Patents

Literature

61results about How to "Improve multiferroic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

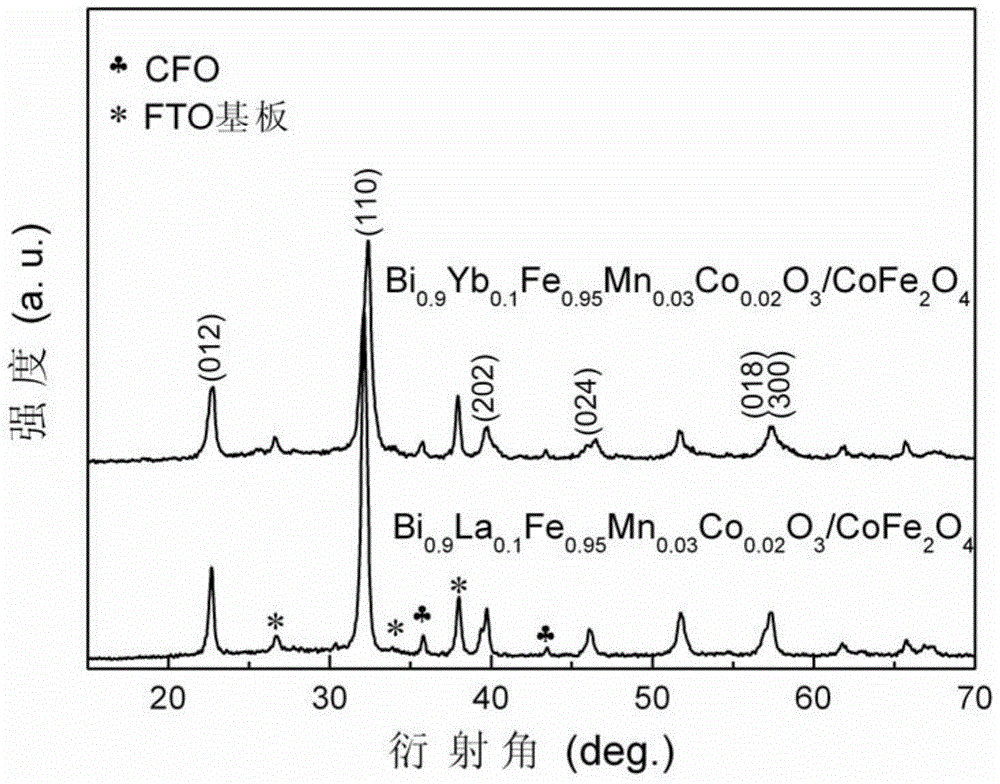

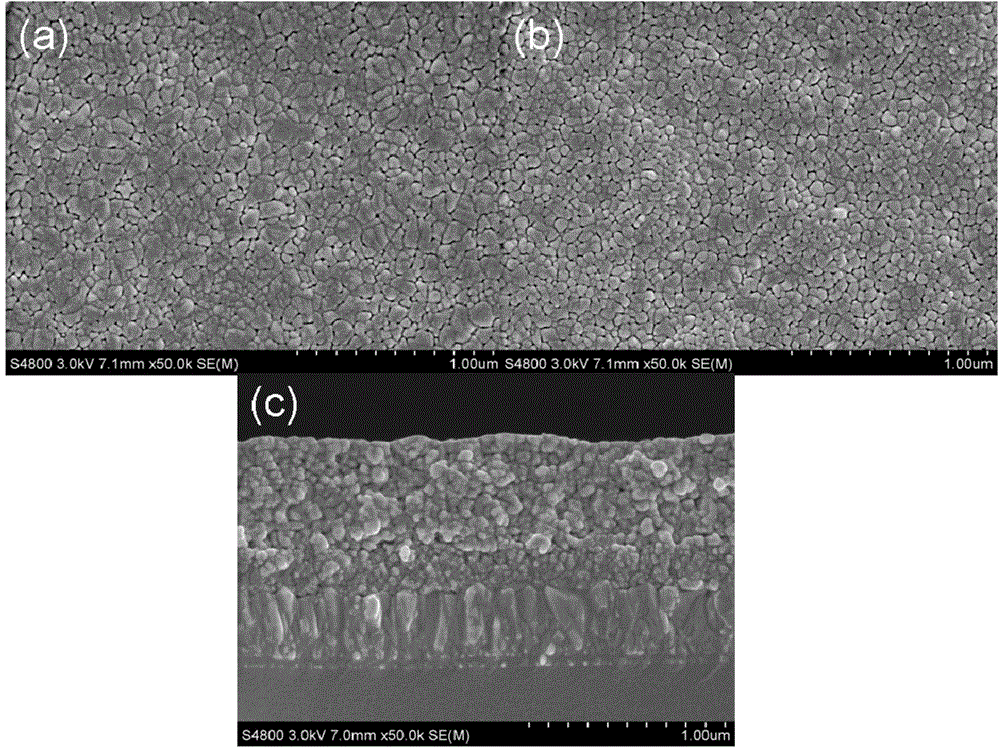

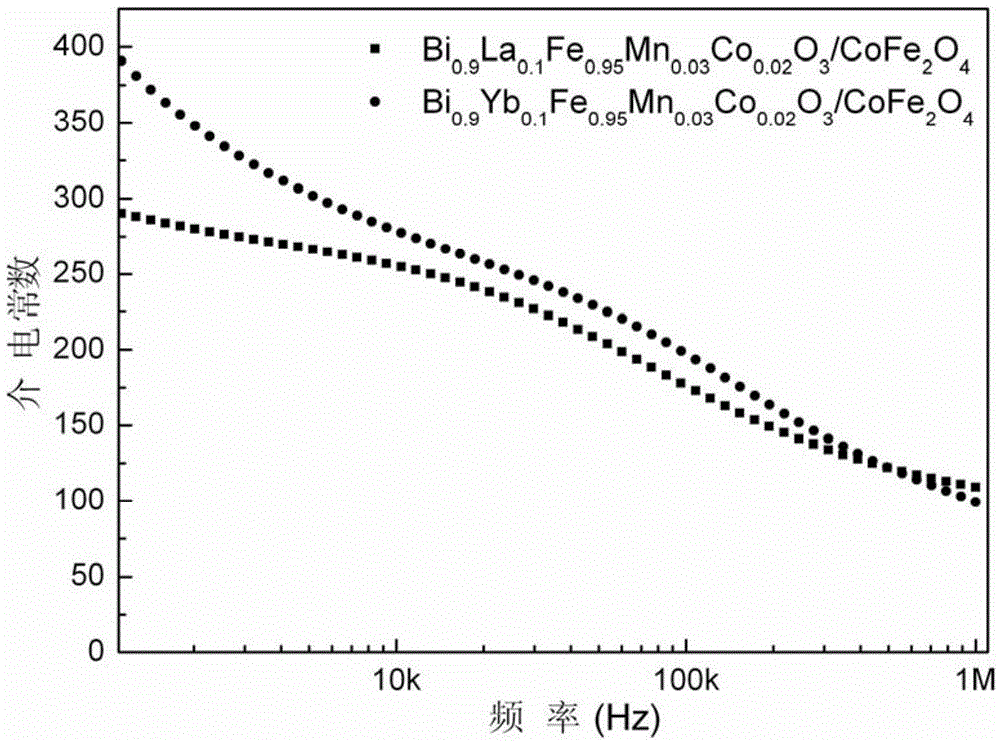

Multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3/CoFe2O4 composite film and preparation method thereof

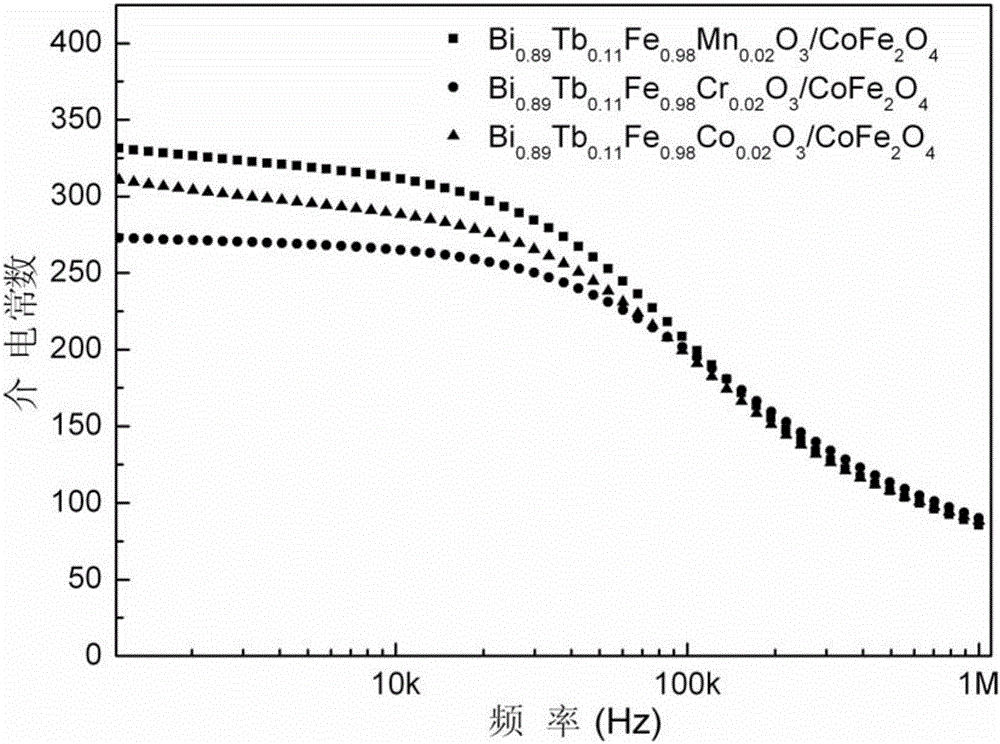

ActiveCN104538140AImprove multiferroic propertiesImprove ferroelectric propertiesInorganic material magnetismInductances/transformers/magnets manufactureComposite filmMultiferroics

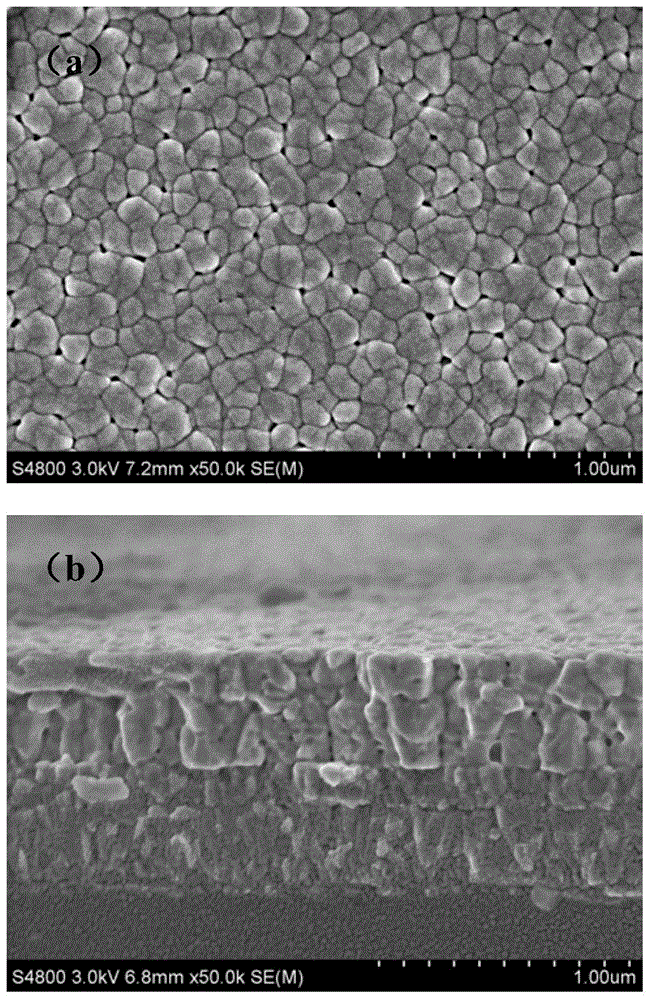

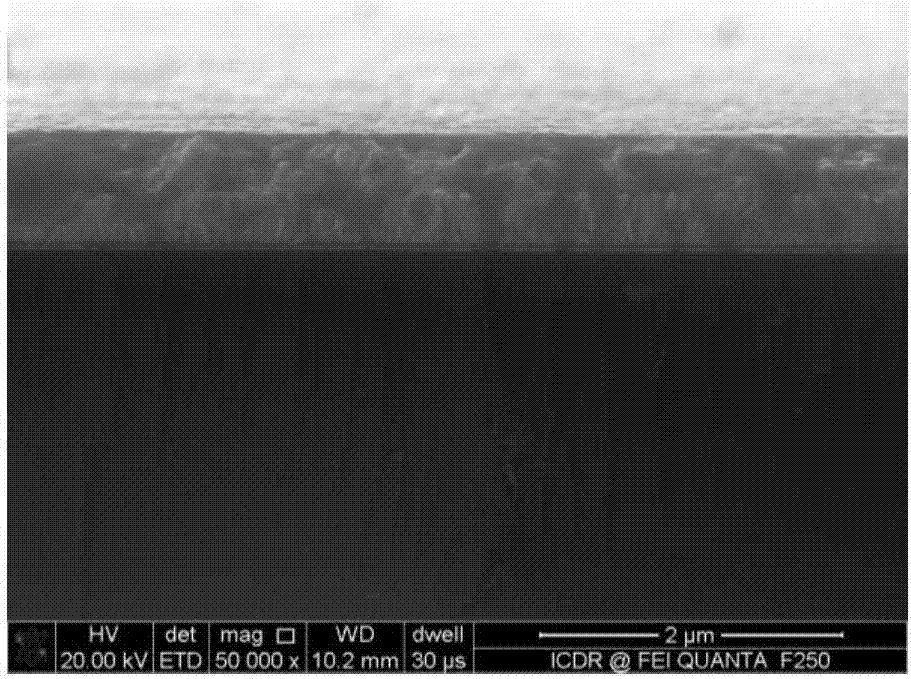

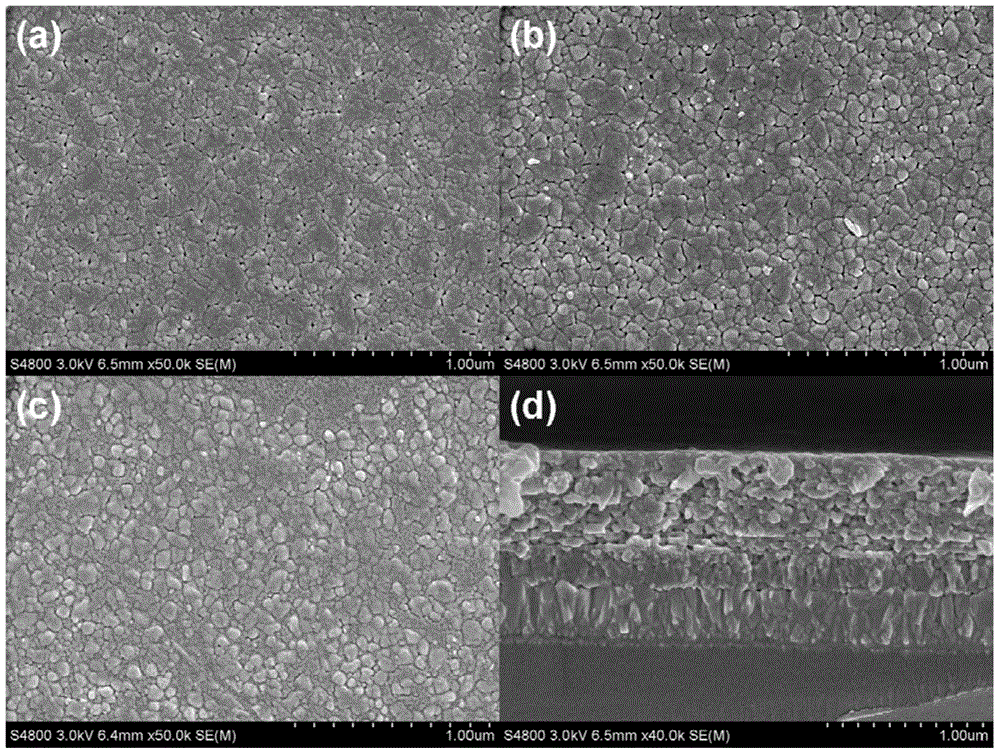

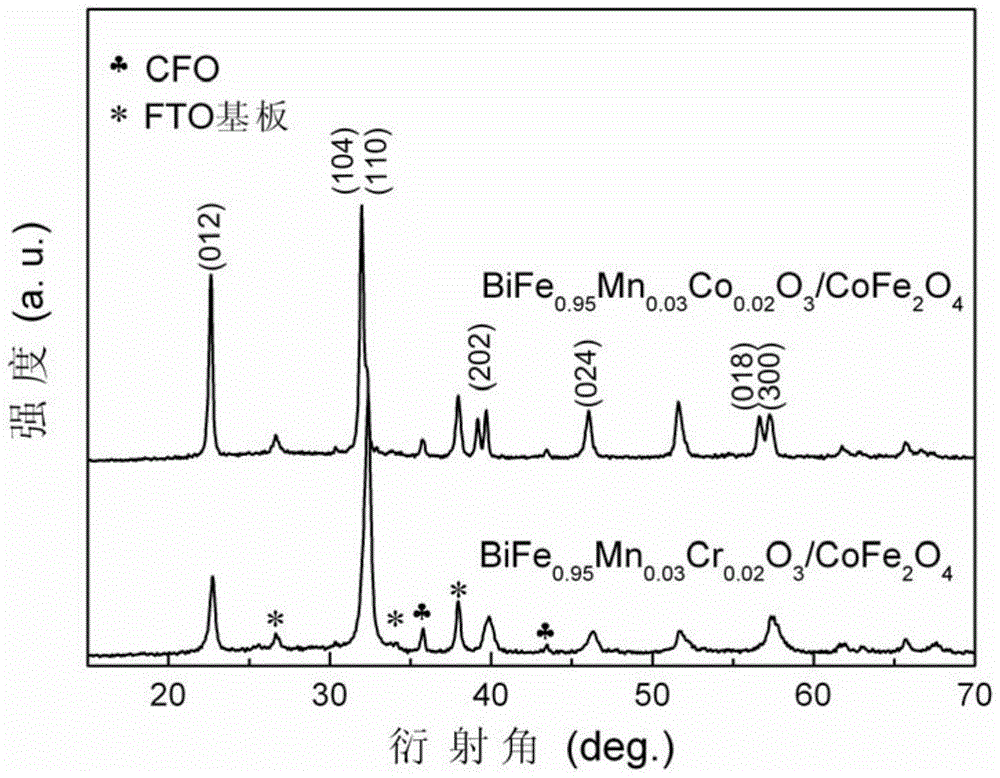

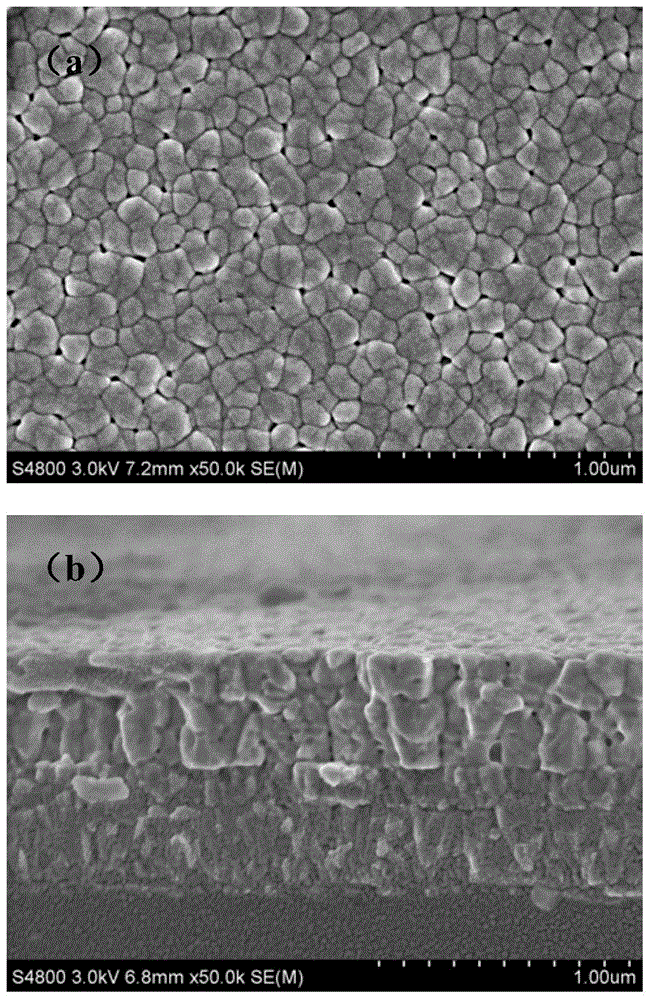

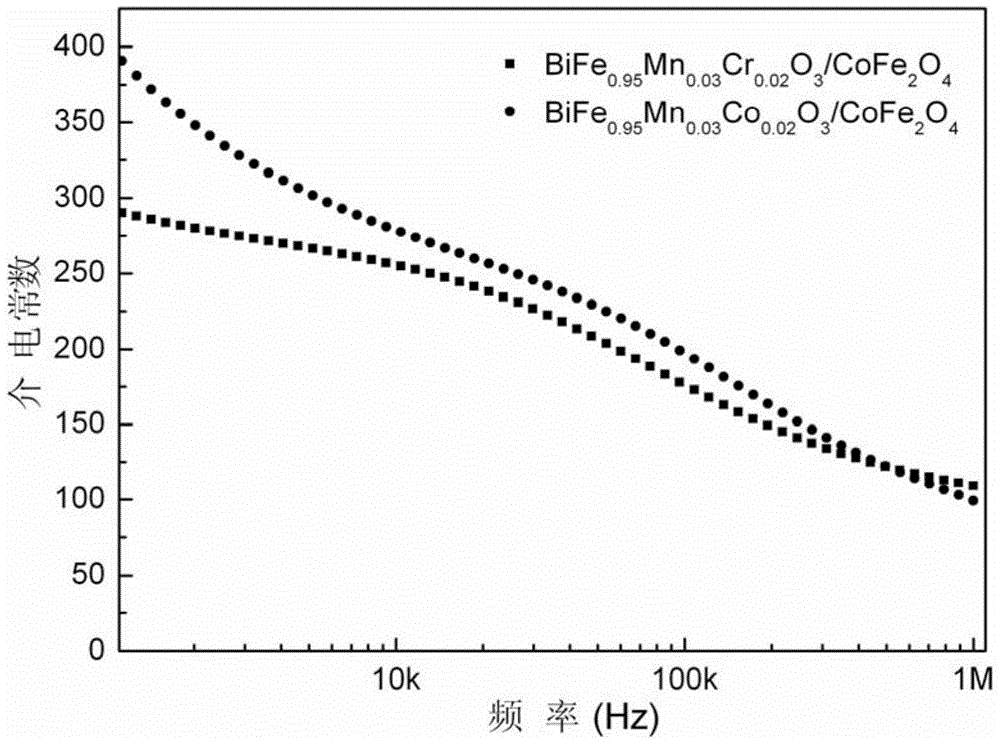

The invention provides a multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe0.97-yMn0.03TMyO3 crystalline state film and a CoFe2O4 crystalline state film. The preparation method comprises the following steps of respectively preparing Bi1-xRExFe0.97-yMn0.03TMyO3 precursor solution and CoFe2O4 precursor solution; spin coating on a substrate to prepare a plurality of layers of CoFe2O4 films, spin coating on the CoFe2O4 films to prepare a plurality of layers of Bi1-xRExFe0.97-yMn0.03TMyO3 films and accordingly obtaining a target product. According to the multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and the preparation method thereof, the device requirement is simple, the prepared film is good in homogeneity, the doping content is easy to control, the ferroelectric property and the ferromagnetic property of the film are improved to a large extent, and the film is high in residual polarization value and residual polarization value.

Owner:SHAANXI UNIV OF SCI & TECH

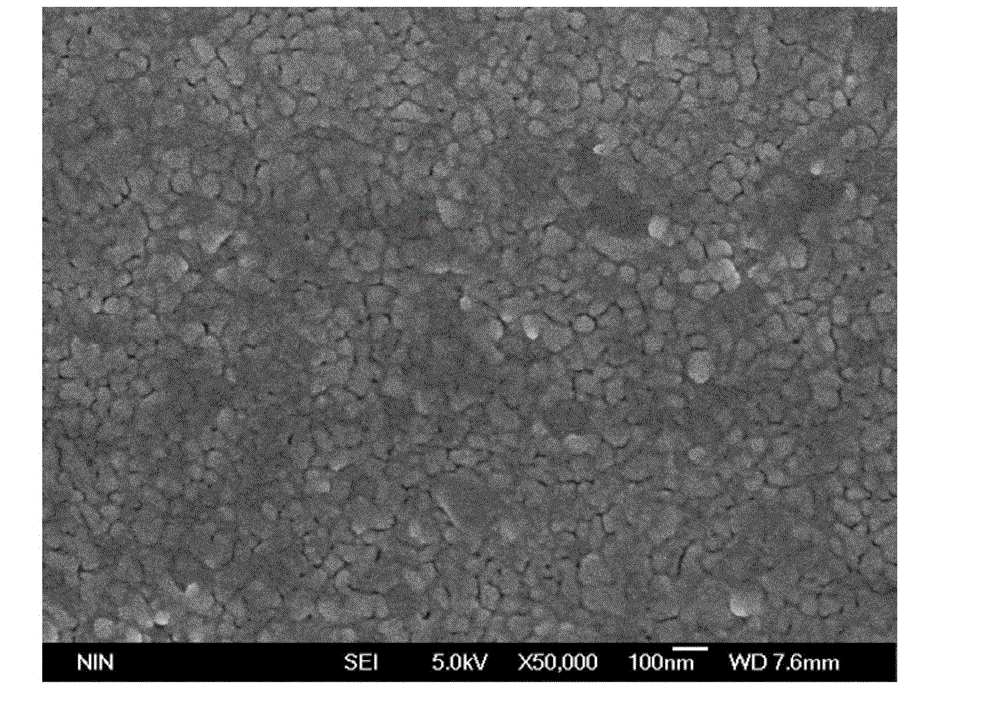

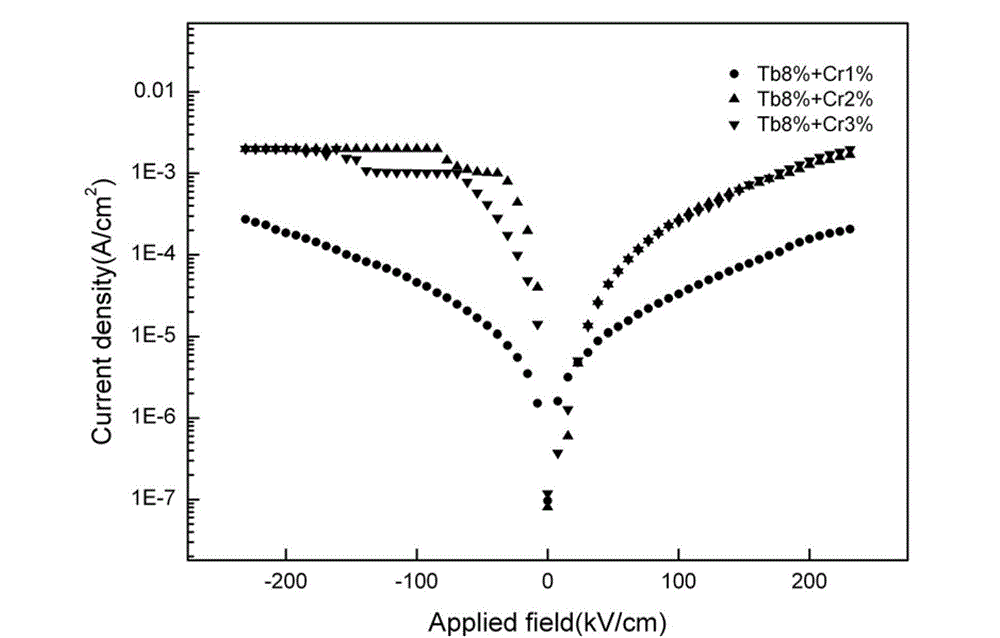

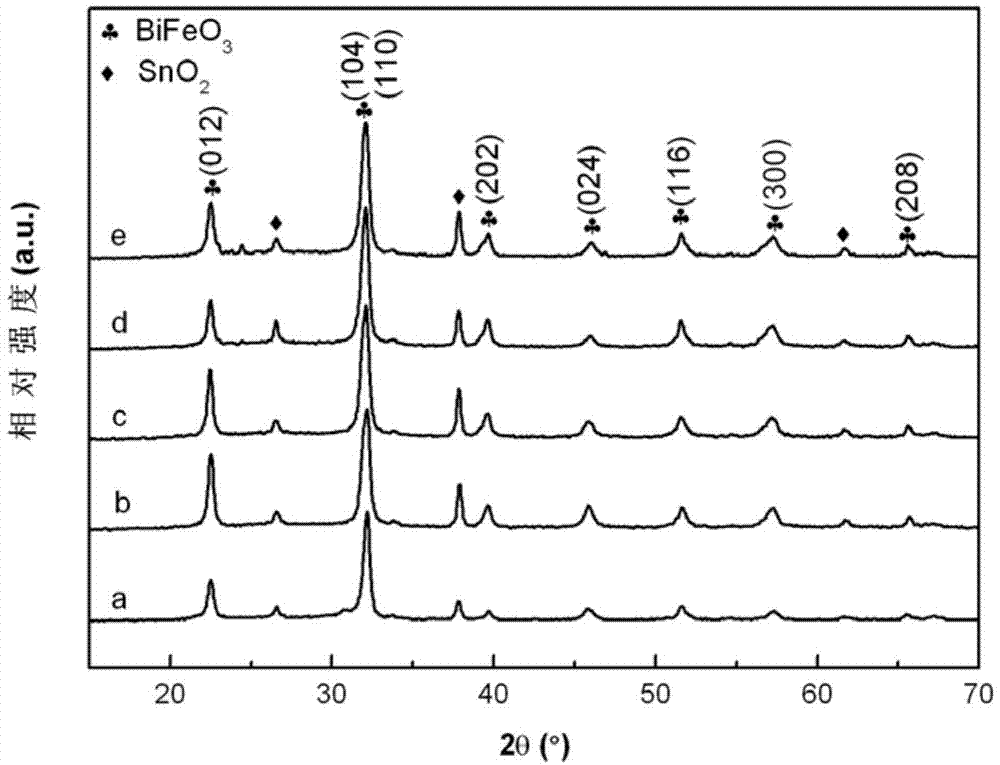

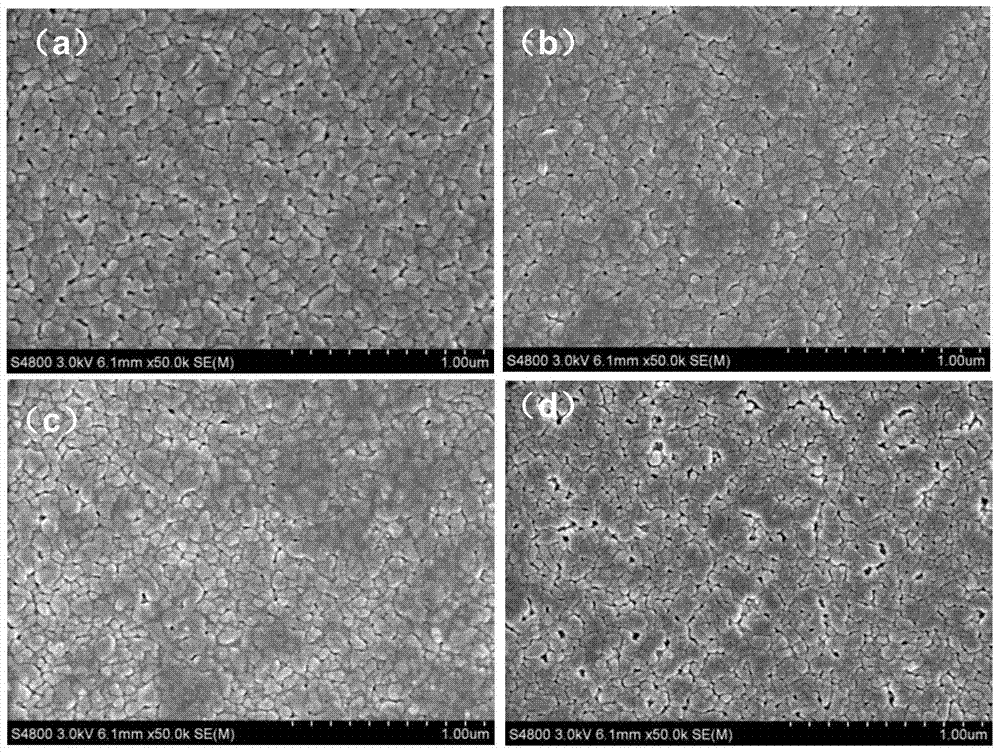

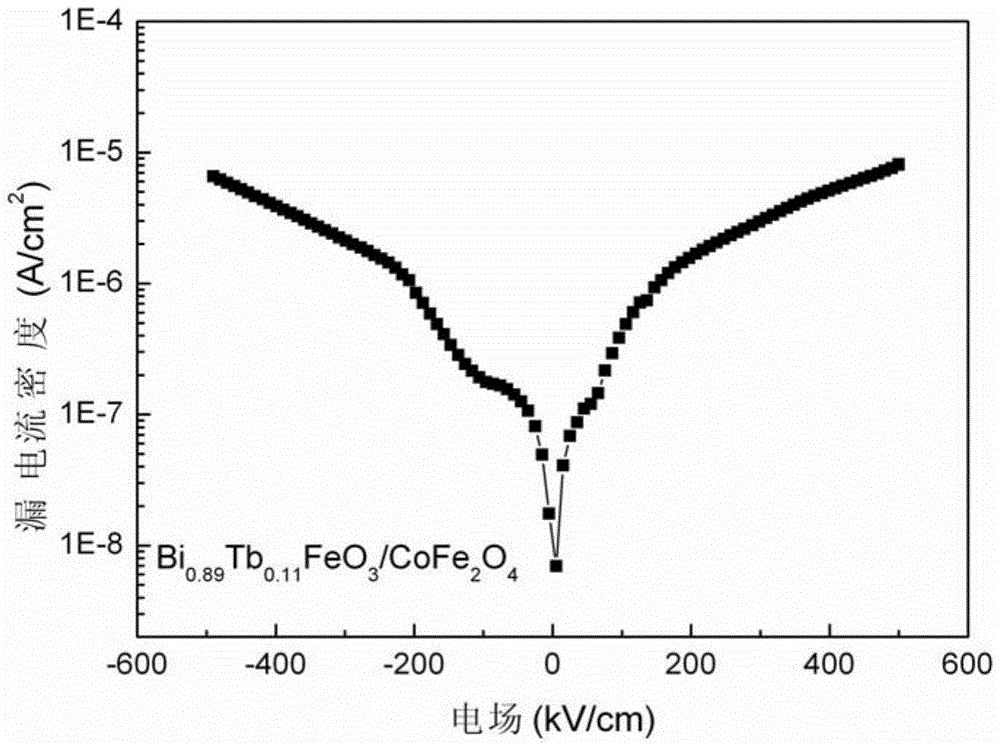

Preparation method of low-leakage current Bi0.92Tb0.08Fe(1-x)CrxO3 film

ActiveCN102976764AImprove multiferroic propertiesImprove electrical performanceAcetic anhydrideLow leakage

The invention provides a preparation method of a low-leakage current Bi0.92Tb0.08Fe(1-x)CrxO3 film. The method comprises the following steps of: dissolving bismuth nitrate, ferric nitrate, terbium nitrate and chromic nitrate at a molar ratio of 0.97:(1-x):0.08:x into the mixed solution of ethylene glycol monomethyl ether and acetic anhydride to form a mixed solution; adding ethanolamine into the mixed solution to adjust the viscosity and the complexing degree to obtain a stable BiFeO3 precursor liquid; and preparing a Tb and Cr co-doped crystalline BiFeO3 film by a spin-coating method and layer-by-layer annealing technology. The film is a crystalline Bi0.92Tb0.08Fe0.99Cr0.01O3 film, wherein the leakage current density is still kept below 10<-4>A / cm<2> in a 150kv / cm test electric field. According to the method provided by the invention, the requirements on equipment are simple, the experimental conditions are easy to realize, the prepared film has good uniformity, and the leakage current of the film is reduced through the co-doping of Tb and Cr.

Owner:SHAANXI UNIV OF SCI & TECH

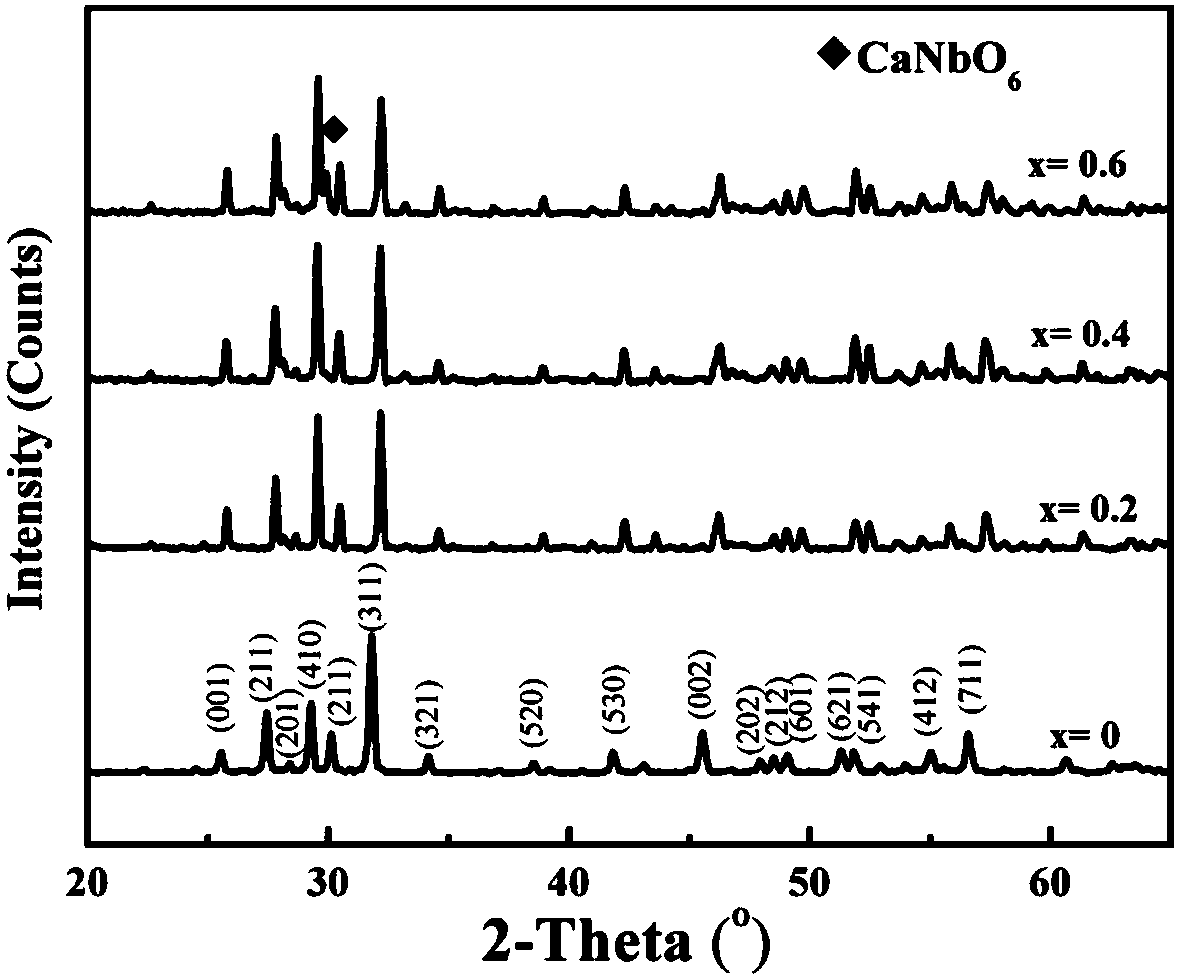

Bi0.92Dy0.08Fe(1-x)MnxO3 ferroelectric film with low coercive field and preparation method of film

ActiveCN103771527AGood uniformityEnhanced ferroelectric and dielectric propertiesIron compoundsEthylene glycol monomethyl etherChemistry

Owner:SHAANXI UNIV OF SCI & TECH

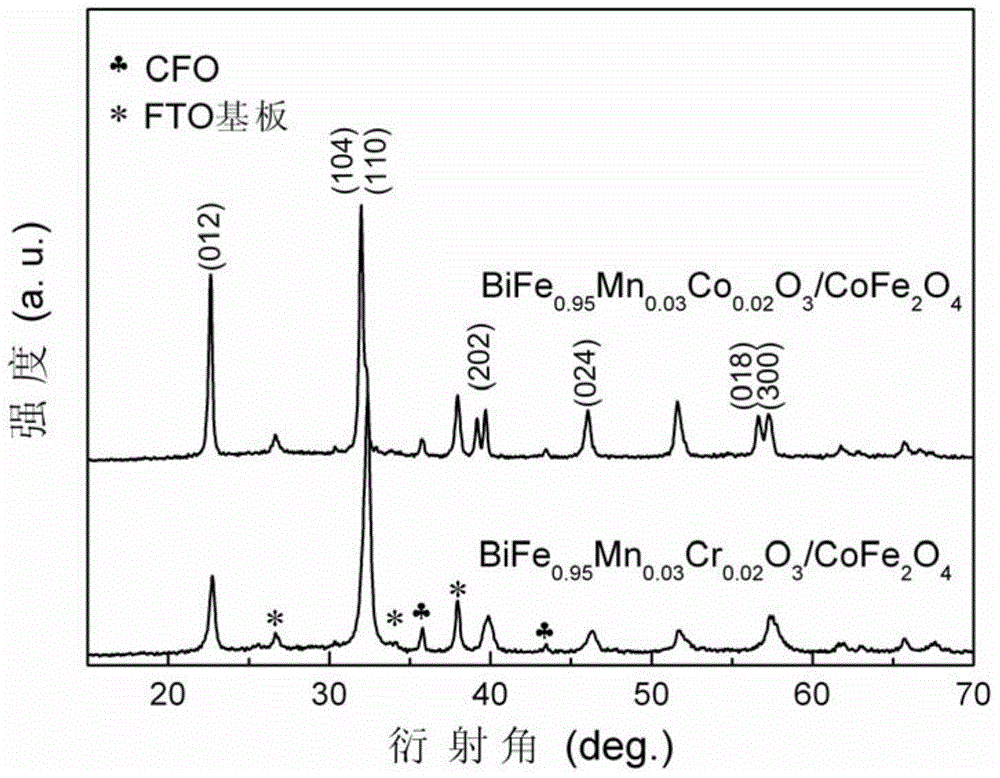

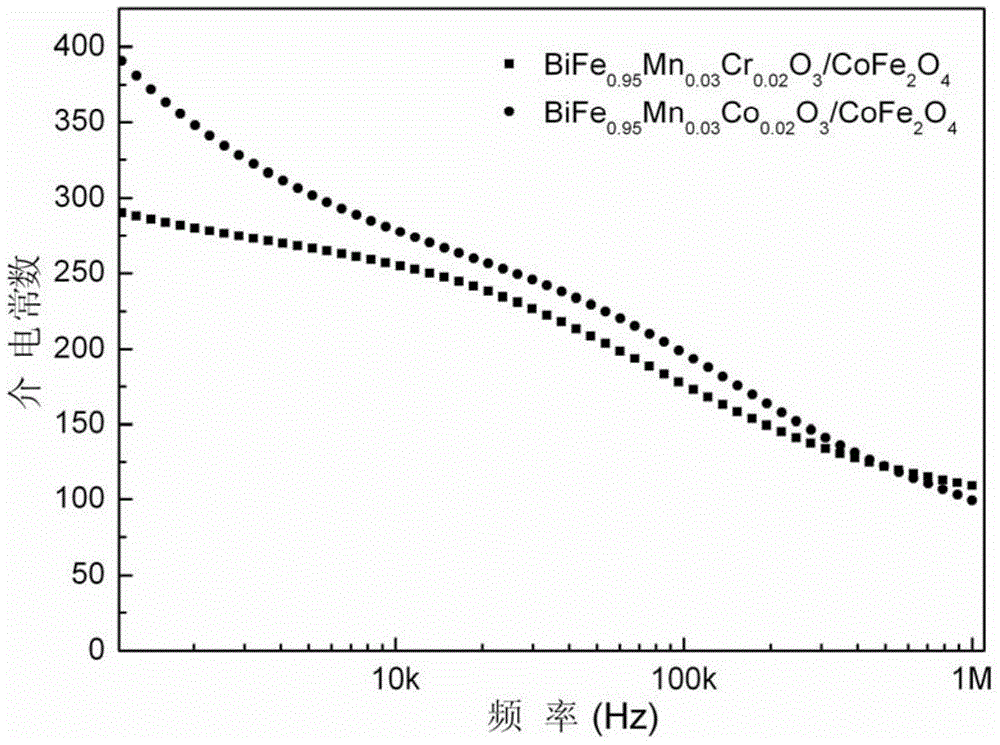

Laminated BiFe(0.97-x)Mn0.03TMxO3/CoFe2O4 multiferroic composite film and preparation method thereof

ActiveCN104476832AImprove multiferroic propertiesHigh saturation magnetizationLaminationLamination apparatusResidual polarizationEquipment requirement

The invention provides a laminated BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 crystallized film and a CoFe2O4 crystallized film which are compounded together. The preparation method comprises the following steps of firstly, preparing a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 precursor solution and a CoFe2O4 precursor solution respectively; and then carrying out spin coating on a substrate to prepare a multi-layer CoFe2O4 film, and then carrying out spin coating on the CoFe2O4 film so as to prepare a multi-layer BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 film, thereby obtaining the target product. According to the invention, the equipment requirement is simple; the prepared film is good in uniformity; chemical components are accurate and controllable; the doped amount is easy to control; the ferroelectric properties and the ferromagnetic property of a film are improved greatly, so that the film has high residual polarization value and a residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

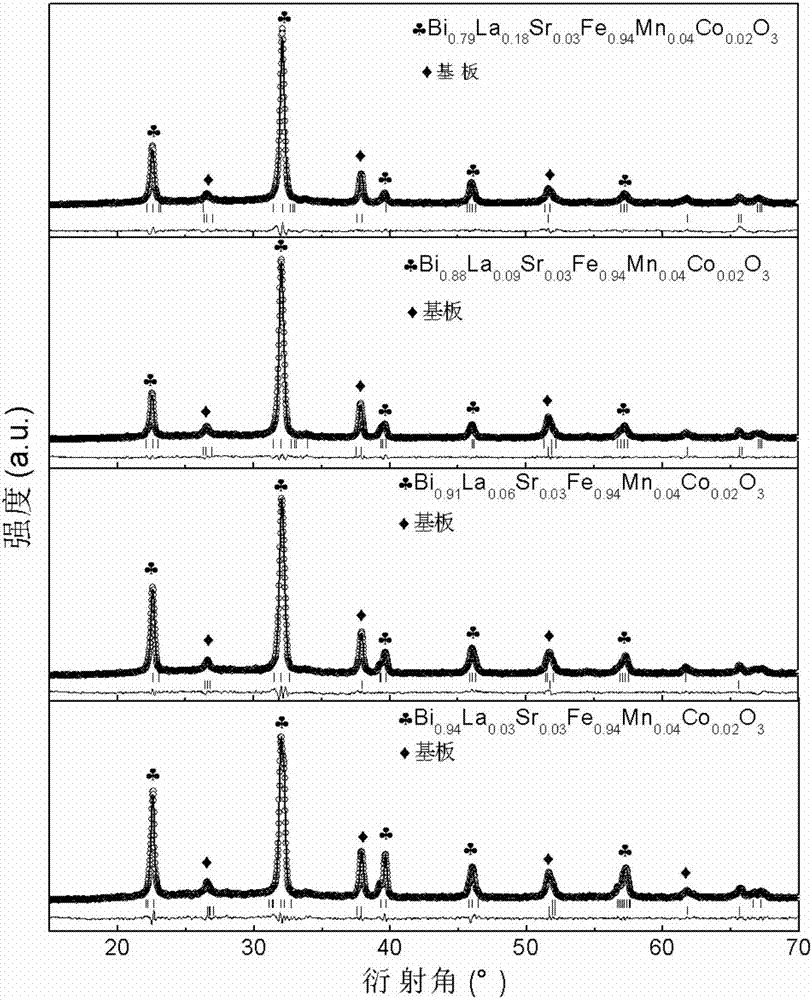

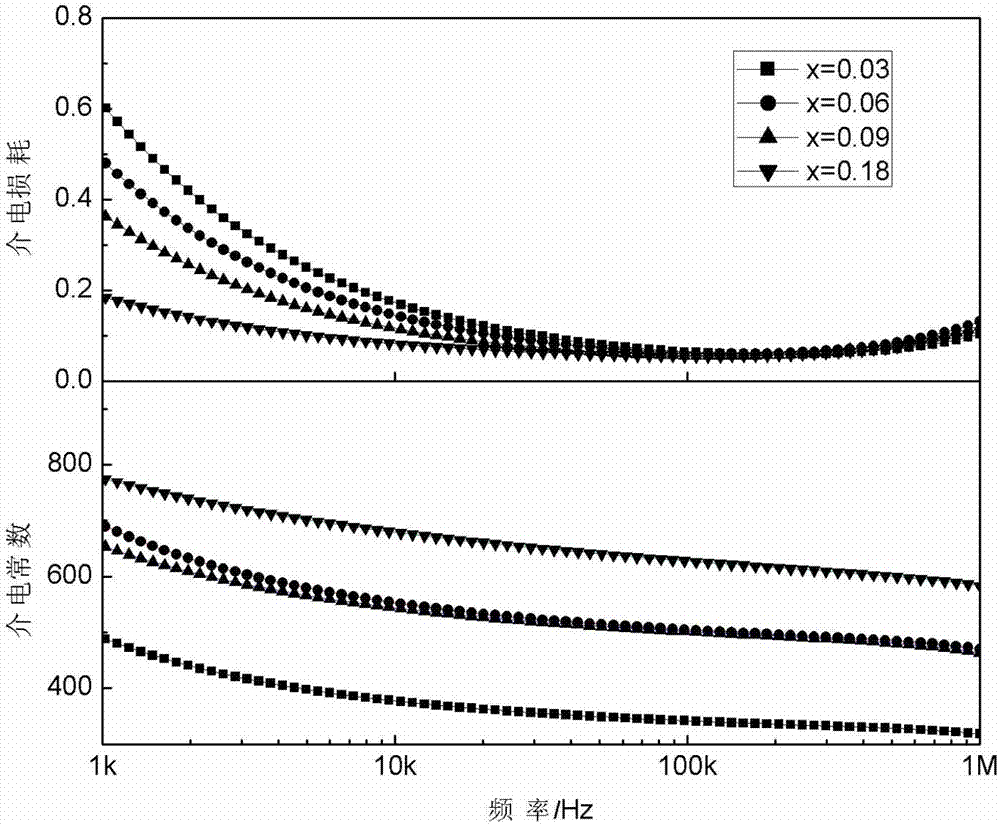

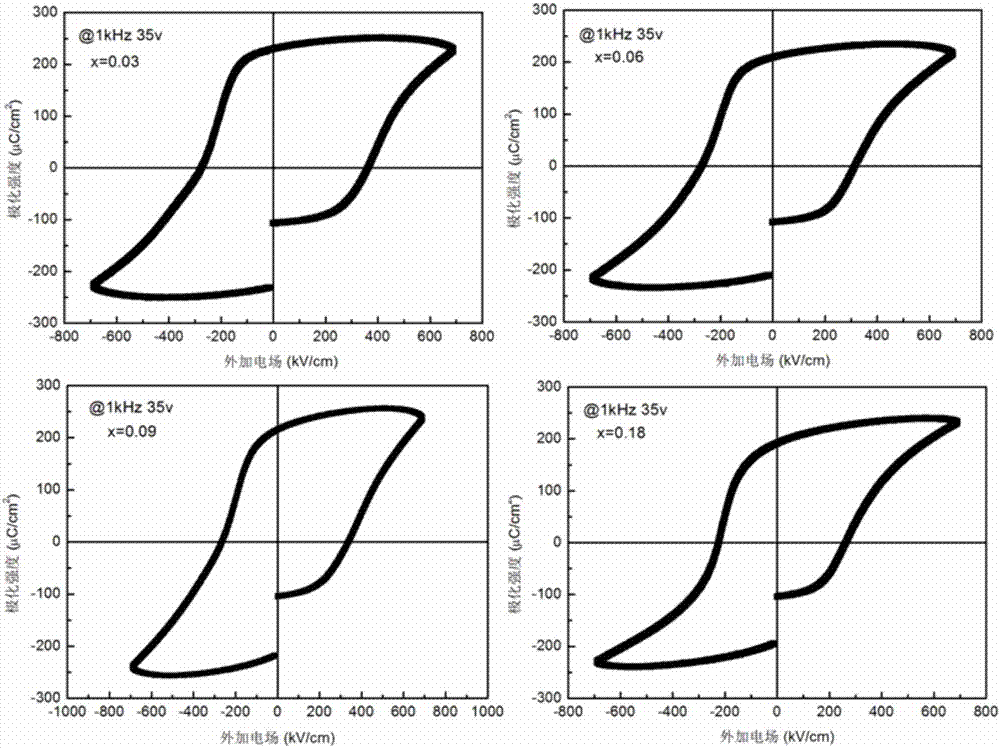

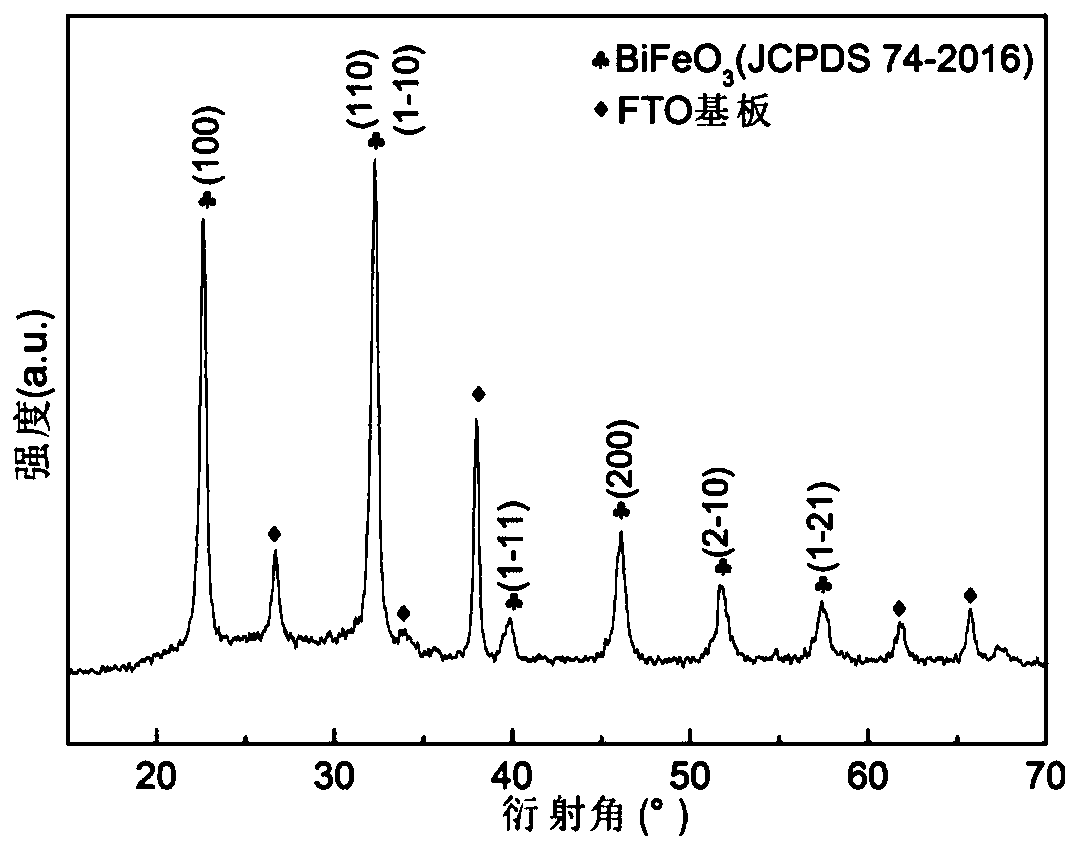

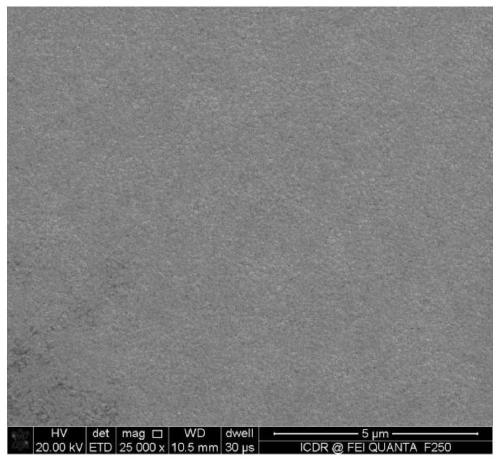

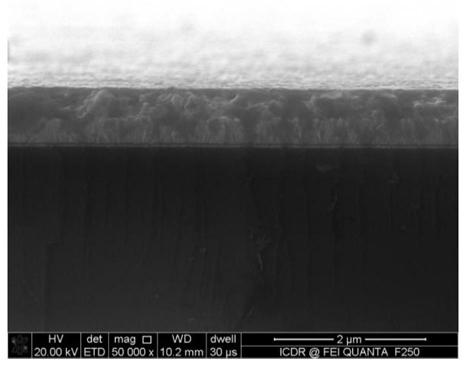

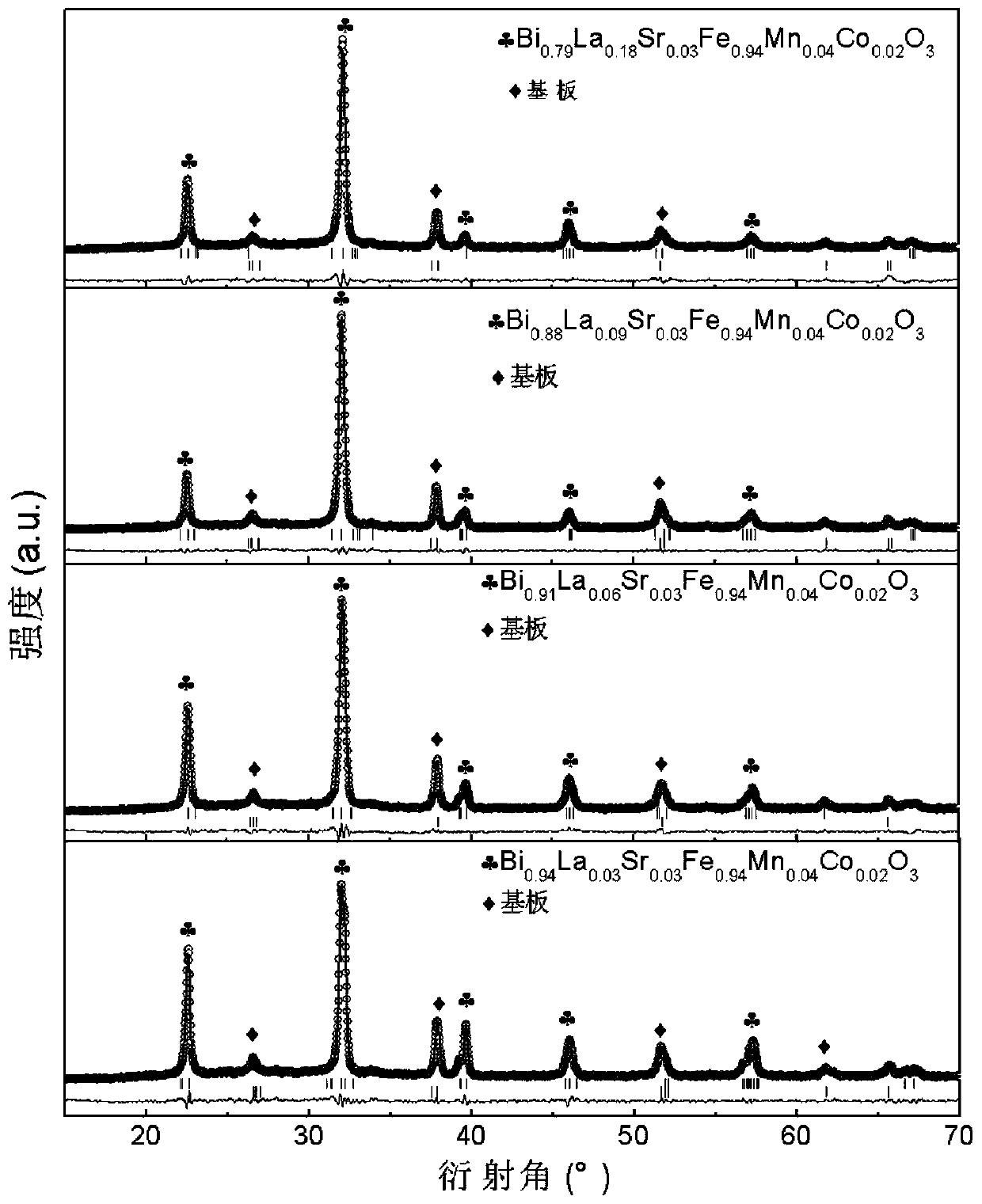

LaSrMnCo codoped bismuth ferrite multiferroic film and preparation method thereof

ActiveCN107117830AGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a LaSrMnCo codoped bismuth ferrite multiferroic film and a preparation method thereof. A Bi(0.97-x)LaxSr0.03Fe0.94Mn0.04Co0.02O3 multiferroic film, namely the LaSrMnCo codoped bismuth ferrite multiferroic film, is prepared by taking bismuth nitrate, lanthanum nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate as raw materials (bismuth nitrate of excessive 5 percent), taking ethylene glycol monomethyl ether and acetic anhydride as solvents and using a spin-coating method and a layer-by-layer annealing process. A sol-gel process is adopted, spin-coating and layer-by-layer annealing methods are adopted, equipment requirements are simple, experimental conditions are easy to realize, the film is suitably prepared on a large surface and an irregularly shaped surface, chemical components are accurately controllable, the multiferroic property of the BiFeO3 film can be improved, the prepared the LaSrMnCo codoped bismuth ferrite multiferroic film has high uniformity and is a multiferroic film with high residual polarization value and low coercive field, and the ferroelectric and dielectric properties of the film are effectively enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

Bi0.90Ho0.10Fe1-XMnXO3 ferroelectric film with high remanent polarization and preparation method thereof

ActiveCN103708562AImprove insulation performanceReduce generationIron compoundsCrystal systemMANGANESE ACETATE

The invention relates to a Bi0.90Ho0.10Fe1-xMnXO3 ferroelectric film with high remanent polarization and a preparation method thereof, wherein x is equal to 0.01-0.05, and the film is of a distorted perovskite structure, has a diamond crystal system and has good uniformity, remanent polarization of 78-108 muC / cm<2>, and a dielectric constant of 196.2-271.8. The preparation method comprises the steps of dissolving bismuth nitrate, ferric nitrate, holmium nitrate and manganese acetate in a mixture prepared by mixing ethylene glycol monomethyl ether and acetic anhydride to obtain a precursor solution; spin-coating the precursor solution on a substrate, coating glue evenly, then baking to obtain a dry film, then annealing to obtain a Bi0.90Ho0.10Fe1-xMnXO3 film, and repeatedly spin-coating the precursor solution, baking and annealing to achieve the required film thickness to obtain the film. According to the Bi0.90Ho0.10Fe1-xMnXO3 ferroelectric film with high remanent polarization and the preparation method thereof, the requirements for equipment are simple, the doping amount is easy to control, and the ferroelectric properties of the BiFeO3 film can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

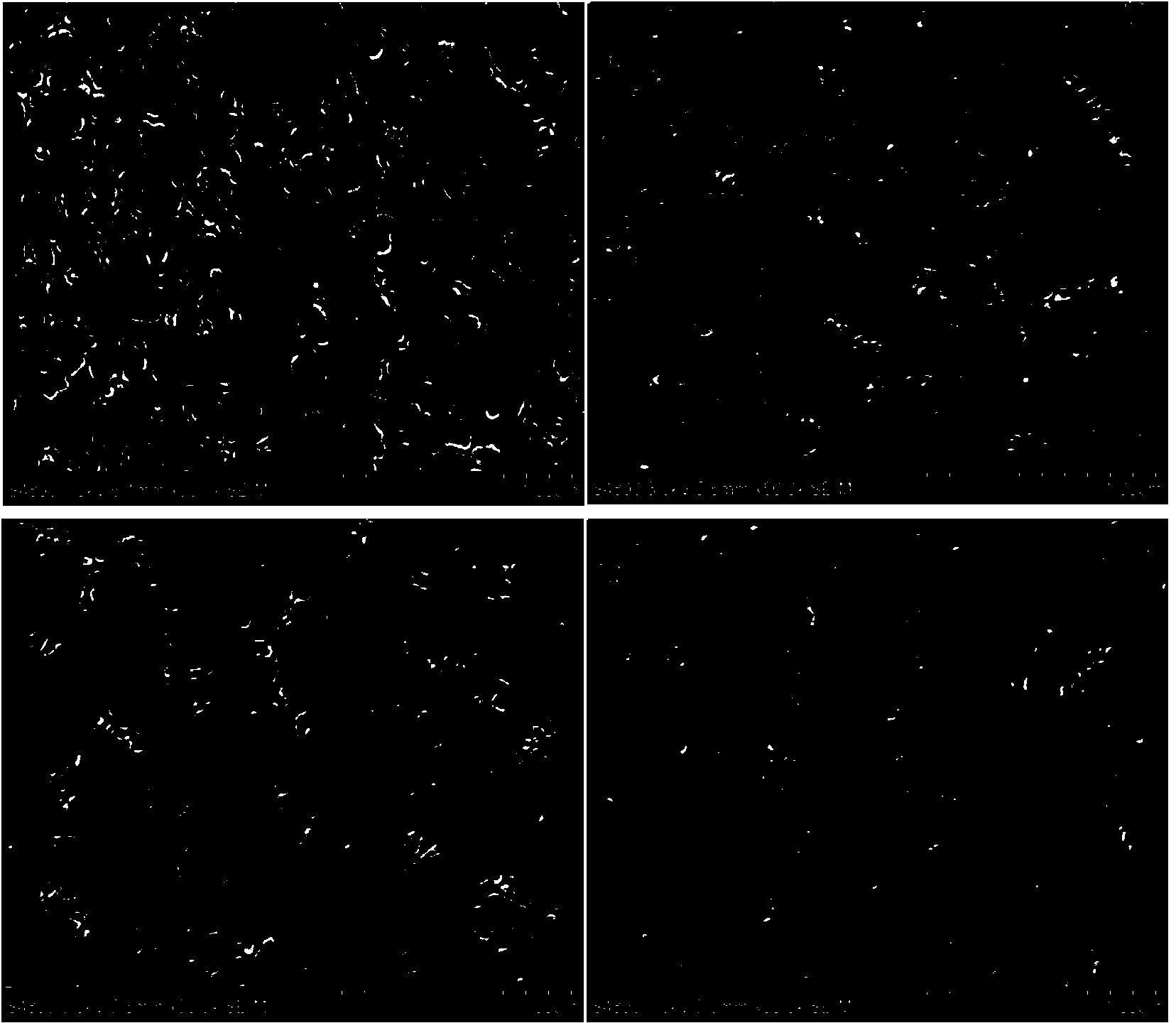

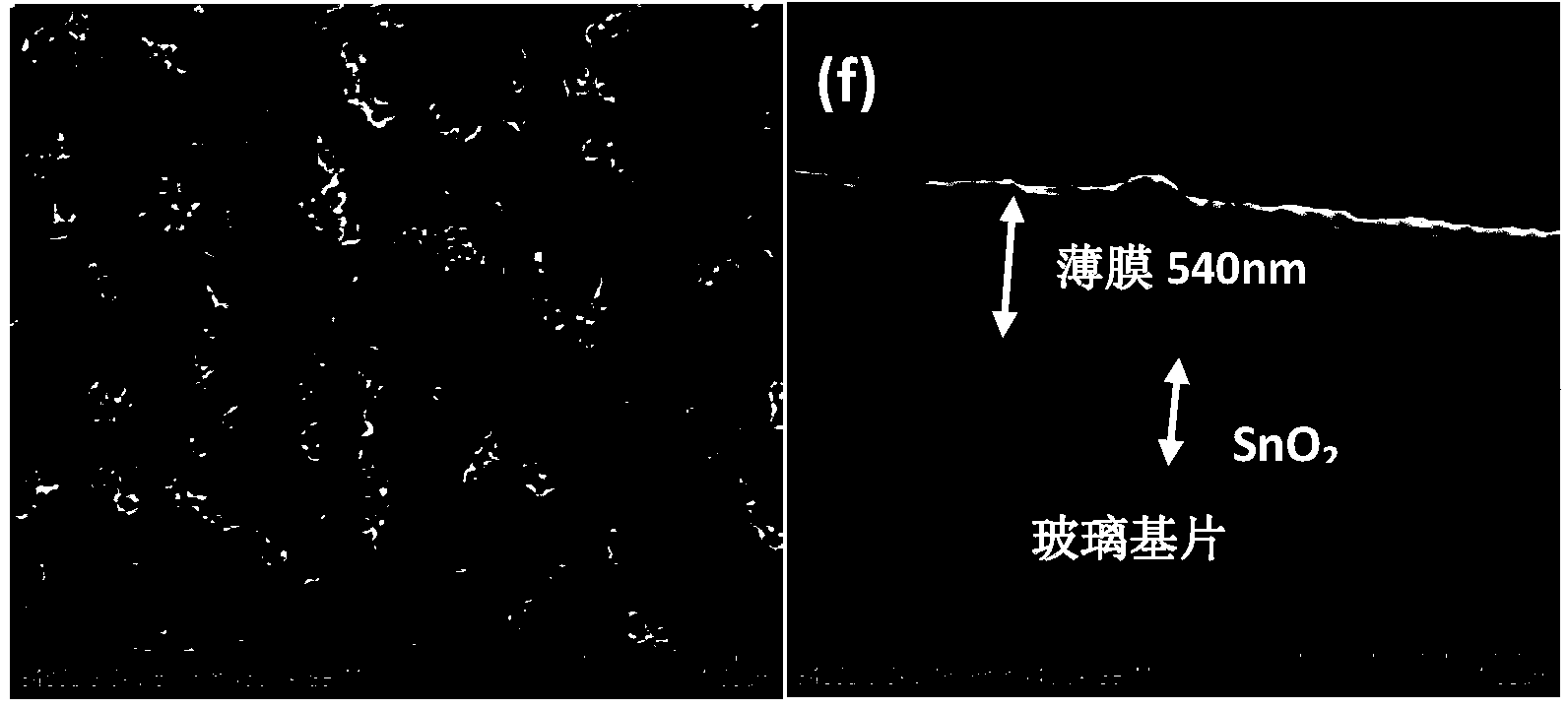

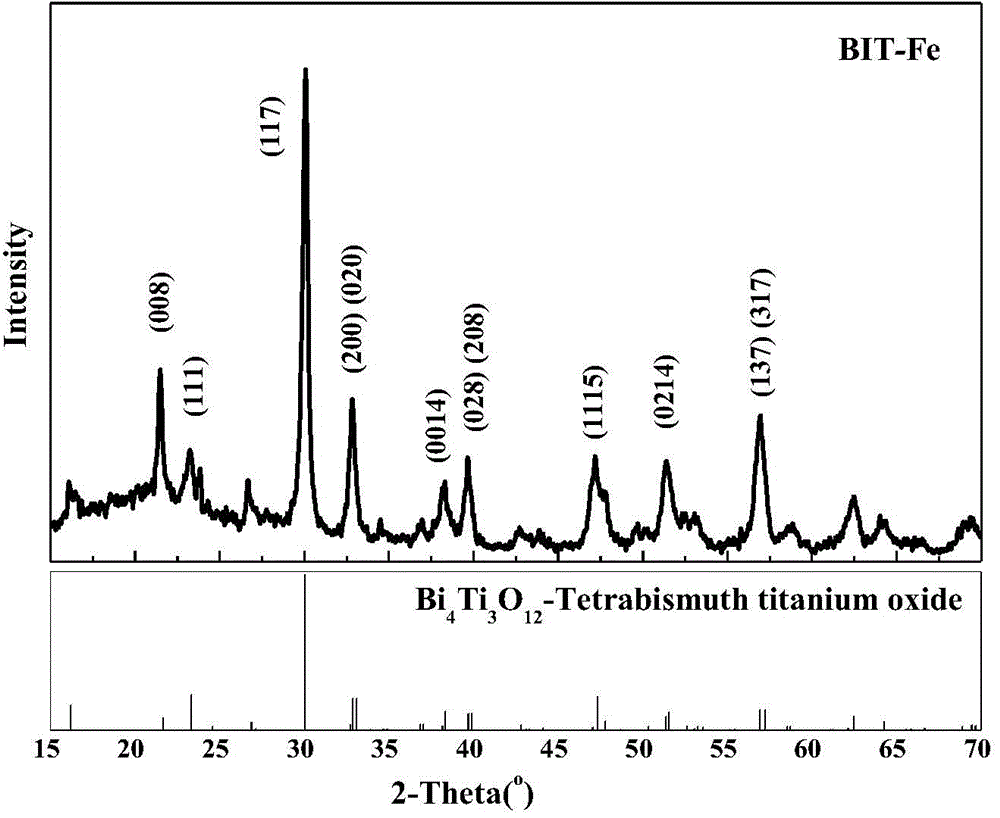

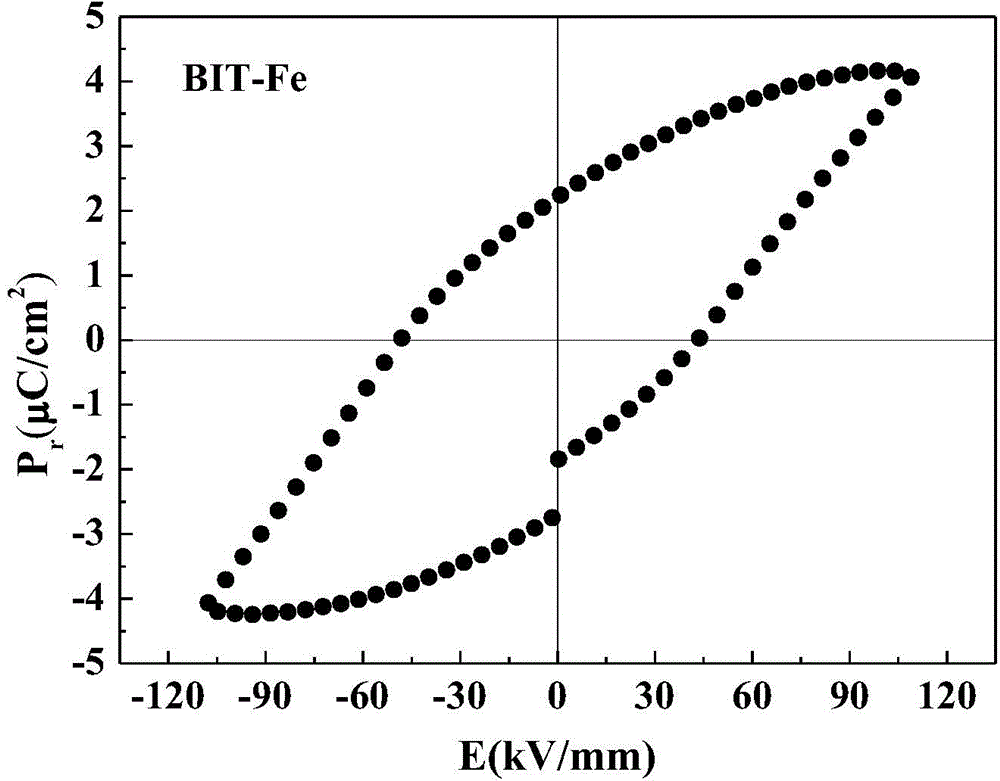

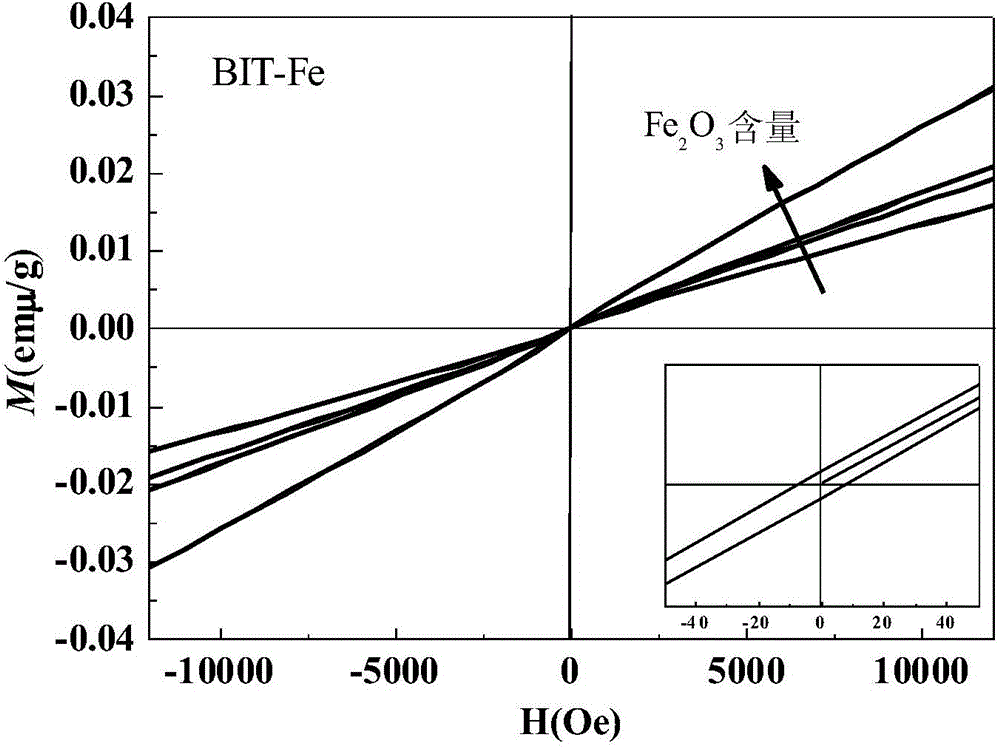

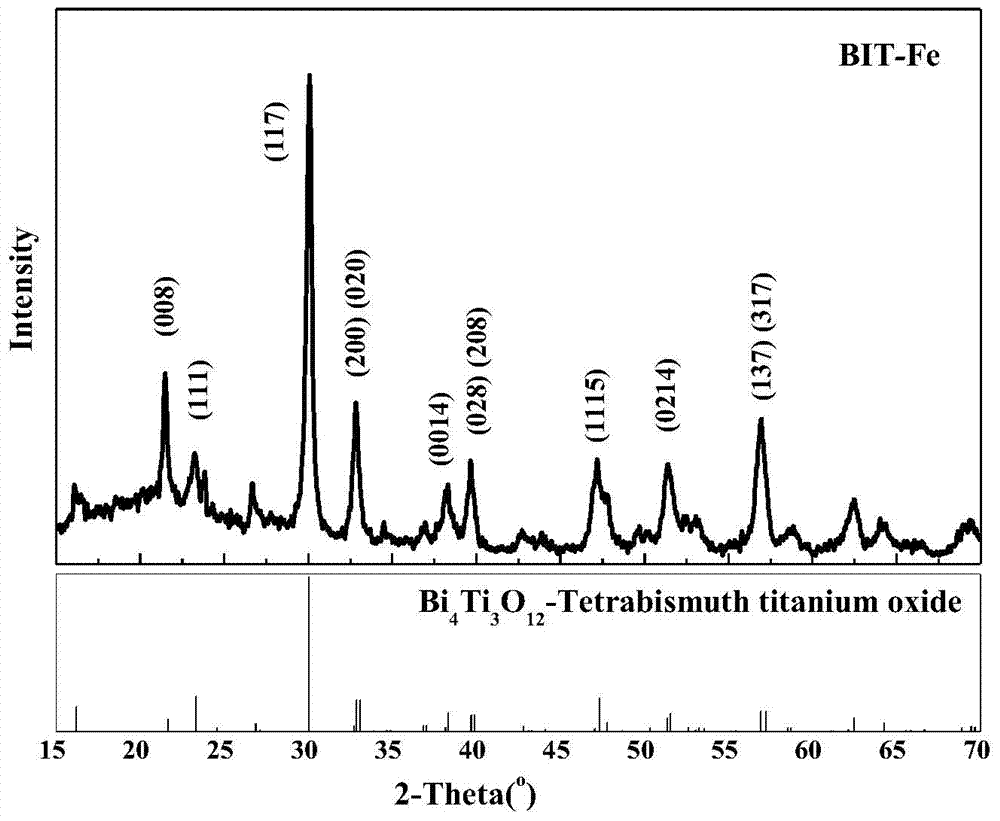

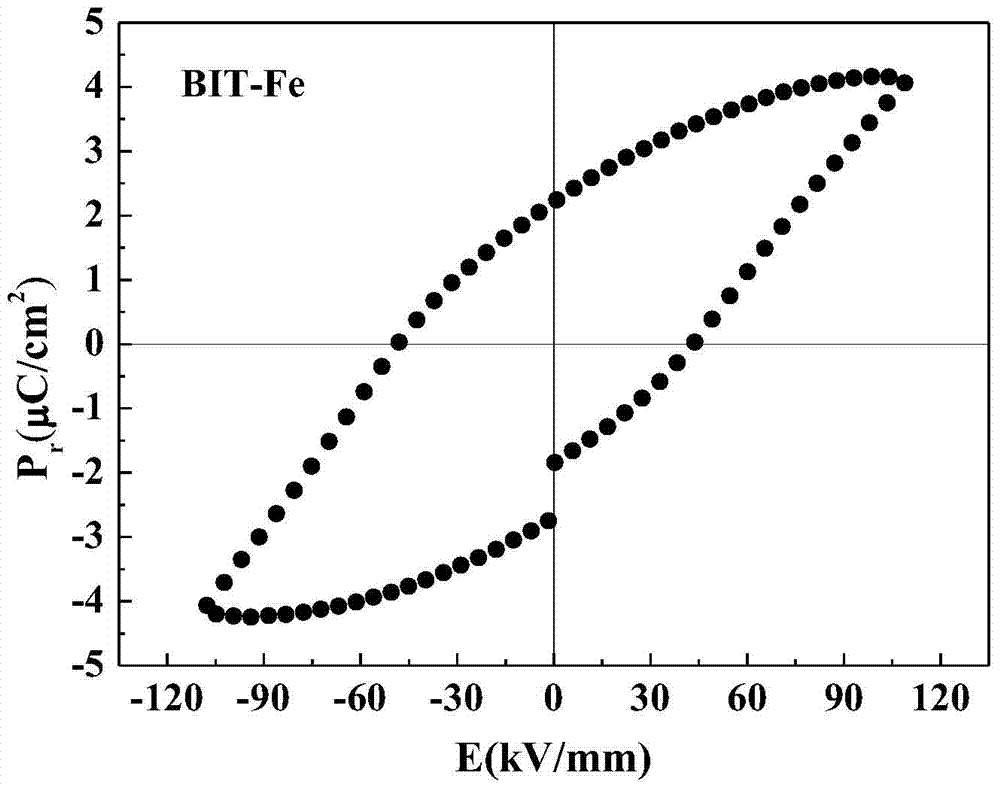

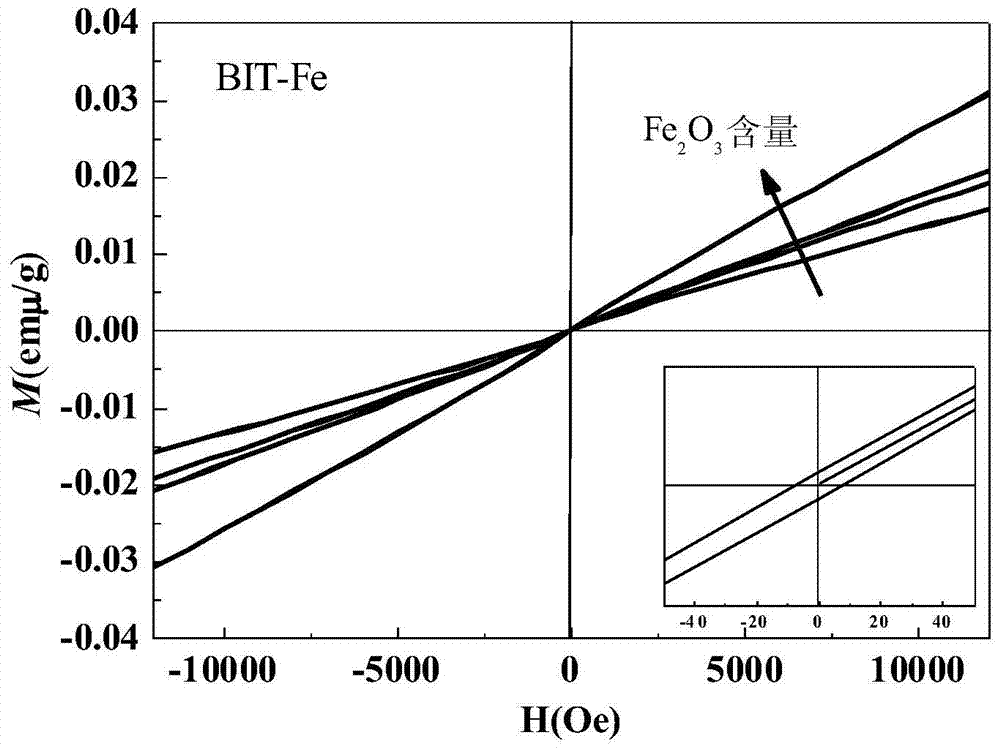

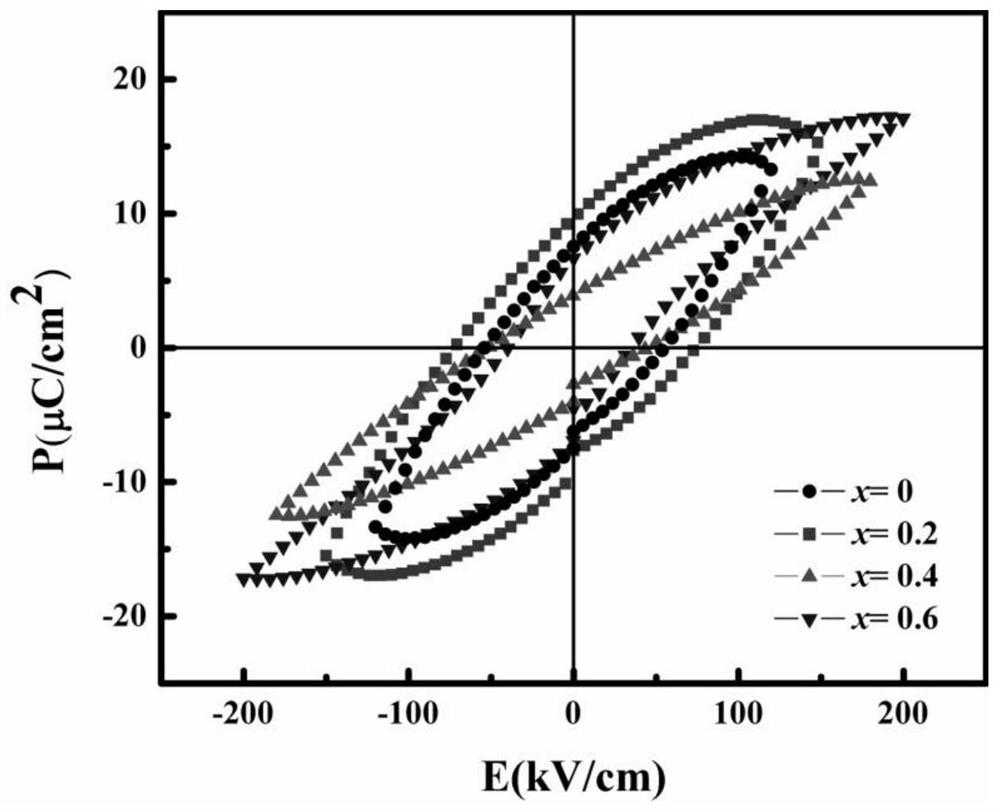

Preparation method of BIT-Fe multiferroic ferroelectric ceramic

ActiveCN104446449AFerroelectricExcellent ferroelectricity and excellent ferroelectricity are retainedMultiferroicsBismuth

The invention provides a preparation method of a BIT-Fe multiferroic ferroelectric ceramic. Bi2O3 (bismuth oxide), TiO2 (titanium dioxide) and Fe2O3 (ferric oxide) are used as raw materials, and the BIT-Fe multiferroic ferroelectric ceramic with a pure phase is prepared by a solid phase method, so that the ceramic has ferroelectricity, ferromagnetism and especially opposite ferromagnetism at the same time, and the BIT-Fe multiferroic ferroelectric ceramic has wide application prospects in spintronics and other fields. The preparation method disclosed by the invention has the characteristics that the preparation technology is simple, the preparation technology meets the requirements of industrialized production, and doped substances are simple and easy to obtain, so that the BIT ceramic has a multiferroic characteristic, the purity of the prepared ceramic is high, the prepared ceramic does not include other sundries or hazardous compounds, such as Pb (plumbum), and the prepared ceramic meets the manufacturing requirements of green electronic materials.

Owner:SHAANXI UNIV OF SCI & TECH

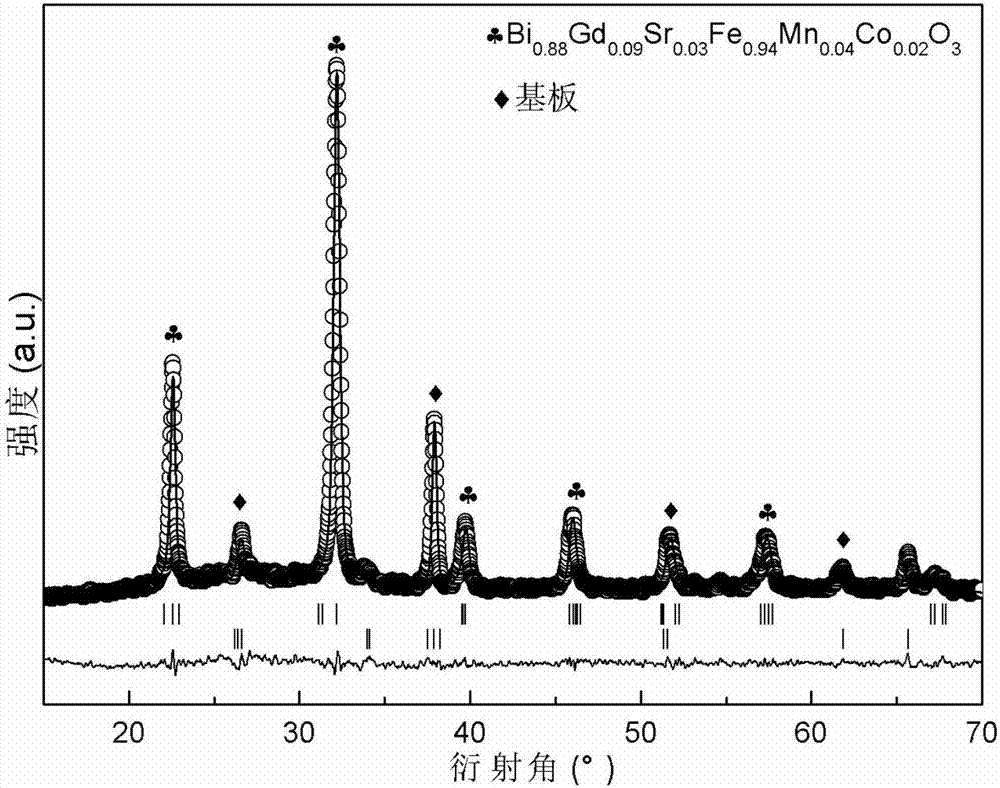

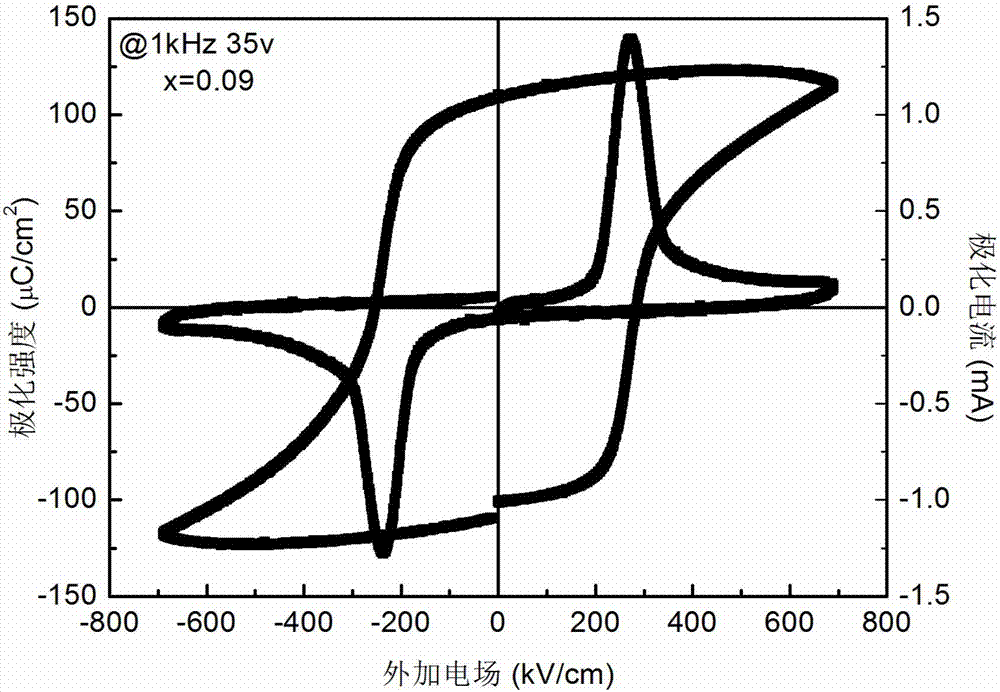

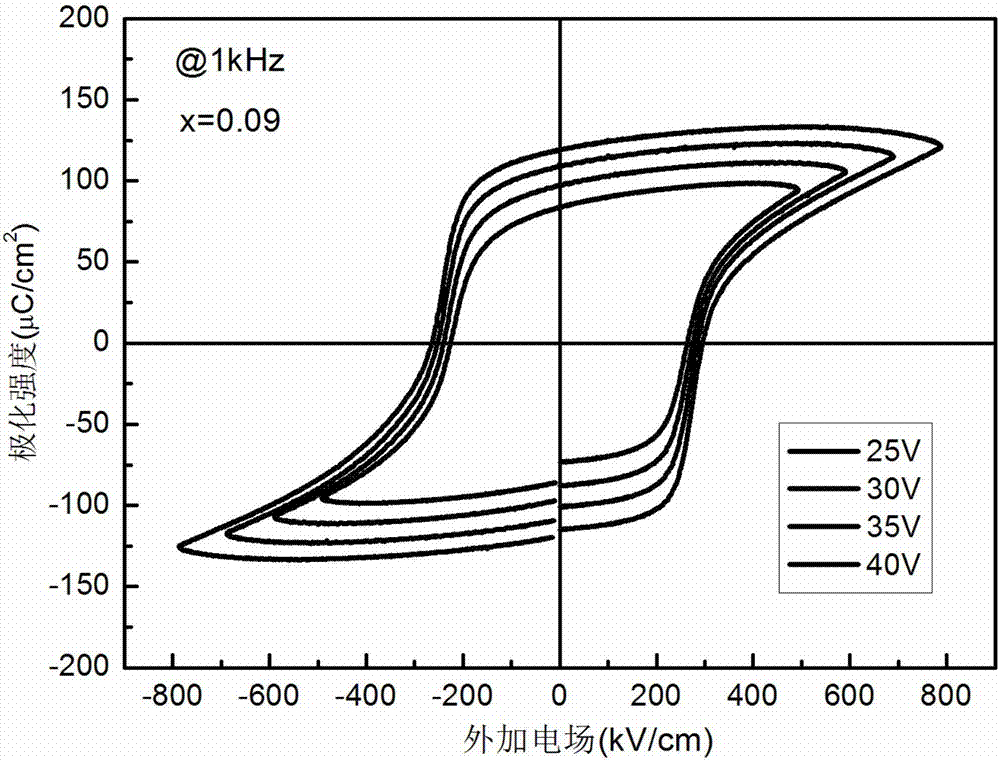

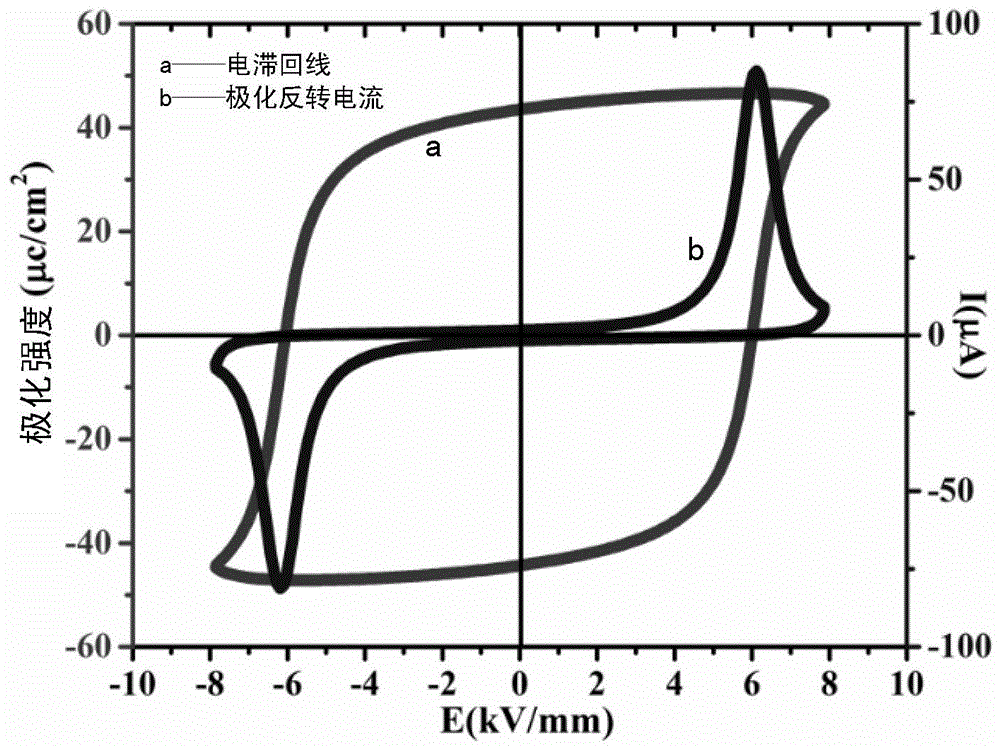

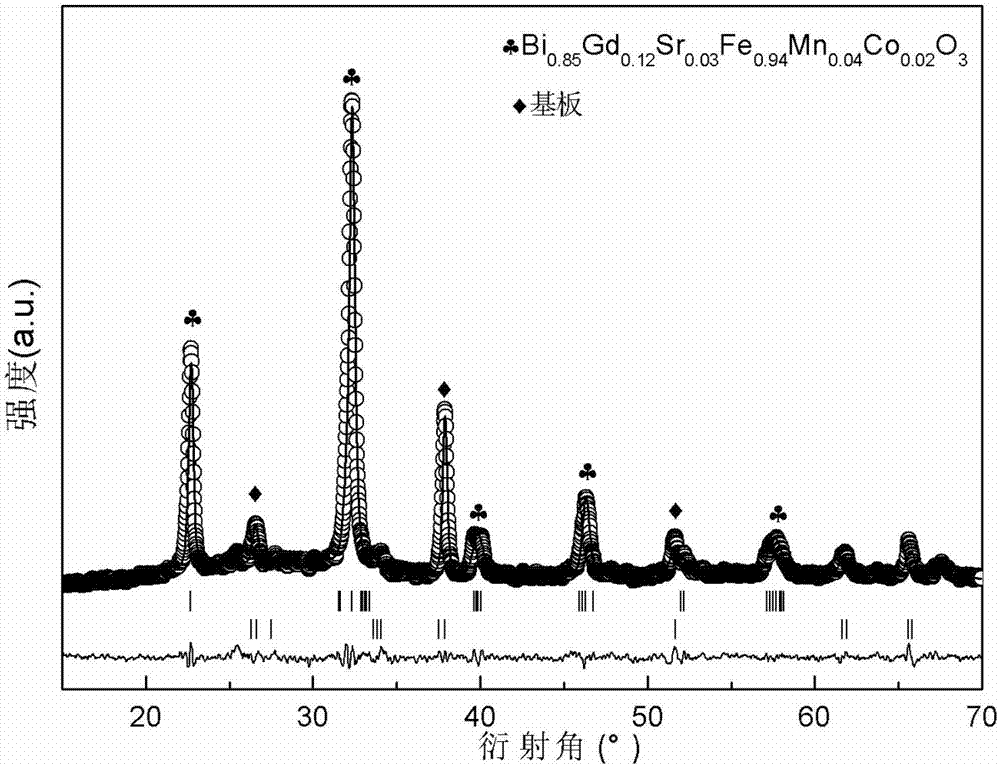

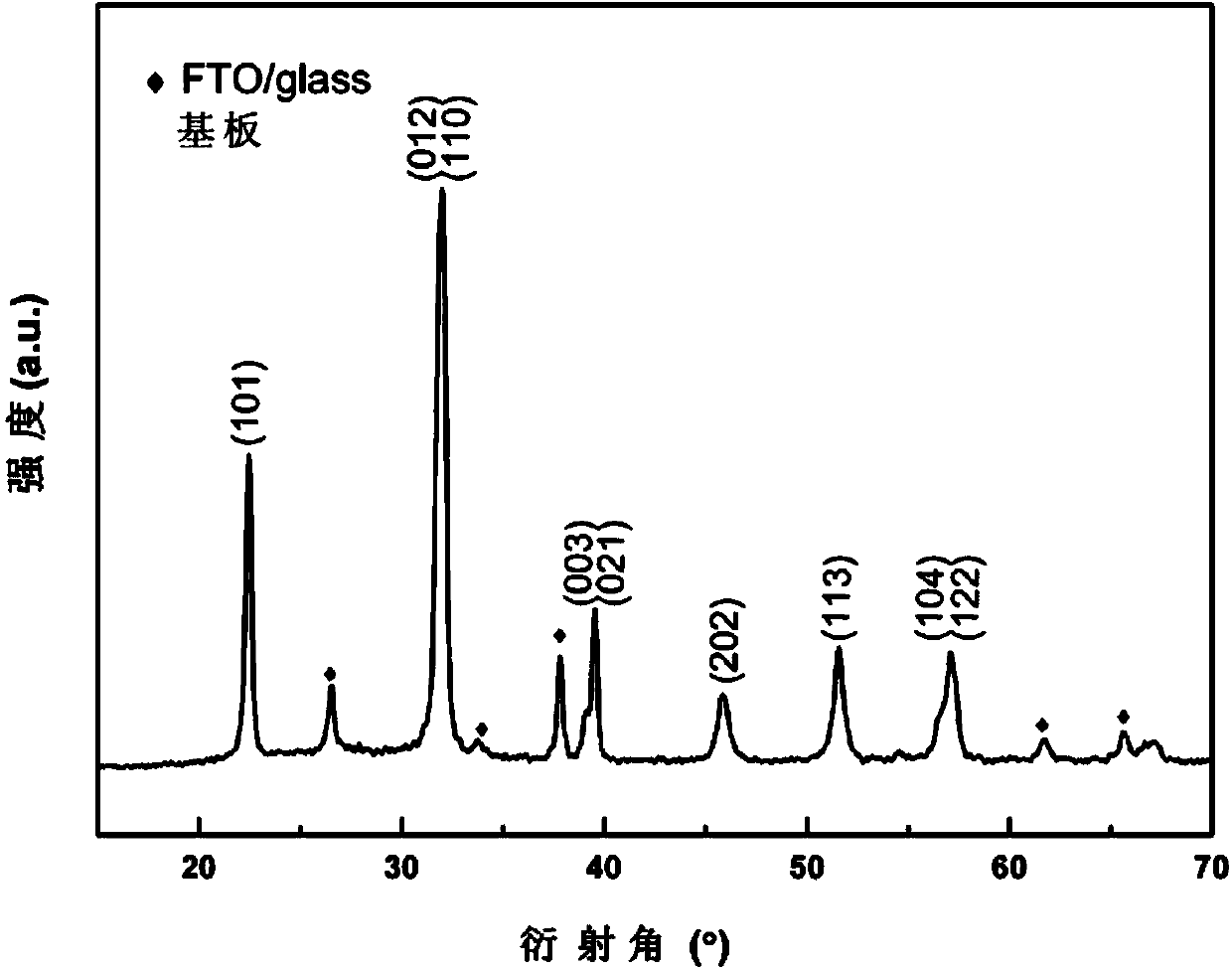

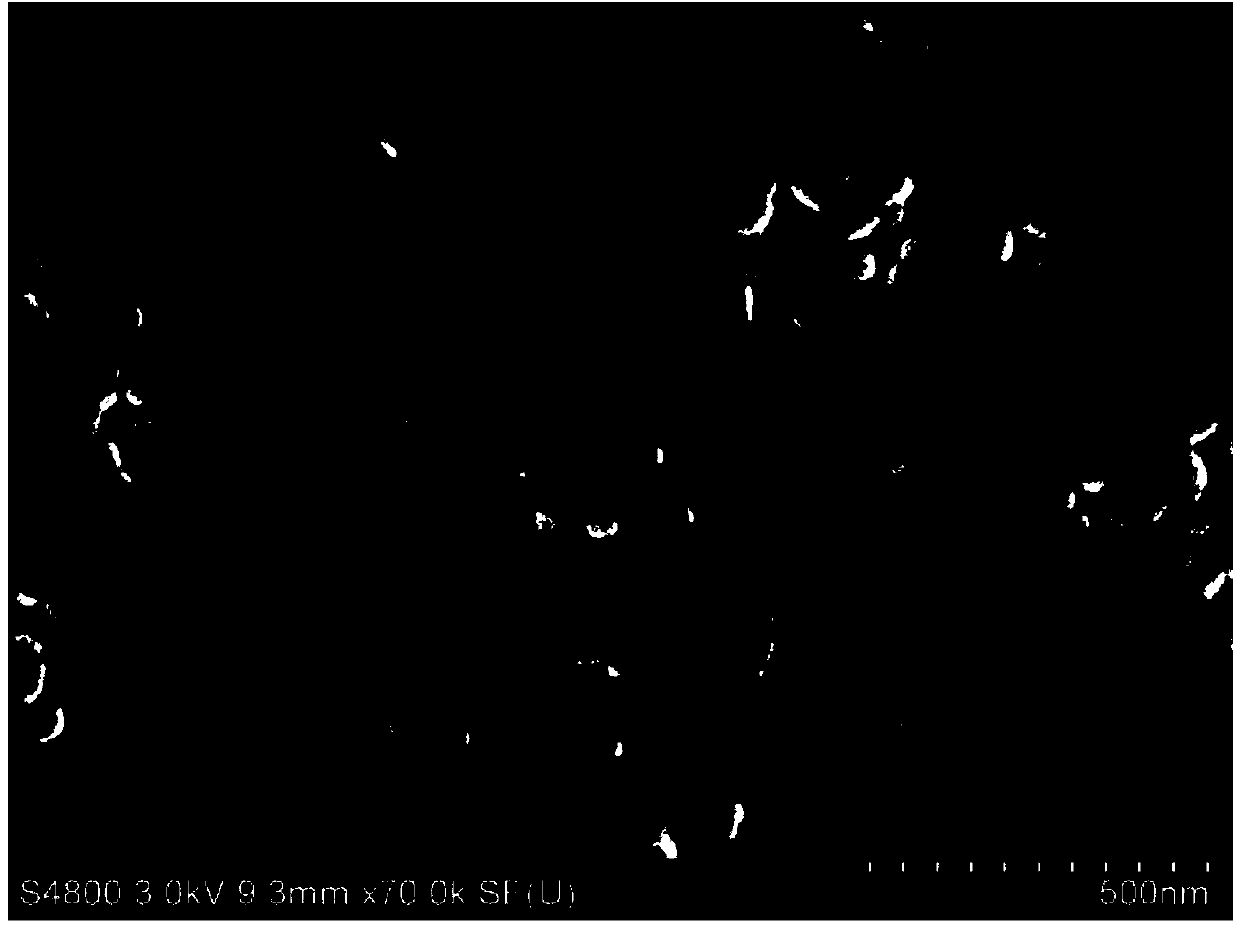

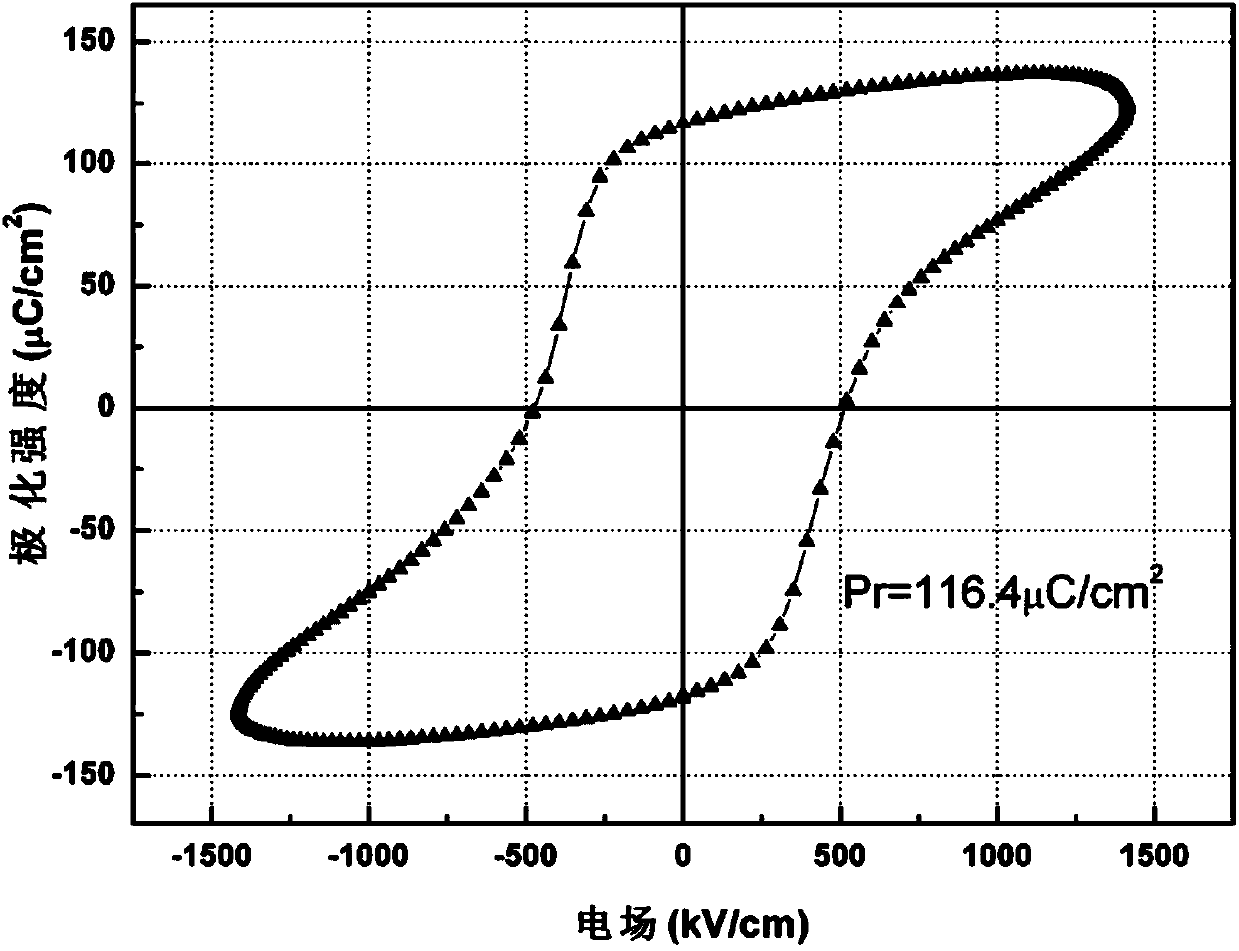

GdSrMnCo codoped bismuth ferrite multiferroic film and making method thereof

ActiveCN107032631AGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a GdSrMnCo codoped bismuth ferrite multiferroic film and a making method thereof. The Bi0.97-xGdxSr0.03Fe0.94Mn0.04Co0.02O3 multiferroic film that is the GdSrMnCo codoped bismuth ferrite multiferroic film is made from bismuth nitrate, gadolinium nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate (5% excessive bismuth nitrate) through a spin coating technology and a layer-by-layer annealing technology by using ethylene glycol monomethyl ether and acetic anhydride as a solvent. The method which adopts a sol-gel process and the spin coating and layer-by-layer annealing technologies has the advantages of simple device requirements, easiness in realization of experimental conditions, suitableness for making a film on a large surface and a surface with an irregular shape, accurate and controllable chemical components, and improvement of the multiferroic performance of a BiFeO3 film; and the produced GdSrMnCo codoped bismuth ferrite multiferroic film has good uniformity and has the ferroelectric stability changing with the applied voltage.

Owner:SHAANXI UNIV OF SCI & TECH

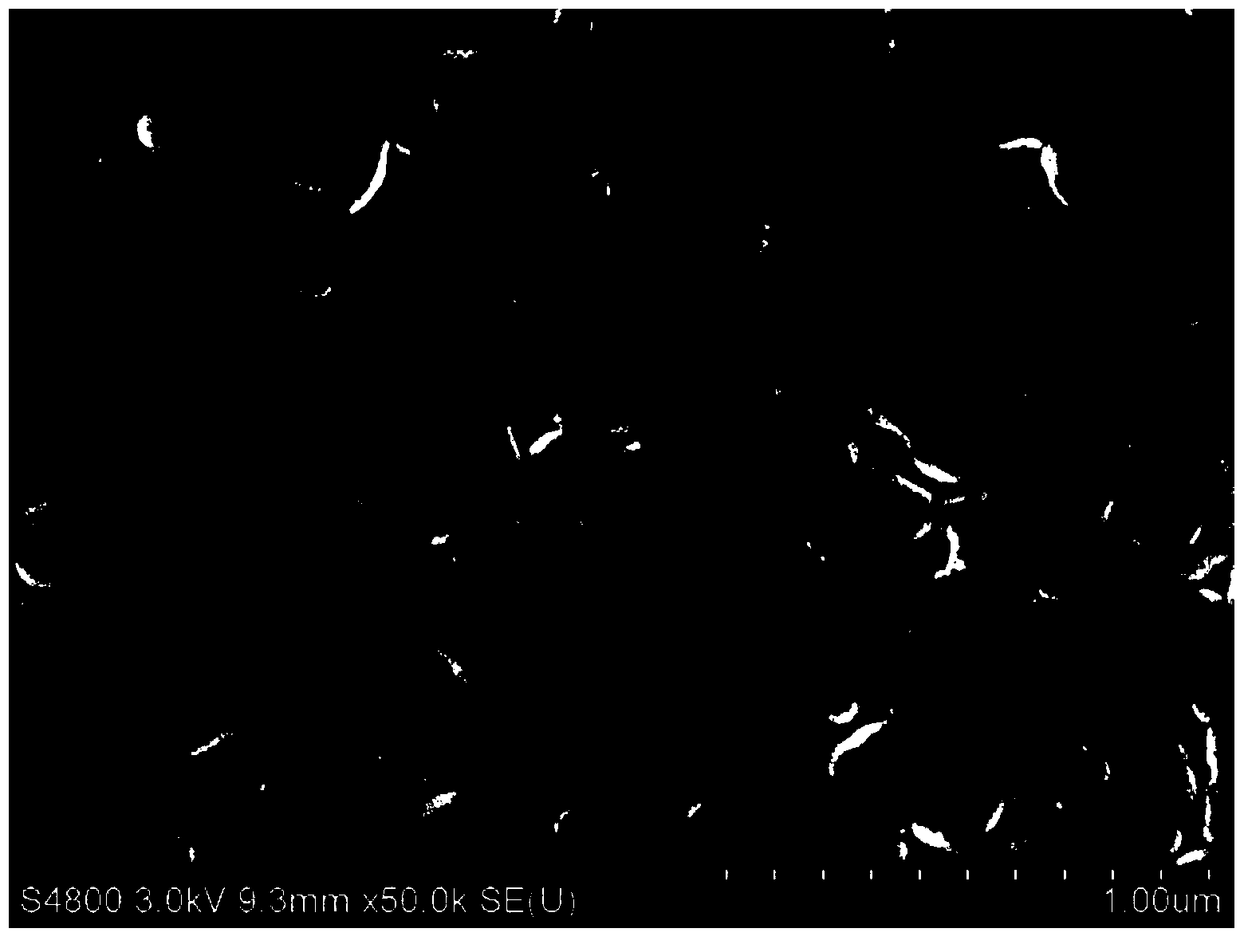

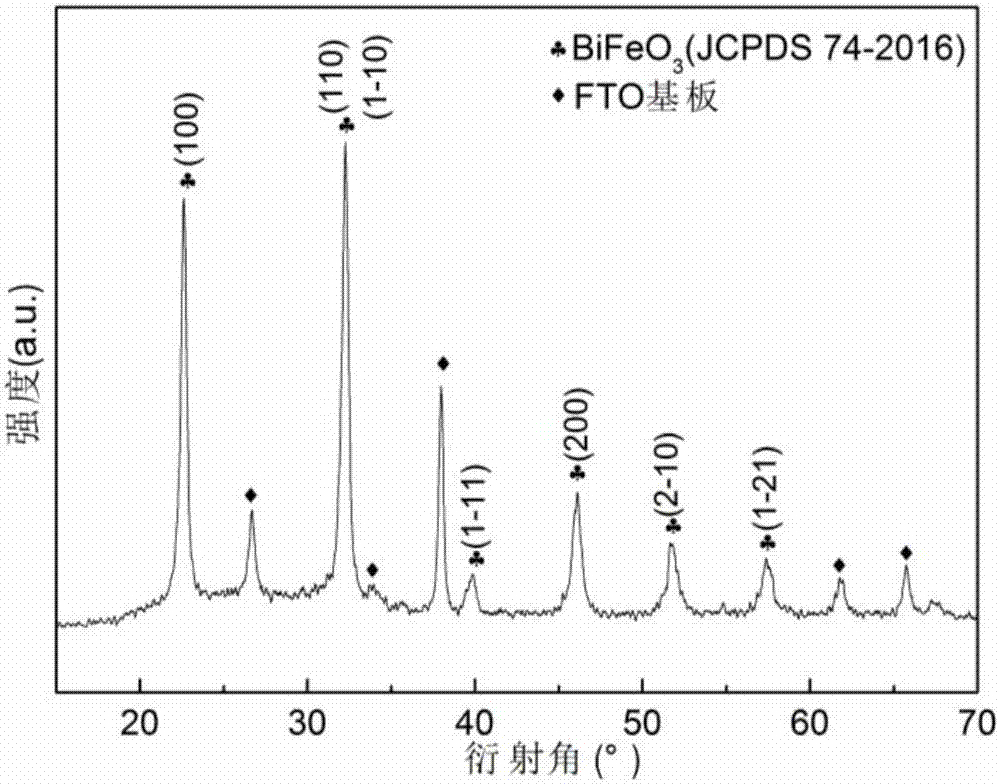

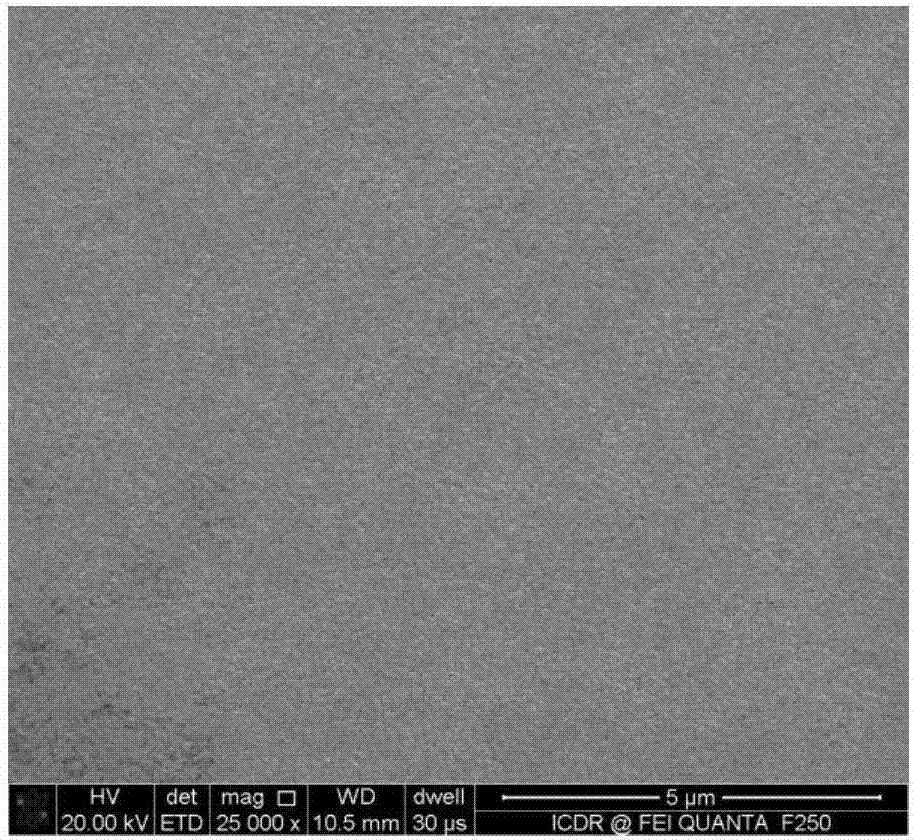

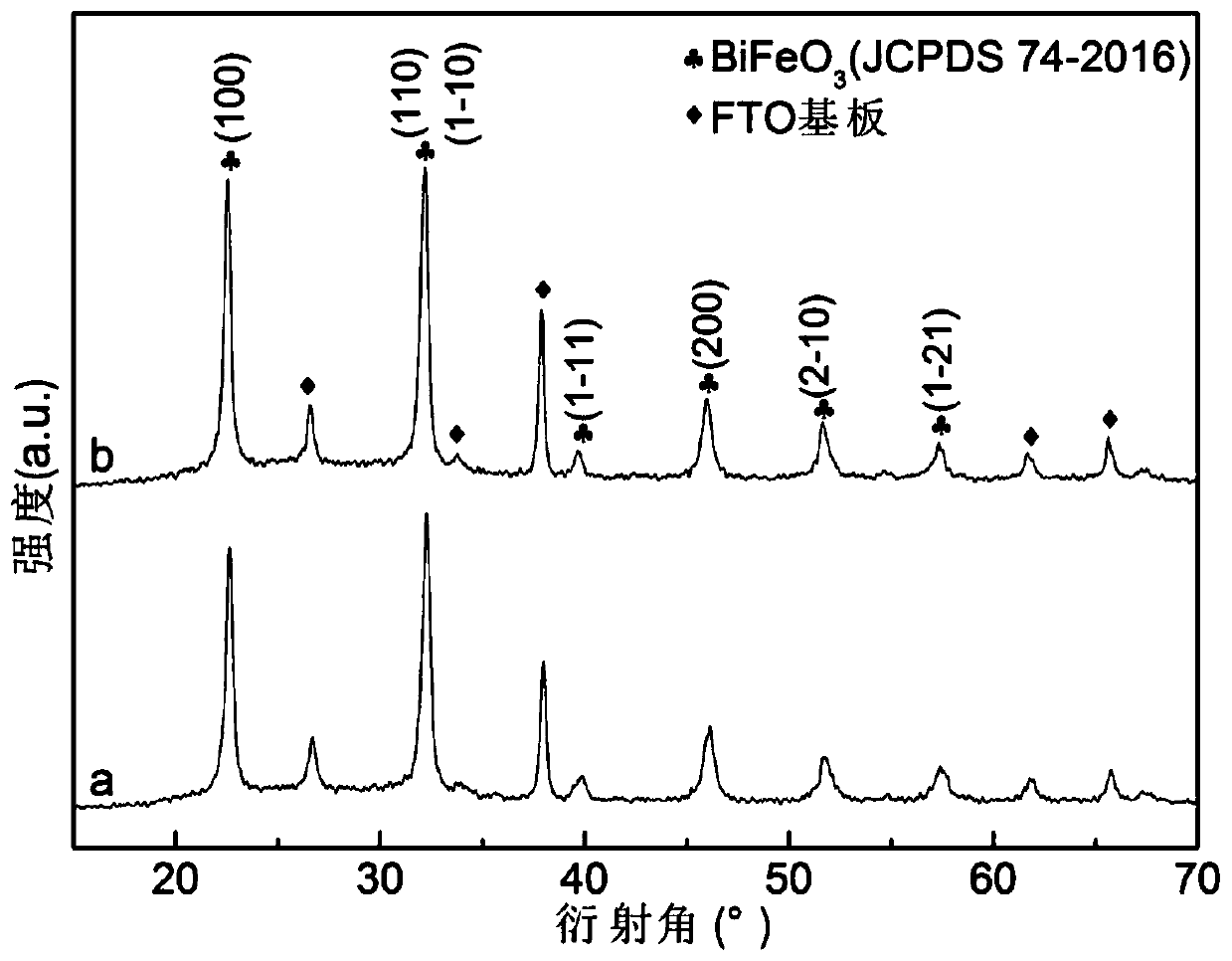

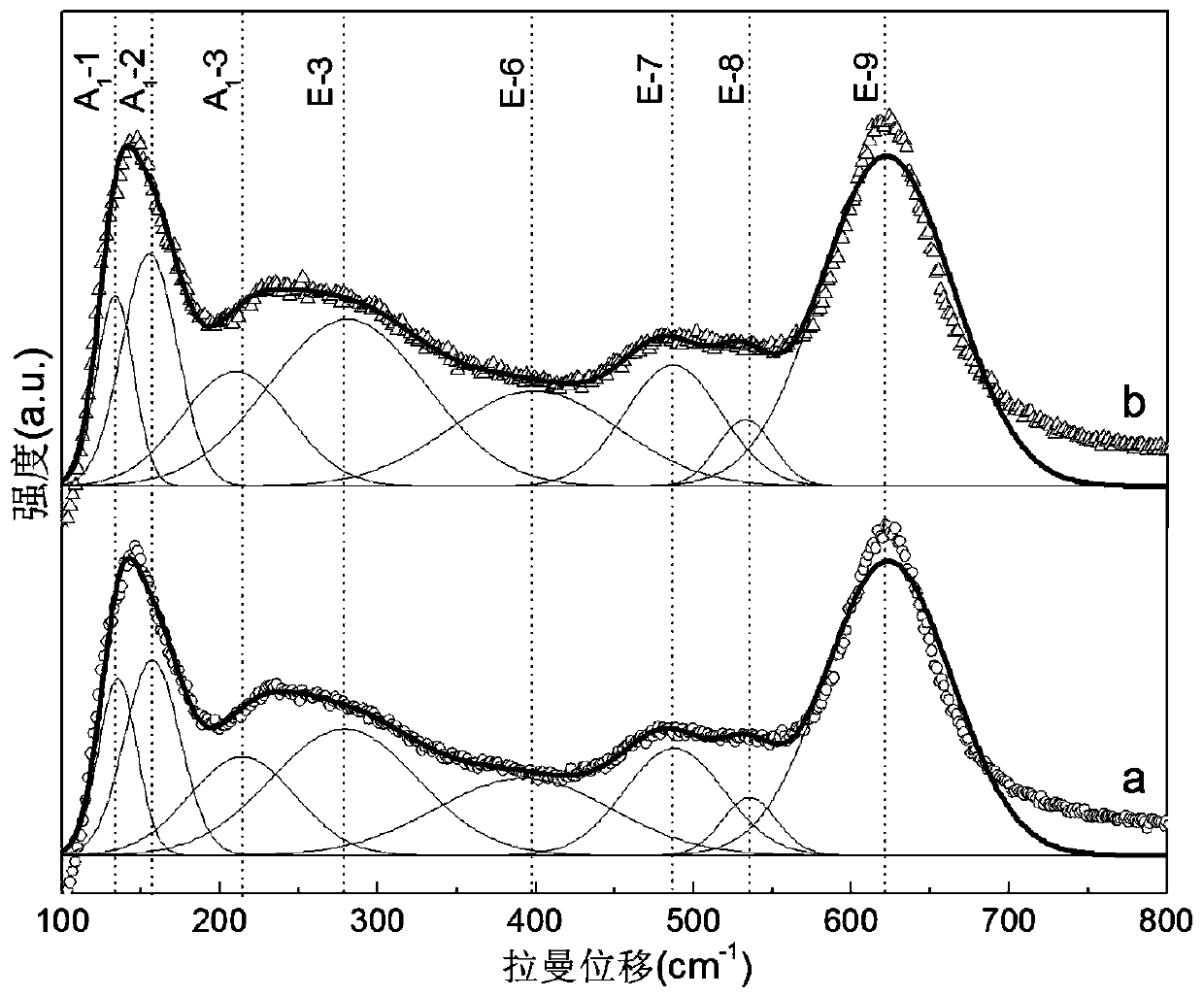

B-site Mn and Cu codoped high remanent polarization BiFeO3 film and preparation method

ActiveCN103613144AImprove multiferroic propertiesDistortionIron compoundsIonEthylene glycol monomethyl ether

The invention relates to a B-site Mn and Cu codoped high remanent polarization BiFeO3 film and a preparation method, the method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and cupric nitrate according to mol ratio of 1.05: [(0.92-0.98)-x]: (0.02-0.08):x in a mixed liquor of ethylene glycol monomethyl ether and acetic anhydride, then uniformly stirring to obtain a BiFeO3 precursor; wherein total metal ion concentration of the BiFeO3 precursor is 0.1-0.5mol / L, X is 0.01-0.03; performing spin coating of the BiFeO3 precursor on a FTO / glass substrate to prepare a wet membrane, baking the wet membrane to obtain a dry membrane, then annealing at 550 DEG C to obtain the crystalline state BiFeO3 film; cooling the crystalline state BiFeO3 film, and repeatedly making the crystalline state BiFeO3 film to reach a required thickness to obtain the B-site Mn and Cu codoped high remanent polarization BiFeO3 film. According to the invention, a sol gel technology is employed, the equipment requirement is simple, the film is prepared on large surface and surfaces with irregular shapes, the chemical component is accurate and controllable, and the regulation and control to its crystal structure can be carried out by codoping thereby the ferroelectric performance of the film is greatly increased.

Owner:盐城梦心缘鞋服有限公司

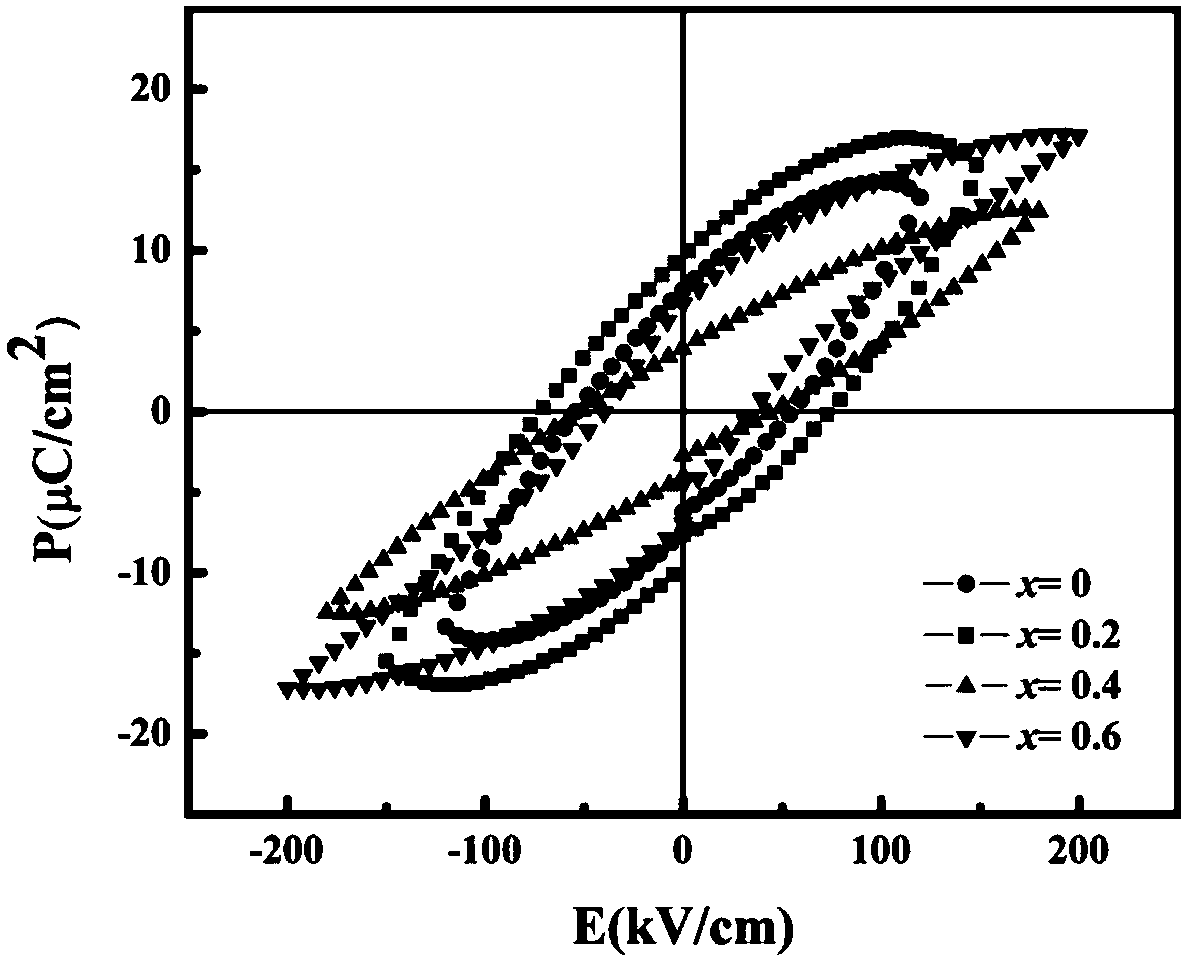

Novel room-temperature multi-ferroic ceramic with high polarization intensity and preparation method of novel room-temperature multi-ferroic ceramic

ActiveCN106242546AImprove ferromagnetic propertiesImprove ferroelectric propertiesChemical compositionRoom temperature

The invention relates to novel room-temperature multi-ferroic ceramic with high polarization intensity and a preparation method of the novel room-temperature multi-ferroic ceramic. The chemical composition of a room-temperature multi-ferroic ceramic material is 0.75 ((1-x)BiFeO<3>-xBiGaO<3>)-0.25Ba<0.85>Ca<0.15>Ti<0.90>Zr<0.10>O3 +yMnCO<3>, wherein x is greater than 0 and is smaller than or equal to 0.05, and y is smaller than or equal to 0.5wt%. By adjusting and controlling components, the novel room-temperature multi-ferroic ceramic material simultaneously having excellent ferromagnetism and excellent ferroelectricity is obtained, and has high remanent polarization intensity (22-44 [mu]C / cm<2>) and high ferromagnetism properties (0.09-0.27emu / g).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

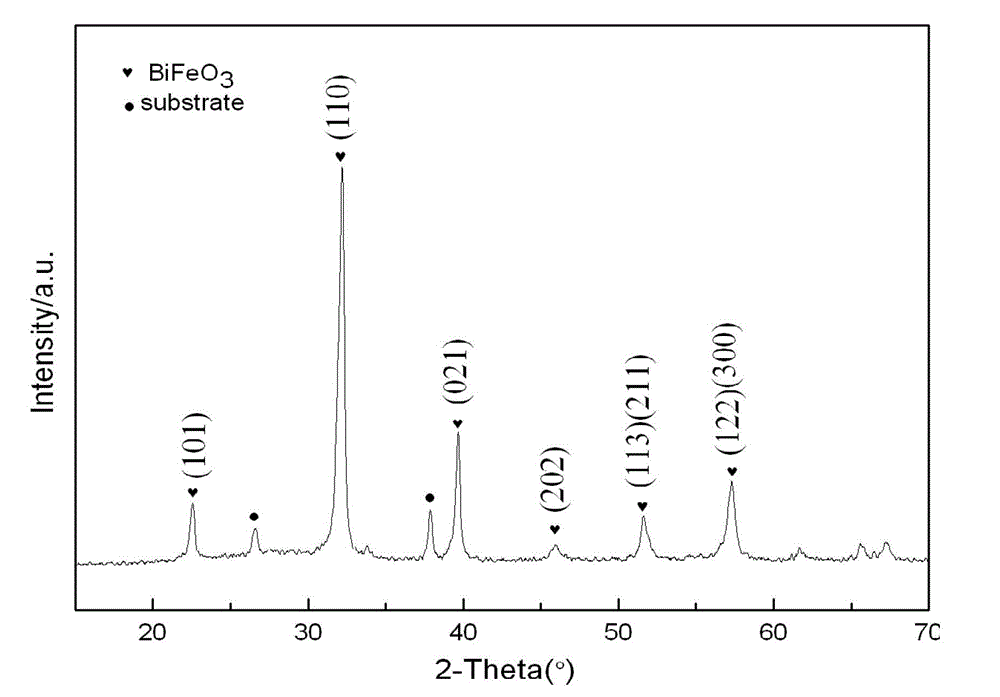

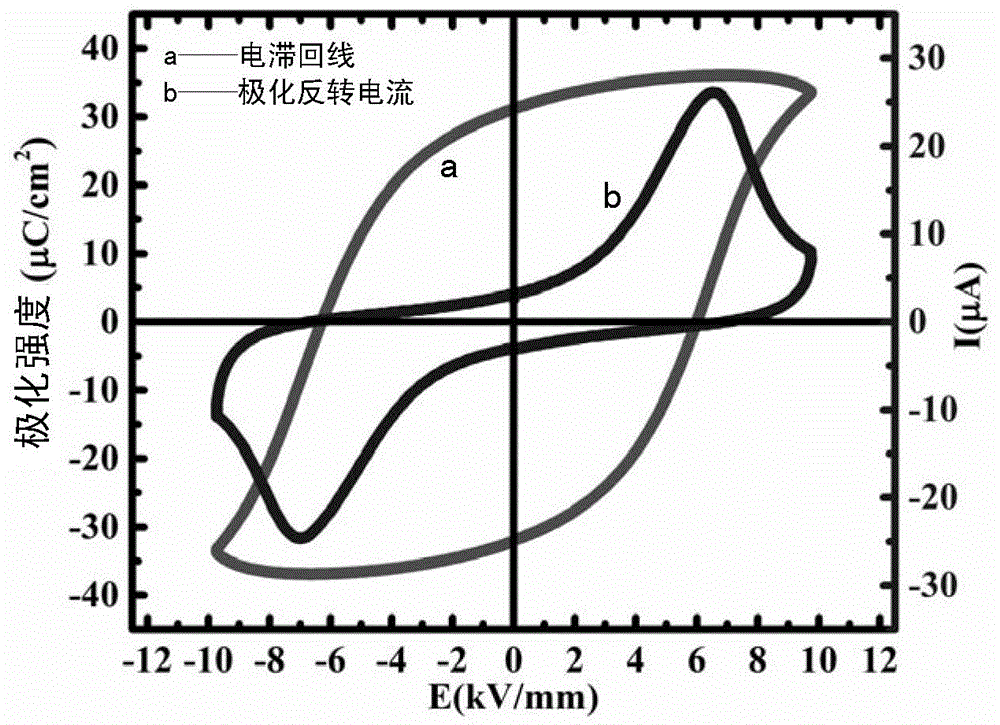

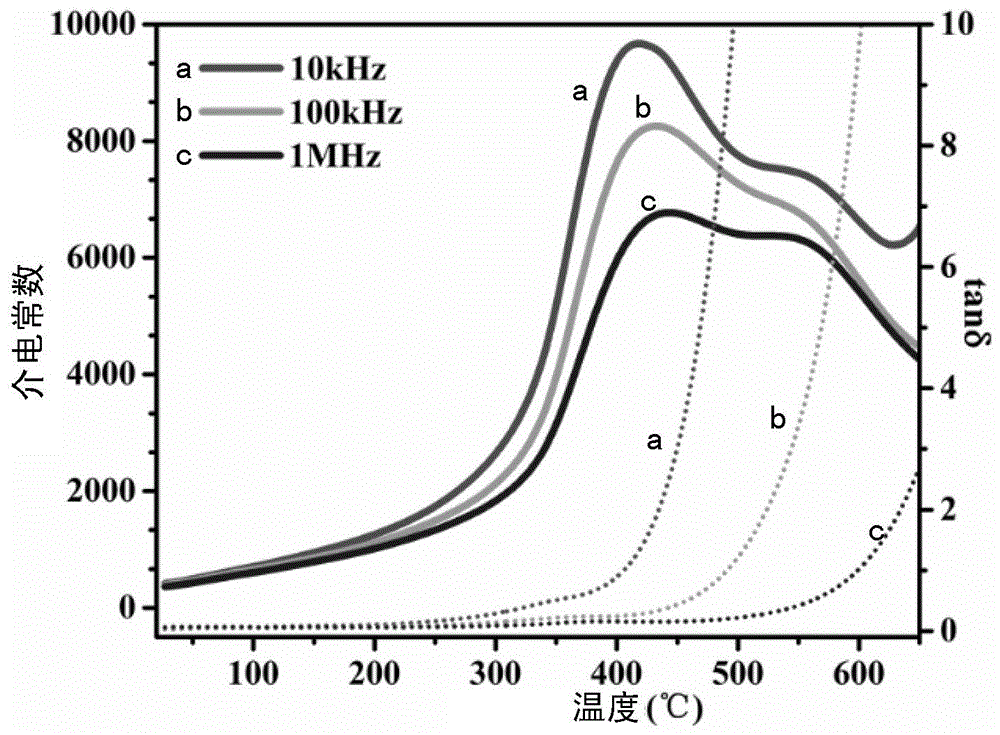

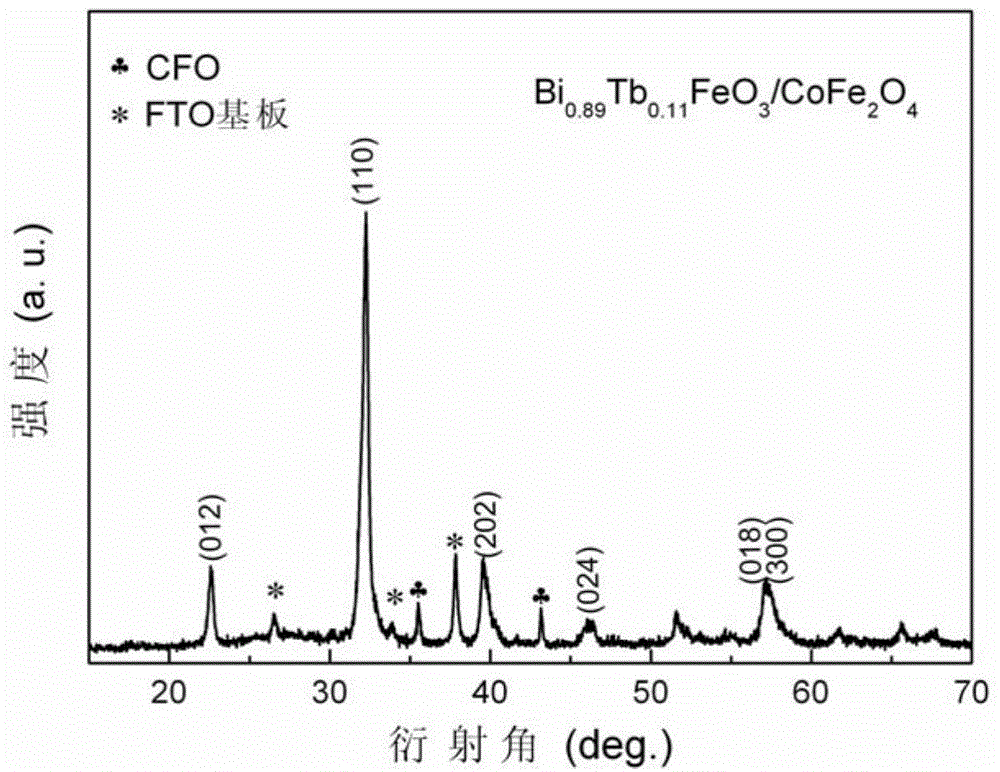

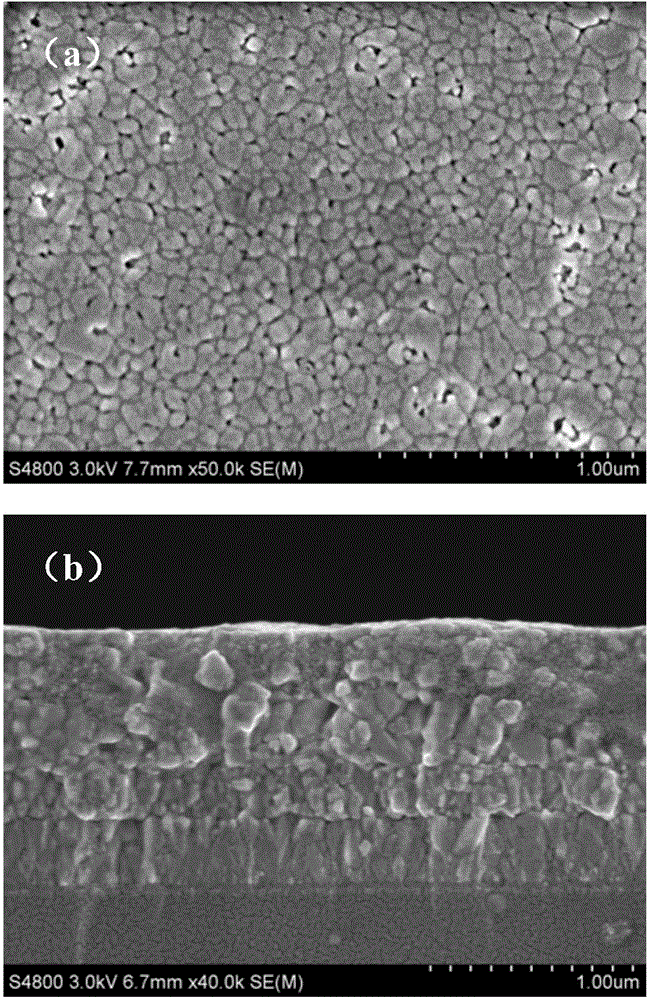

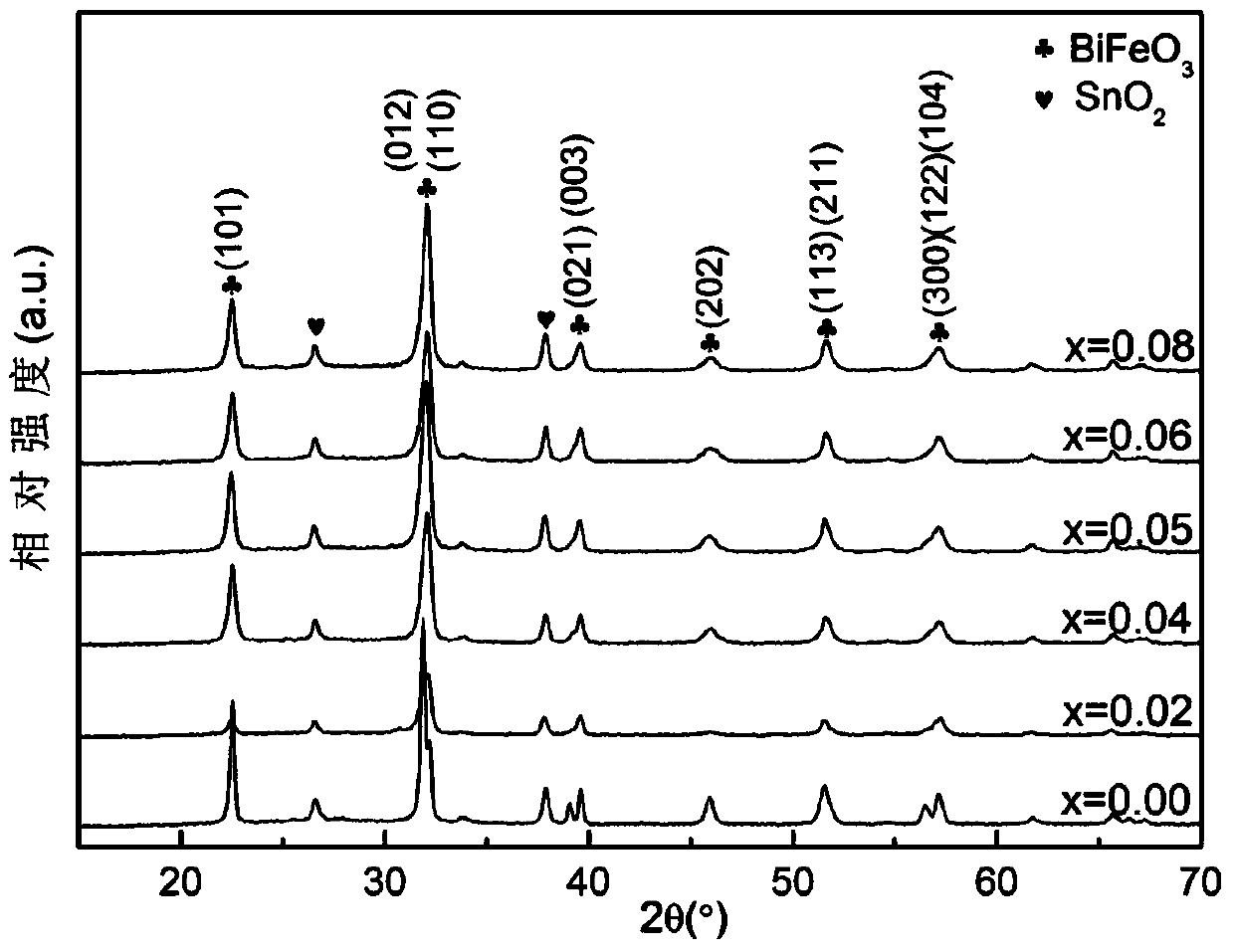

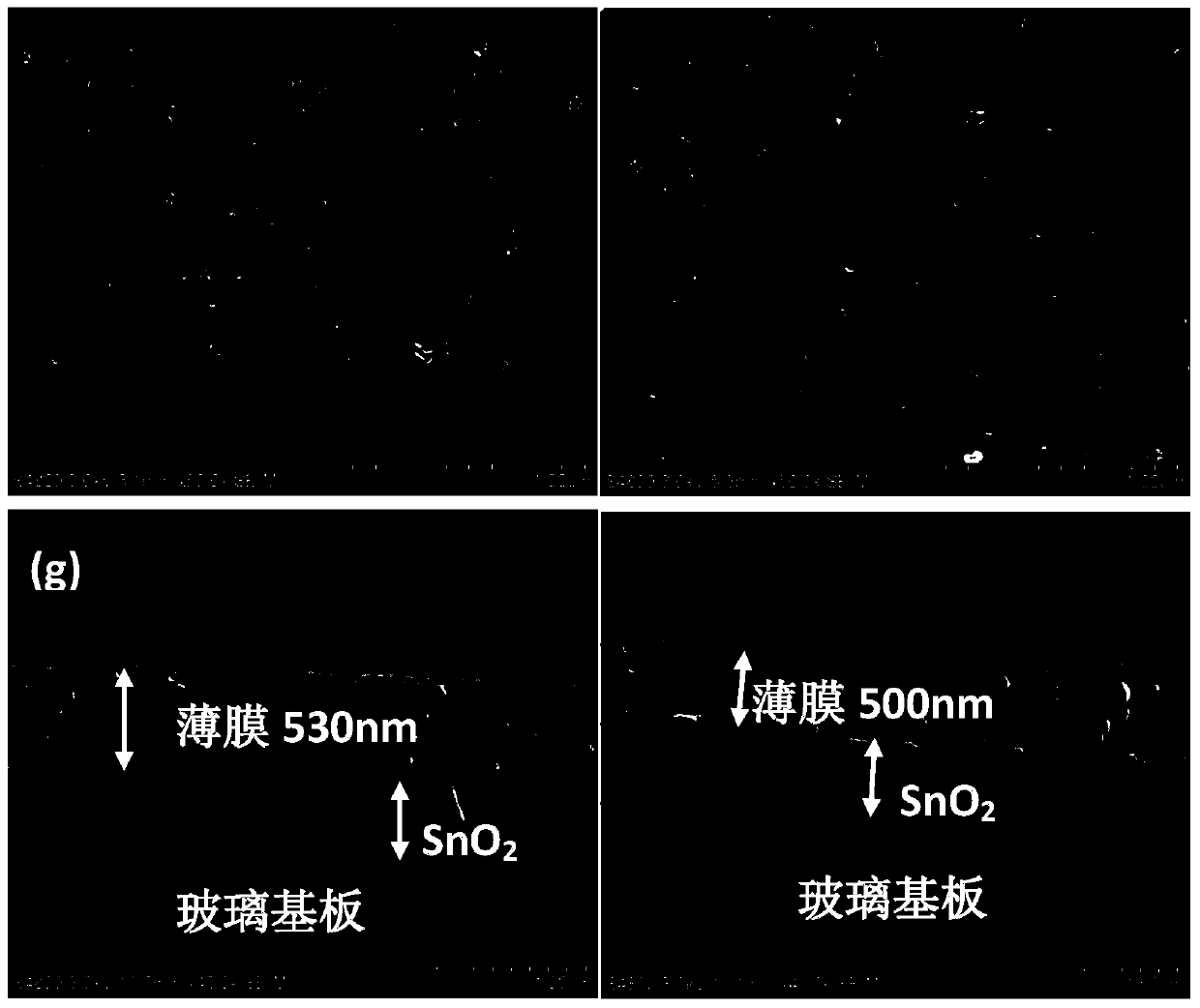

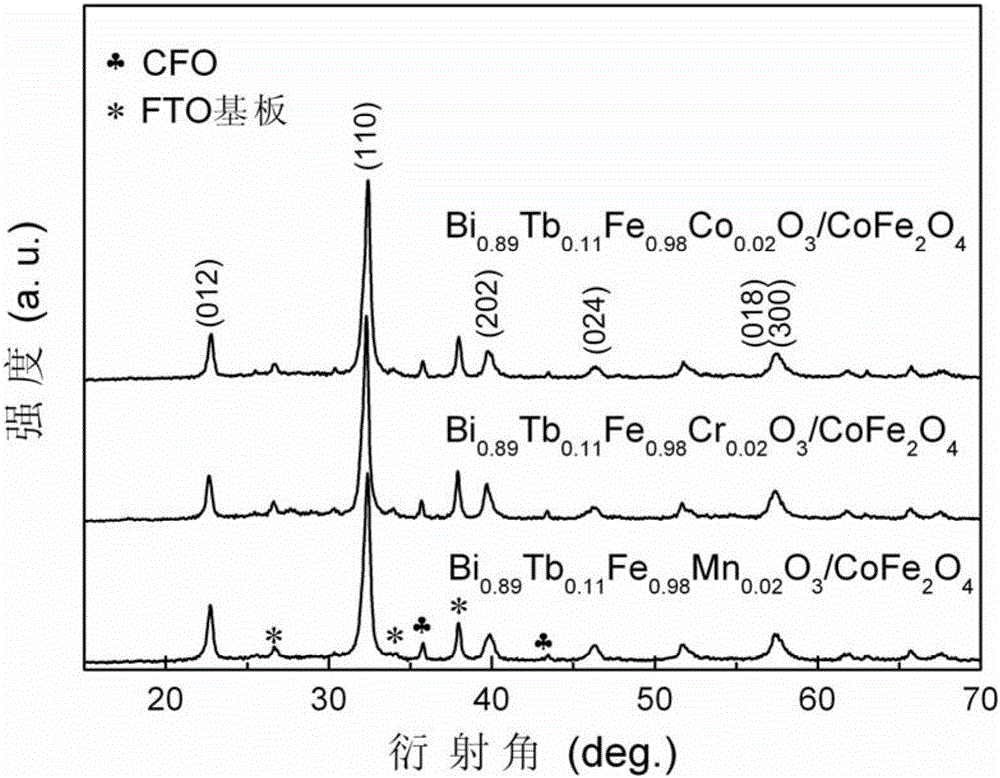

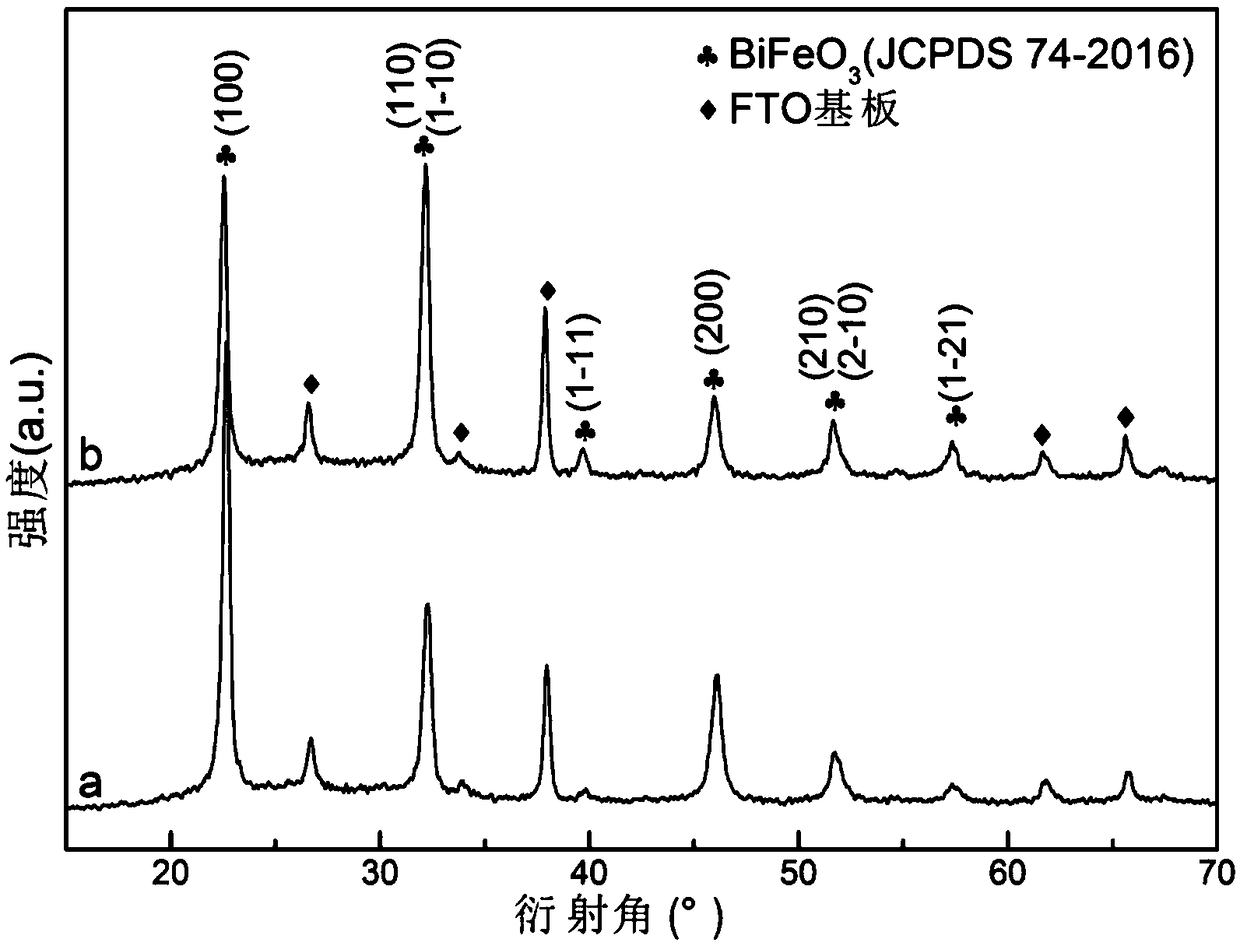

Bi1-xRExFeO3/CoFe2O4 multiferroic composite membrane and preparation method thereof

ActiveCN104538139APrecise and controllable chemical compositionSimple equipment requirementsInorganic material magnetismInductances/transformers/magnets manufactureChemistryChemical composition

The invention provides a Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane and a preparation method thereof. The composite membrane comprises a Bi1-xRExFeO3 crystalline state membrane and a CoFe2O4 crystalline state membrane which are combined together, wherein RE is Ce, Pr, Tb, Eu or Yb, x is equal to 0.05-0.15; in the preparation, Bi1-xRExFeO3 precursor solution and CoFe2O4 precursor solution are firstly prepared respectively; and then, multi-layer CoFe2O4 membrane is prepared by spinning on a substrate, and the multi-layer Bi1-xRExFeO3 membrane is prepared by spinning on the CoFe2O4 membrane, so the target product is obtained. The facility request is simple, the homogeneity of the prepared membrane is good, the chemical composition can be accurately controlled, the doping content is easily controlled, and the ferroelectric property and ferromagnetic property of the membrane are greatly improved, so the Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

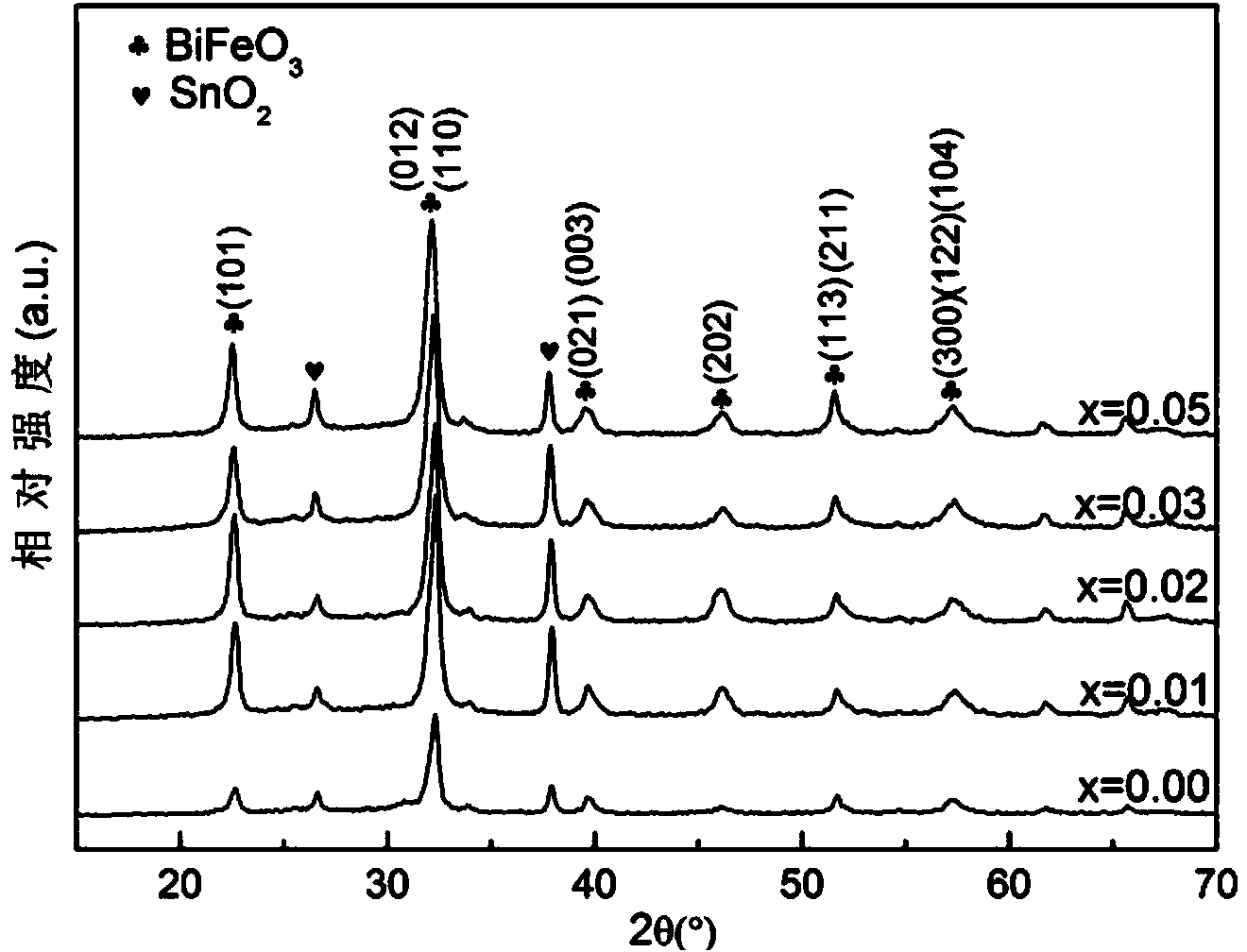

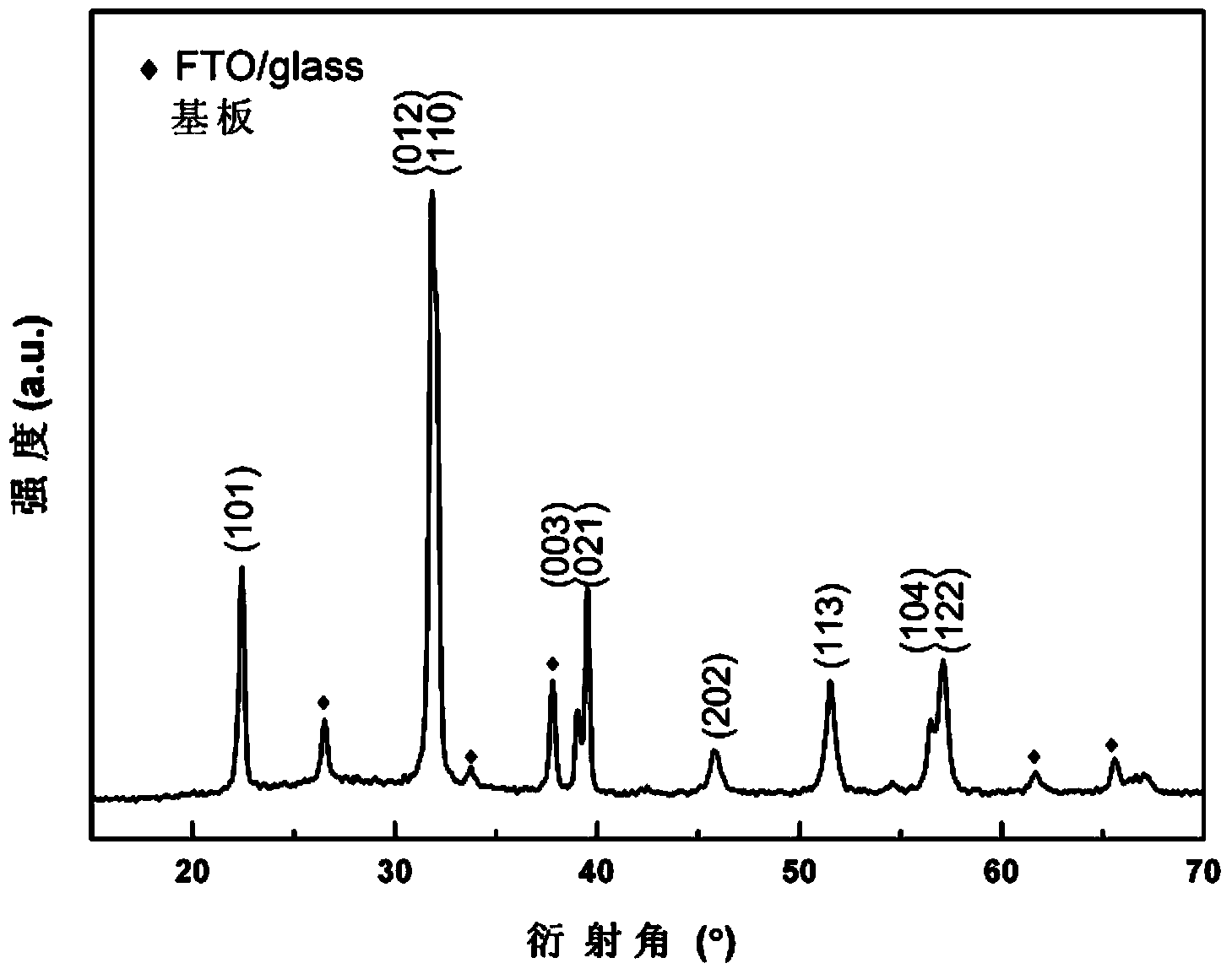

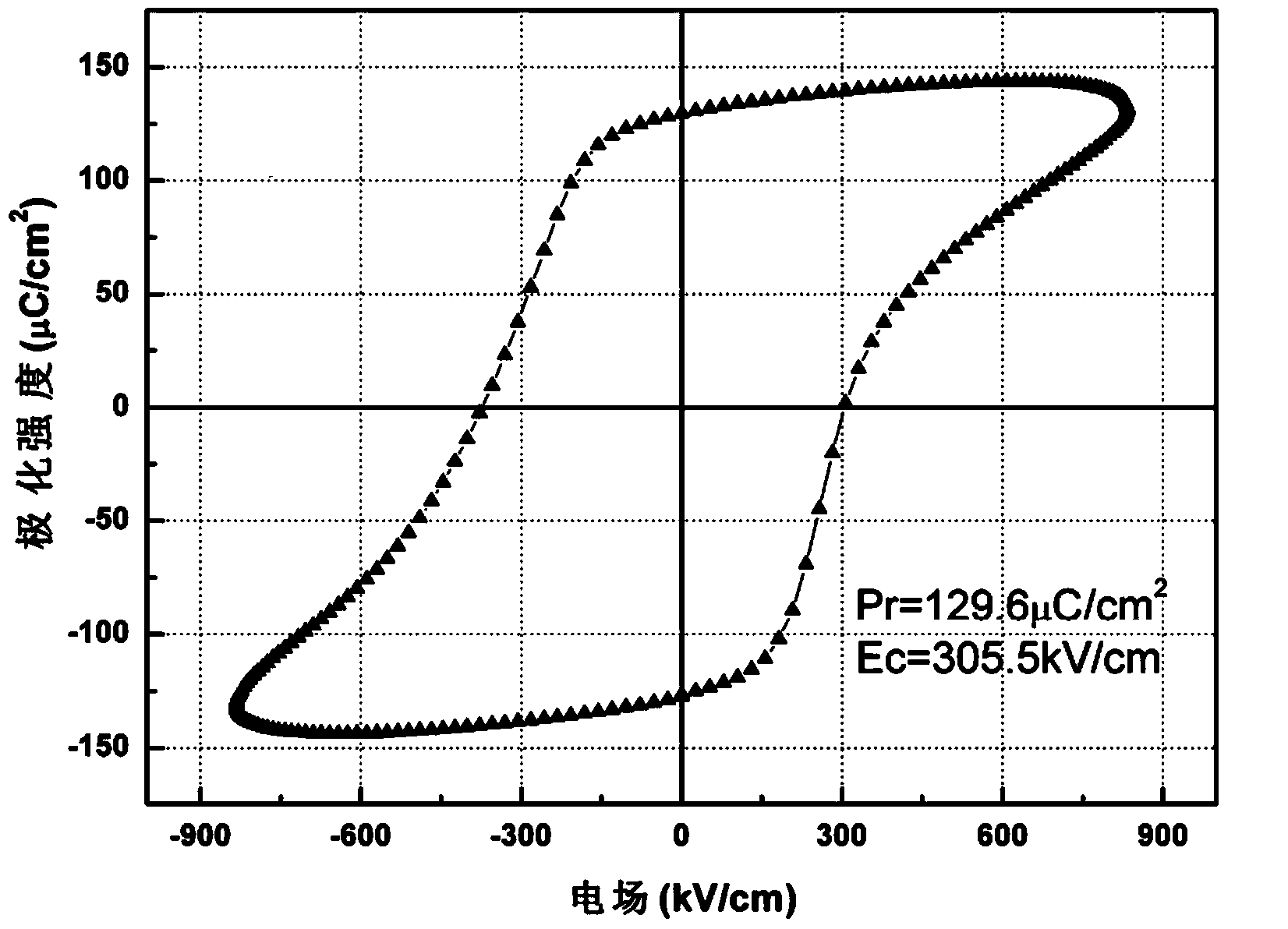

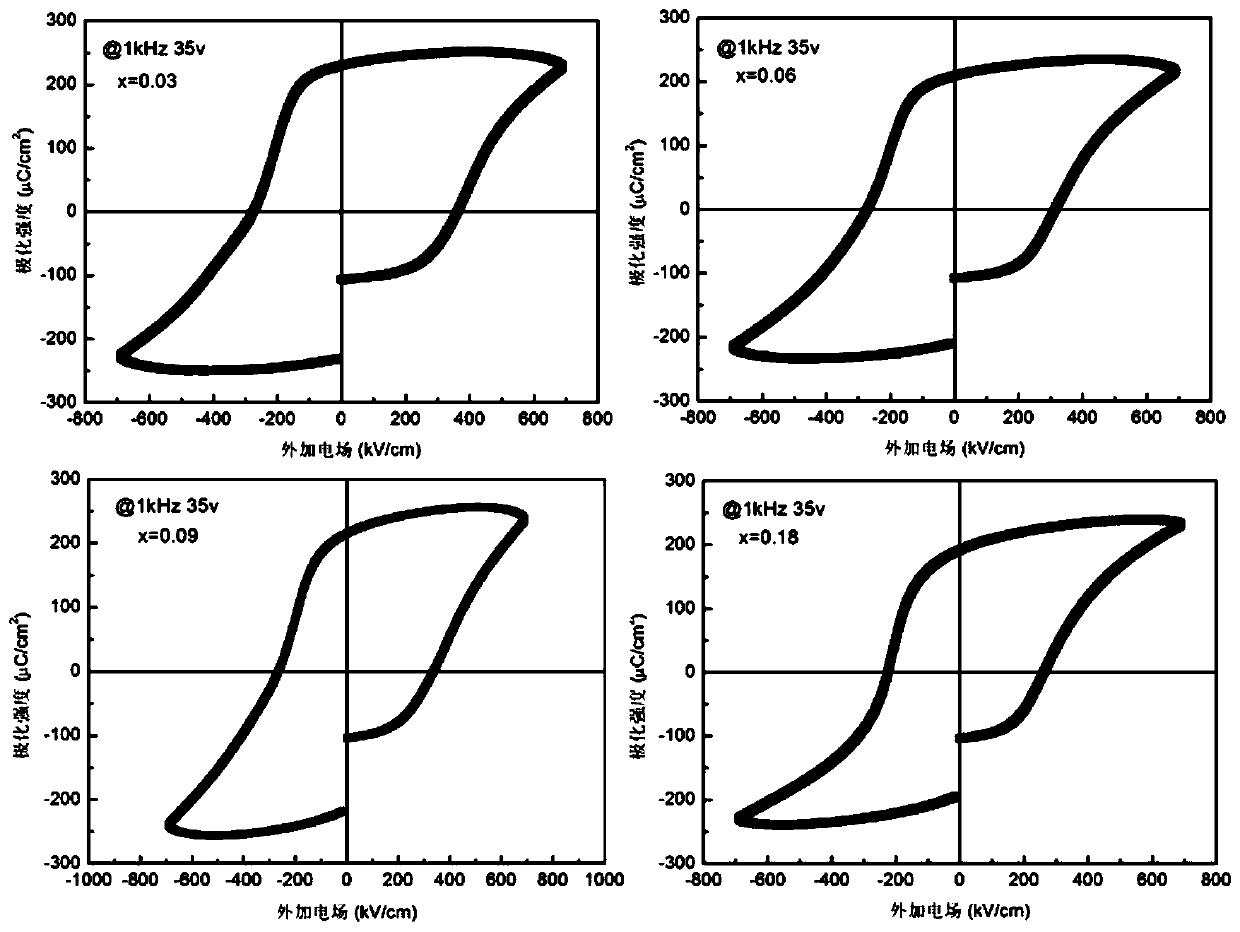

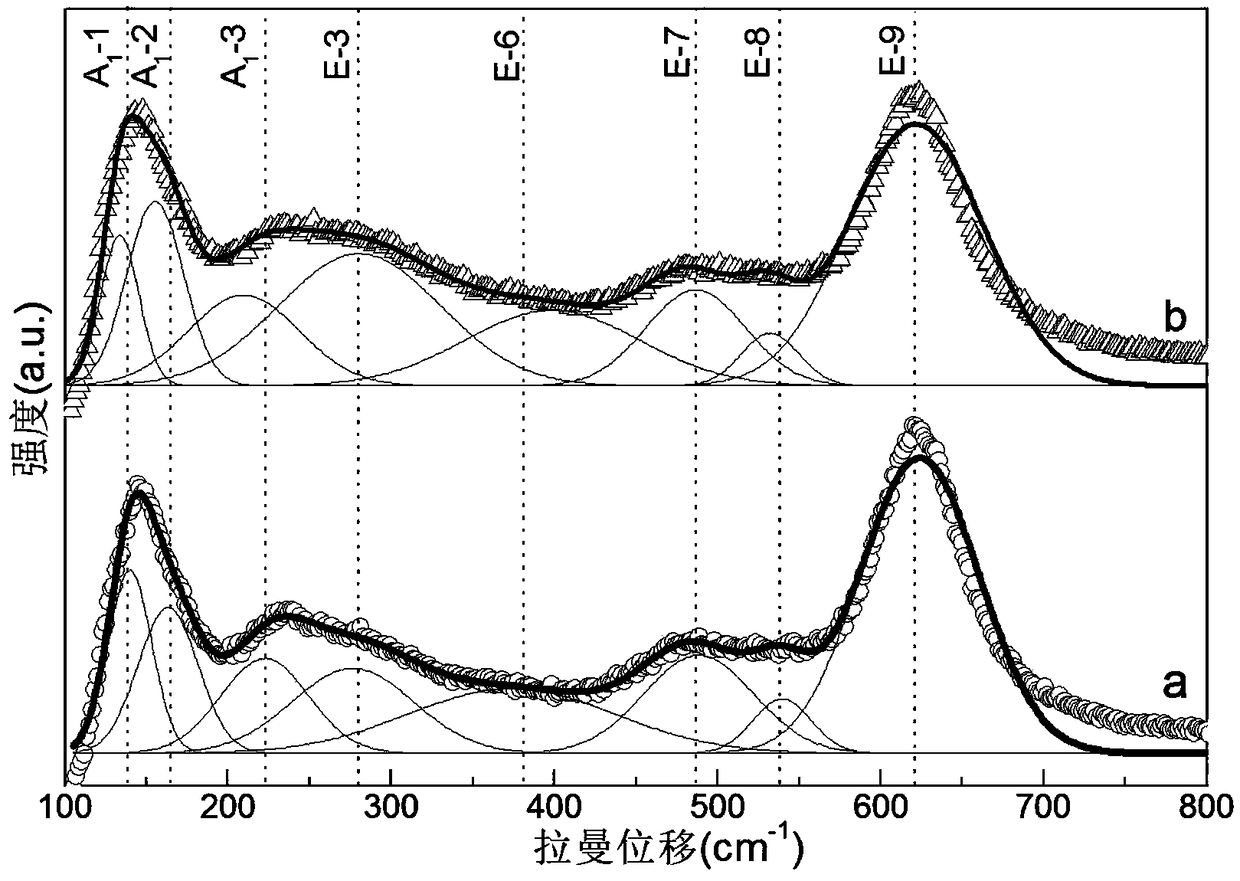

BiFe1-XMnXO3 ferroelectric film with high remnant polarization and preparation method thereof

ActiveCN103739019AImprove electrical performanceInhibition of price changeIron compoundsAcetic acidMANGANESE ACETATE

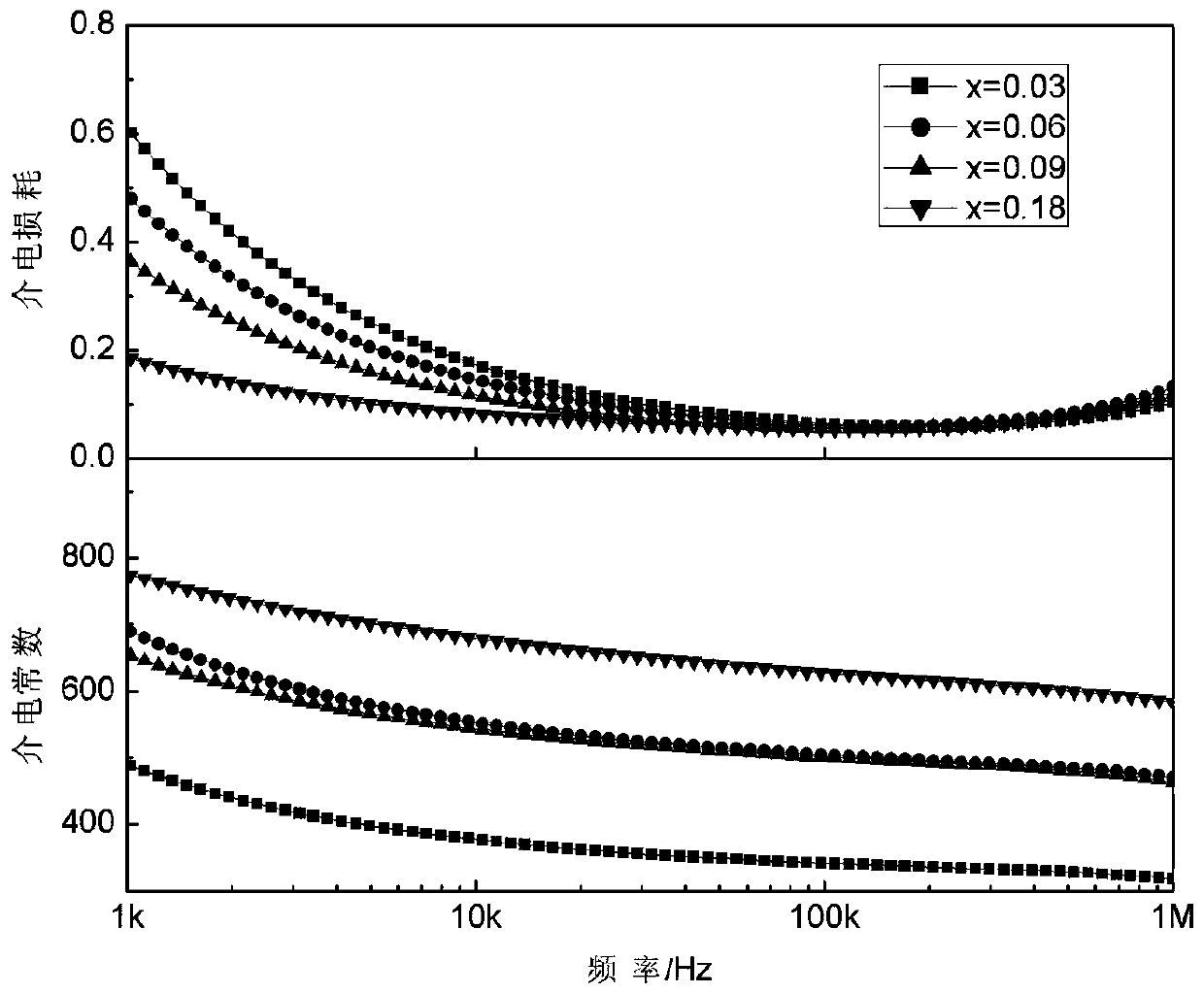

The invention discloses a BiFe1-XMnXO3 ferroelectric film with high remnant polarization and a preparation method thereof, and x is equal to 0.02-0.08. The BiFe1-XMnXO3 ferroelectric film is of a twisty perovskite structure, belongs to a rhombohedral system, and is good in uniformity. At the frequency of 1kHz, the remnant polarization is 100-130.4mu C / cm<2>. The preparation method comprises the steps of: dissolving bismuth nitrate, ferric nitrate and manganese acetate in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride according to a molar ratio of 1.05:(1-x) to obtain a precursor solution; and spinning the precursor solution on a substrate, homogenating and baking to obtain a dry film; annealing to obtain the BiFe1-XMnXO3 ferroelectric film, repeatedly carrying out the steps of spinning the precursor solution, baking, and annealing till a required film thickness is reached, thus obtainng the BiFe1-XMnXO3 ferroelectric film with high remnant polarization. The BiFe1-XMnXO3 ferroelectric film is simple in requirement of equipment, easily controllable in doping amount, and capable of greatly improving ferroelectric properties and dielectric properties of a BiFeO3 film.

Owner:SHAANXI UNIV OF SCI & TECH

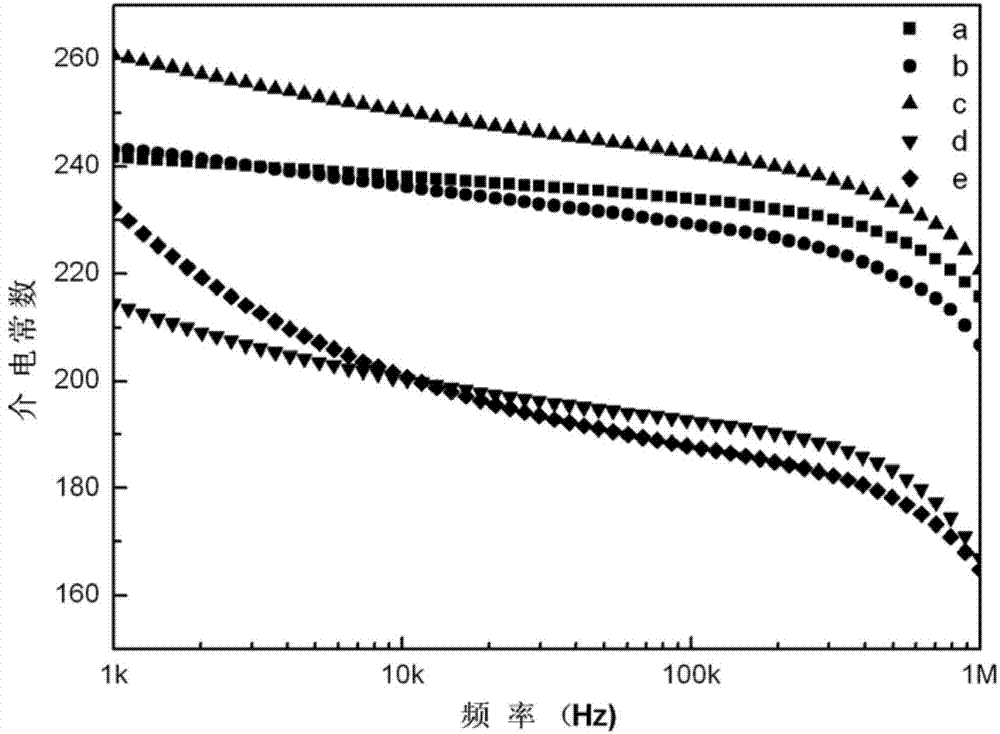

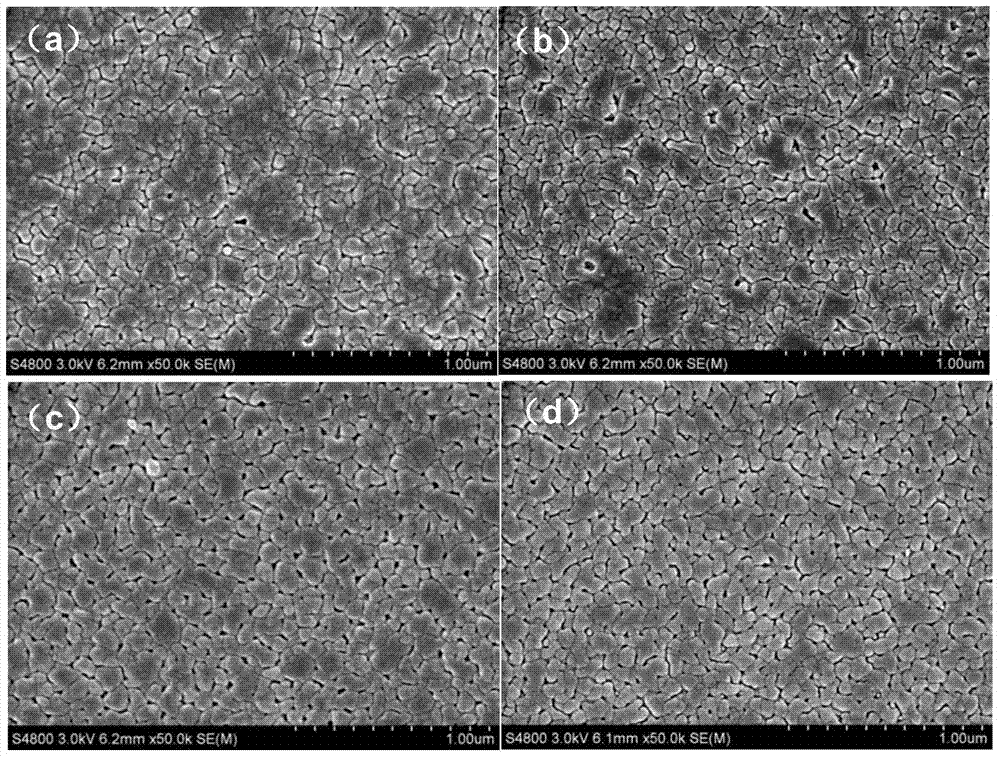

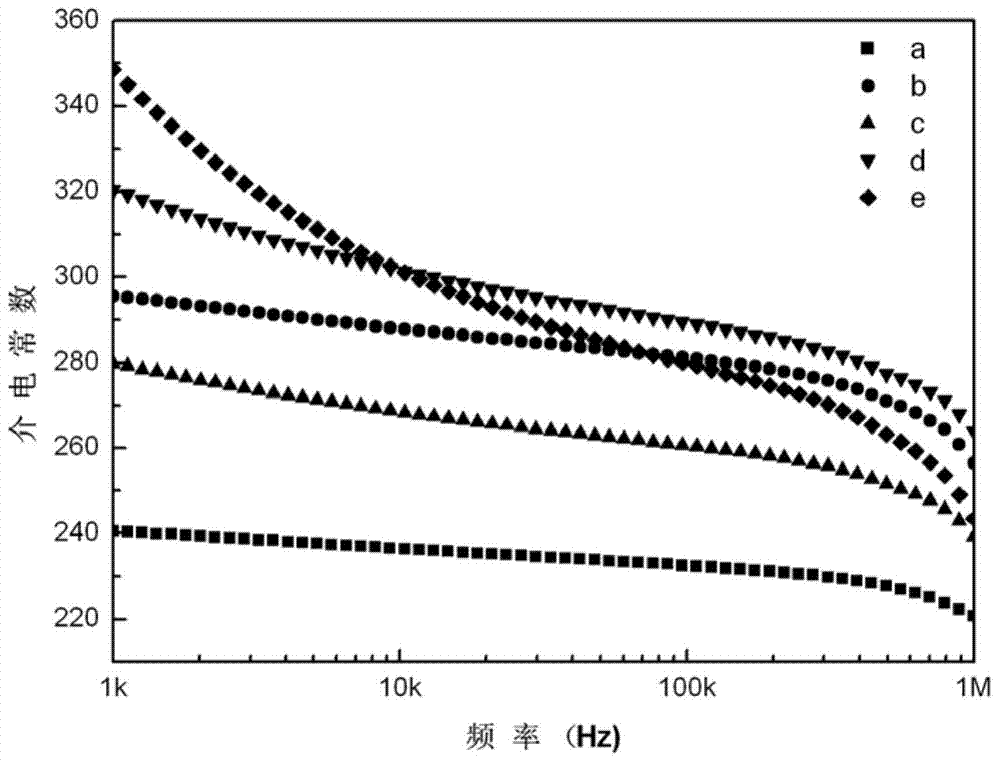

Bi0.90Dy0.10Fe1-XMnxO3 ferroelectric film with high dielectric constant, and preparation method for Bi0.90Dy0.10Fe1-XMnxO3 ferroelectric film with high dielectric constant

ActiveCN103663564AReduce volatilityImprove insulation performanceIron compoundsCooking & bakingDielectric

The invention provides a Bi0.90Dy0.10Fe1-XMnxO3 ferroelectric film with a high dielectric constant, and a preparation method for the Bi0.90Dy0.10Fe1-XMnxO3 ferroelectric film with the high dielectric constant. The film adopts a rhombohedral structure and has high homogeneity, the remanent polarization ranges from 59.3 [mu]C / cm<2> to 95.2 [mu]C / cm<2>, the coercive field ranges from 280 kV / cm to 368 kV / cm, and the high dielectric constant ranges from 239.2 to 348.57. The preparation method includes the following steps: bismuth nitrate, ferric nitrate, dysprosium nitrate and manganese acetate are dissolved in a mixed liquor of ethylene glycol monomethyl ether and acetic anhydride, so as to obtain a precursor; a substrate is spin-coated with the precursor; glue evening and baking are carried out in sequence to obtain a dry film; the dry film is annealed to obtain a Bi0.90Dy0.10Fe1-XMnxO3 film; the procedures of precursor spin-coating, baking and annealing are repeated until a required film thickness is reached, so that the film is obtained. The ferroelectric film has the advantages of simple equipment requirements and high controllability of the doping amount; the dielectric properties of a BiFeO3 (bismuth ferrite) film can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

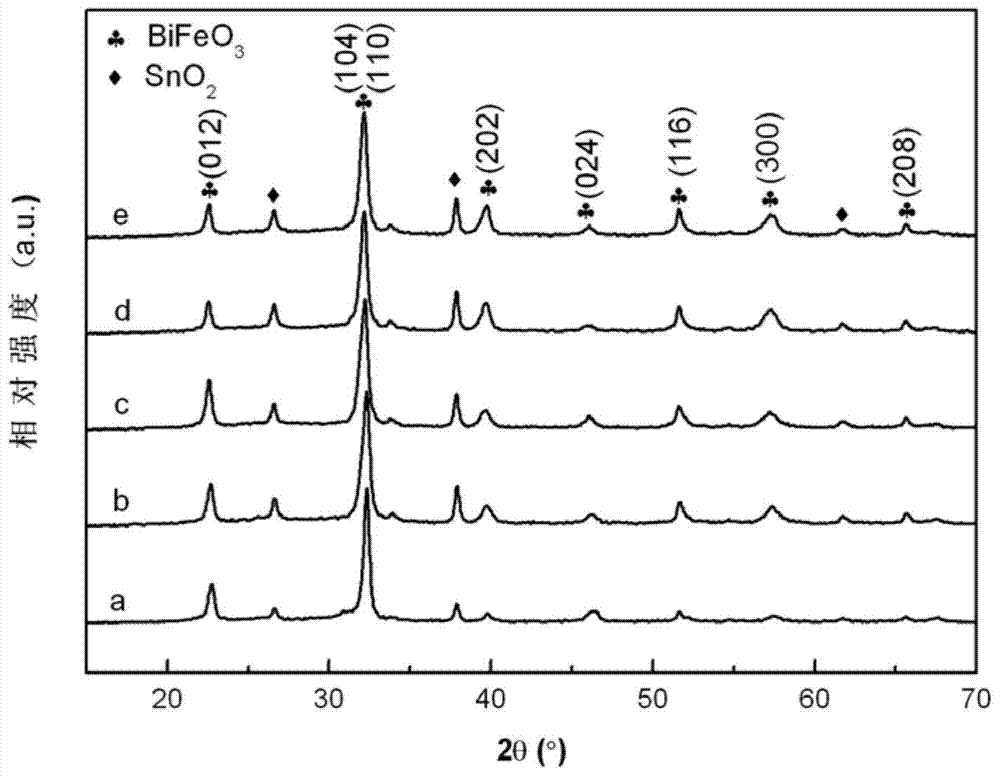

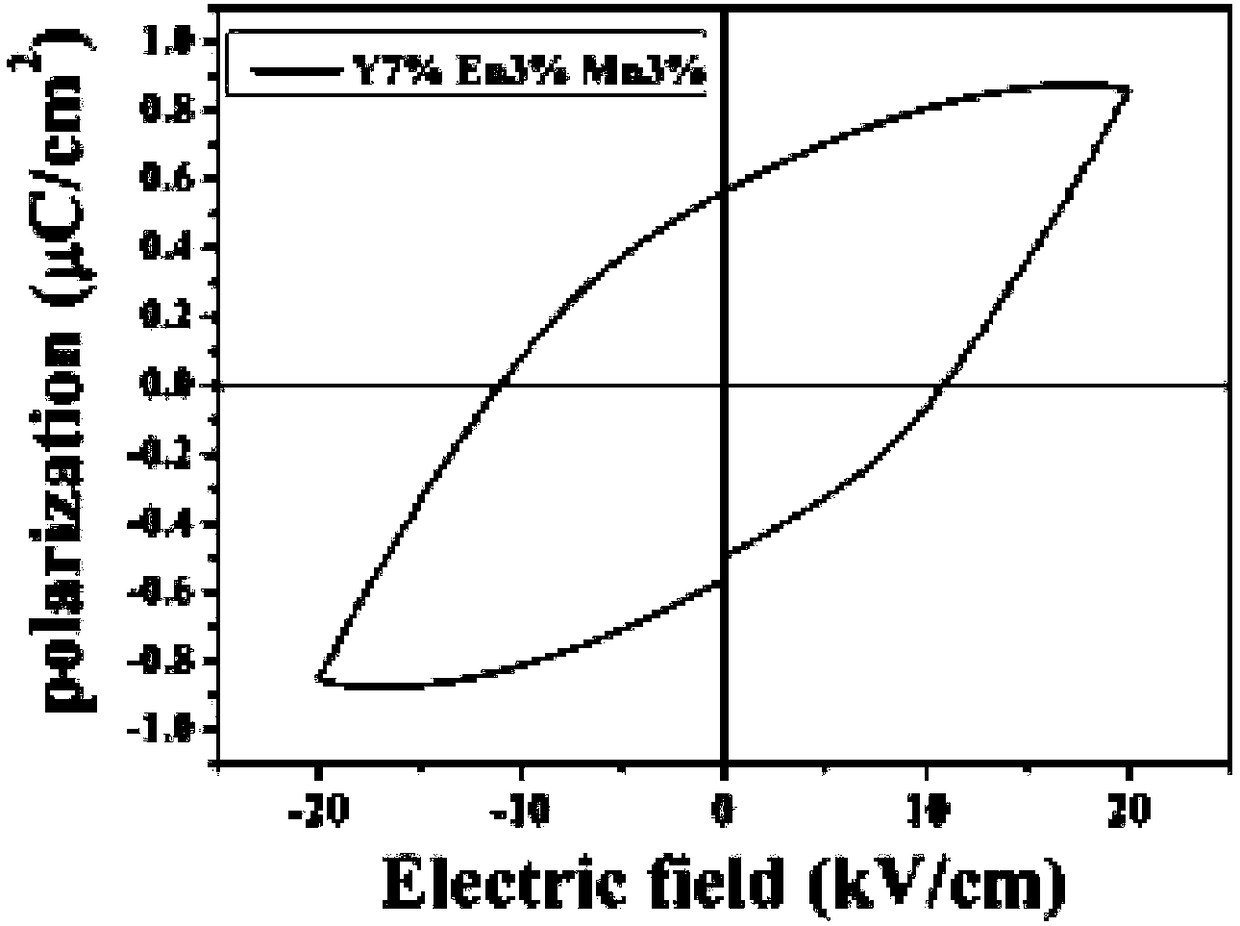

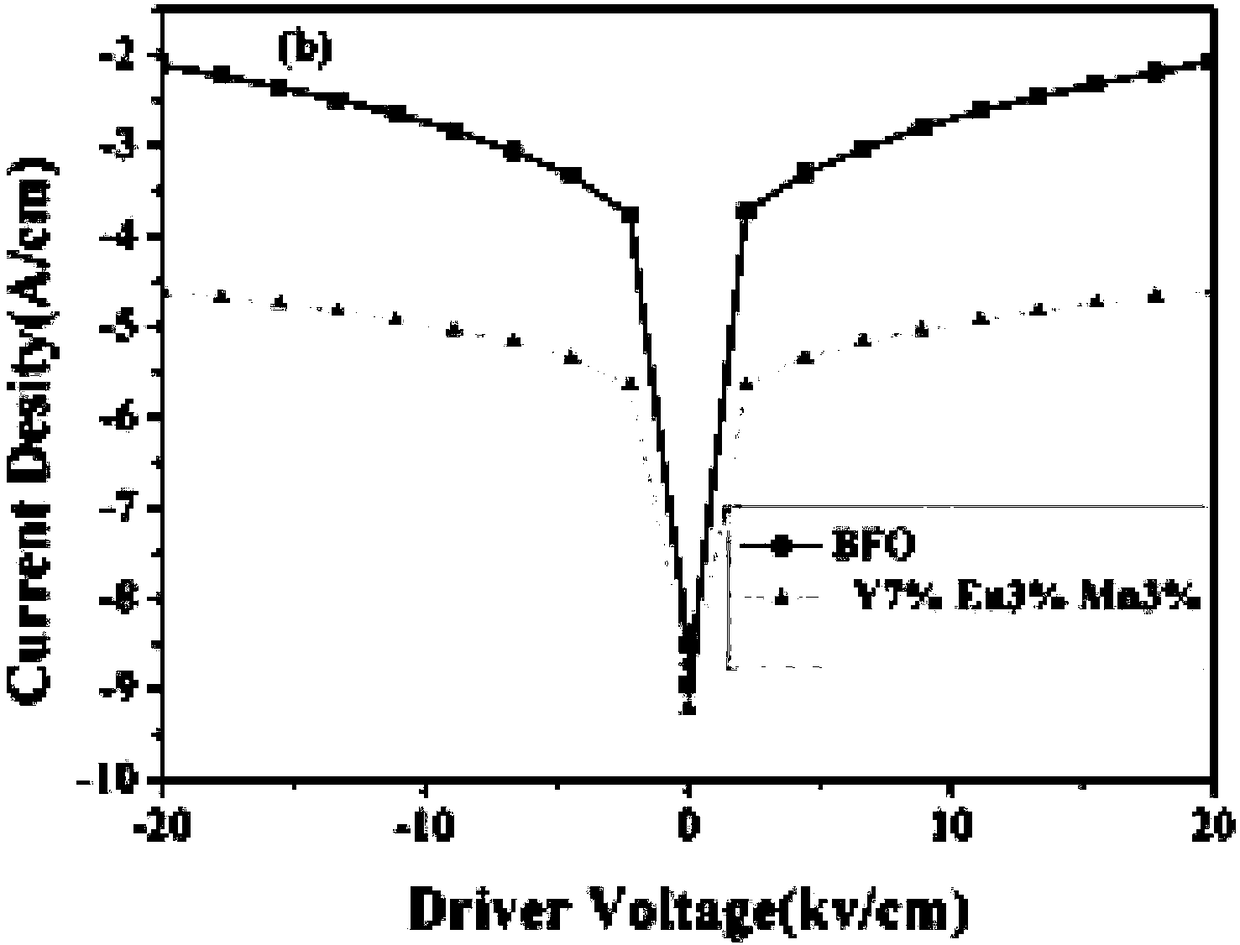

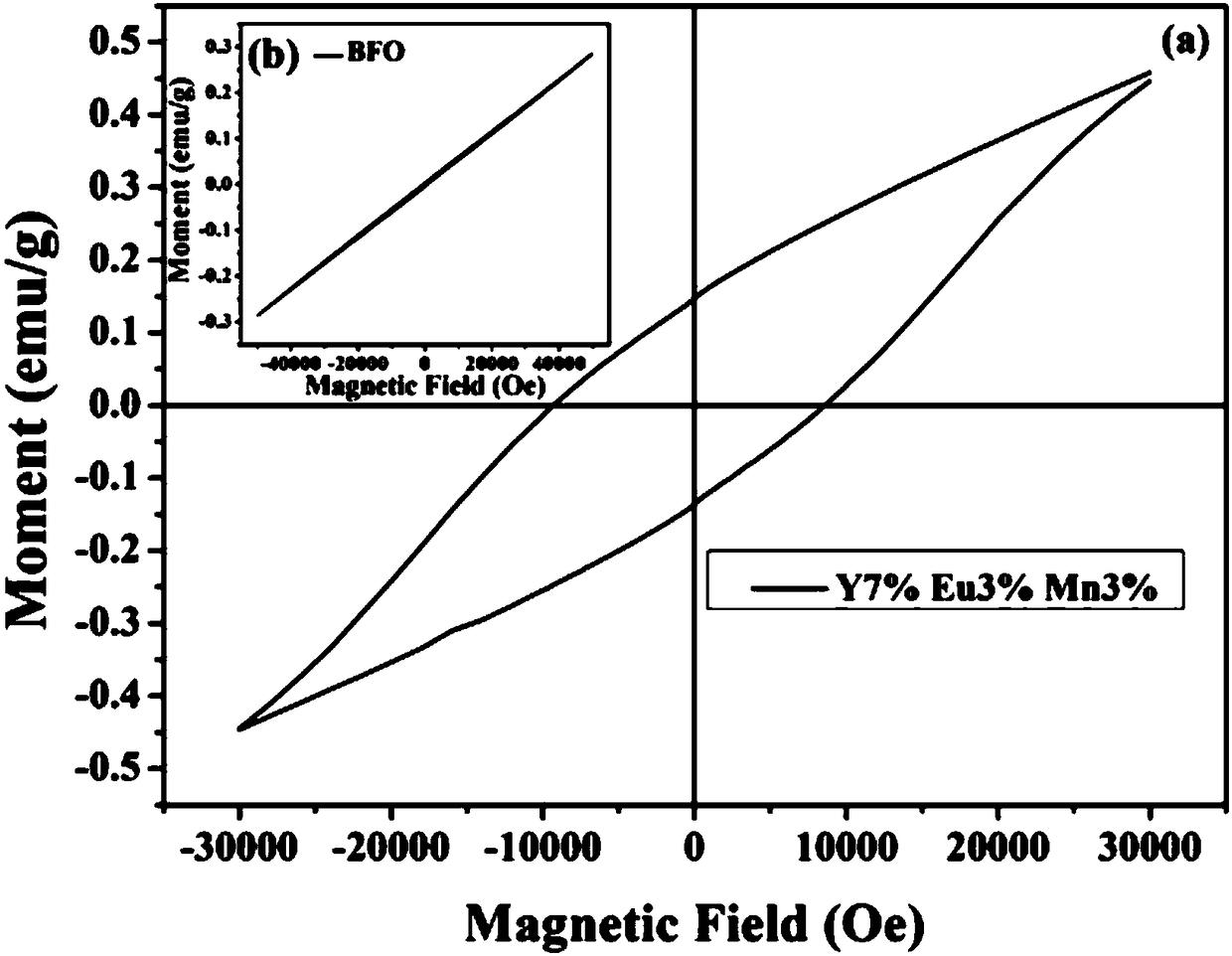

Yttrium, europium and manganese codoped bismuth ferrite and preparation method thereof

InactiveCN108328658AImprove multiferroic propertiesIron compoundsGel preparationManganeseCrystallinity

The invention discloses a preparation method of yttrium, europium and manganese codoped bismuth ferrite. The method comprises the following steps of S01, weighing and taking Y2O3, Eu2O3 and Bi2O3 intonitric acid; performing stirring until a clear solution is obtained; S02, adding MnO and Fe(NO3)3.9H2O into the solution obtained in S01 according to the proportion of the quantity sum of three element substances of Y, Eu and Bi to the quantity sum of the two kinds of element substances of Mn and Fe to be 1:1; performing full and continuous stirring to obtain a precursor solution; S03, adding tartaric acid and deionized water into the precursor solution obtained in the S02; performing continuous stirring to form xerogel; S04, putting the xerogel obtained in the S03 in a drying box; performingpreroasting for 2h at 250 DEG C; then, performing sintering annealing for 2h under the condition of 550 DEG C. The invention also discloses the yttrium, europium and manganese codoped bismuth ferriteprepared by the preparation method. The yttrium, europium and manganese codoped bismuth ferrite and the preparation method of the yttrium, europium and manganese codoped bismuth ferrite provided by the invention have the advantages that the process is simple; the crystallinity degree is high; the current leakage density can be reduced.

Owner:NANJING UNIV OF POSTS & TELECOMM

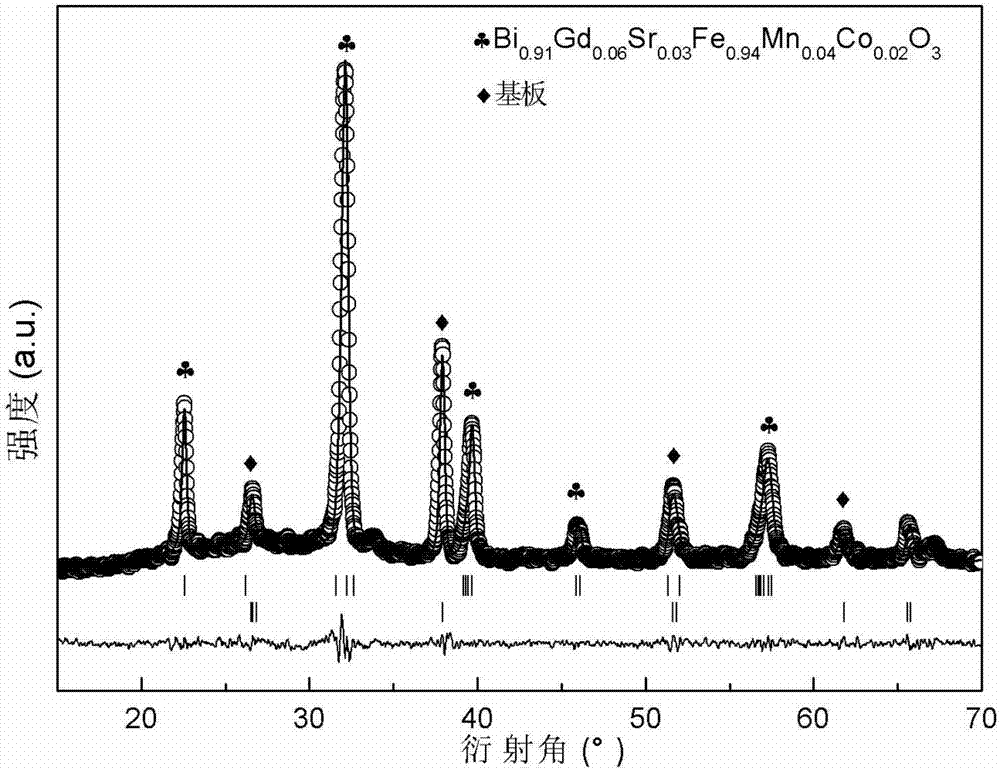

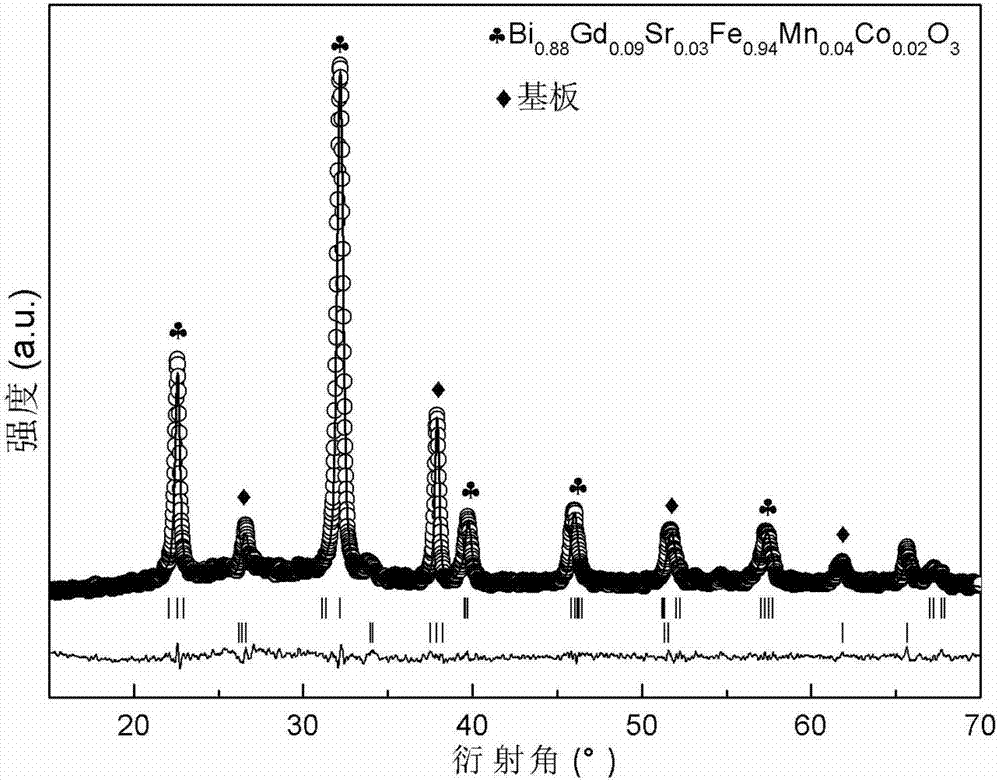

GdSrMnCo codoped bismuth ferrite superlattice film and preparation method thereof

The invention provides a GdSrMnCo codoped bismuth ferrite superlattice film and a preparation method thereof. A Bi0.91Gd0.06Sr0.03Fe0.94Mn0.04Co0.02O3 / Bi0.88Gd0.09Sr0.03Fe0.94Mn0.04Co0.02O3 superlattice film, namely the GdSrMnCo codoped bismuth ferrite superlattice film, is prepared from bismuth ferrite films doped according to different Gd concentrations, wherein the crystal structures of the bismuth ferrite films are trigonal structures and the space groups thereof are in a coexistent state of R3c: H and R3m: R. In the preparation method, a sol-gel process is adopted, and a spin coating and layer-by-layer annealing method is adopted; equipment requirements are low; the preparation method is suitable for preparing films on large surfaces and irregularly-shaped surfaces; and chemical components are precise and controllable; the multi-ferrous performance of BiFeO3 films can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

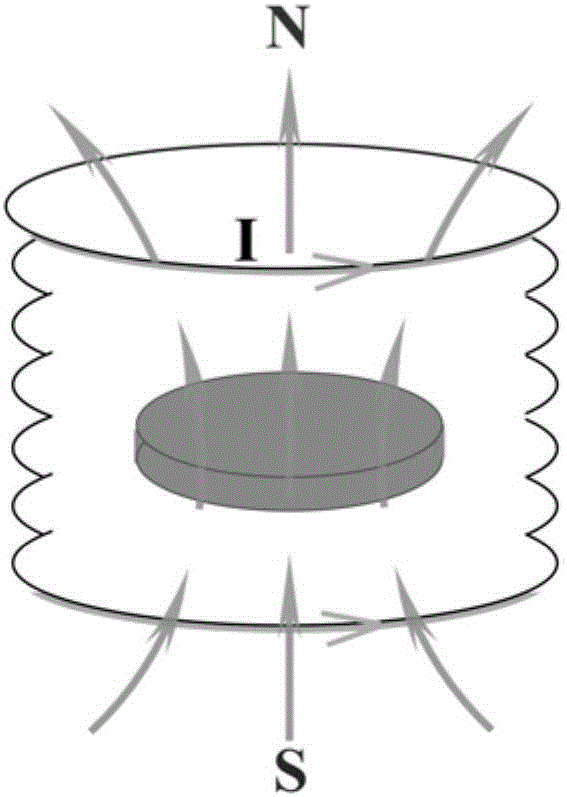

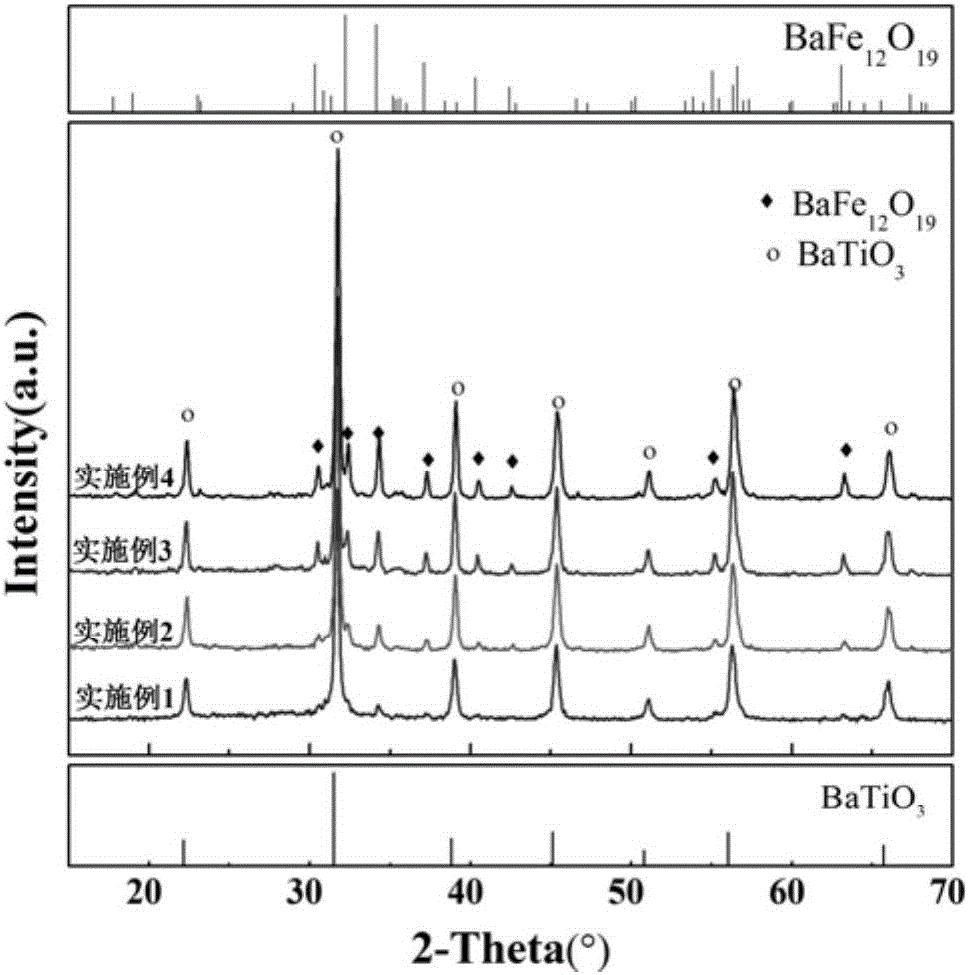

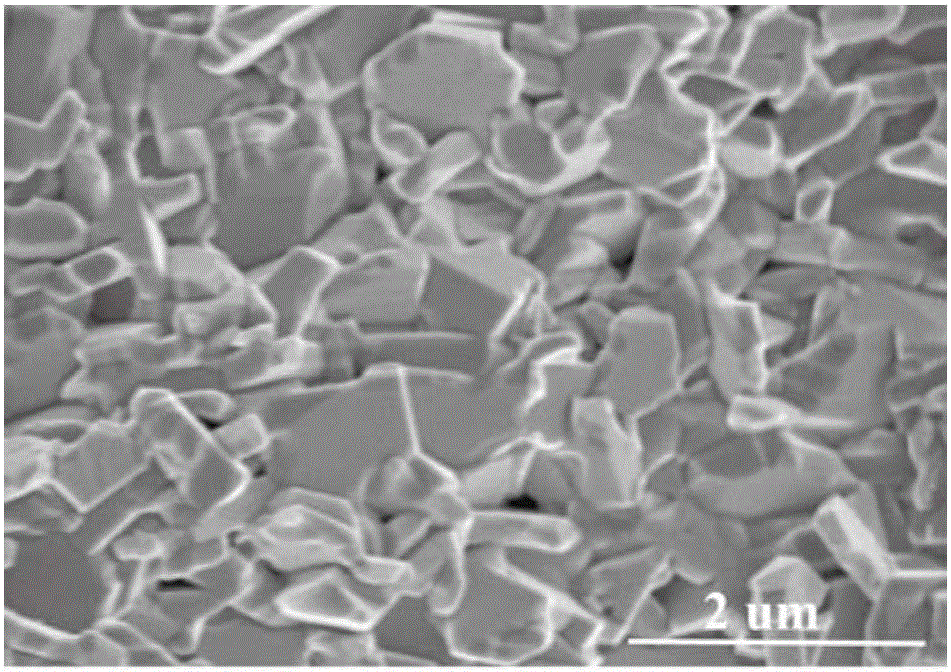

Method for preparing multi-ferrous composite ceramic material by low-temperature magnetic field heat treatment

ActiveCN106587995AExcellent ferroelectricImprove ferromagnetic propertiesPower flowComposite ceramic

The invention provides a method for preparing multi-ferrous composite ceramic material by low-temperature magnetic field heat treatment. According to the method, BaTiO3-BaFe12O19 composite ceramic is subjected to heat treatment by an external magnetic field, so that the multiferroic performance of the composite ceramic is improved. The method comprises the steps as follows: preparing nanoBaTiO3 and BaFe12O19 powder with a hydrothermal method or a microwave hydrothermal method, preparing a BaTiO3-BaFe12O19 blank sample A from nanoBaTiO3 and the BaFe12O19 powder in a ratio of (1-x):x by uniform mixing; sintering the blank sample A in a microwave sintering furnace to obtain BaTiO3-BaFe12O19 composite ceramic B after cooling with the furnace; putting the obtained composite ceramic B in a magnetic field sintering furnace in a nitrogen atmosphere for low-temperature heat treatment at a magnetic flux current of 10-14 A and a temperature of 400-450 DEG C, and preserving heat for 60-90 minutes to obtain the composite ceramic material with excellent multiferroic performance. The method has the advantages that the maximum magnetization strength of the material is increased by about 80% and the maximum polarization strength is improved by about 11% with the addition of a low-temperature magnetic field heat treatment process during preparation of ceramic, , and the method is low in preparation cost, easy to operate, environment-friendly and pollution-free in process and does not require rapid quenching after magnetic field heat treatment.

Owner:SHAANXI UNIV OF SCI & TECH

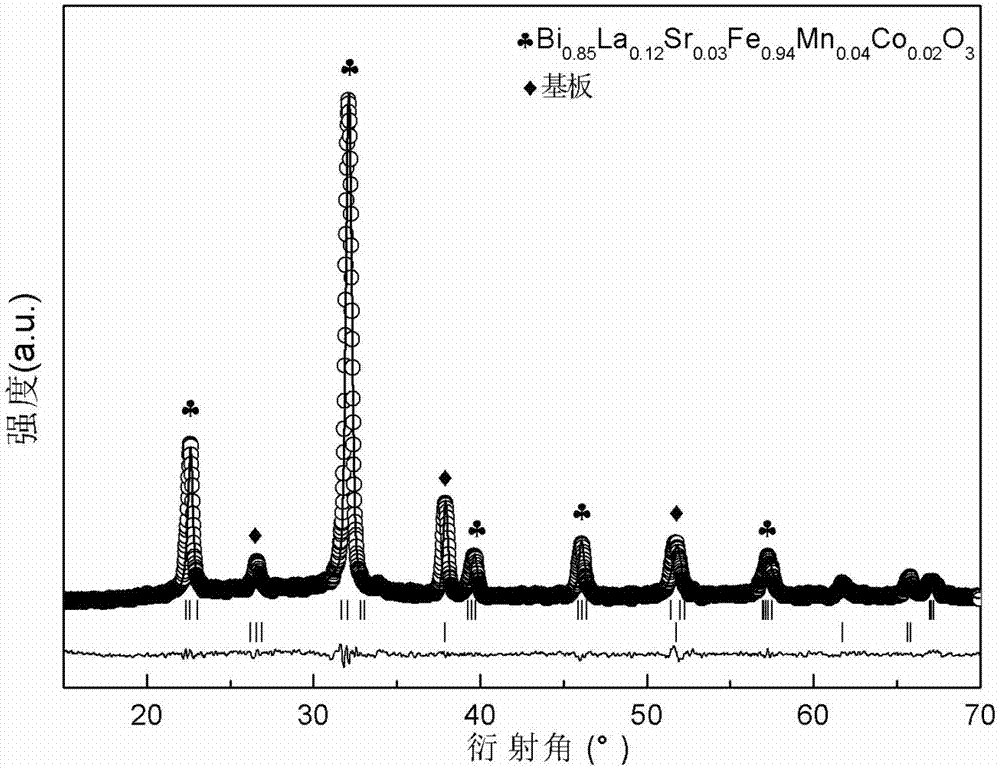

LaSrMnCo/GdSrMnCo codoped bismuth ferrite superlattice film and preparation method thereof

The invention provides an LaSrMnCo / GdSrMnCo codoped bismuth ferrite superlattice film and a preparation method thereof. A Bi0.85La0.12Sr0.03Fe0.94Mn0.04Co0.02O3 / Bi0.85Gd0.12Sr0.03Fe0.94Mn0.04Co0.02O3 superlattice film, namely the LaSrMnCo / GdSrMnCo codoped bismuth ferrite superlattice film, is prepared from bismuth ferrite films doped according to different elements, wherein the crystal structures of the bismuth ferrite films are trigonal structures and the space groups thereof are in a coexistent state of R3c: H and R3m: R. In the preparation method, a sol-gel process is adopted, and a spin coating and layer-by-layer annealing method is adopted; equipment requirements are low; the preparation method is suitable for preparing films on large surfaces and irregularly-shaped surfaces; chemical components are precise and controllable; nd the multi-ferrous performance of BiFeO3 films can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and preparation method thereof

ActiveCN103626236AImprove multiferroic propertiesPromote productionIron compoundsMANGANESE ACETATEAcetic anhydride

The invention discloses a B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and a preparation method thereof. The preparation method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and nickel acetate according to a molar ratio of 1.05:[(0.92-0.98)-x]:(0.02-0.08):x in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride, uniformly stirring to obtain a BiFeO3 precursor solution, wherein the total metal ion concentration in the BiFeO3 precursor solution is 0.1-0.5mol / L, and x is equal to 0.01 to 0.03; spin coating the BiFeO3 precursor solution on a FTO / glass substrate to prepare a wet film, baking the wet film to obtain a dried film, annealing at the temperature of 550 DEG C for 8-13 minutes, thus obtaining a crystalline state BiFeO3 film; repeatedly operating until the BiFeO3 film reaches the needed thickness after the crystalline state BiFeO3 film is cooled, thus obtaining the B-site Mn and Ni co-doped high-remanent polarization BiFeO3 film. According to the method, a sol-gel process is adopted, the equipment requirement is simple, the method is suitable for preparing films on large surfaces and out-of-shape surfaces, the chemical constituents are accurately controlled, and the crystal structure is regulated through co-doping, so that the ferroelectric properties of the film are greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of pure phase nanocrystalline yttrium doped bismuth ferrite

InactiveCN110002505AImprove multiferroic propertiesGood photocatalytic effectNanotechnologyIron compoundsPhoto catalyticHigh energy

The invention belongs to the technical field of yttrium doped bismuth ferrite preparation, and discloses a preparation method of pure phase nanocrystalline yttrium doped bismuth ferrite. According tothe method, iron oxide, bismuth oxide and yttrium oxide are used as raw materials, the above raw materials are subjected to high-energy ball milling by a mechanical alloying method to obtain amorphousyttrium doped bismuth ferrite, and the amorphous yttrium doped bismuth ferrite is subjected to high-temperature heat treatment to produce the pure yttrium doped bismuth ferrite nanocrystalline structure. The yttrium doped bismuth ferrite prepared by the method has good multiferroic property and superior photo-catalytic effects.

Owner:东北大学秦皇岛分校

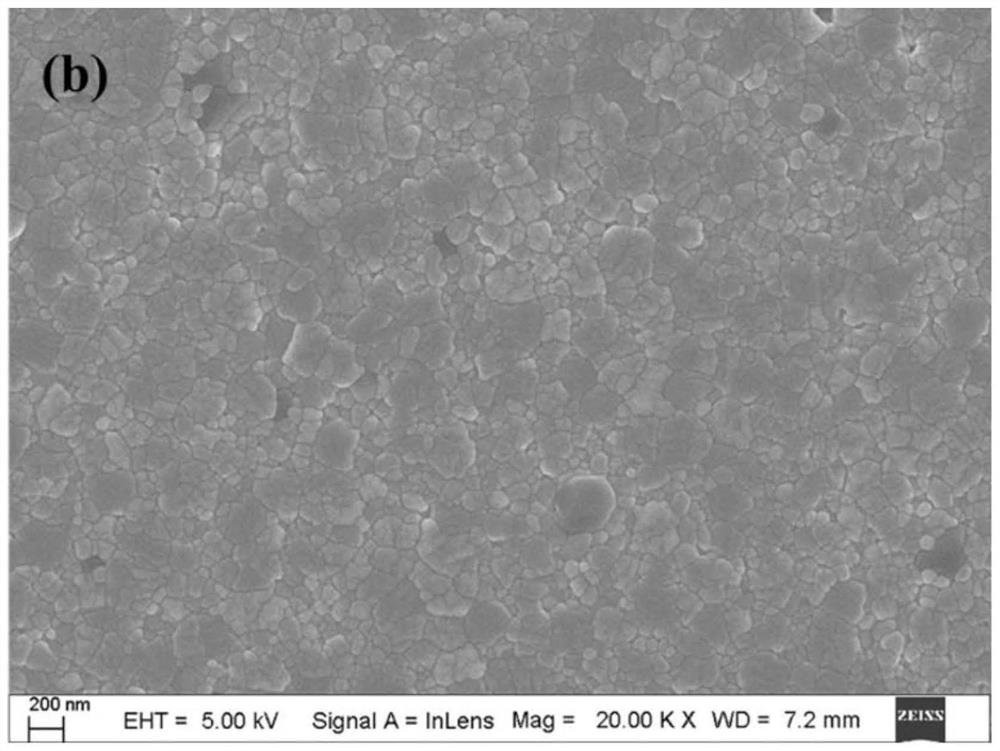

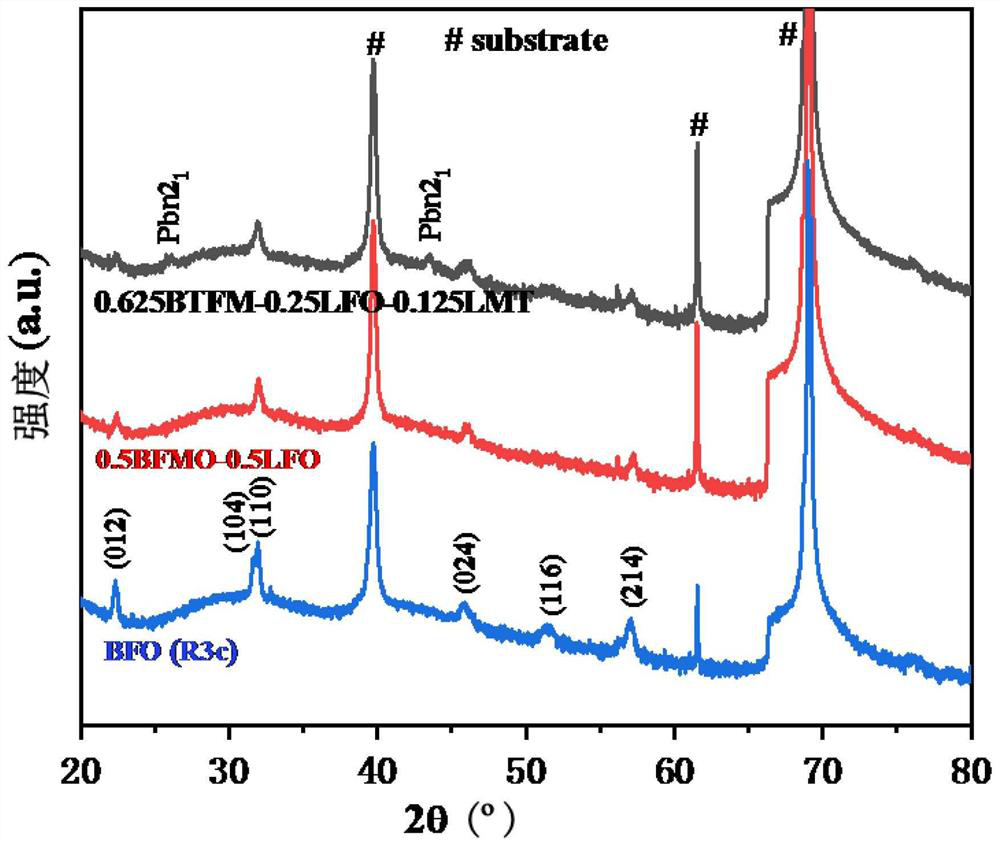

Solid solution multiferroic film, preparation method and electronic device applied to 5G storage technology

PendingCN113248248ALarge room temperature electric polarizationLow Room Temperature Leakage Current DensityDigital storageLeakage current densityPerovskite (structure)

The invention relates to a solid solution multiferroic thin film, a preparation method and an electronic device comprising the multiferroic thin film and applied to a 5G storage technology. The thin film is a complex oxide solid solution with a pseudo perovskite structure, and the chemical formula of the thin film is (1-x<1>-x<2>)LM<(1-y) / 2>Fe<y>N<(1-y) / 2>O<3>x<1>Rx<2>Q, wherein y is equal to 0-1, x<1> is equal to 0-1, x<2> is equal to 0-1, and the sum of x<1> and x<2> is less than or equal to 1; L is selected from one or more of Bi, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu or Y; M and N are respectively selected from Mg, Ti, Hf, Co, Mn, Ni or Zr, and can be the same or different; R is LFeO3; Q is an oxide of L, M and N; and the thin film is a rhombohedral phase and orthorhombic phase solid solution and is polycrystal. The thin film has higher room-temperature electric polarization intensity and lower room-temperature leakage current density.

Owner:SHENZHEN INST OF ADVANCED TECH

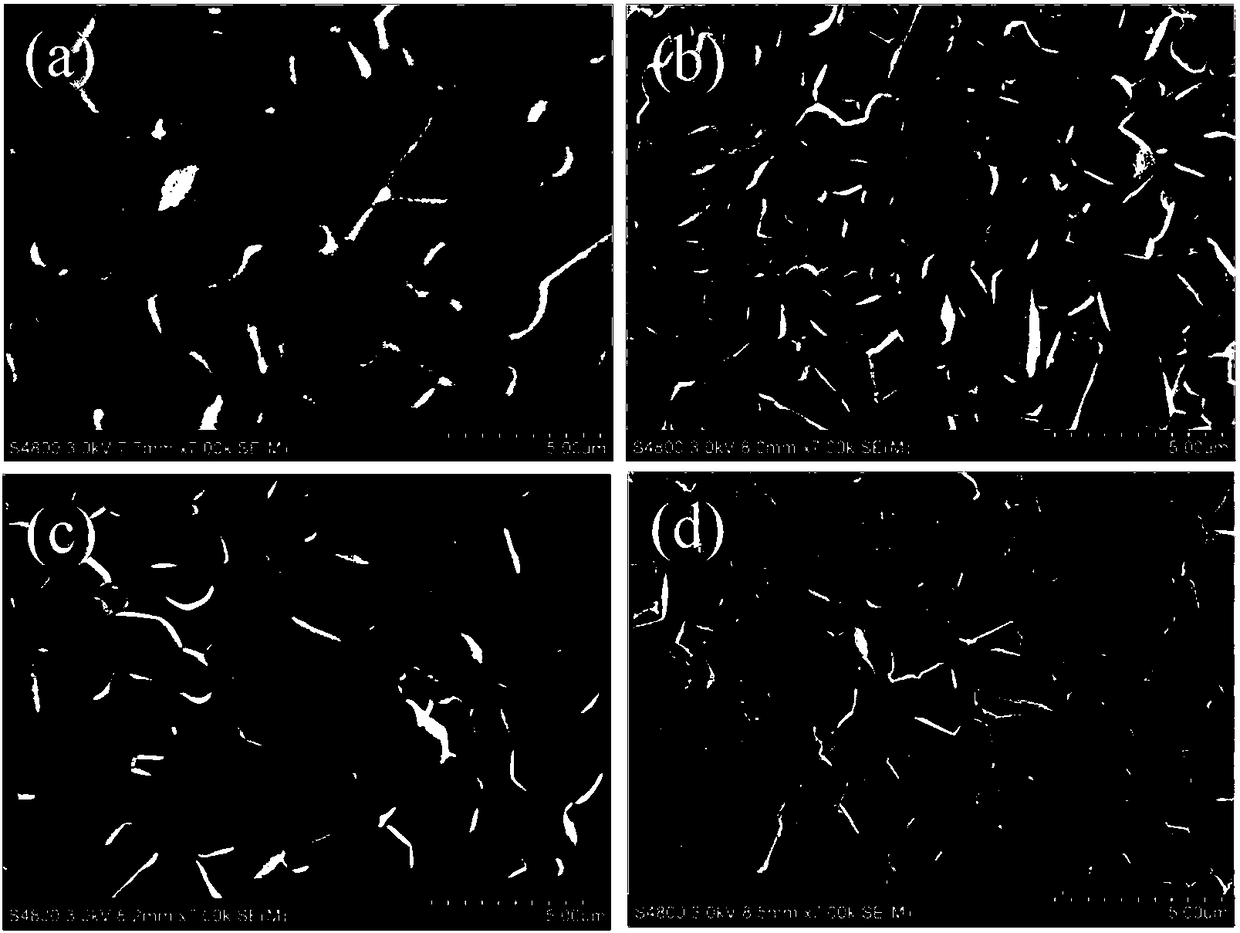

HoSrMnZn co-doped bismuth ferrite multiferroic film and preparation method thereof

ActiveCN107082579AHigh polarizationReduce Fe <sup>2+<</sup> CoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a HoSrMnZn co-doped bismuth ferrite multiferroic film and a preparation method thereof. According to the invention, bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate are used as raw materials (wherein bismuth nitrate is 5% excess in amount), ethylene glycol monomethyl ether and acetic anhydride are used as solvents, and a spin-coating process and a layer-upon-layer annealing process are employed to prepare a Bi<0.89>Ho<0.08>Sr<0.03>Fe<0.97-x>Mn<0.03>Zn<x>O<3> multiferroic film, i.e., the HoSrMnZn co-doped bismuth ferrite multiferroic film. According to the invention, a sol-gel process is employed, and the spin-coating and layer-upon-layer annealing processes are utilized; requirements on equipment are simple; experimental conditions are easy to realize; the preparation method is suitable for preparation of films on large surfaces and surfaces with irregular shapes and allows chemical components to be accurate and controllable; and the prepared HoSrMnZn co-doped bismuth ferrite multiferroic film has good uniformity and improves the multiferroic performance of a BiFeO3 film.

Owner:SHAANXI UNIV OF SCI & TECH

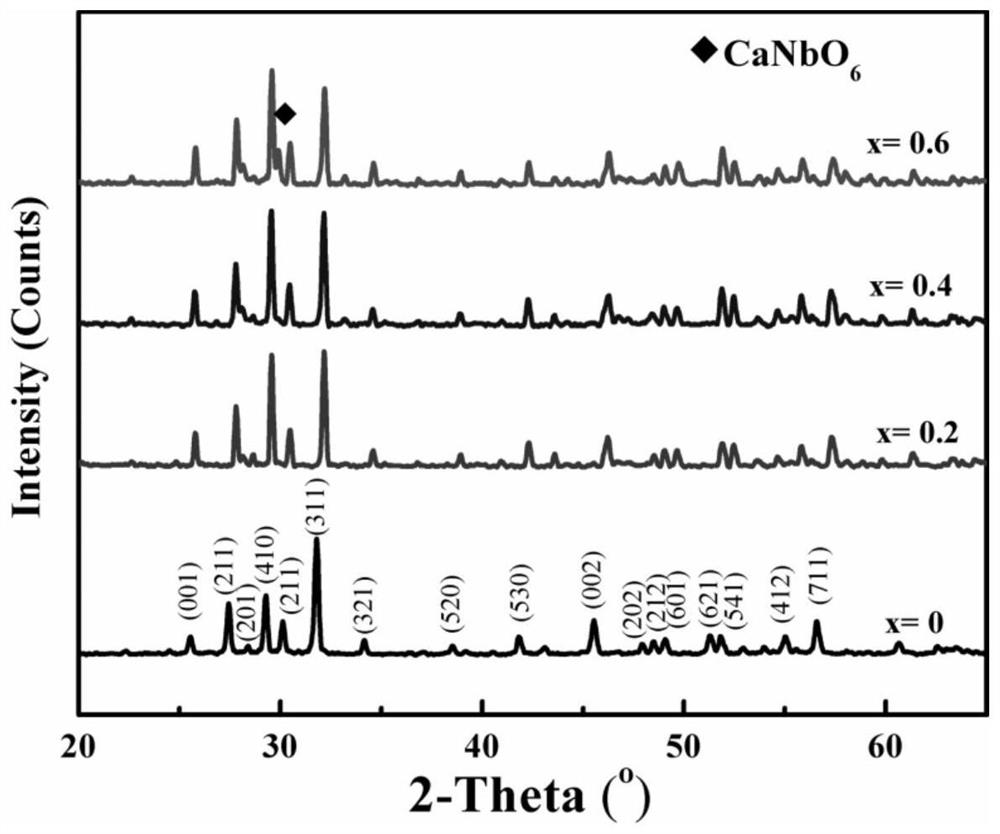

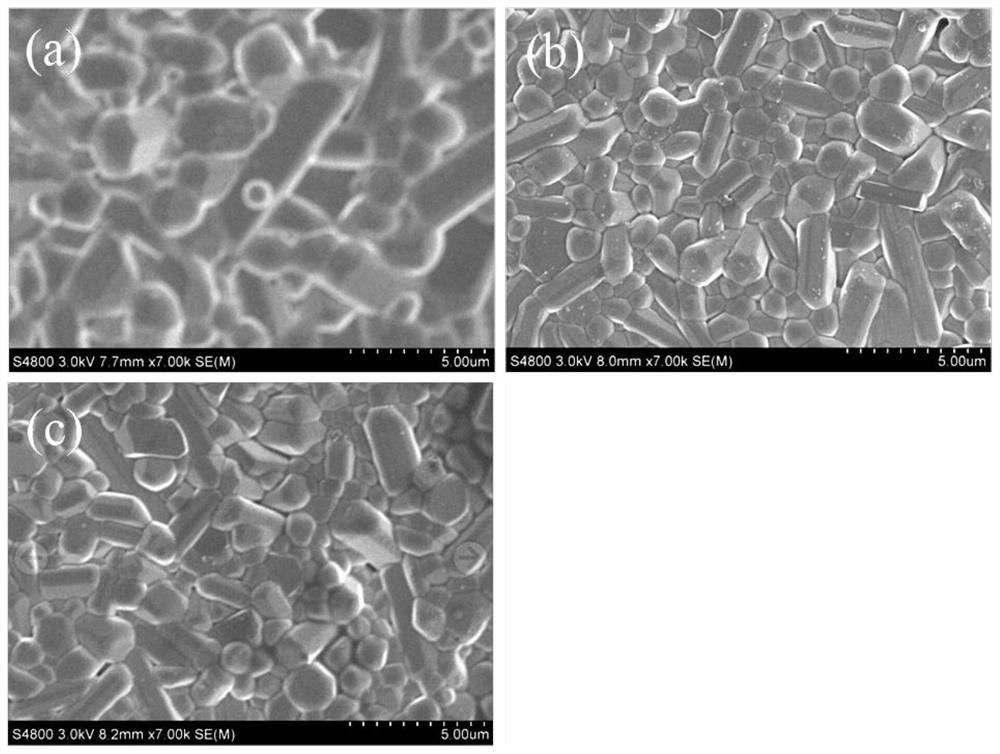

Tungsten bronze monophase multiferroic ceramic material and preparation method thereof

The invention provides a tungsten bronze monophase multiferroic ceramic material and a preparation method thereof. The preparation method includes following steps: 1, preparing pure-phase ceramic powder: well mixing all weighed powder to form ingredients, subjecting the ingredients to ball milling, drying and sieving sequentially to obtain a discharged material which is the pure-phase ceramic powder; 2, subjecting the pure-phase ceramic powder to isostatic cool pressing to obtain a sample, and sintering the sample to obtain a sintered sample; 3, sequentially polishing and cleaning the sinteredsample, uniformly coating the front and the back of the sintered sample with electrode slurry, and sintering the sample coated with the electrode slurry to obtain the tungsten bronze monophase multiferroic ceramic material corresponding to the pure-phase ceramic powder. Ferroelectricity and ferromagnetism of tungsten bronze monophase ceramic can be enhanced. The tungsten bronze ceramic material prepared by the method can improve purity and grain morphology of ceramic, and multiferroic performance of the ceramic is improved greatly.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of hosrmnzn co-doped bismuth ferrite superlattice film and preparation method thereof

The invention provides a HoSrMnZn codoping bismuth ferrite superlattice film and a preparation method thereof. The concomitant element-doped bismuth ferrite film of which the crystal structure is the trigonal crystal structure and the space group is R3c:H and R3m:R is used for preparing the Bi0.89Ho0.08Sr0.03Fe0.96Mn0.03Zn0.01O3 / Bi0.89Ho0.08Sr0.03Fe0.95Mn0.03Zn0.02O3 superlattice film, namely the HoSrMnZn codoping bismuth ferrite superlattice film. A sol gel technology is used, and a spin-coating and layer-to-layer annealing method is used. The device requirement is simple. The preparation method is suitable for preparing the film on the large surface and the surfaces with the irregular shapes, and the chemical components can be accurately controlled. The multiferroic property of the BiFeO3 film can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method of bit-fe multiferroic ferroelectric ceramics

ActiveCN104446449BFerroelectricExcellent ferroelectricity and excellent ferroelectricity are retainedMultiferroicsElectronic materials

The invention provides a preparation method of a BIT-Fe multiferroic ferroelectric ceramic. Bi2O3 (bismuth oxide), TiO2 (titanium dioxide) and Fe2O3 (ferric oxide) are used as raw materials, and the BIT-Fe multiferroic ferroelectric ceramic with a pure phase is prepared by a solid phase method, so that the ceramic has ferroelectricity, ferromagnetism and especially opposite ferromagnetism at the same time, and the BIT-Fe multiferroic ferroelectric ceramic has wide application prospects in spintronics and other fields. The preparation method disclosed by the invention has the characteristics that the preparation technology is simple, the preparation technology meets the requirements of industrialized production, and doped substances are simple and easy to obtain, so that the BIT ceramic has a multiferroic characteristic, the purity of the prepared ceramic is high, the prepared ceramic does not include other sundries or hazardous compounds, such as Pb (plumbum), and the prepared ceramic meets the manufacturing requirements of green electronic materials.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of tungsten bronze type single-phase multiferroic ceramic material and preparation method thereof

Owner:SHAANXI UNIV OF SCI & TECH

A kind of hosrmnzn co-doped bismuth ferrite multiferroic thin film and preparation method thereof

The invention provides a HoSrMnZn co-doped bismuth ferrite multiferroic film and a preparation method thereof. According to the invention, bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate are used as raw materials (wherein bismuth nitrate is 5% excess in amount), ethylene glycol monomethyl ether and acetic anhydride are used as solvents, and a spin-coating process and a layer-upon-layer annealing process are employed to prepare a Bi<0.89>Ho<0.08>Sr<0.03>Fe<0.97-x>Mn<0.03>Zn<x>O<3> multiferroic film, i.e., the HoSrMnZn co-doped bismuth ferrite multiferroic film. According to the invention, a sol-gel process is employed, and the spin-coating and layer-upon-layer annealing processes are utilized; requirements on equipment are simple; experimental conditions are easy to realize; the preparation method is suitable for preparation of films on large surfaces and surfaces with irregular shapes and allows chemical components to be accurate and controllable; and the prepared HoSrMnZn co-doped bismuth ferrite multiferroic film has good uniformity and improves the multiferroic performance of a BiFeO3 film.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of lasrmnco co-doped bismuth ferrite multiferroic thin film and preparation method thereof

ActiveCN107117830BGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

Owner:SHAANXI UNIV OF SCI & TECH

a bi 1‑x re x fe 1‑y tm y o 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104575907BImprove ferroelectric propertiesReduce volatilityInorganic material magnetismInductances/transformers/magnets manufactureComposite filmNanotechnology

The invention provides a Bi1-xRExFe1-yTMyO3 / CoFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe1-yTMyO3 crystalline film and a CoFe2O4 crystalline film which are compounded together. The preparation comprises the following steps: firstly preparing Bi1-xRExFe1-yTMyO3 precursor solution and CoFe2O4 precursor solution respectively; then spin-coating to prepare a plurality of layers of CoFe2O4 films on a substrate; next preparing a plurality of layers of Bi1-xRExFe1-yTMyO3 films on the CoFe2O4 films through spin coating to obtain a target product. The equipment requirement is simple, the prepared film is good in uniformity, chemical components are accurate and controllable, the doping content is easy to control, and the ferroelectric property and the ferromagnetic property of the film are greatly improved, and the film has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

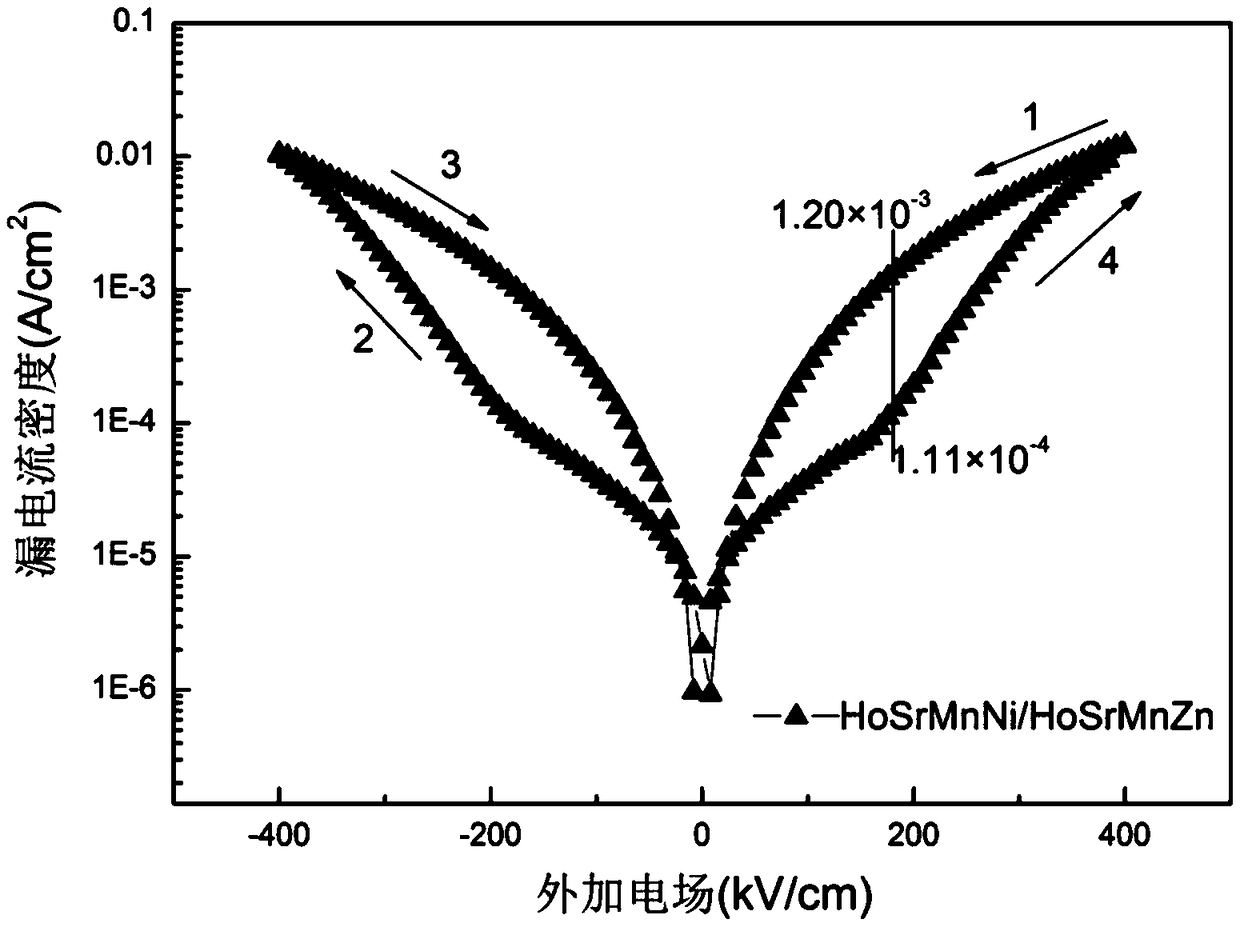

A kind of hosrmnni/hosrmnzn co-doped bismuth ferrite superlattice film and preparation method thereof

ActiveCN107245704BImprove uniformityChemical composition is easy to controlLiquid/solution decomposition chemical coatingNickel compoundsSpace groupBismuth

The invention provides a HoSrMnNi / HoSrMnZn co-doped bismuth ferrite superlattice film and a preparation method of the HoSrMnNi / HoSrMnZn co-doped bismuth ferrite superlattice film. A different-element-doped bismuth ferrite film with a crystal structure being of a trigonal crystal structure and space groups being concomitant R3c:H and R3m:R is used for preparing a Bi0.89Ho0.08Sr0.03Fe0.96Mn0.03Ni0.01O3 / Bi0.89Ho0.08Sr0.03Fe0.95Mn0.03Zn0.02O3 superlattice film, namely the HoSrMnNi / HoSrMnZn co-doped bismuth ferrite superlattice film. The sol-gel technology is adopted, spin coating and layer-by-layer annealing methods are adopted, equipment requirements are simple, the film is suitable for being prepared in a large surface or an irregularly-shaped surface, chemical constituents are accurate and controllable, and the multiferroic performance of a BiFeO3 film can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

a laminated bife 0.97-x mn 0.03 tm x o 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104476832BImprove multiferroic propertiesHigh saturation magnetizationLaminationLamination apparatusComposite filmNanotechnology

The invention provides a laminated BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 crystallized film and a CoFe2O4 crystallized film which are compounded together. The preparation method comprises the following steps of firstly, preparing a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 precursor solution and a CoFe2O4 precursor solution respectively; and then carrying out spin coating on a substrate to prepare a multi-layer CoFe2O4 film, and then carrying out spin coating on the CoFe2O4 film so as to prepare a multi-layer BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 film, thereby obtaining the target product. According to the invention, the equipment requirement is simple; the prepared film is good in uniformity; chemical components are accurate and controllable; the doped amount is easy to control; the ferroelectric properties and the ferromagnetic property of a film are improved greatly, so that the film has high residual polarization value and a residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com