Ore dressing purifying method for high-purity quartz sand

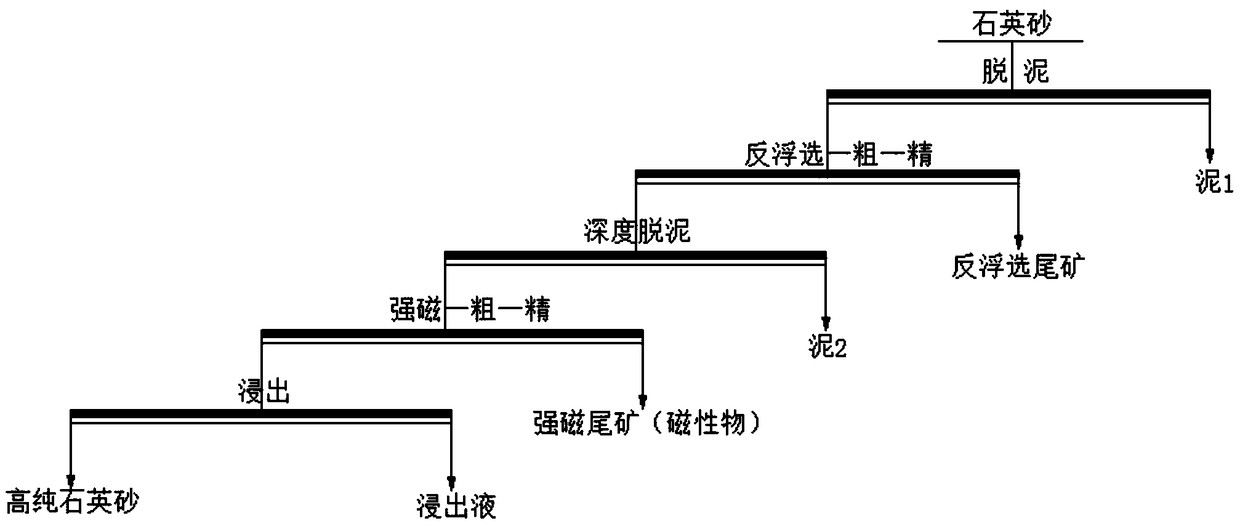

A technology of high-purity quartz sand and purification method, which is applied in the field of non-metallic ore beneficiation and purification, can solve the problems of difficulty in realizing standardized supply of raw materials, unstable product quality, and low high-grade reserves, etc., and achieves high yield, low production cost, high value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A certain quartz sand SiO 2 Grade 99.1942%, Al 2 o 3 Content 0.5242%, Fe 2 o 3 content of 0.1388%, first desliming the quartz sand less than 0.3mm, the desliming amount is 16.37wt%, and the bottom flow is the deslimed sand; then the deslimed sand is fed into the flotation machine for reverse flotation, and the reverse flotation process is a rough selection 1. One-time selection, the dosage of rough selection pH regulator sulfuric acid is 1000g / t, the dosage of dispersant sodium hexametaphosphate is 1500g / t, and the collector is a combination of sodium oleate and dodecylamine, which are added separately, and the dosage is 5000g / t respectively , 800g / t, the amount of selected dodecylamine is 400g / t, and the bottom of the tank is flotation concentrate; then the flotation concentrate is subjected to deep desliming, the desliming amount is 5.12wt%, and the coarse-grained grade is deslimed concentrate ore; then the deslimed concentrate is fed into the strong magnetic sepa...

Embodiment 2

[0037] A certain quartz sand SiO 2 Grade 98.7701%, Al 2 o 3 Content 0.4983%, Fe 2 o 3 content of 0.2720%, desliming the quartz sand less than 0.3mm, the desliming amount is 10.00wt%, and the bottom flow is the deslimed sand; then the deslimed sand is fed into the flotation machine for reverse flotation, and the reverse flotation process is a rough selection 1. One-time selection, the dosage of rough selection pH regulator sulfuric acid is 1000g / t, the dosage of dispersant sodium hexametaphosphate is 1500g / t, and the collector is a combination of sodium oleate and dodecylamine, which are added separately, and the dosage is 5000g / t respectively , 800g / t, the amount of selected dodecylamine is 400g / t, the bottom of the tank is flotation concentrate; then the flotation concentrate is deslimed in depth, the desliming amount is 5.00wt%, and the coarse-grained grade is desliming concentrate ore; then the deslimed concentrate is fed into the strong magnetic separator for magnetic ...

Embodiment 3

[0040] A certain quartz sand SiO 2 Grade 98.4813%, Al 2 o 3 Content 0.6897%, Fe 2 o 3 content of 0.3948%, desliming the quartz sand less than 0.3mm first, the desliming amount is 20.00wt%, and the bottom flow is deslimed sand; then the deslimed sand is fed into the flotation machine for reverse flotation, and the reverse flotation process is a rough selection 1. One-time selection, the dosage of rough selection pH regulator sulfuric acid is 1000g / t, the dosage of dispersant sodium hexametaphosphate is 1500g / t, and the collector is a combination of sodium oleate and dodecylamine, which are added separately, and the dosage is 5000g / t respectively , 800g / t, the amount of selected dodecylamine is 400g / t, and the bottom of the tank is flotation concentrate; then the flotation concentrate is deslimed deeply, the desliming amount is 10.00wt%, and the coarse-grained grade is deslimed concentrate ore; then the deslimed concentrate is fed into the strong magnetic separator for magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com