Novel room-temperature multi-ferroic ceramic with high polarization intensity and preparation method of novel room-temperature multi-ferroic ceramic

A technology of multiferroic ceramics and polarization strength, applied in the field of functional ceramics, can solve the problems that cannot be improved at the same time, limit the application of BFO-based multiferroic materials, etc., and achieve the effects of easy industrial production, easy parameter control, and reduced system loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Composition of multiferroic ceramics:

[0048] 0.75BiFeO 3 -0.25Ba 0.85 Ca 0.15 Ti 0.90 Zr 0.10 o 3 +0.5wt%MnCO 3

[0049] (1) Calculate the composition Bi in the powder raw material according to the composition of the above chemical formula 2 o 3 、BaCO 3 、TiO 2 , ZrO 2 , CaCO 3 , MnCO 3 , Fe 2 o 3 The quality and according to composition ratio preparation, mixed with wet ball milling method, briquette after drying, obtain ceramic powder after calcining, mix 24 hours according to the mass ratio of raw material: ball: alcohol=1:2:1, make each component well mixed. After drying, pass through a 40-mesh sieve, briquette, heat up to 800°C at a heating rate lower than 5°C / min in an air atmosphere, and keep warm for 5 hours to synthesize ceramic powder.

[0050] (2) Grinding the ceramic powder obtained in step (1) and passing through a 40-mesh sieve. Then according to the mass ratio of raw material: ball: alcohol=1:2:0.8, finely grind for 24 hours, and dry th...

Embodiment 2

[0056] Composition of multiferroic ceramics:

[0057] 0.75 (0.98BiFeO 3 -0.02BiGaO 3 )-0.25Ba 0.85 Ca 0.15 Ti 0.90 Zr 0.10 o 3 +0.5wt%MnCO 3

[0058] Repeat the preparation method of Example 1 by the above-mentioned formula.

[0059] (1) Measure the electric hysteresis loop, magnetic hysteresis loop and piezoelectric performance of the ceramic element in this embodiment at room temperature, and the test results are shown in Table 1.

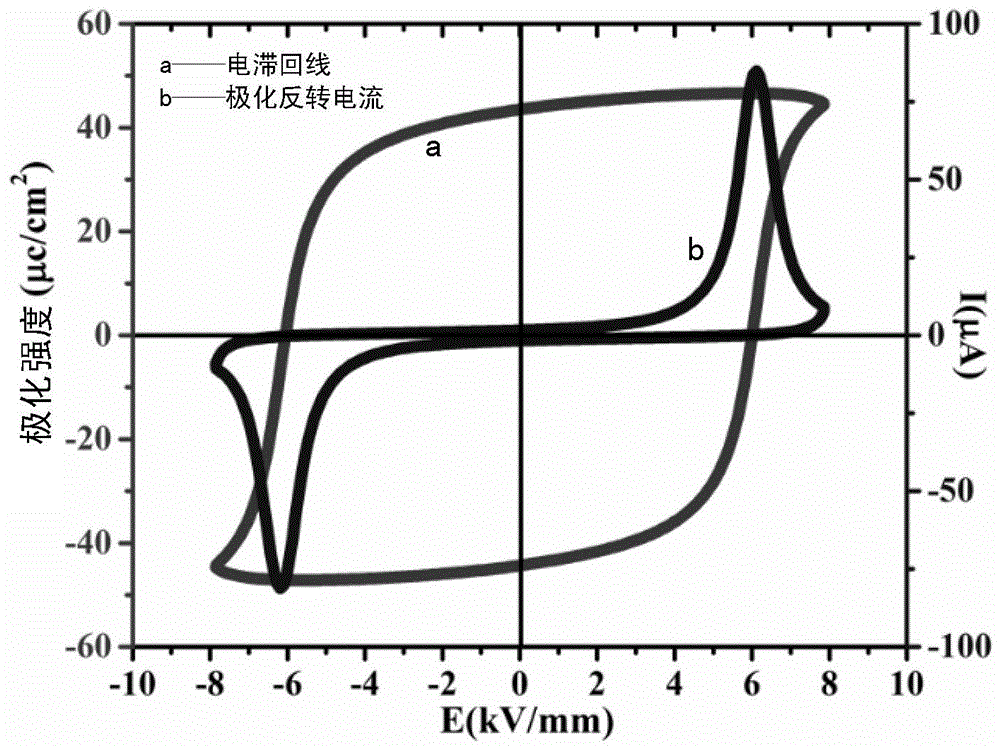

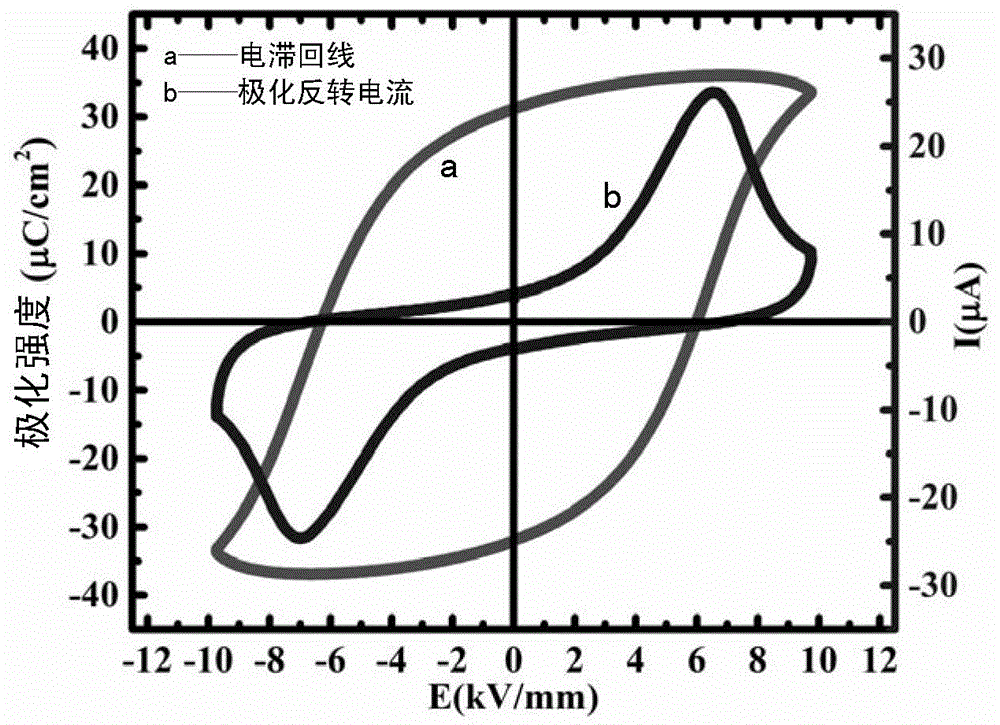

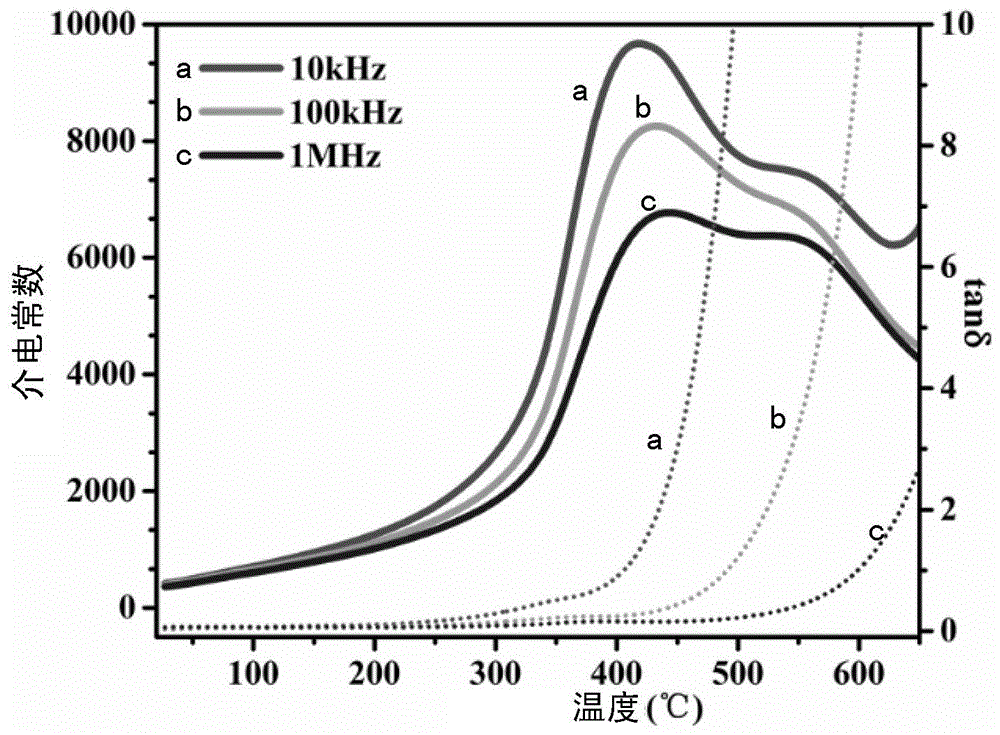

[0060] (2) The measurement of the hysteresis loop under room temperature is carried out to the ceramic element of the present embodiment, test result sees figure 1 , the remnant polarization reaches 43.86μC / cm 2 , an obvious polarization current reversal peak can be observed, indicating that there are a large number of electric domain reversals in the system under electric field loading, and after polarization treatment d 33 It is 90pC / N, indicating that the ceramic element has excellent ferroelectricity; figure 2 In order to measure...

Embodiment 3

[0062] Composition of multiferroic ceramics:

[0063] 0.75 (0.75BiFeO 3 -0.04BiGaO 3 )-0.25Ba 0.85 Ca 0.15 Ti 0.90 Zr 0.10 o 3 +0.5wt%MnCO 3

[0064] Repeat the preparation method of Example 1 by the above-mentioned formula.

[0065] (1) Measure the electric hysteresis loop, magnetic hysteresis loop and piezoelectric performance of the ceramic element in this embodiment at room temperature, and the test results are shown in Table 1.

[0066] The main test results of Examples 1, 2, and 3 are respectively listed in the following table 1. In the table, Pr is the remanent polarization, Ms is the saturation magnetization, Mr is the remanent magnetization, and Ec is the magnetic coercive field;

[0067]Table 1 Test conditions (100mHz) and remanent polarization Pr properties of ceramic materials at room temperature

[0068]

[0069] It can be seen from Table 1 that by introducing BiGaO into the BFO-BCZT system 3 , can greatly improve the multiferroic properties of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com