Magnetic levitation combined beneficiation method for biotite type ore containing rubidium

A mineral processing method, biotite technology, applied in flotation, chemical instruments and methods, magnetic separation, etc., can solve the problems of few research reports on dressing and smelting, and achieve the effect of meeting industrial production requirements, low equipment damage, and high-efficiency recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The biotite-type rubidium-containing ore in a certain place in Guangdong has a rubidium grade of 0.12%, and the gangue minerals mainly include quartz and feldspar.

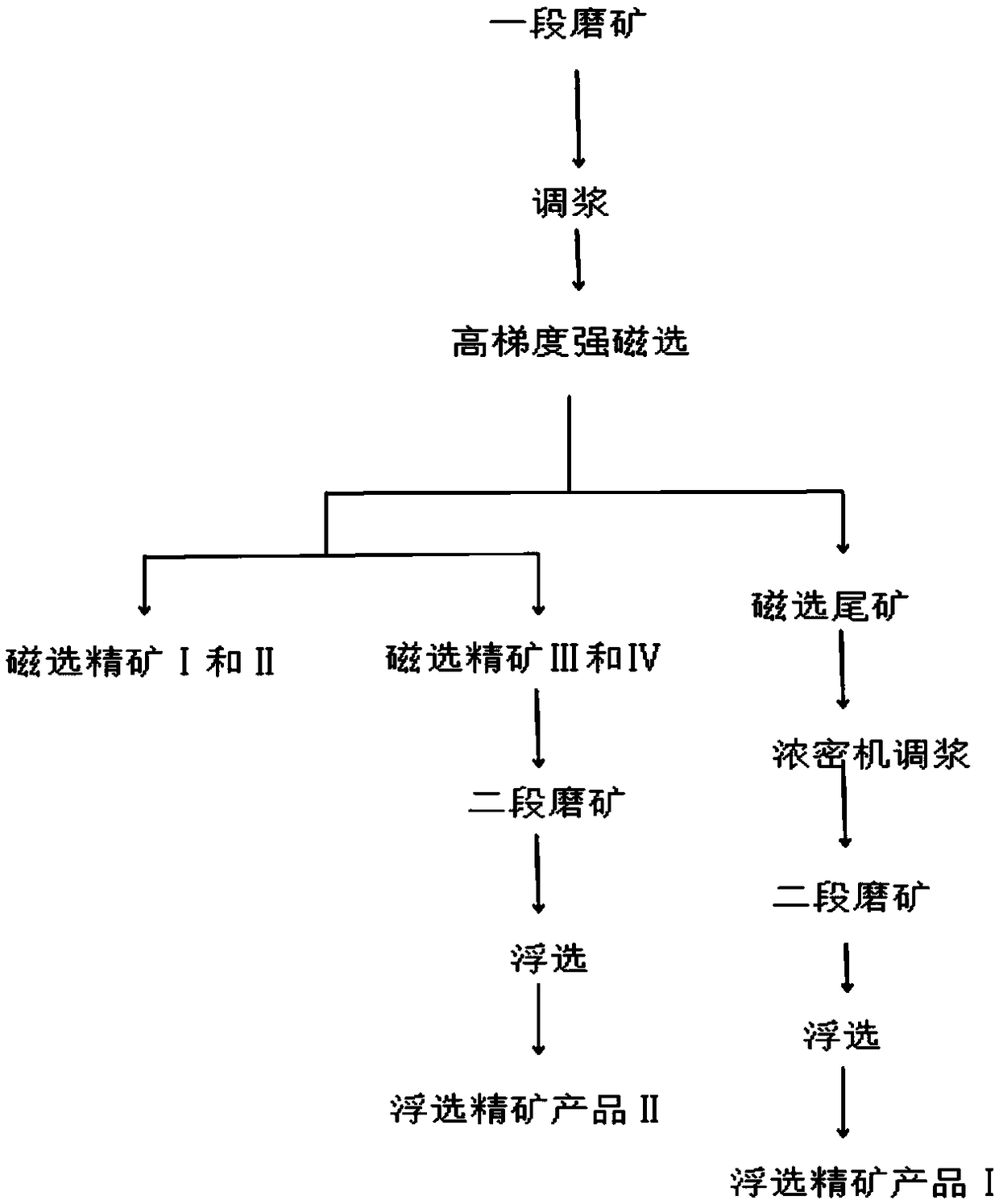

[0034]The ore is ground to -0.074mm, accounting for 62%, the concentration of the ore grinding pulp is 66.7%, and the concentration of the prepared pulp is 25%, and then enters the strong magnetic separator for magnetic separation. The magnetic field strength is 1.45T. After each magnetic separation, water After rinsing, magnetic separation is performed for the second time, and the number of magnetic separations is four times to obtain magnetic separation concentrates I-IV respectively, and the grade of rubidium oxide in the magnetic separation concentrate is 0.22%. The magnetic separation concentrates III and IV enter the grinding machine for secondary grinding through slurry adjustment. The pulp concentration of the grinding is 65%, and the grinding products enter the flotation machine for flotation. The ...

Embodiment 2

[0040] The biotite-type rubidium-containing ore in a certain place in Sichuan has a rubidium grade of 0.1%, and the gangue minerals mainly include quartz, feldspar and calcite.

[0041] The ore is ground to -0.074mm, accounting for 65%, the concentration of the ore grinding pulp is 66.7%, and the concentration of the prepared pulp is 30%, and then enters the strong magnetic separator for magnetic separation. The magnetic field strength is 1.5T. After each magnetic separation, water After rinsing, magnetic separation is performed for the second time. The number of magnetic separations is four times to obtain magnetic separation concentrates I-IV respectively. The grade of rubidium oxide in the magnetic separation concentrate is 0.21%. The magnetic separation concentrates III and IV enter the ore grinding machine for secondary grinding through slurry adjustment, and the concentration of the ore pulp is 60%, and the grinding products enter the flotation machine for flotation. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com