Method for preparing lanthanum-strontium-manganese-oxygen film

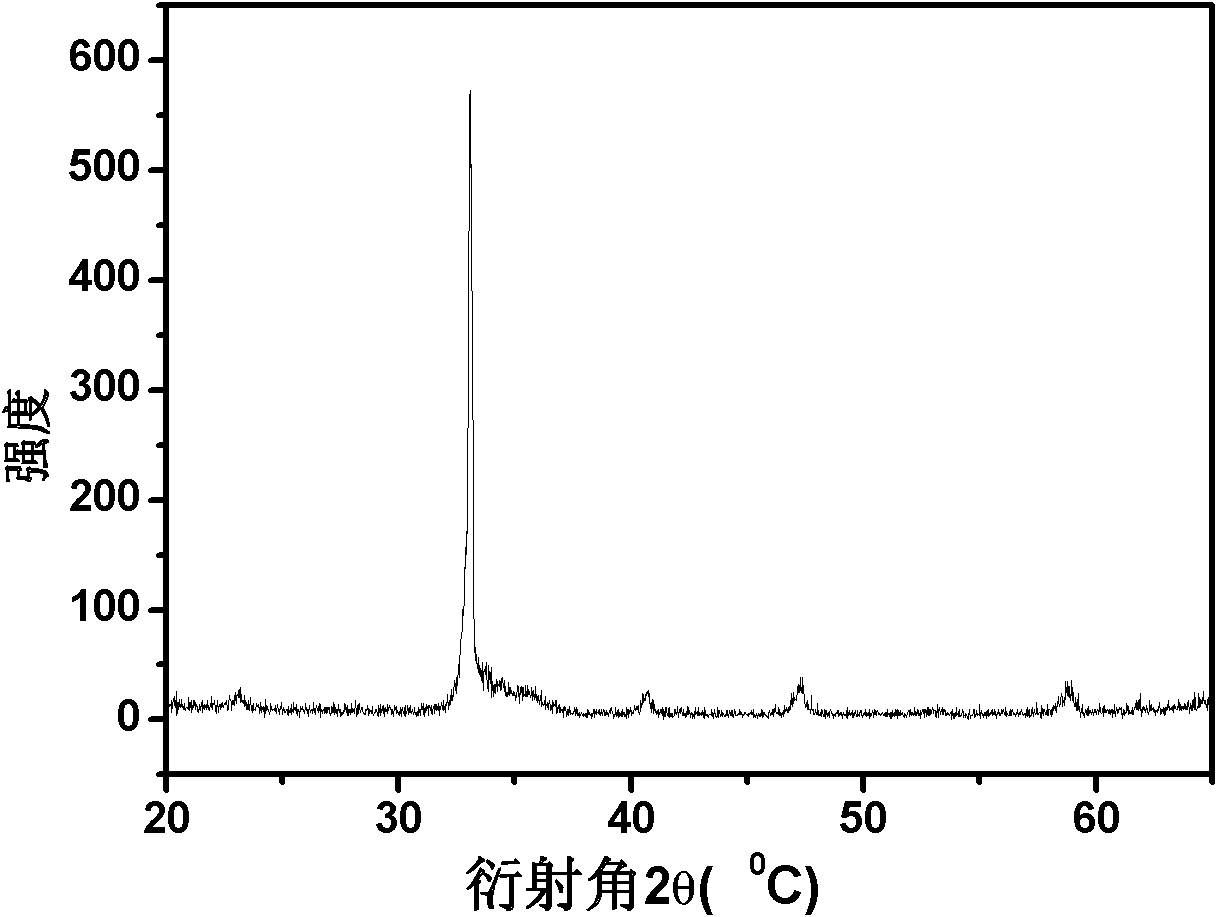

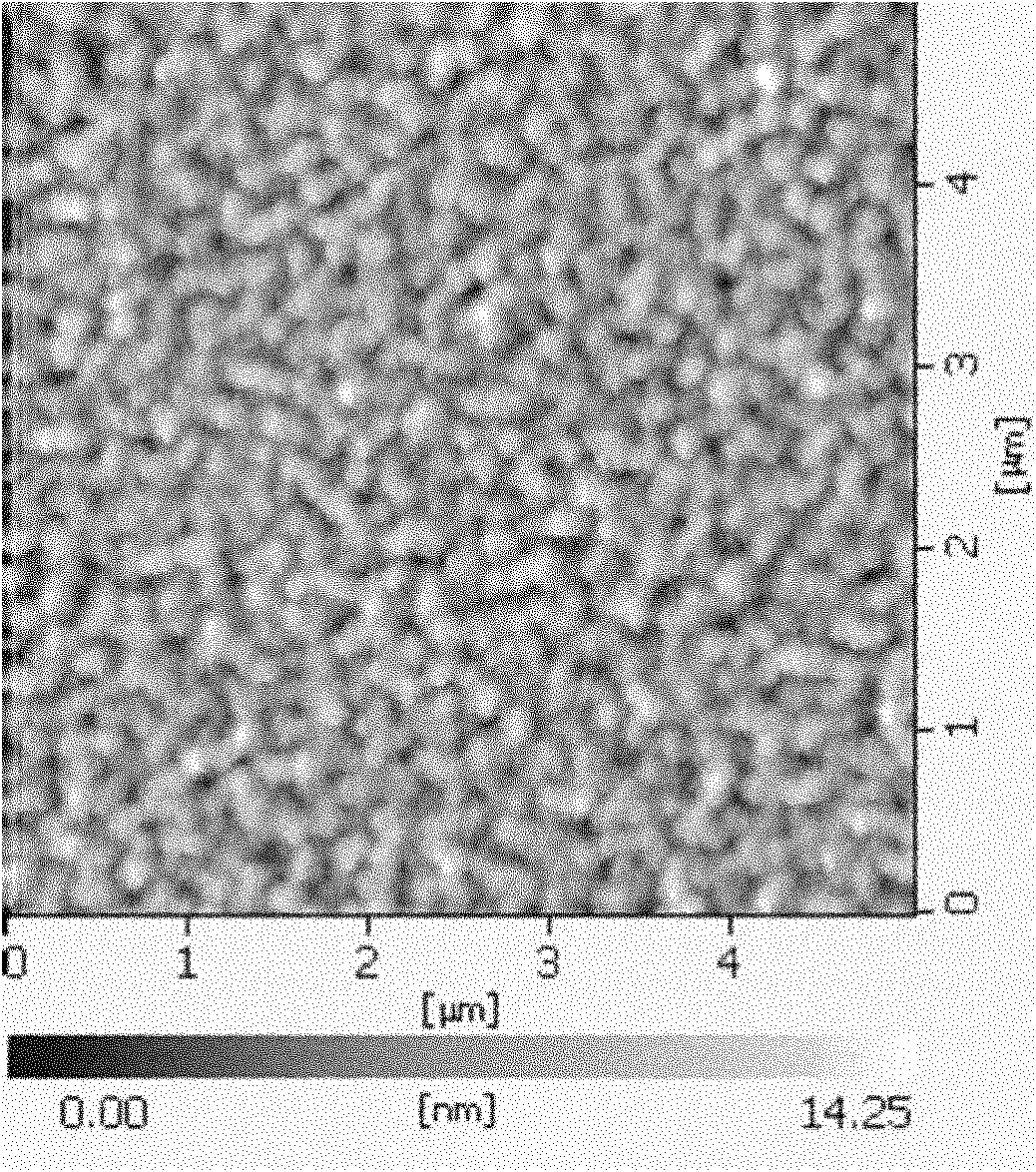

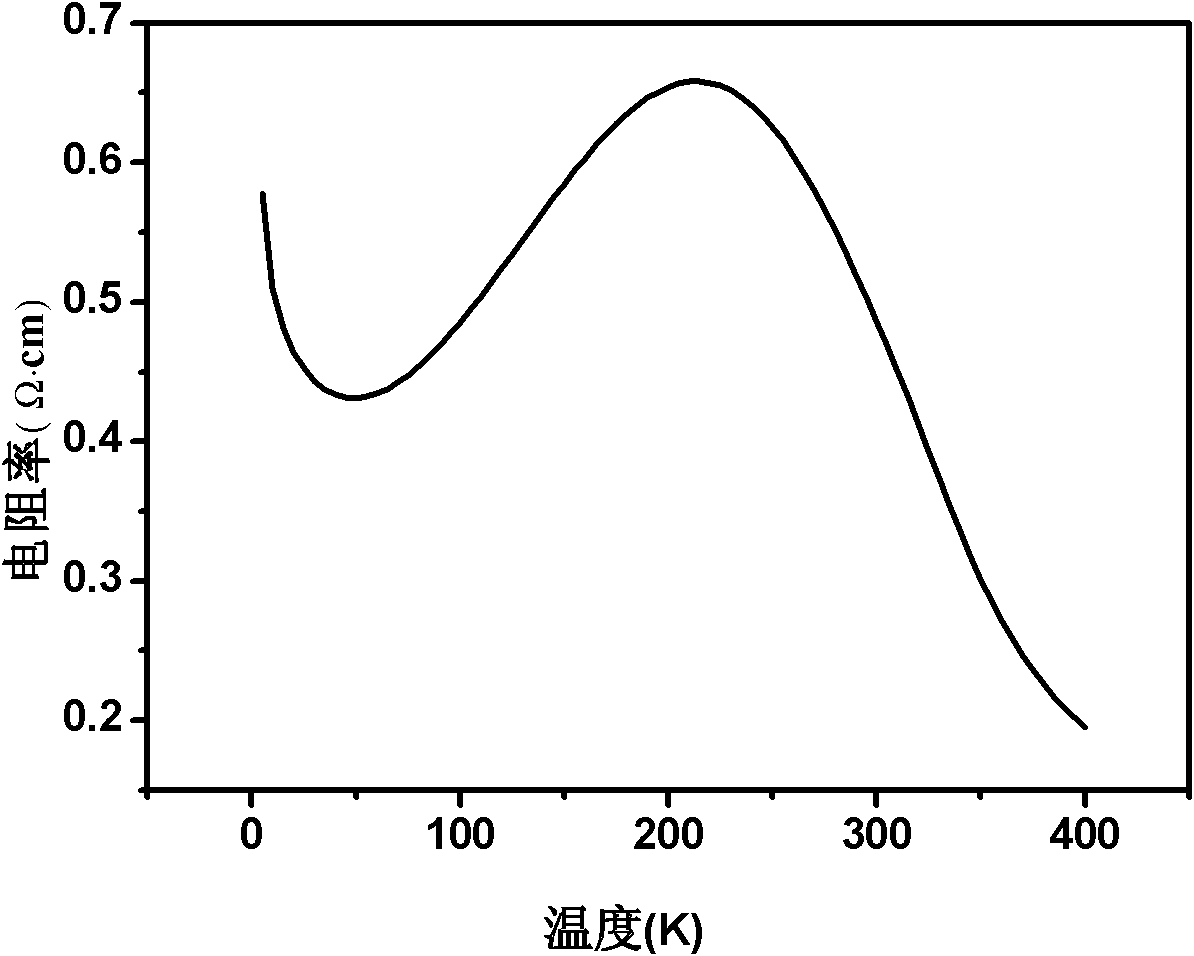

A technology of lanthanum strontium manganese oxide film and strontium acetate, which is applied in the field of magnetic film preparation, can solve problems such as cracks on the surface of the film and environmental pollution, and achieves the effects of small roughness, small environmental pollution and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A. Preparation of precursor solution

[0046] Dissolve the three solutes of lanthanum acetate, strontium acetate and manganese acetate with a molar ratio of 7:3:10 in a mixed solvent formed by acetic acid (CH3COOH) and deionized water with a volume ratio of 4:1, and heat to 60-80°C The solute is completely dissolved, and the concentration of the solution is 0.15mol / L; the obtained transparent yellow solution is left to stand at room temperature for 48 to 72 hours; it is filtered with a 0.2 μm microporous membrane to obtain stable lanthanum strontium manganese oxide ( LSMO) precursor solution;

[0047] B. Preparation of thin film materials

[0048] Add the prepared precursor solution dropwise onto the cleaned silicon substrate rotating at a high speed, the substrate speed is 5000 rpm, and keep it for 30 seconds, the solvent evaporates quickly to obtain a gel film; place the gel film in an annealing furnace Carry out heat treatment in stages, that is: first keep warm at...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is that the final annealing temperature is 750° C., and the rest of the content is exactly the same as that described in embodiment 1. The thickness of the obtained lanthanum strontium manganese oxide thin film is close to that of Example 1.

Embodiment 3

[0052]The difference between this example and Example 1 lies in that the final annealing temperature is 750° C., the annealing time is 60 minutes, and the rest of the content is exactly the same as that described in Example 1. The thickness of the obtained lanthanum strontium manganese oxide thin film is close to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com