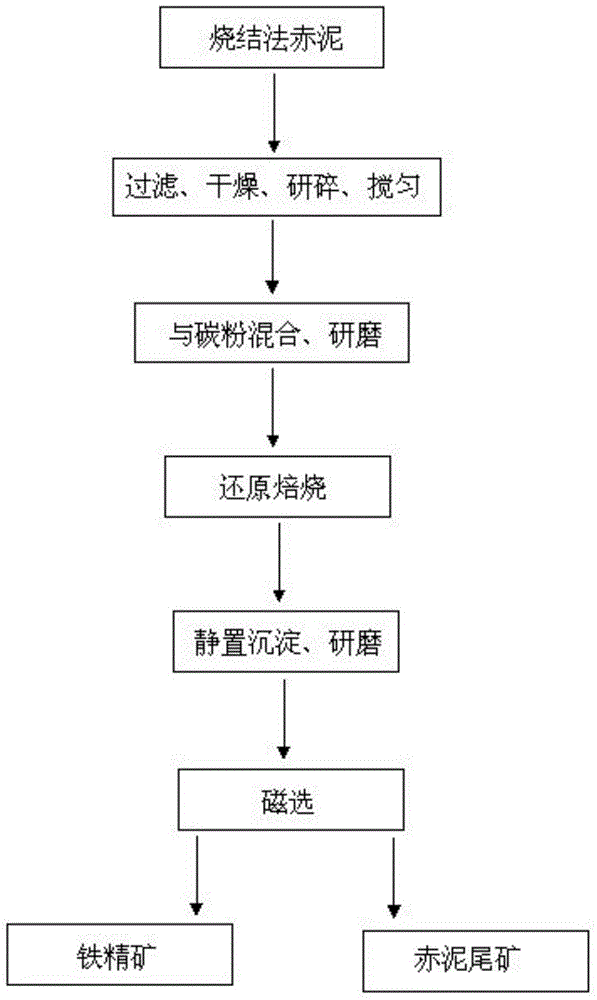

Method used

Image

Examples

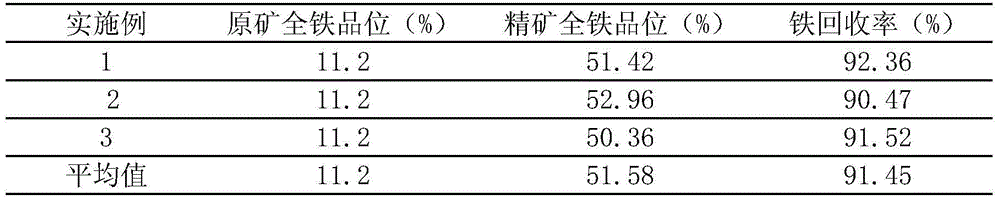

Embodiment 1

[0028] The processing method of reclaiming iron in a kind of sintering method red mud of the present invention, its specific steps are as follows:

[0029] (1) Filtrate the sintering method red mud with a total iron grade of 21.8%, heat and dry in a drying oven, then grind, mix, and divide by quartering method, and sample 50 g of sintering method red mud sample;

[0030] (2) Mix the carbon powder and the sintered red mud sample according to the mass ratio of 1:0.5 to obtain the mixed material, and then grind the mixed material to an average particle size of less than 0.074mm, and the mixed material with a particle size of less than 0.074mm accounts for 80- 100%;

[0031] (3) Roast the mixed material at 600°C for 20 minutes without air isolation. After the roasting is completed, put the roasted mixed material into cold water for quenching at a high temperature of 600°C to obtain a cooled red mud sample ;

[0032] (4) Let the cooled red mud sample stand for precipitation to ob...

Embodiment 2

[0035] The processing method of reclaiming iron in a kind of sintering method red mud of the present invention, its specific steps are as follows:

[0036] (1) Filtrate the sintering method red mud with a total iron grade of 21.8%, heat and dry in a drying oven, then grind and mix, divide by quartering, and sample 70 g of the sintering method red mud sample;

[0037] (2) Mix the carbon powder and the sintered red mud sample according to the mass ratio of 1:1 to obtain the mixed material, and then grind the mixed material to an average particle size of less than 0.074mm, and the mixed material with a particle size of less than 0.074mm accounts for 80- 100%;

[0038] (3) Roast the mixed material at 800°C for 30 minutes without air isolation. After the roasting is completed, put the roasted mixed material into cold water for quenching at a high temperature of 800°C to obtain a cooled red mud sample ;

[0039] (4) Let the cooled red mud sample stand for precipitation to obtain a...

Embodiment 3

[0042] The processing method of reclaiming iron in a kind of sintering method red mud of the present invention, its specific steps are as follows:

[0043] (1) Filtrate the sintering method red mud with a total iron grade of 21.8%, heat and dry in a drying oven, then grind, mix, and divide by quartering method, and sample 90 g of sintering method red mud sample;

[0044] (2) Mix the carbon powder and the sintered red mud sample according to the mass ratio of 1:1 to obtain the mixed material, and then grind the mixed material to an average particle size of less than 0.074mm, and the mixed material with a particle size of less than 0.074mm accounts for 80- 100%;

[0045] (3) Roast the mixed material at a temperature of 1000 °C and isolate the air for 40 minutes. After the roasting is completed, under the high temperature condition of 1000 °C, quickly put the roasted mixed material into cold water for quenching to obtain cooled red mud sample;

[0046] (4) Let the cooled red mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com