Method for preparing diamond-like film by liquid-phase electro-deposition technology

A diamond thin film and electrodeposition technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of low deposition rate and difficult experimental operation, and achieve the effects of low deposition temperature, simple preparation equipment, and expanded selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1. Using high-purity dimethyl sulfoxide as the electrolyte, polished high-purity graphite and substrate silicon as the anode and cathode, the distance between the electrodes is 7mm, the reaction temperature is 50°C, and a 500V high-frequency pulse direct current is applied between the two poles Voltage. Before deposition, the silicon wafer used as the substrate was ultrasonically treated in acetone for 10 minutes to remove surface impurities, and then soaked in hydrofluoric acid solution for 5 minutes to remove surface oxides.

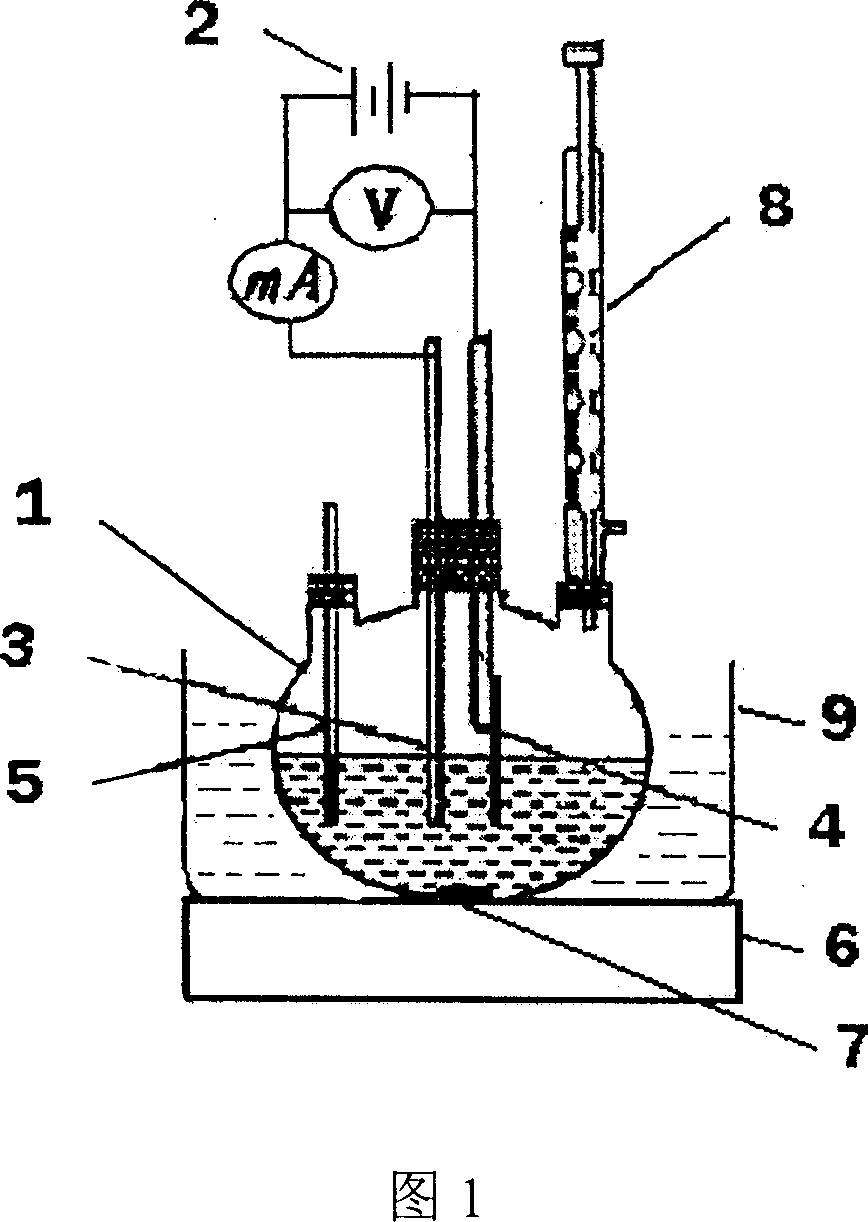

[0018] The preparation device is shown in Figure 1. High-purity graphite 3 is used as the anode, the substrate silicon wafer 4 is the cathode, the 0-3000V high-frequency pulsed DC voltage power supply 2 is the external power supply, and high-purity dimethyl sulfoxide is used as the electrolyte. 7 and the magnetic heating stirrer 6 stir the electrolytic solution and control the temperature of the water bath 9, the thermometer 5 inserted i...

Embodiment 2

[0019] Embodiment 2. In this embodiment, the reaction temperature is 70° C., and a high-frequency pulsed DC voltage of 300 V is applied between the two poles. Others are the same as embodiment 1.

Embodiment 3

[0020] Embodiment 3. In this embodiment, the reaction temperature is 90° C., and a high-frequency pulsed DC voltage of 50 V is applied between the two poles. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com