Preparing method of composite magnetism-gathering medium for horizontal ring type high-gradient high intensity magnetic separator

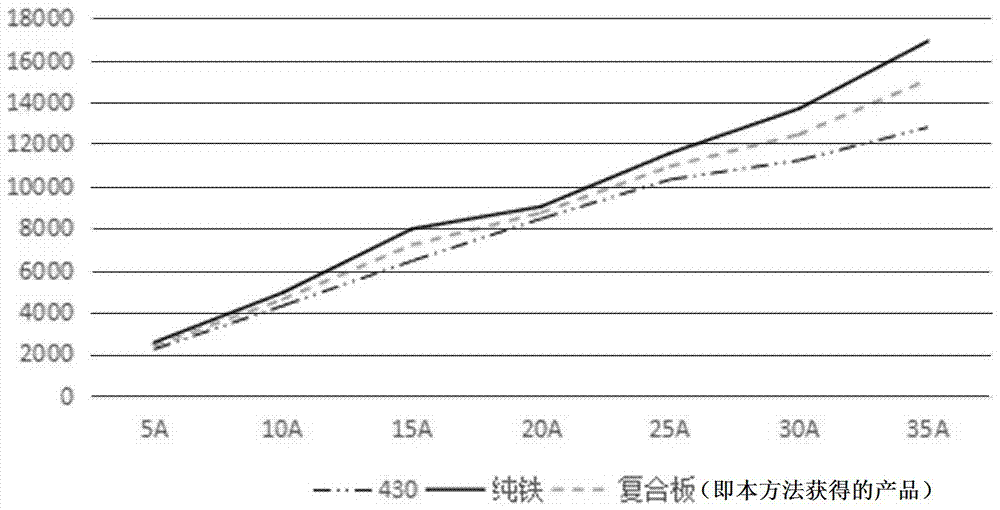

A technology of magnetic concentration medium and high gradient, which is applied in the field of preparation of composite magnetic concentration medium for flat ring strong magnetic separator, can solve the problems of low magnetic field gradient and poor wear resistance and corrosion resistance of single ferritic stainless steel magnetic concentration medium , to achieve the effects of reducing tailings emissions, lowering manufacturing costs, and improving metal recovery rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

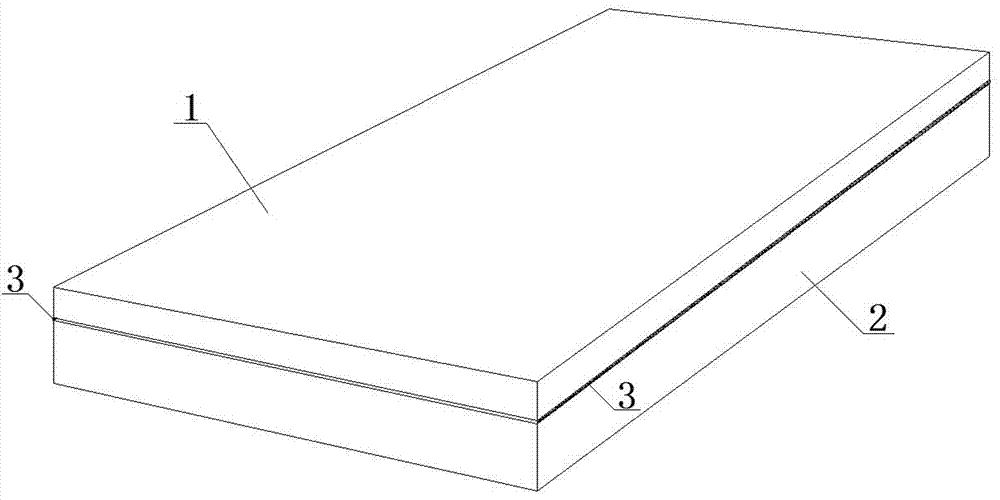

[0023] A method for preparing a composite magnetic gathering medium for a flat-ring high-gradient strong magnetic separator, which is composed of ultra-pure ferritic stainless steel and industrial pure iron, wherein the ultra-pure ferritic stainless steel is a rectangular plate with a thickness of 5mm, and industrial pure iron It is a rectangular plate with a thickness of 10mm, and the length and width of the two are equal. The ultra-pure ferritic stainless steel is the ultra-pure ferritic stainless steel that has been pickled and annealed with a Cr content greater than 16%. Industrial pure iron is rolled industrial pure iron. ; With a concentration of 20-30g / l trisodium phosphate solution and 20-30g / l sodium hydroxide solution prepared in a ratio of 1:1 to plate-shaped ultra-pure ferritic stainless steel 1, plate-shaped industrial pure iron 2 Carry out degreasing, derusting, descaling cleaning, cleaning temperature is 90 ℃; after cleaning, dry in reducing atmosphere;

[0024]...

Embodiment 2

[0029] A method for preparing a composite magnetic gathering medium for a flat-ring high-gradient strong magnetic separator, which is composed of ultra-pure ferritic stainless steel and industrial pure iron, wherein the ultra-pure ferritic stainless steel is a rectangular plate with a thickness of 9 mm, and industrial pure iron It is a rectangular plate with a thickness of 14mm, and the length and width of the two are equal. The ultra-pure ferritic stainless steel is the ultra-pure ferritic stainless steel that has been pickled and annealed with a Cr content greater than 16%. Industrial pure iron is rolled industrial pure iron. ; With a concentration of 20-30g / l trisodium phosphate solution and 20-30g / l sodium hydroxide solution prepared in a ratio of 1:1 to plate-shaped ultra-pure ferritic stainless steel 1, plate-shaped industrial pure iron 2 Carry out degreasing, derusting and descaling cleaning, the cleaning temperature is 60°C; after cleaning, dry in a reducing atmosphere;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com