A kind of hosrmnzn co-doped bismuth ferrite superlattice film and preparation method thereof

A technology of superlattice and bismuth ferrite, applied in the field of HoSrMnZn co-doped bismuth ferrite superlattice film and its preparation, to achieve the effect of easy reaction, low cost and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Use bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.96:0.03:0.01 dissolved in volume ratio In the mixed solution of ethylene glycol methyl ether and acetic anhydride of 3:1, obtain the stable precursor solution A that the total concentration of metal ions is 0.3mol / L;

[0033] Using bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.95:0.03:0.02 and the volume ratio is 3: 1 in the mixed solution of ethylene glycol methyl ether and acetic anhydride, obtain the stable precursor solution B that the total concentration of metal ions is 0.3mol / L;

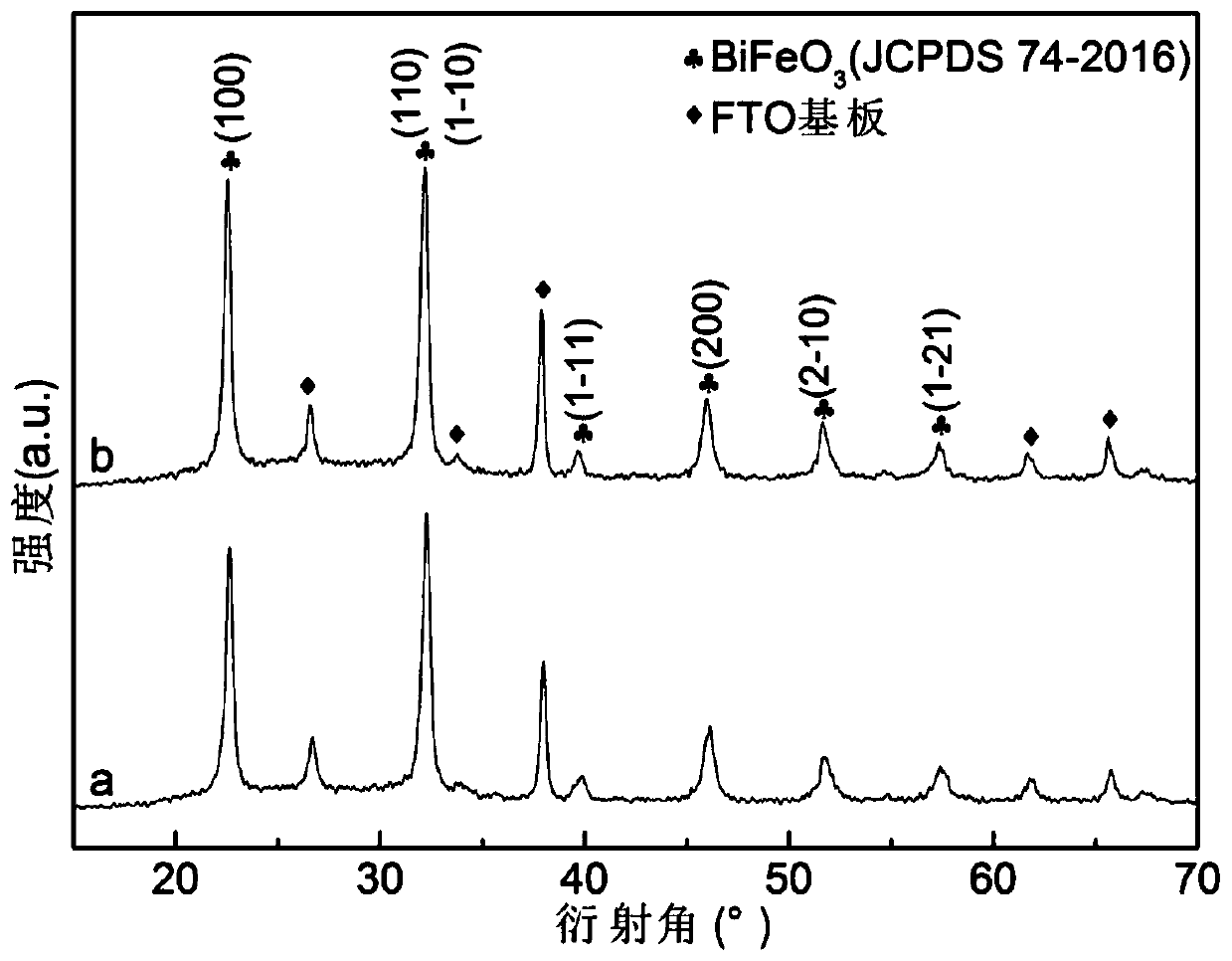

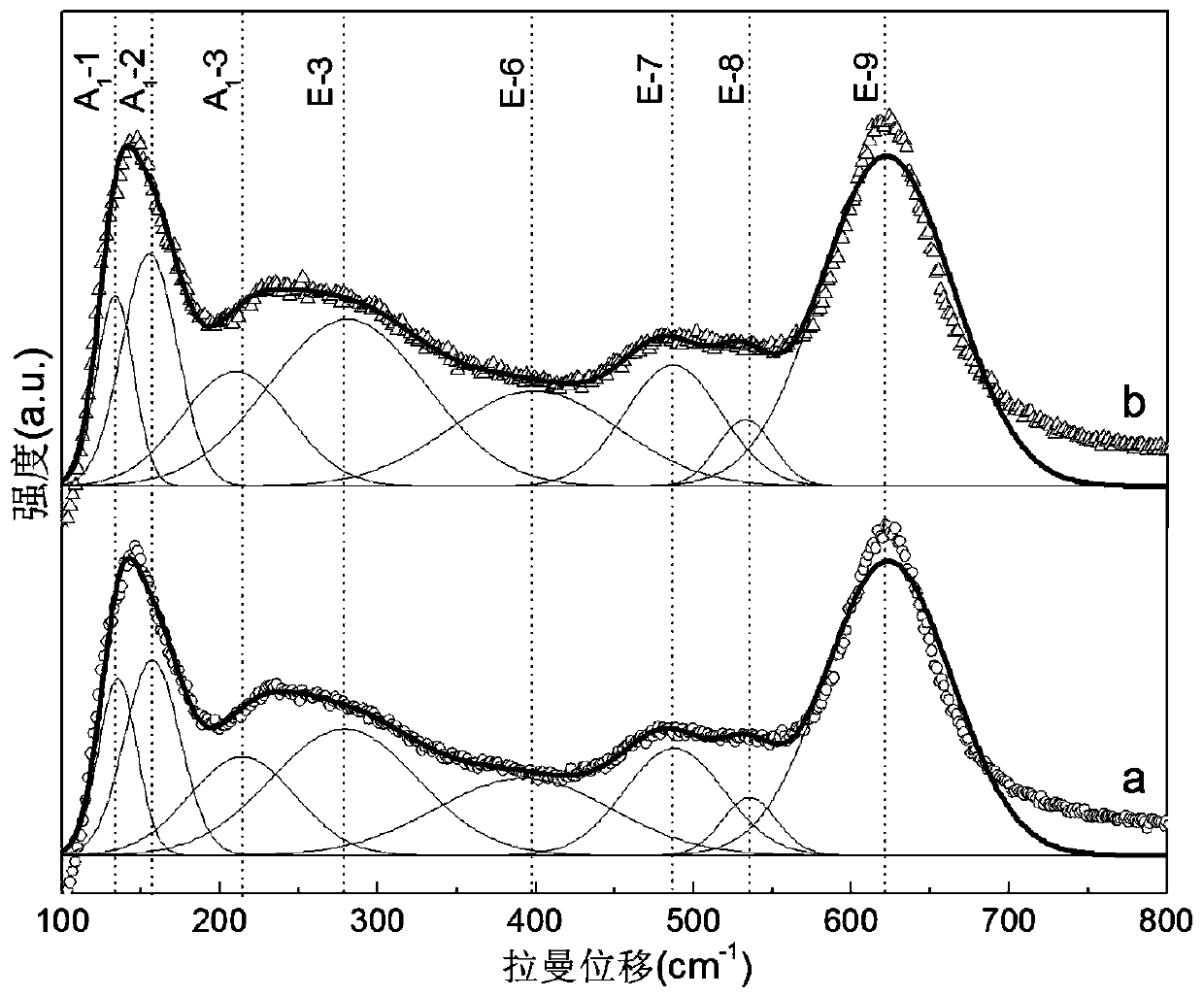

[0034] Step 2: Clean the FTO / glass substrate, and then irradiate it under ultraviolet light until the surface of the FTO / glass substrate reaches atomic c...

Embodiment 2

[0041] Step 1: Using bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.96:0.03:0.01 dissolved in volume ratio In the mixed solution of ethylene glycol methyl ether and acetic anhydride of 1:1, obtain the stable precursor solution A that the total concentration of metal ions is 0.1mol / L;

[0042] Using bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.95:0.03:0.02 and the volume ratio is 1: 1 in the mixed solution of ethylene glycol methyl ether and acetic anhydride, obtain the stable precursor solution B that the total concentration of metal ions is 0.1mol / L;

[0043] Step 2: Clean the FTO / glass substrate, and then irradiate it under ultraviolet light until the surface of the FTO / glass substrate reaches atomic...

Embodiment 3

[0047] Step 1: Use bismuth nitrate, holmium nitrate, strontium nitrate, ferric nitrate, manganese acetate and zinc nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.96:0.03:0.01 dissolved in volume ratio In the mixed solution of ethylene glycol methyl ether and acetic anhydride of 2:1, obtain the stable precursor solution A that the total concentration of metal ions is 0.2mol / L;

[0048] Using bismuth nitrate, holmium nitrate, strontium nitrate, iron nitrate, manganese acetate and zinc nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.95:0.03:0.02 and the volume ratio is 2: 1 in the mixed solution of ethylene glycol methyl ether and acetic anhydride, obtain the stable precursor solution B that the total concentration of metal ions is 0.2mol / L;

[0049] Step 2: Clean the FTO / glass substrate, and then irradiate it under ultraviolet light until the surface of the FTO / glass substrate reaches atomic cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com