A kind of lasrmnco co-doped bismuth ferrite multiferroic thin film and preparation method thereof

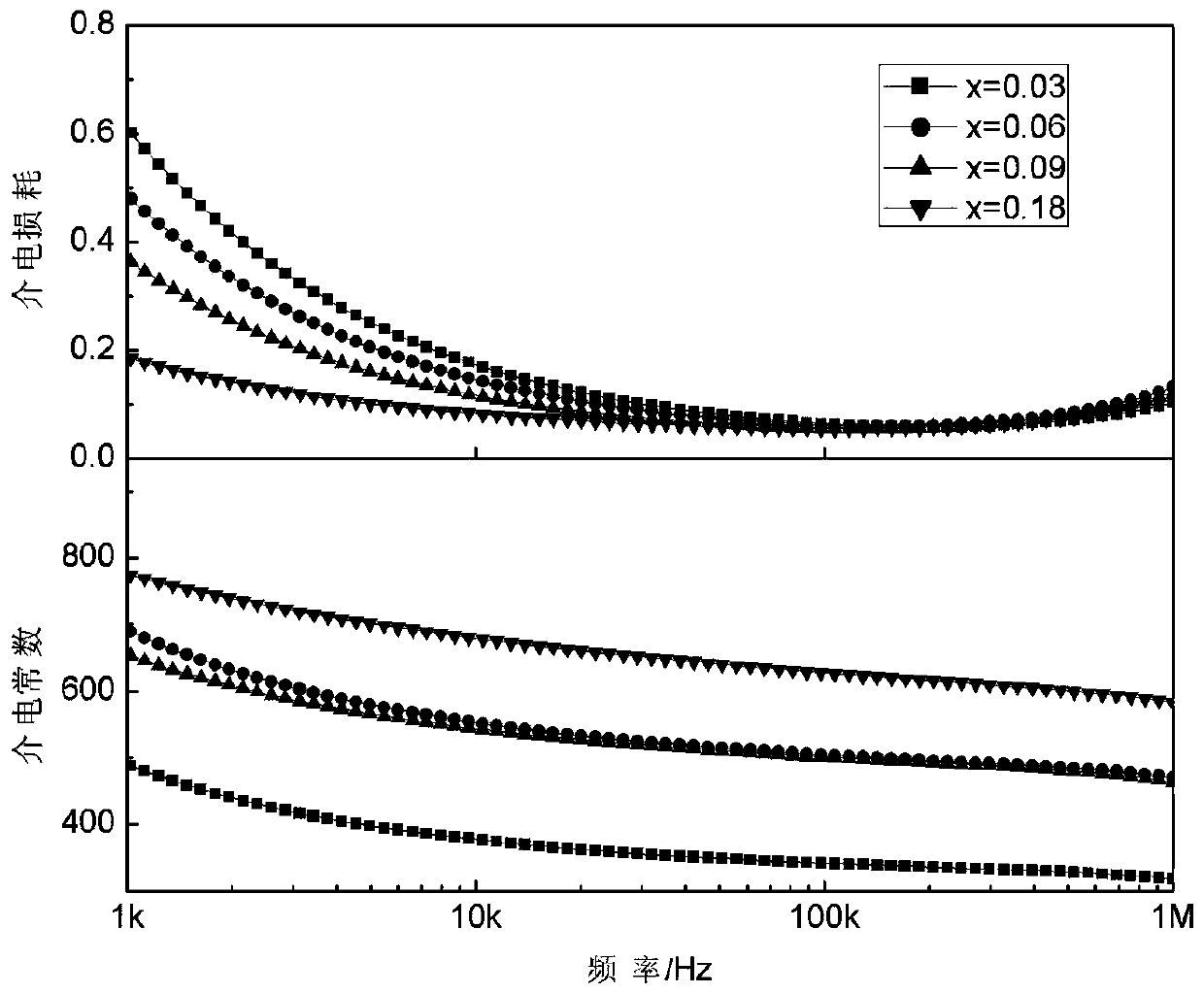

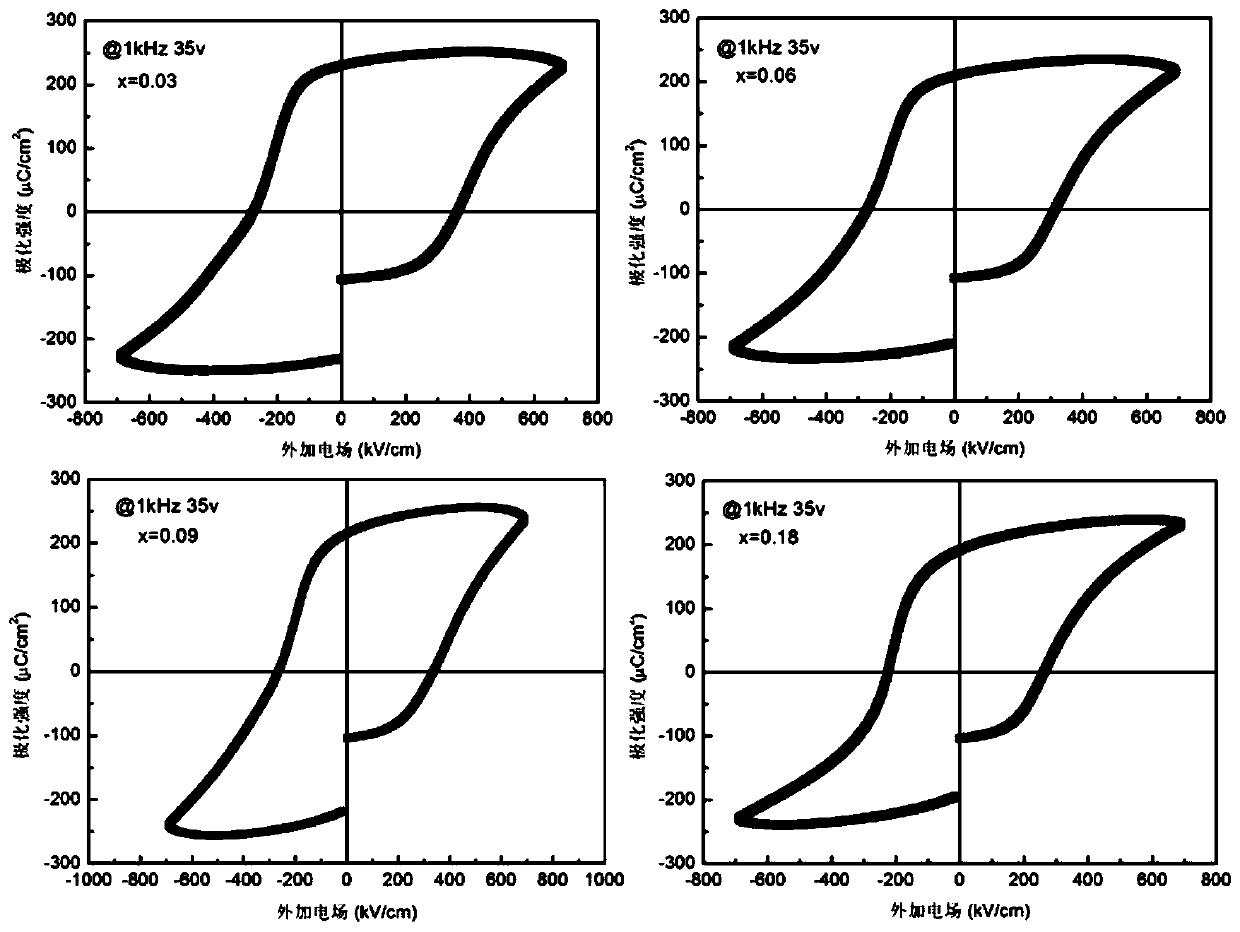

A multiferroic thin film, bismuth ferrite technology, applied in the direction of coating, etc., to achieve the effects of suppressing valence fluctuations, good dielectric and ferroelectric properties, and easy experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

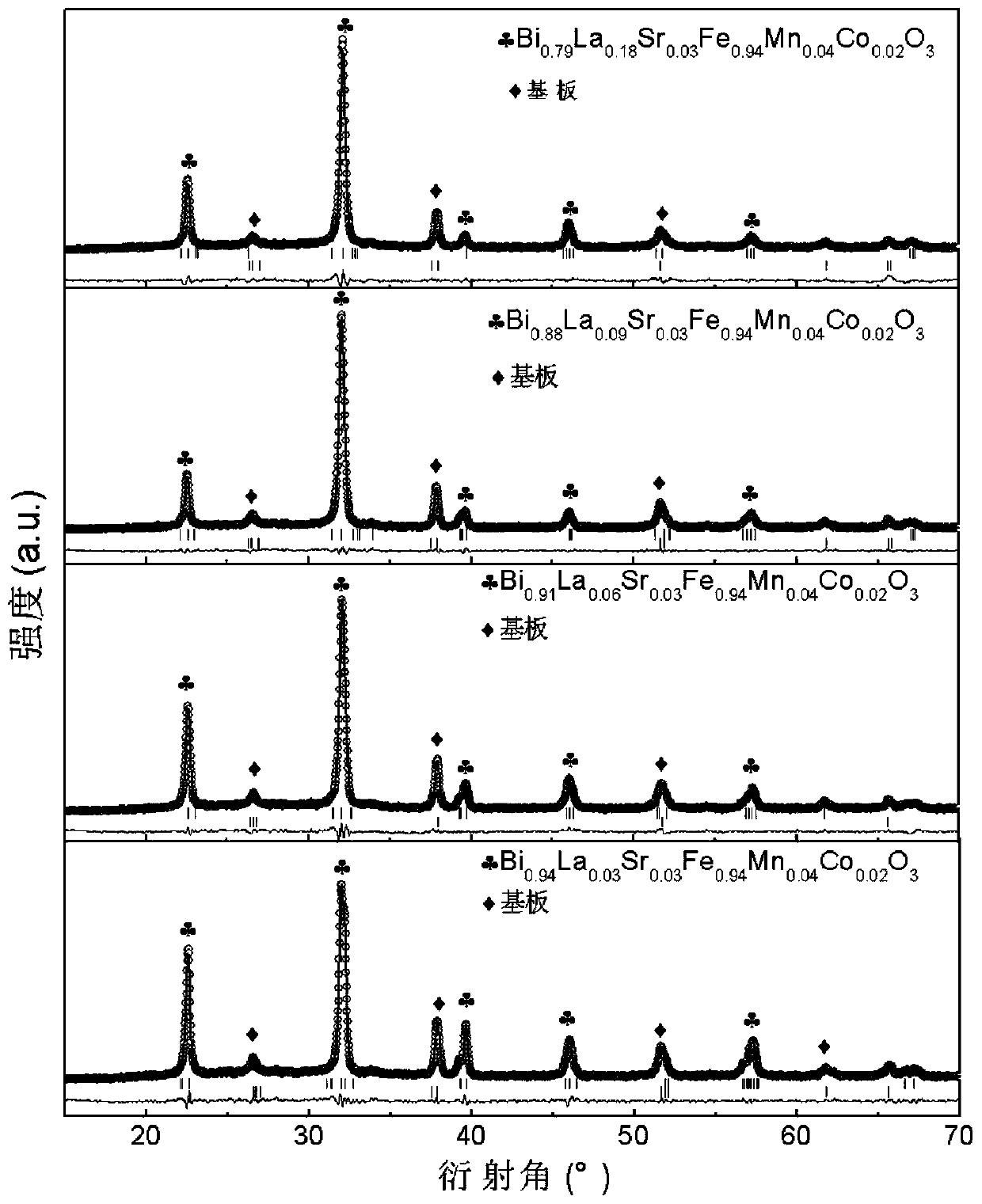

[0030] Step 2: Using bismuth nitrate, lanthanum nitrate, strontium nitrate, iron nitrate, manganese acetate and cobalt nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.99:0.03:0.03:0.94:0.04:0.02 (x=0.03 ) is dissolved in ethylene glycol methyl ether, stirs 30min, then adds acetic anhydride, stirs 90min, obtains the stable precursor solution that metal ion total concentration is 0.3mol / L; Wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0031] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with an ultraviolet light irradiation instrument for 40 minutes, so that the surface of the FTO / glass substrate reaches atomic cleanliness, and then spin-coat the precursor solution on the FTO / gl...

Embodiment 2

[0035] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

[0036] Step 2: Taking bismuth nitrate, lanthanum nitrate, strontium nitrate, iron nitrate, manganese acetate and cobalt nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.96:0.06:0.03:0.94:0.04:0.02 (x=0.06 ) is dissolved in ethylene glycol methyl ether, stirs 30min, then adds acetic anhydride, stirs 90min, obtains the stable precursor solution that metal ion total concentration is 0.3mol / L; Wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0037] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with an ultraviolet light irradiation instrument for 40 minutes, so that the surface of the FTO / glass substrate reaches atomic cleanliness, and then spin-coat the precursor solution on the FTO / g...

Embodiment 3

[0041] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

[0042] Step 2: Using bismuth nitrate, lanthanum nitrate, strontium nitrate, iron nitrate, manganese acetate and cobalt nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.93:0.09:0.03:0.94:0.04:0.02 (x=0.0 .09) be dissolved in ethylene glycol methyl ether, stir 30min, then add acetic anhydride, stir 90min, obtain the stable precursor solution that the total concentration of metal ions is 0.3mol / L; wherein the volume of ethylene glycol methyl ether and acetic anhydride The ratio is 3:1;

[0043] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with a UV irradiator for 40 minutes, so that the surface of the FTO / glass substrate reaches atomic cleanliness, and then spin-coat the precursor solution on the FTO / glass substrate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com