Novel dry-process white cement raw material preparation device and process

A technology for preparing device and white cement, which is applied to cyclone devices, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of poor dispersibility, large consumption, concentrated in the coarser particles, etc., to improve the wear resistance life. , to avoid the increase of vibration and improve the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

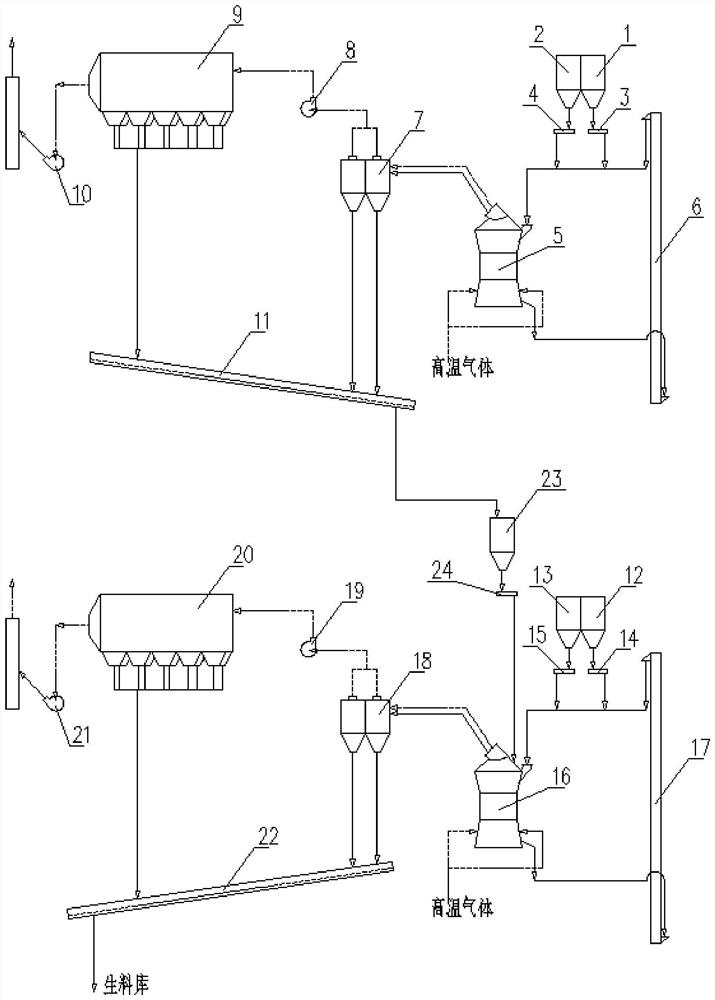

[0053] A novel dry-process white cement raw meal preparation device, the novel dry-process white cement raw meal preparation device includes a silicon-aluminum raw material grinding system and a calcium raw material grinding system, and the silicon-aluminous raw material grinding system is easy Grinding the silicon-aluminum raw materials with poor grindability, the calcareous raw material grinding system grinds and sorts the calcareous raw materials with good grindability, and grinds the qualified ones with the silicon-aluminum raw material grinding system Fineness silicon-aluminum raw materials are mixed.

[0054] Calcium raw materials with good grindability (limestone, etc.) and silica-alumina raw materials with poor grindability (quartz sandstone, pyrophyllite, etc.) are dried and ground separately with two sets of grinding systems and equipment, instead of mixed powder Grinding is beneficial to reduce the content of raw materials with poor grindability such as silicon and ...

Embodiment 2

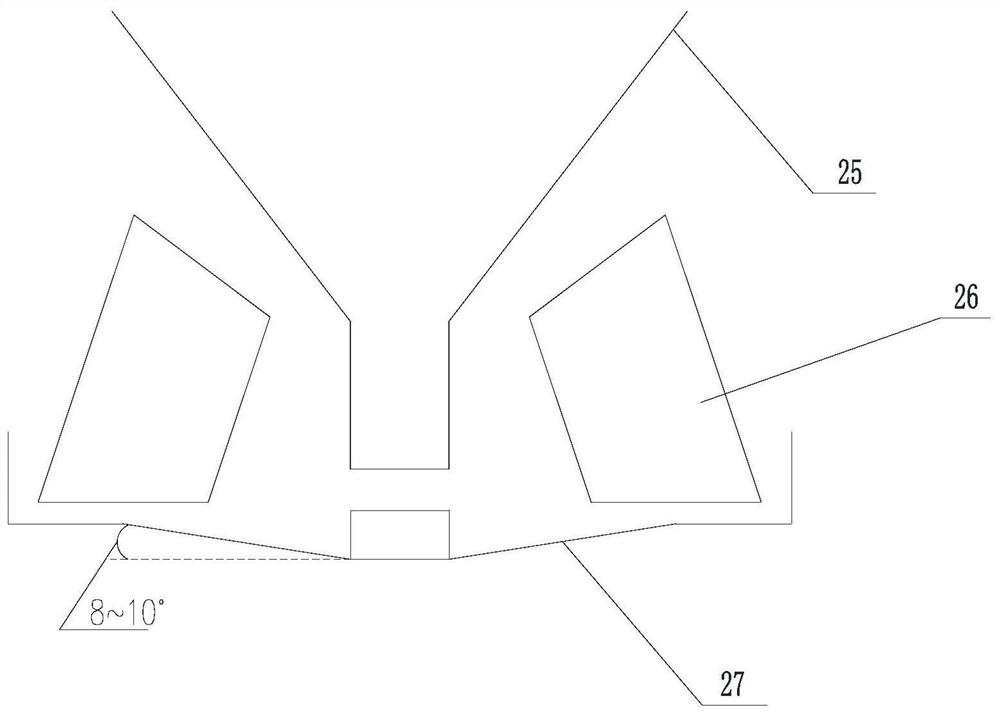

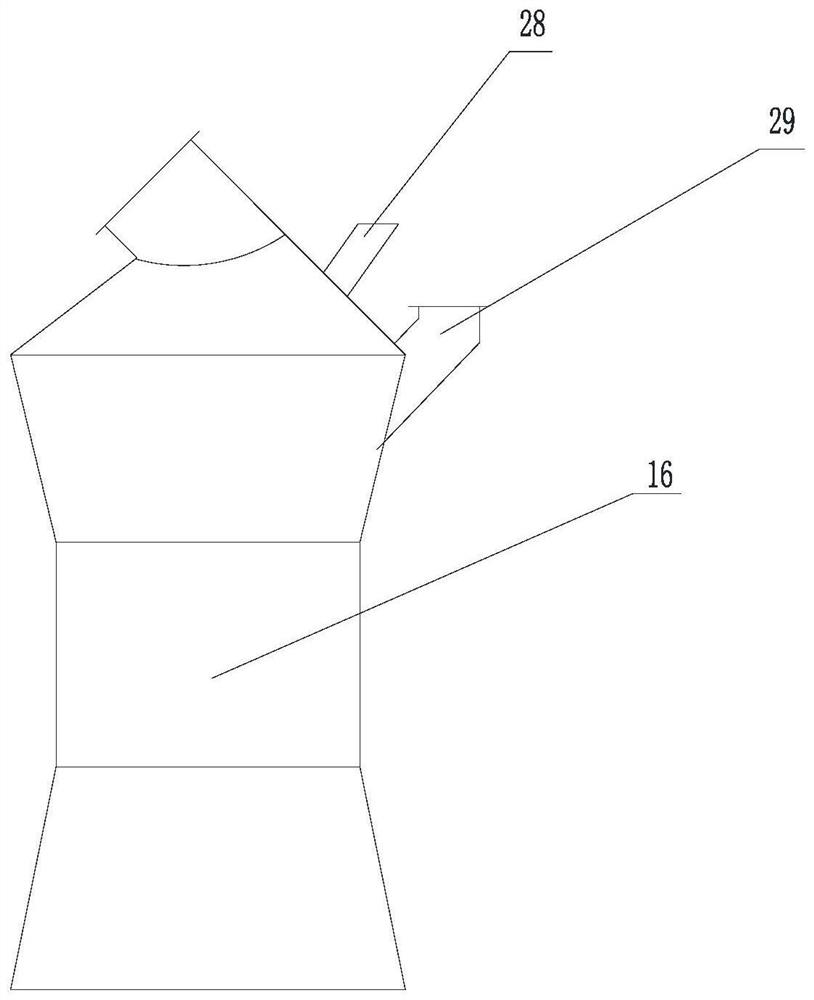

[0060] The silicon-aluminum raw material grinding system includes: a silicon raw material storage bin 1 and a measuring scale A3 located below it, an aluminum raw material storage bin 2 and a measuring scale B4 located below it, a roller mill A5, and an elevator A6, cyclone A7, circulation fan A8, dust collector A9, system fan A10, finished product conveying chute A11, calcareous raw material fine powder storage bin, weighing scale E24, hoist A6;

[0061] The discharge port of metering balance A3 and metering balance B4 communicates with the feed inlet of roller mill A5, and the discharge port of described roller mill A5 is connected with cyclone A7, and the air outlet of described cyclone A7 is connected with circulating fan A8. The dust collector A9 is connected, the air outlet of the dust collector A9 is exhausted through the system fan A10, and the finished product conveying chute A11 is arranged below the bottom outlet of the dust collector A9 and the bottom outlet of the ...

Embodiment 3

[0072]A novel dry-process white cement raw meal preparation process, the novel dry-process white cement raw meal preparation process uses the novel dry-process white cement raw meal preparation device described in any one of the above, the novel dry-process white cement raw The material preparation process includes the following steps:

[0073] Step 1: Quartz sandstone and pyrophyllite silicon-aluminum raw materials are measured by weighing scale and weighing scale respectively according to the proportion, and then sent to roller mill A5. After high-efficiency grinding and drying, the materials are sent to the built-in roller mill A5 by wind The high-efficiency powder separator is used for sorting, and the finished products after sorting are collected by the cyclone A7 and sent to the siliceous raw material fine powder storage bin 23 for storage through the conveying chute A11;

[0074] Step 2: After the dust-containing gas exiting the cyclone A7 is collected by the dust colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com