Patents

Literature

34results about How to "Meet raw material demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

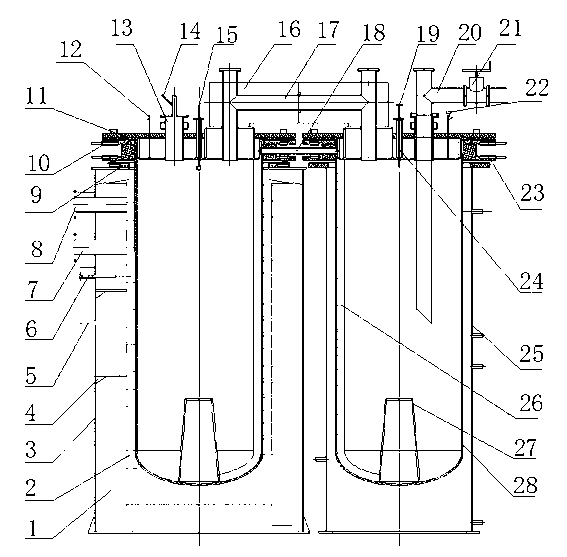

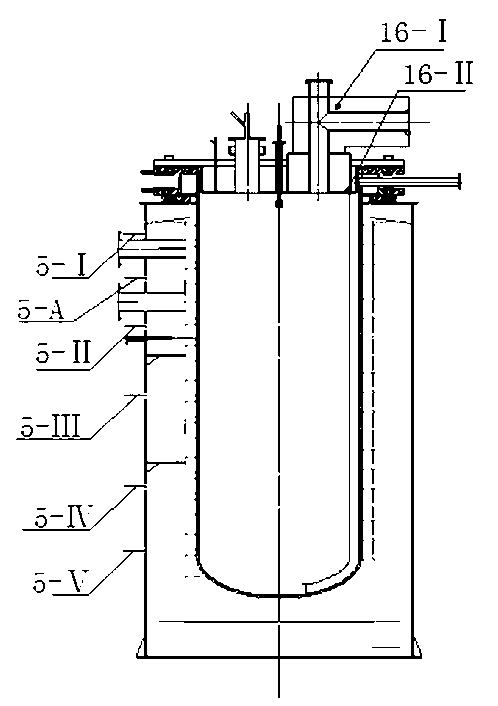

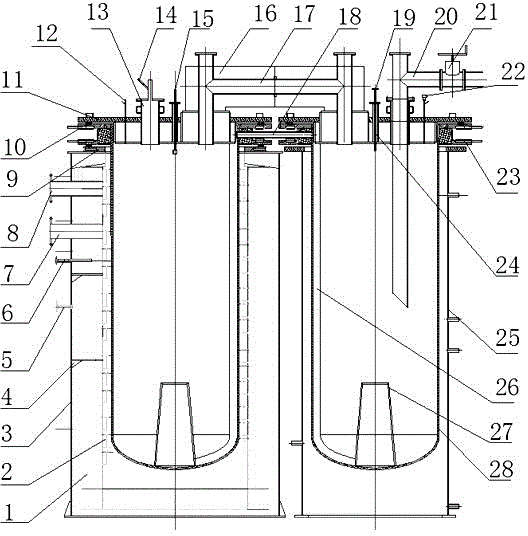

15-ton inverted-U-shaped combination device and production process for producing sponge titanium

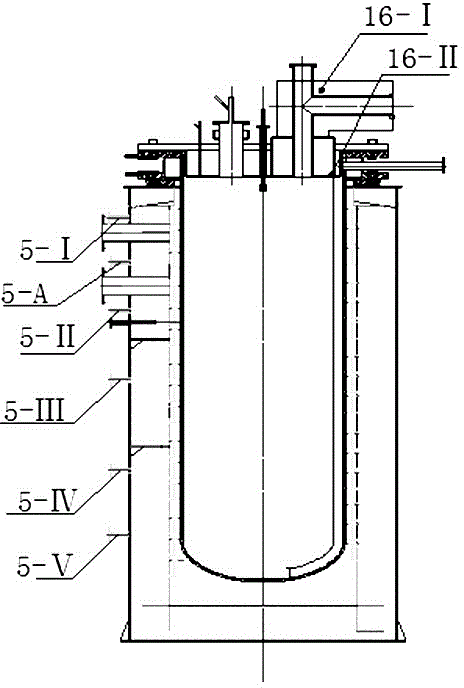

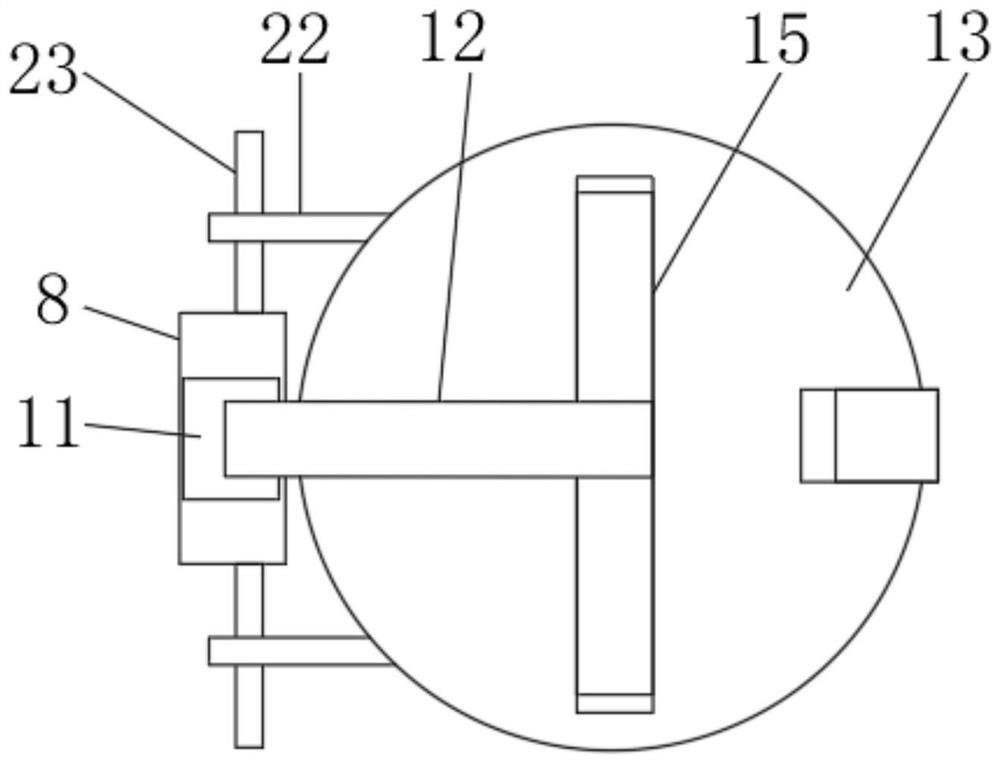

The invention relates to a 15-ton inverted-U-shaped combination device and a production process for producing sponge titanium. The 15-ton inverted-U-shaped combination device is composed of a reaction furnace, a reactor 28, a reactor cover 11 and a cooling water jacket 25, wherein the reactor 28 comprises a cold-end reactor and a hot-end reactor which are arrayed in parallel; the two reactors are communicated via the reactor cover 11 above; the cold-end reactor is located in the cooling water jacket 25; and the hot-end reactor is located in the reaction furnace. A large furnace has the advantages of being low in energy consumption, high in capacity, stable in quality, and high in labour productivity; and with the progress of a production technology for sponge titanium, the furnace profile is developed towards a large-size direction. The invention provides a 15-ton inverted-U-shaped combination device and a production process for sponge titanium.

Owner:朝阳金达钛业股份有限公司

Method for preparing low acid-value fatty acid methyl ester

ActiveCN102153465AHigh reactivityShort reaction timeOrganic compound preparationCarboxylic acid esters preparationDistillationSolid acid

The invention relates to a method for synthesizing low acid-value fatty acid methyl ester by esterification reaction and aims at providing the method with the characteristics that a process is simple; a catalyst and a product are easy to separate and can be recycled; the reaction conversion rate is high; and the obtained fatty acid methyl ester has low acid value. The method for preparing the lowacid-value fatty acid methyl ester sequentially comprises the following steps of: 1, feeding fatty acid and a resin catalyst together or feeding the fatty acid and a solid acid catalyst together, andthen heating the mixture with stirring; 2, after a temperature of a reaction system is raised to 50 to 80 DEG C, dropwise adding methanol into the reaction system, distilling the methanol and water generated in the reaction process, sampling and monitoring the reaction conversion rate in the reaction process and finishing the reaction until the acid value reaches below 0.5mgKOH / g, wherein the pressure of the reaction system is in the range of 10 to 101Kpa and the reaction time is in the range of 4 to 6 hours; and 3, after finishing the reaction, filtering out the catalyst, carrying out reduced pressure distillation on filtrate to separate out excessive methanol and water to obtain a finished product and directly recycling the resin catalyst or the solid acid catalyst.

Owner:ZANYU TECH GRP CO LTD

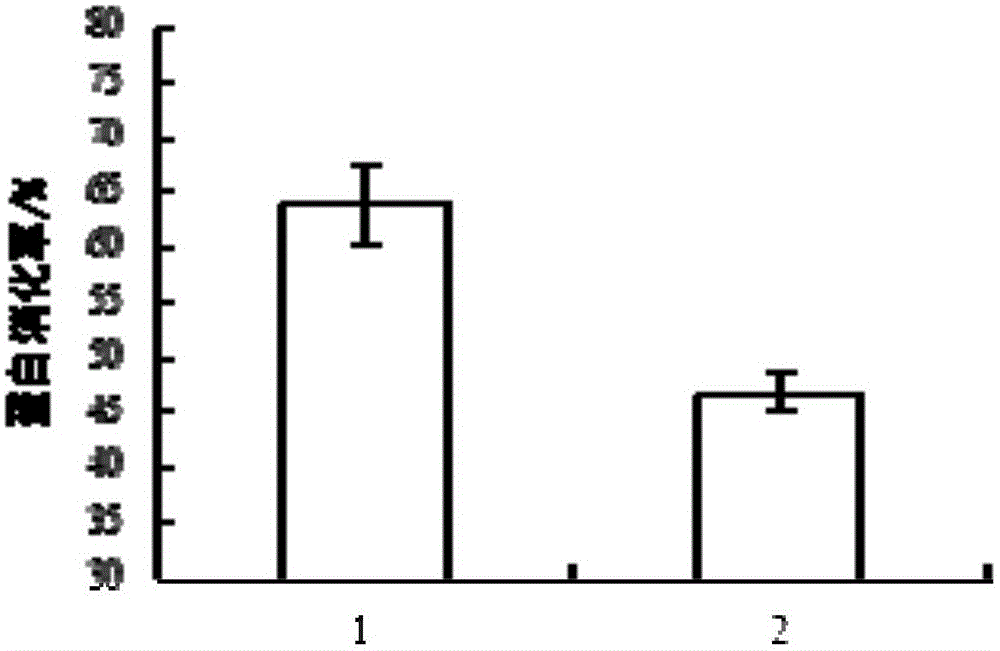

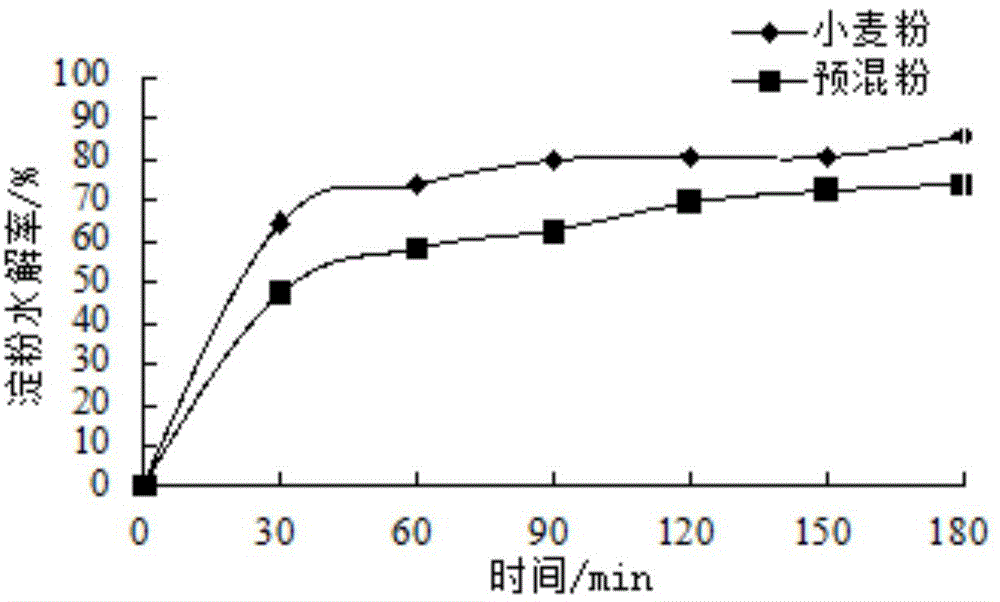

Whole grain premixed dumpling flour containing puffed sorghum, and preparation method thereof

The invention discloses a whole grain premixed dumpling flour containing puffed sorghum and a preparation method thereof. According to the whole grain premixed dumpling flour, wheat flour and whole grain red sorghum puffed powder are taken as total flour materials, wherein weight ratio of wheat flour to the whole grain red sorghum puffed powder ranges from 5:5 to 7:3; and the whole grain premixed dumpling flour is prepared via adding vital gluten, soy isolate protein, and konjac glucomannan for mixing at an appropriate ratio. According to the preparation method, puffing technology is adopted for processing whole grain sorghum powder, so that problems caused by application of whole grain sorghum powder in dumpling wrapper processing are solved, wherein the problems are that: adding ratio is low, molding is difficult to realize, product palatability is poor, and protein digestibility is low. The obtained whole grain premixed dumpling flour possesses unique color and scorch aroma flavor of sorghum puffed powder; mouthfeel of dumpling wrappers prepared from the whole grain premixed dumpling flour is smooth; technology demands of hand made or machine made dumpling wrappers are satisfied; dumpling kinds are increased; application method is simple; and the whole grain premixed dumpling flour is suitable for household dumpling preparation, restaurant fancy cooking, and coarse cereal dumpling production of processing enterprises.

Owner:NORTHWEST A & F UNIV

Method for preparing calcium silicate board from low-grade limestone

ActiveCN105218059AReduce procurement costsMeet raw material demandLime productionCalcium silicateLower grade

The invention discloses a method for preparing a calcium silicate board from low-grade limestone. The method comprises steps as follows: 1) crushing and homogenization of low-grade limestone; 2) calcination; 3) digestion: the calcined low-grade limestone in Step 2) is digested and transferred into a storage tank; 4) preparation of mixed slurry: a siliceous material, paper fibers and alkali-resistant short glass fibers are added to slurry in the storage tank in Step 3), and mixed slurry is prepared; 5) blank formation: a blank is prepared from the mixed slurry obtained in Step 4) and trimmed; 6) autoclaved curing: the trimmed blank in Step 5) is transferred into an autoclave for autoclaved curing, pressure relief, cooling, drying, edging and sanding are performed, and the calcium silicate board is prepared. The low-grade limestone can be matched and utilized again, the requirement for raw materials in production of the calcium silicate board is met, the production cost is reduced, the green industry is formed, and energy is saved.

Owner:武钢资源集团乌龙泉矿业有限公司

A kind of high-strength and high-conductivity cucrzrmg series copper alloy wire material and preparation method thereof

ActiveCN108060323BHigh strengthIncrease the number ofConductive materialMetal/alloy conductorsPower flowIngot casting

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

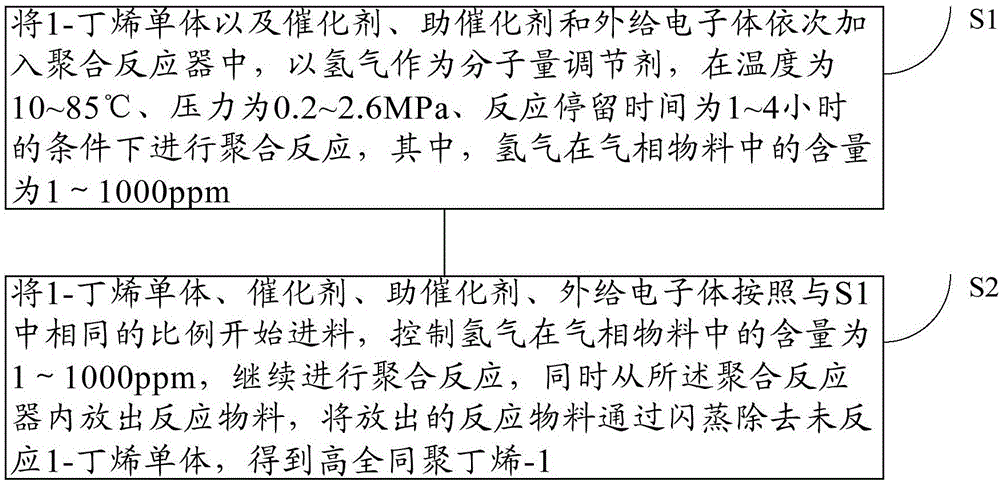

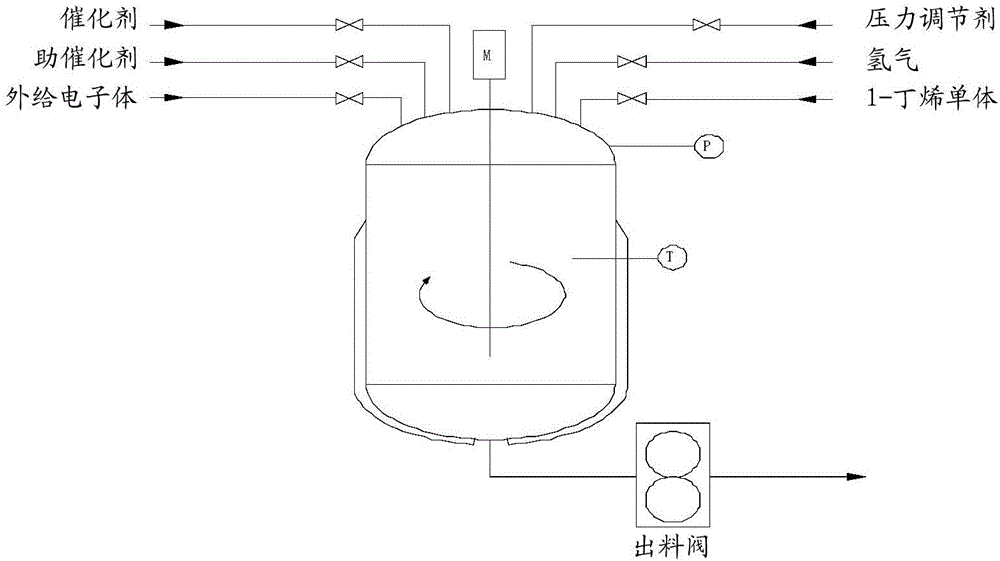

A continuous production method for highly isotactic poly(1-butene)

A continuous production method for highly isotactic poly(1-butene) is provided in embodiments of the invention and belongs to the field of polymers. Continuous stable production of the highly isotactic poly(1-butene) is achieved, continuous stability of product quality can be ensured and the molecular weight distribution of products is controlled. The method includes S1) adding a 1-butene monomer, a catalyst, a cocatalyst and an external electron donor into a polymerization reactor in order, and performing polymerization at 10-85 DEG C under 0.2-2.6 MPa with hydrogen being adopted as a molecular weight adjusting agent, reaction residence time being 1-4 h and the content of the hydrogen in a gaseous material being 1-1000 ppm; and S2) charging according to a ratio same as the ratio in the steps S1), controlling the content of the hydrogen in the gaseous material to be 1-1000 ppm, continuing polymerization, discharging the reaction material from the polymerization reactor at the same time, and removing the unreacted 1-butene monomer from the discharged reaction material through flash evaporation to obtain the highly isotactic poly(1-butene). The method can be used for industrial production of the highly isotactic poly(1-butene).

Owner:山东省滕州瑞达化工有限公司

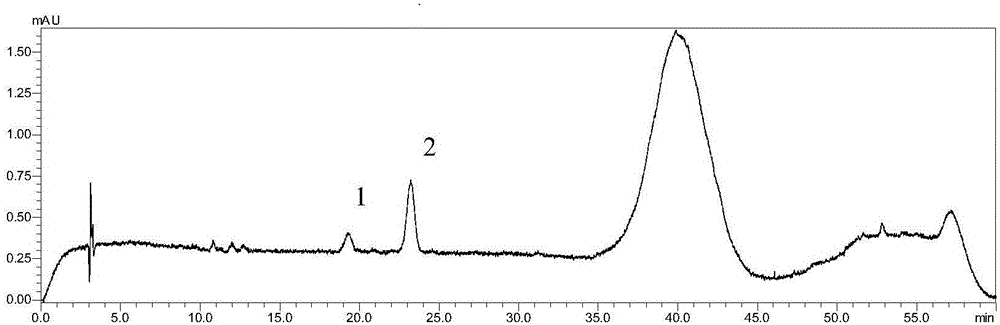

Preparation method of pure natural ligustrum quihoui carr fruit's anthocyanin

ActiveCN105017201APromote development and utilizationLow costOrganic chemistryLigustrum quihouiFood resources

A preparation method of pure natural ligustrum quihoui carr fruit's anthocyanin belongs to the technical field of deep-processing of food resources. The invention relates to a solvent extraction and column chromatography combination technique for purification and preparation of high-purity anthocyanin. The preparation method is characterized by low cost, simple preparation technology, short production cycle, safe and nontoxic reagent, high extraction purity, easy industrial production and the like, and is of great significance for developing high value-added ligustrum quihoui carr fruit products. The prepared ligustrum quihoui carr fruit's anthocyanin with anthocyanin purity being 30-35% is nutritious and safe, is stable, is easy to store, and has a wide application prospect in fields of food, medicine, biochemistry and the like. Through preparation of the anthocyanin product in ligustrum quihoui carr fruit, full utilization of ligustrum quihoui carr fruit is raised, and a ligustrum quihoui carr fruit's anthocyanin purification technology is given attention. Thus, waste ligustrum quihoui carr fruit is changed into valuable things, providing powerful guarantee for realizing economic value of the ligustrum quihoui carr fruit.

Owner:JILIN UNIV

Improved refining process of 1, 4-dihydroxy anthraquinone

ActiveCN112920036AMeet raw material demandNo wasteQuinone separation/purificationXylyleneDistillation

The invention relates to the technical field of fine chemical engineering, in particular to an improved refining process of 1, 4-dihydroxy anthraquinone. The process comprises the following steps: adding xylene into a reaction container to dissolve a 1, 4-dihydroxy anthraquinone crude product until solids are not reduced any more to obtain a 1, 4-dihydroxy anthraquinone crude product solution; adding an aqueous alkali solution into the 1, 4-dihydroxy anthraquinone crude product solution to extract phthalic acid and p-chlorophenolsulfonic acid, and carrying out settling separation to obtain an aqueous alkali layer and an insoluble substance layer so as to obtain a xylene layer; carrying out water vapor distillation on the xylene layer, recycling the obtained xylene solvent, and filtering and washing the remaining aqueous solution to obtain a refined product of 1, 4-dihydroxy anthraquinone. The product treated by the process disclosed by the invention can effectively meet the raw material requirement of solvent dye, basically has no waste, and the yield can reach 95-97%, and even 98-99% according to the internal standard.

Owner:JIANGSU HUAER CHEM

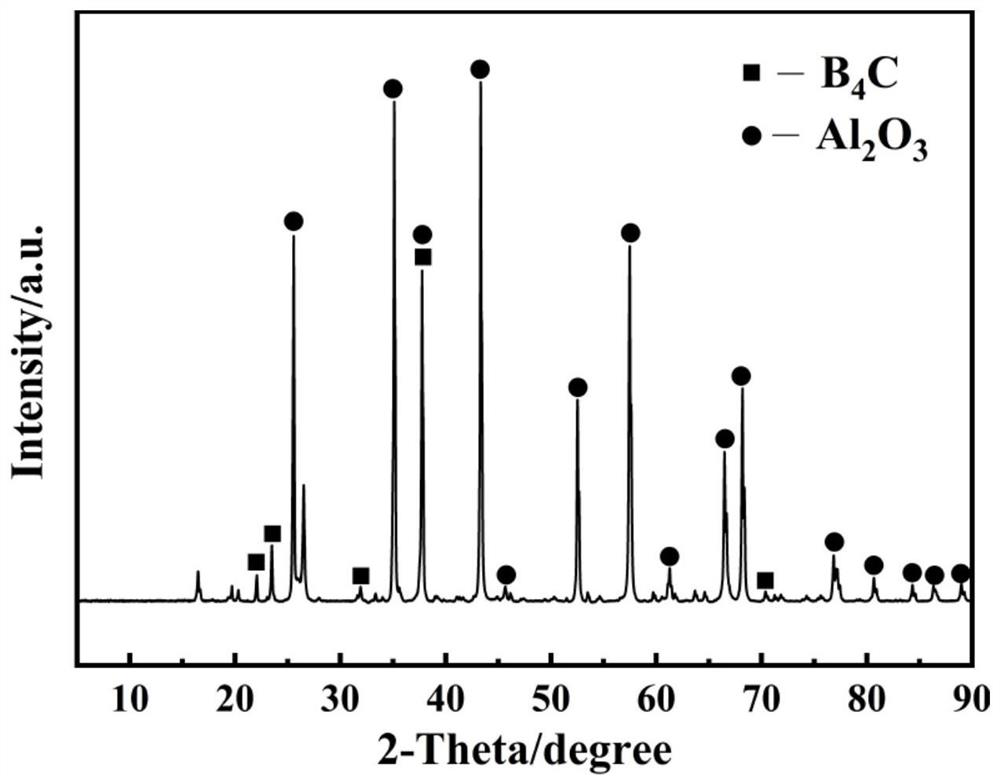

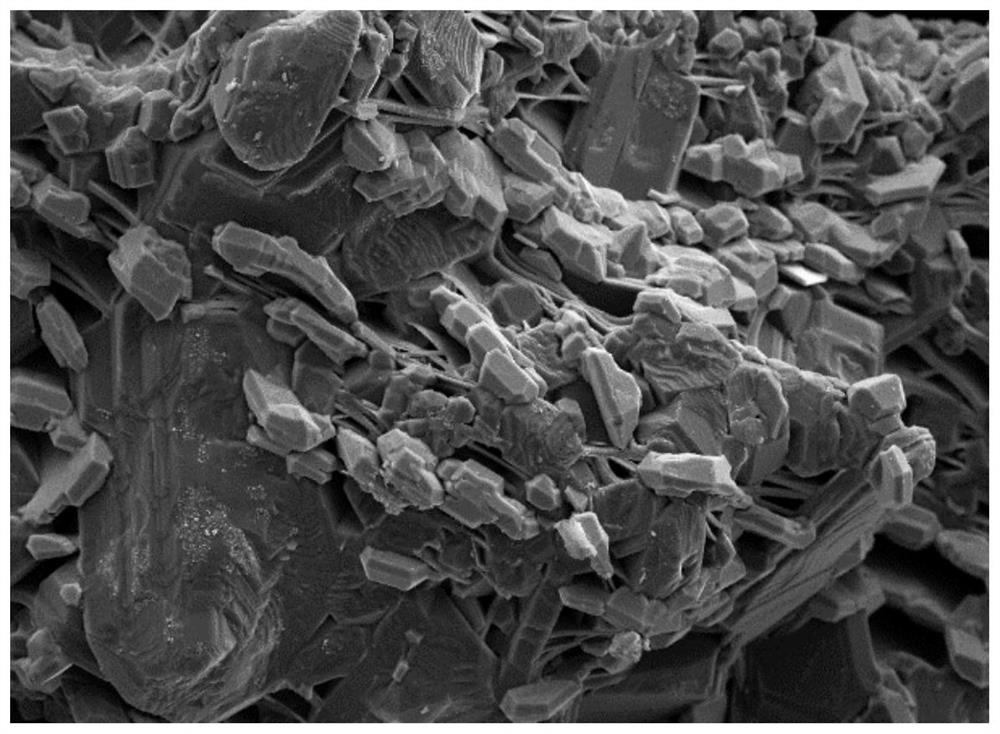

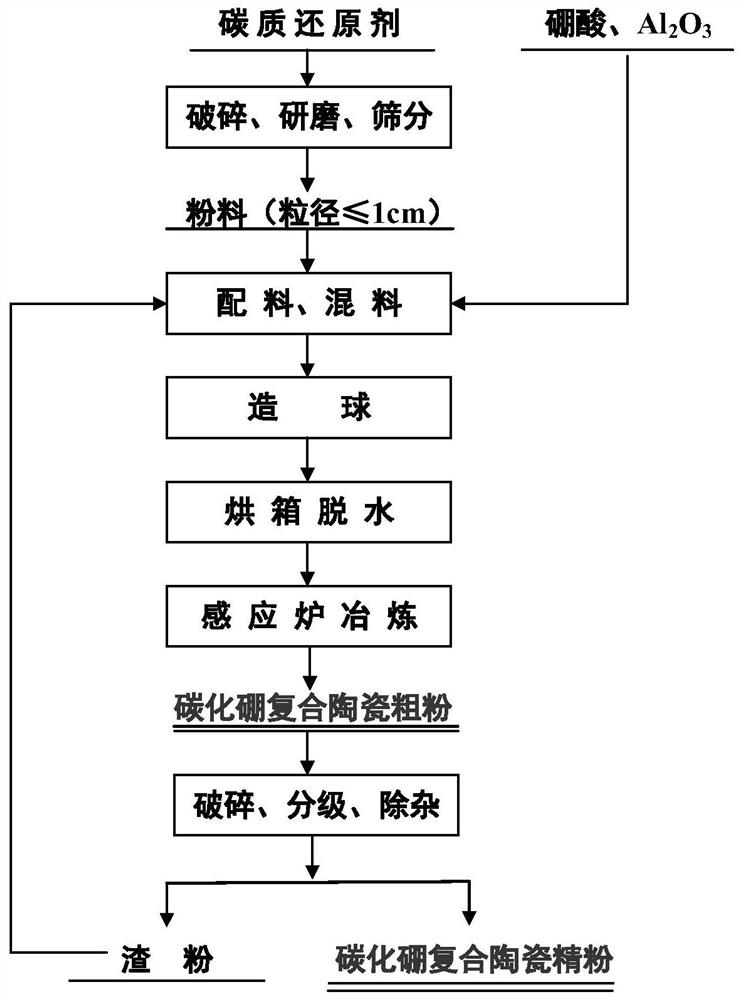

A method of adding alumina powder to prepare boron carbide aluminum composite ceramic powder

The invention discloses a method for preparing boron carbide aluminum composite ceramic powder by adding alumina powder. The steps are as follows: (1) first crush the carbonaceous reducing agent into powder; (2) crush the carbonaceous reducing agent powder, boric acid powder and Al 2 o 3 The powder is batched, mixed, and pressed into pellets according to a certain proportion, and then the pellets are dried; (3) the pellets are put into a heating furnace for high-temperature smelting to prepare boron carbide composite ceramic coarse powder; (4 ) breaking the obtained coarse powder and classifying and removing impurities; (5) reclaiming and reusing the obtained slag powder, and using the boron carbide composite ceramic fine powder to make boron carbide composite ceramic sintering raw materials. Compared with traditional electric arc furnace smelting, the present invention improves the utilization rate of raw materials, significantly reduces production cost and energy consumption; directly adds Al to the configured raw materials 2 o 3 Compared to the in situ generation of Al in the reaction 2 o 3 There are obvious advantages; the fracture toughness of the boron carbide composite ceramics is obviously improved; the process can reduce environmental pollution and reduce high-temperature gas emissions.

Owner:NORTHEASTERN UNIV LIAONING

Fertilizer and preparation method thereof

InactiveCN104529590AEasy to makeEasy to processAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiammonium phosphateChemistry

The invention relates to a fertilizer, which comprises the following components (weight percentage): 53-65% of rape straw, 17-25% of urea, 4-8% of diammonium phosphate, 6-12% of water, 3-8% of magnesium sulfate, 2-3% of phosphorus pentoxide, 2-6% of potassium sulfate, 6-8% of potassium chloride and 3-6% of zinc sulfate. With the technical means, the fertilizer provided by the invention has the characteristics of simple making and convenient processing, and can meet the demand of crops for raw materials according to common planting methods. By using the rape straw as the main raw material, the resource is rationally utilized, and other common raw materials are also added to effectively meet the demand of the fertilizer for necessary elements. The fertilizer can adapt to raw materials needed by planting of different plants, and increases the plant yield.

Owner:ZUNYI LIMANFENG FERTILIZER IND

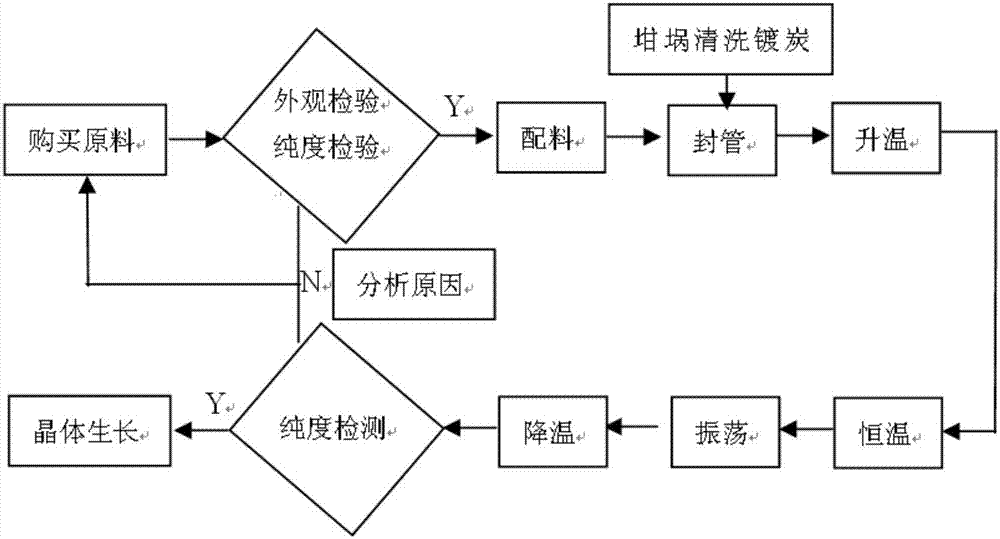

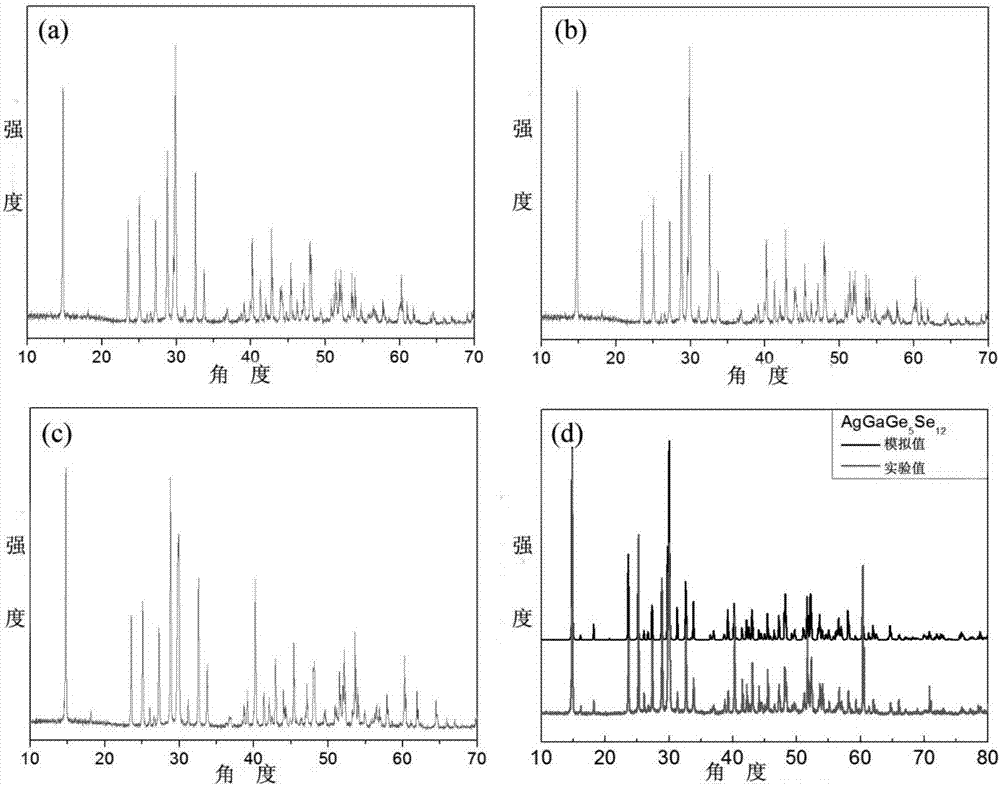

Rapid synthesis method of AgGaGenSe2(n+1) series compounds

InactiveCN107161958AFast synthesis rateA large amount of single synthesisAfter-treatment apparatusSelenium/tellurium compounds with other elementsPhotochemistryRaw material

The invention relates to a rapid synthesis method of AgGaGenSe2(n+1) series compounds and aims at solving the problems that an existing conventional AgGaGenSe2(n+1) (n=2,3,4,5) series compound element high temperature synthesis method is low in synthesis speed and the proportion of ingredients is difficult to control. The synthesis method comprises the following steps: taking high-purity Ag2Se, Ga2Se3 or AgGaSe2 and GeSe2 as initial raw materials, adjusting the molar ratio of GeSe2, and rapidly synthesizing the AgGaGenSe2(n+1) series compounds, namely AgGaGe2Se6, AgGaGe3Se8, AgGaGe4Se10 and AgGaGe5Se12. Specific operation steps are as follows: (1) pretreatment on a synthesis crucible; (2) determination of a raw material ratio; (3) heating oscillation; and (4) cooling. The characteristics of convenient operation, high synthesis speed and easy-to-control components are realized by adopting the method provided by the invention for synthesizing the AgGaGenSe2(n+1) series compounds.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

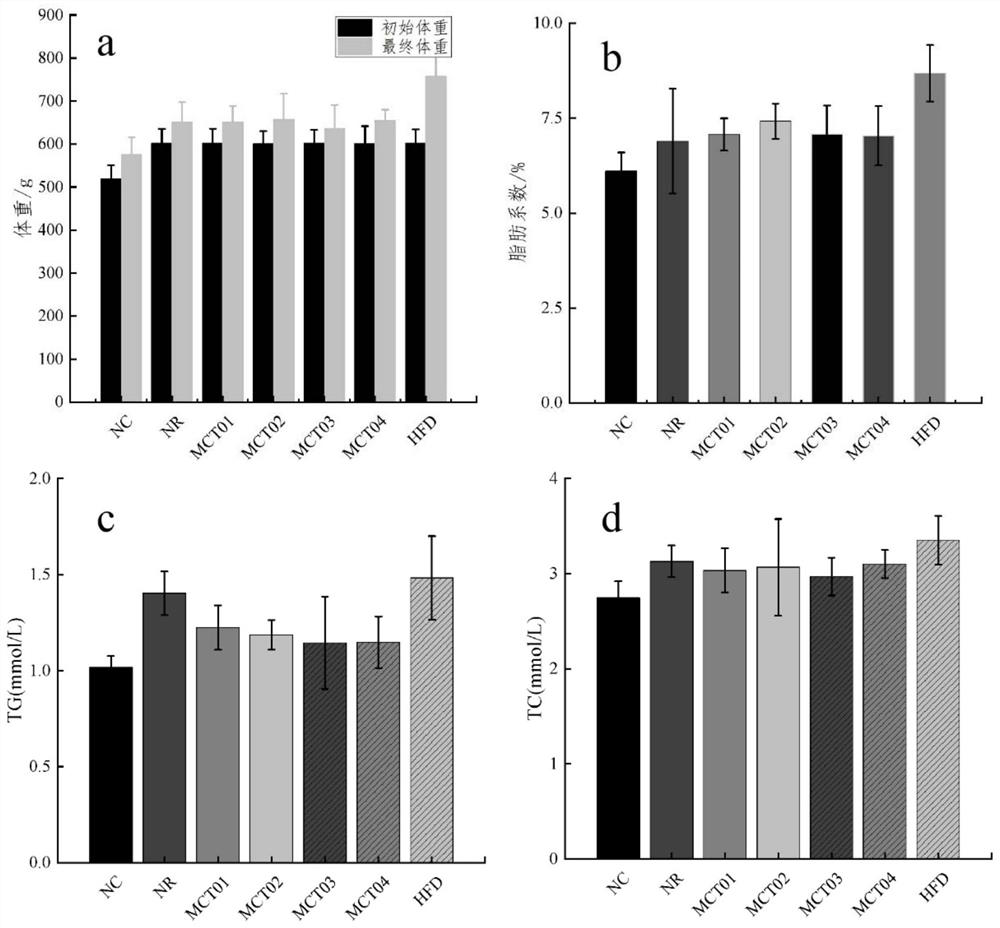

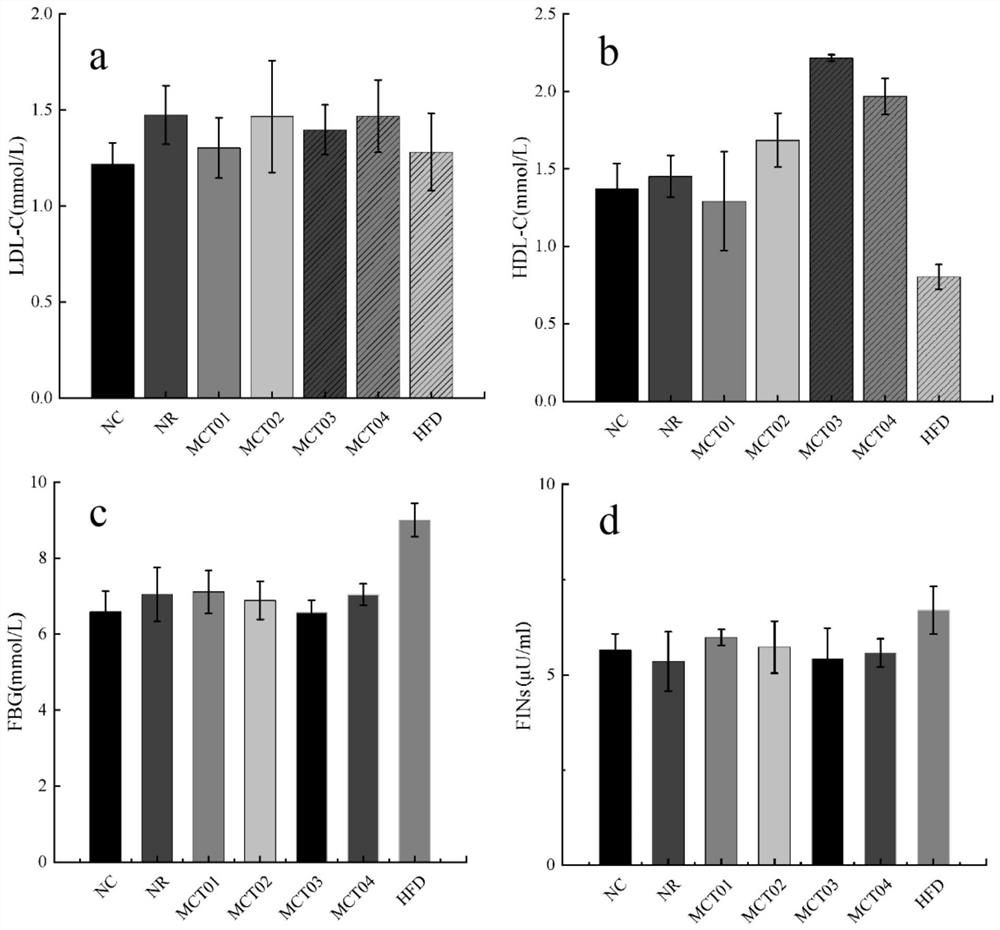

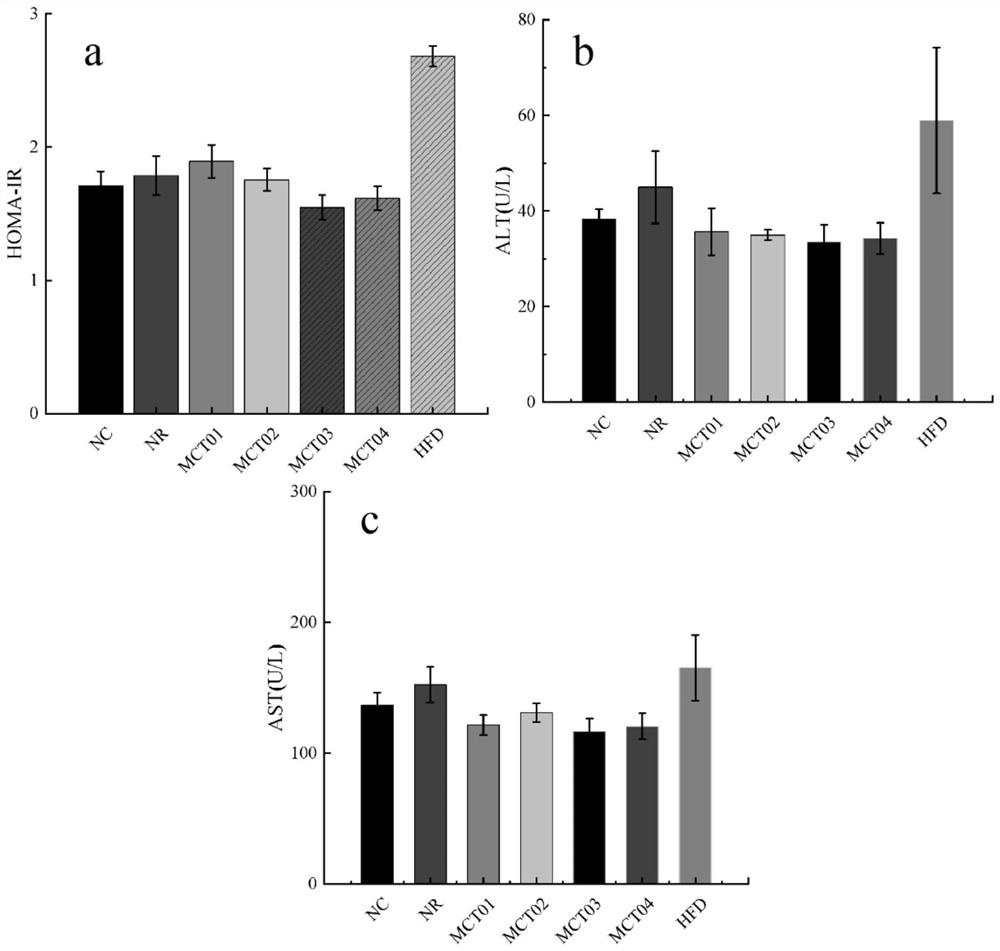

Caprylic/capric acid-lauric acid medium-carbon chain oil and preparation method and application thereof

PendingCN112920908AImprove glucose and lipid metabolism disordersImprove health and living standardsFatty acid esterificationFermentationDietingNutrition

The invention relates to caprylic / capric acid-lauric acid medium-carbon chain oil and a preparation method and application thereof. Camphor tree seed kernel oil and caprylic acid are subjected to binary ester exchange, and fatty acid on glycerol skeleton molecules of the camphor tree seed kernel oil is recombined,the fatty acid incaprylic / capric acid-lauric acid medium-carbon chain oil is calculated by mass and the mass ratio of caprylic acid to the camphor tree seed kernel oil in the caprylic / capric acid-lauric acid medium-carbon chain oil is 0.3-0.6. Camphor tree seed kernel oil is utilized to construct the caprylic / capric lauric acid medium-carbon chain oil product capable of rapidly supplementing energy in a body and remarkably improving glucose and lipid metabolism disorder in the body, high-value utilization of camphor tree seed resources can be promoted, the situation that medium-carbon chain oil products in China mainly depend on import is ended, and the diet and nutritional requirements of consumers, especially patients with metabolic syndrome, athletes, patients with long-carbon-chain fatty acid transport, metabolism and absorption disorders and critical patients are met.

Owner:NANCHANG UNIV

Method for preparing calcium silicate board from low-grade limestone

ActiveCN105218059BReduce procurement costsMeet raw material demandLime productionCalcium silicateLower grade

The invention discloses a method for preparing a calcium silicate board from low-grade limestone. The method comprises steps as follows: 1) crushing and homogenization of low-grade limestone; 2) calcination; 3) digestion: the calcined low-grade limestone in Step 2) is digested and transferred into a storage tank; 4) preparation of mixed slurry: a siliceous material, paper fibers and alkali-resistant short glass fibers are added to slurry in the storage tank in Step 3), and mixed slurry is prepared; 5) blank formation: a blank is prepared from the mixed slurry obtained in Step 4) and trimmed; 6) autoclaved curing: the trimmed blank in Step 5) is transferred into an autoclave for autoclaved curing, pressure relief, cooling, drying, edging and sanding are performed, and the calcium silicate board is prepared. The low-grade limestone can be matched and utilized again, the requirement for raw materials in production of the calcium silicate board is met, the production cost is reduced, the green industry is formed, and energy is saved.

Owner:武钢资源集团乌龙泉矿业有限公司

Economic and environmental-friendly planting method of morinda officinalis

PendingCN111183863AEasy to cause lossChurn does not causeRoot crop cultivationReceptacle cultivationPharmaceutical industryInsect pest management

The invention discloses an economic and environmental-friendly planting method of morinda officinalis. The planting method comprises the steps of digging planting grooves in the ground of a morinda officinalis planting region, sleeving a permeable cloth bag in each planting groove, stuffing each cloth bag with soil, then growing morinda officinalis seedlings in the soil in the cloth bags, performing water and fertilizer management and disease and insect pest management, enabling the morinda officinalis to grow, when the morinda officinalis is gathered, digging out the soil around the cloth bags, and taking out the cloth bags so as to harvest the morinda officinalis. The planting method disclosed by the invention is environmentally-friendly, water and soil erosion cannot be caused during gathering, the problems of planting waterlogging and the like are solved, the economic returns of planting households are increased, raw material requirements for pharmaceutical industry are met, marketrequirements are further met, the planting method is simple and easy to operate, economic and environmental-friendly, and the planting method is worth large-area promotion for planting.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI +1

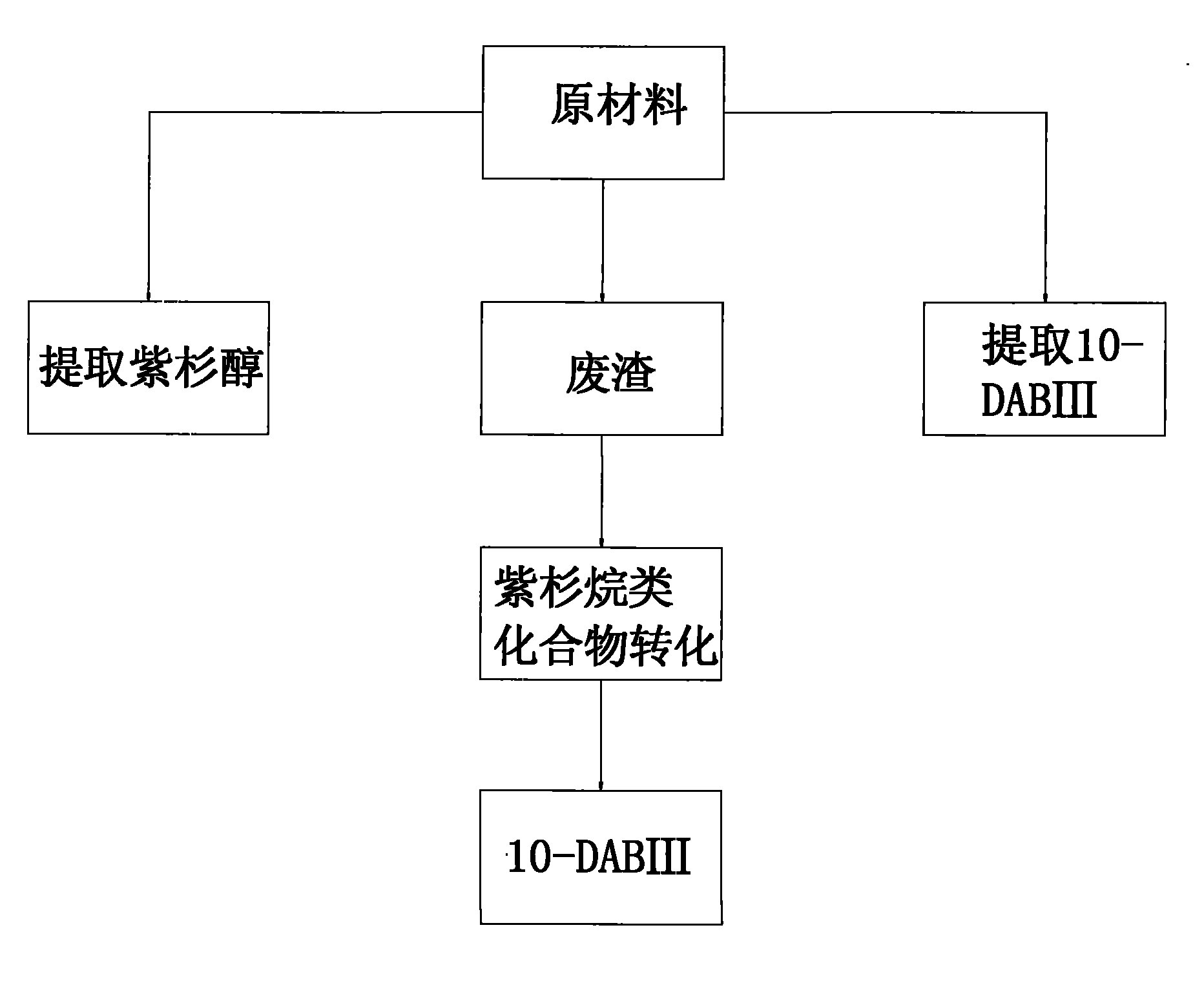

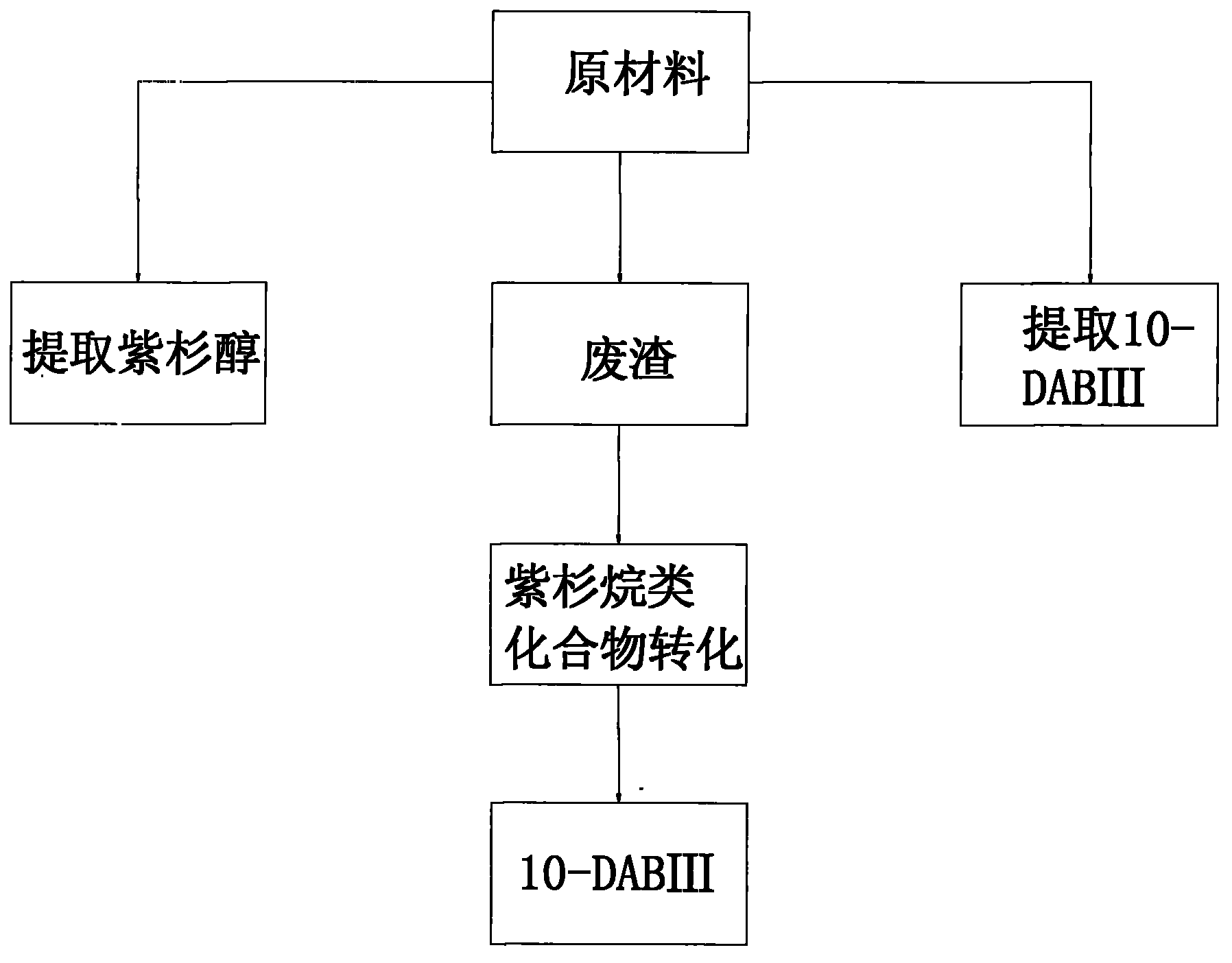

Method for catalyzing and synthesizing 10-deacetylbaccatin (DAB) III by utilizing biocatalysts

InactiveCN101892274AMeet raw material demandReduce manufacturing costMicroorganism based processesFermentationDocetaxelEconomic benefits

The invention relates to a method for catalyzing and synthesizing 10-deacetylbaccatin (DAB) III by utilizing biocatalysts. The method comprises the following step of: adding fusarium mairei and xylosidase as biocatalysts to a substrate to carry out a catalytic reaction to generate the 10-DAB, wherein the substrate is waste residues from taxol extraction. In the method, the waste residues which are obtained from the taxol extraction and contain a large quantity of taxane compounds are subjected to secondary catalysis and conversion so that the taxane compounds are converted into the 10-DAB III used as a chemical intermediate for synthesizing the taxol, thereby the requirement on raw materials of semi-synthesizing the taxol or docetaxel is greatly met and the purposes of comprehensively utilizing the waste residues from extraction, reducing the production cost and improving the economic benefits of enterprises are achieved.

Owner:HEFEI MEIFU BIOLOGICAL SCI

Process for preparing lithium fluoride from lepidolite

PendingCN113929118ALow costShort processLithium halidesAmmonium salt fertilisersDouble saltAluminium salts

The invention relates to a process for preparing lithium fluoride from lepidolite. The process comprises the following steps: 1, acidifying lepidolite; 2, soaking clinker in water; 3, aluminum deposition; 4, purifying; and 5, concentrating and precipitating lithium. The process has the advantages that 1, lithium and fluorine in the low-grade lepidolite are comprehensively utilized to generate the lithium fluoride, a fluorine-containing raw material does not need to be introduced additionally, and compared with a process for producing the lithium fluoride from hydrofluoric acid and lithium carbonate, the cost is low, the flow is short, and the operation is simple; 2, lithium fluoride mother liquor generated by the process is returned to an aluminum precipitation section and can form double salt with aluminum sulfate to effectively remove impurity salts, so that alkaline substances used in an impurity removal section can be effectively saved; and 3, the reserves of the lepidolite in China are very rich, how to comprehensively utilize various elements in the lepidolite to turn waste into wealth is the primary responsibility of each scientific worker, and the lithium fluoride prepared by the process meets the ever-increasing raw material demand of lithium battery electrolyte lithium hexafluorophosphate, and is of great significance to development of lithium battery new energy in China.

Owner:山东泰普锂业科技有限公司

A kind of preparation method of titanium powder or titanium alloy powder special for porous titanium film

ActiveCN109226775BNo melting phenomenonAvoid incomplete hydrogenationTransportation and packagingMetal-working apparatusHydrogenation reactionTitanium alloy

The invention discloses a preparation method of titanium powder or titanium alloy powder special for porous titanium film. The method comprises: 1. placing the pressed titanium block or titanium alloy block in a furnace; 2. vacuumizing the furnace and keeping it warm ; 3. Fill hydrogen into the furnace to carry out self-propagating hydrogenation reaction; 4. Titanium block or titanium alloy block absorb hydrogen and saturate to obtain titanium hydride block or titanium hydride block; 5. Crushing and sieving; 6. Coarse powder crushing; 7. Titanium powder or titanium alloy dehydrogenation powder obtained by heat preservation and dehydrogenation; 8. Titanium powder and titanium alloy powder obtained by crushing, sieving, magnetic separation and flotation. The present invention utilizes the heat released by the hydrogenation reaction to meet the heat energy supply required for the continuation of the hydrogenation reaction to carry out a self-propagating hydrogenation reaction, reducing the increase in heat generated by the reaction, avoiding incomplete hydrogenation of the titanium block or titanium alloy block, and improving the efficiency of the titanium block or titanium alloy block. The degree of hydrogenation embrittlement of titanium alloy block can finally obtain finer and uniform titanium powder or titanium alloy powder, which improves the quality of titanium powder or titanium alloy powder.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Beauty facial cleanser

InactiveCN107823081AMeet raw material demandLow costCosmetic preparationsToilet preparationsCherry juiceCleansers skin

The invention discloses a cosmetic facial cleanser, which is prepared by weight parts from the following raw materials: 1-2 parts of vitamin C, 12-13 parts of cherry juice, 10-12 parts of glycerin, and 2-4 parts of squalane , 3-7 parts of mugwort leaves, 4-8 parts of lavender, 25-40 parts of honey and 15-26 parts of milk. The beauty facial cleanser of the present invention has the functions of skin care, whitening and beauty, meets the raw material requirements of the facial cleanser, saves costs, enriches the effects, and improves economic benefits.

Owner:黄康

15-ton inverted-U-shaped combination device and production process for producing sponge titanium

The invention relates to a 15-ton inverted-U-shaped combination device and a production process for producing sponge titanium. The 15-ton inverted-U-shaped combination device is composed of a reaction furnace, a reactor 28, a reactor cover 11 and a cooling water jacket 25, wherein the reactor 28 comprises a cold-end reactor and a hot-end reactor which are arrayed in parallel; the two reactors are communicated via the reactor cover 11 above; the cold-end reactor is located in the cooling water jacket 25; and the hot-end reactor is located in the reaction furnace. A large furnace has the advantages of being low in energy consumption, high in capacity, stable in quality, and high in labour productivity; and with the progress of a production technology for sponge titanium, the furnace profile is developed towards a large-size direction. The invention provides a 15-ton inverted-U-shaped combination device and a production process for sponge titanium.

Owner:朝阳金达钛业股份有限公司

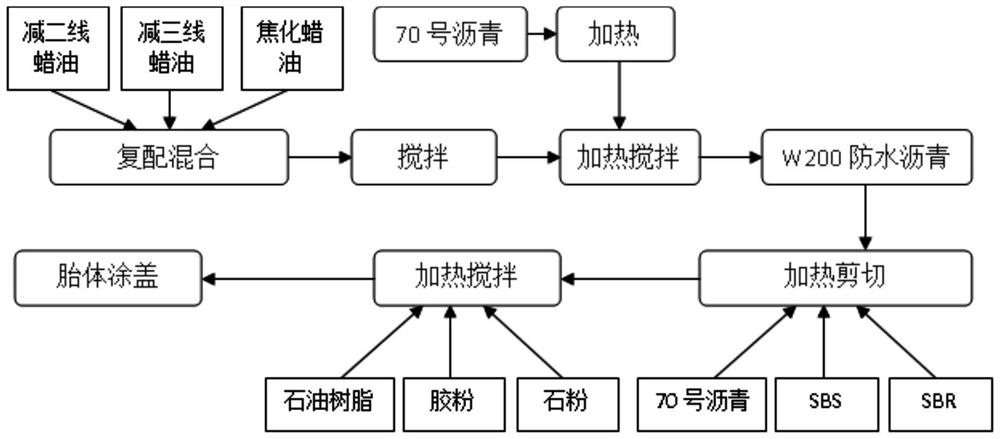

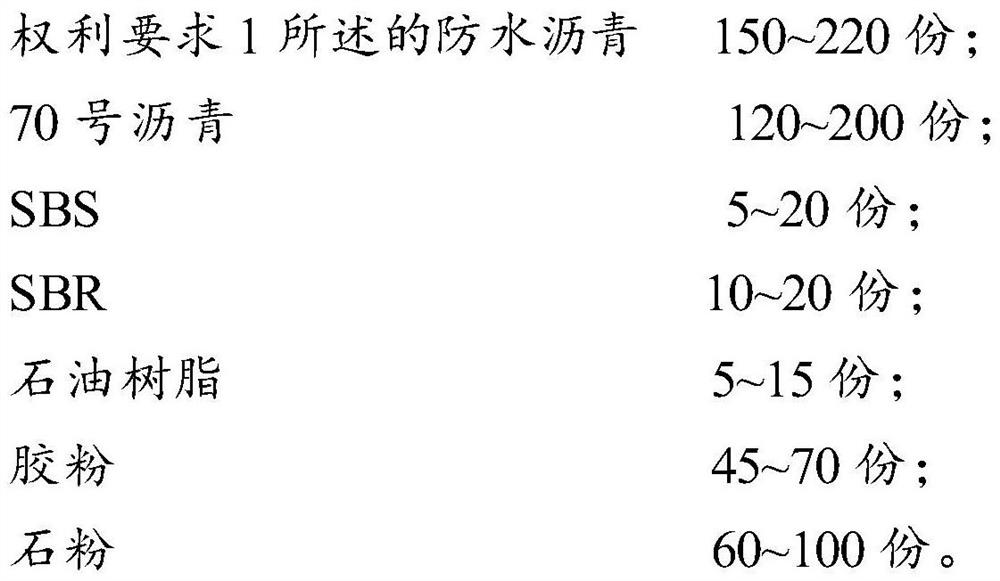

Waterproof asphalt and waterproof coiled material

ActiveCN113265152AImprove low temperature performanceImprove production stabilityTextiles and paperBuilding insulationsProcess engineeringAsphalt

The invention provides waterproof asphalt which comprises the following components in parts by weight: 40-70 parts of No.70 asphalt; and 40 to 70 parts of base oil. The No.70 asphalt is residual oil obtained by distilling blended crude oil; the base oil comprises second line vacuum distillation wax oil; third line vacuum distillation wax oil; and coker gas oil. the second line vacuum distillation wax oil and the third line vacuum distillation wax oil are side fractions obtained by reduced pressure distillation of blended crude oil; and the blended crude oil comprises the crude oil and the coker gas oil. According to the waterproof asphalt provided by the invention, a crude oil blending method and a base oil compounding method are mutually coordinated and matched, so that the defects of waterproof asphalt raw materials and base oil in the traditional sense are overcome, and the technical difficulties that W200 # waterproof asphalt is unstable in performance index and high and low temperature performance conflicts are solved; and the technical problems of low-temperature performance, stripping performance, heat resistance and the like of the self-adhesive waterproof coiled material based on the W200 waterproof asphalt are effectively improved. The invention further provides a waterproof roll.

Owner:SHANDONG JINGBO PETROCHEM +1

Skin whitening and tendering facial cleanser

InactiveCN107648162AWith skin careWith whiteningCosmetic preparationsToilet preparationsCleansers skinVitamin

The invention discloses a whitening and rejuvenating facial cleanser, which is prepared by weight parts of the following raw materials: 1-2 parts of loofah extract, 12-13 parts of papaya extract, 10-12 parts of glycerin, squalane 2-4 parts, 3-7 parts of aloe extract, 4-8 parts of lavender, 25-40 parts of vitamin E and 15-26 parts of milk. The whitening and rejuvenating facial cleanser of the present invention has the functions of skin care, whitening and beauty, meets the raw material requirements of facial cleanser, saves cost, enriches effects, and improves economic benefits.

Owner:黄康

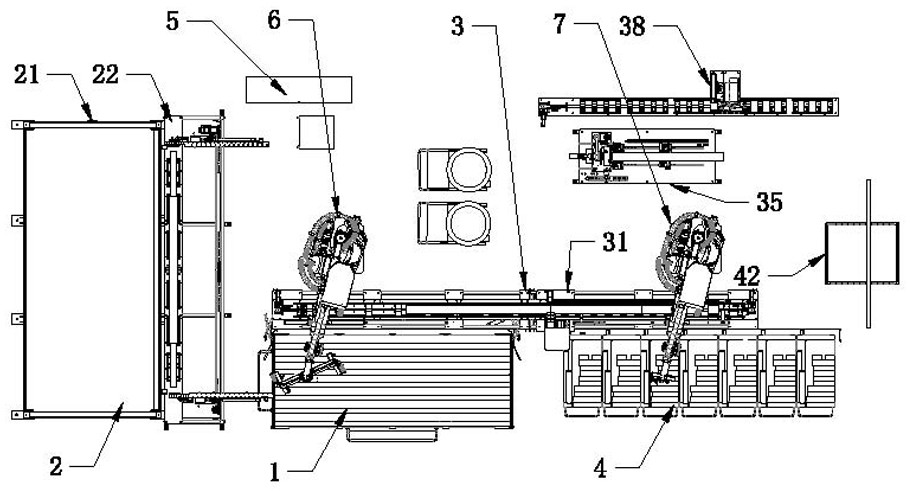

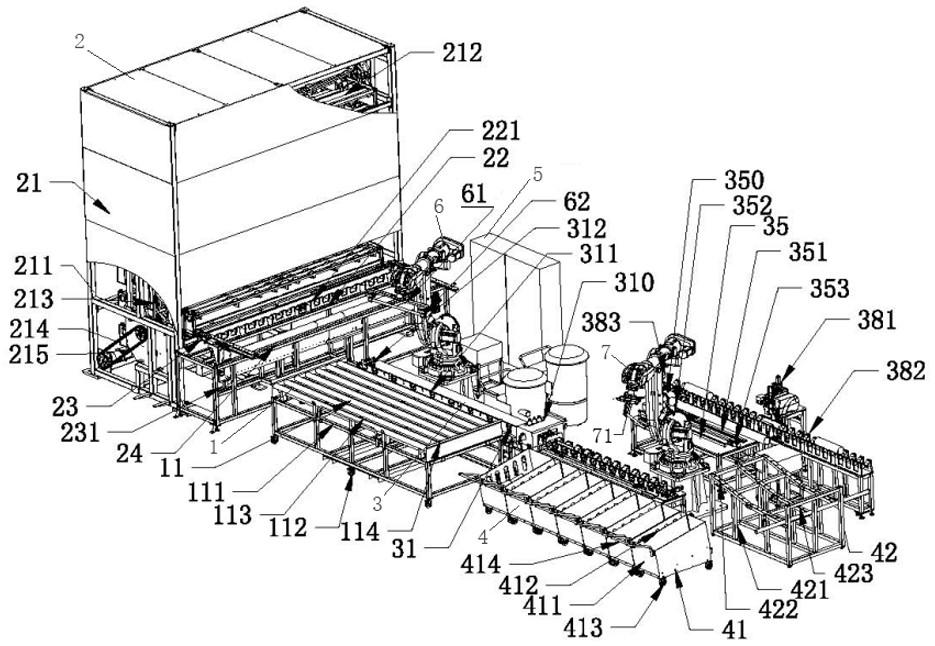

Automatic production line for plastic pipeline processing

ActiveCN113370305ARealize automatic feeding processRealize continuous production of mixed materialsWelding/soldering/cutting articlesMetal working apparatusProduction lineProcess engineering

The invention discloses an automatic production line for plastic pipeline processing. A finished product sorting device is arranged beside a pipeline processing device; a raw material feeding device is arranged at one end of the finished product sorting device; a pipeline storage device is arranged beside the raw material feeding device; the raw material feeding device comprises a feeding trolley and a feeding robot; and the feeding trolley is arranged in the working range of the feeding robot, and two ends of the feeding trolley are adjacent to the finished product sorting device and the pipeline storage device separately. The automatic production line has the advantages that the raw material feeding device is grabbed by the feeding robot, automatic feeding of raw materials is achieved, and manual secondary carrying feeding is omitted, so that the labor intensity is reduced, and the production efficiency is improved; batch storage and taking of raw materials of various specifications can be achieved through the pipeline storage device, the raw material requirement of the production line within a period of time is met, continuous mixed material production of the production line can be achieved, the material supplementing period is prolonged, and material shortage is reduced; and the finished product sorting device can achieve automatic sorting, and manual sorting operation in the later period is reduced.

Owner:SUNRUI MARINE ENVIRONMENT ENG

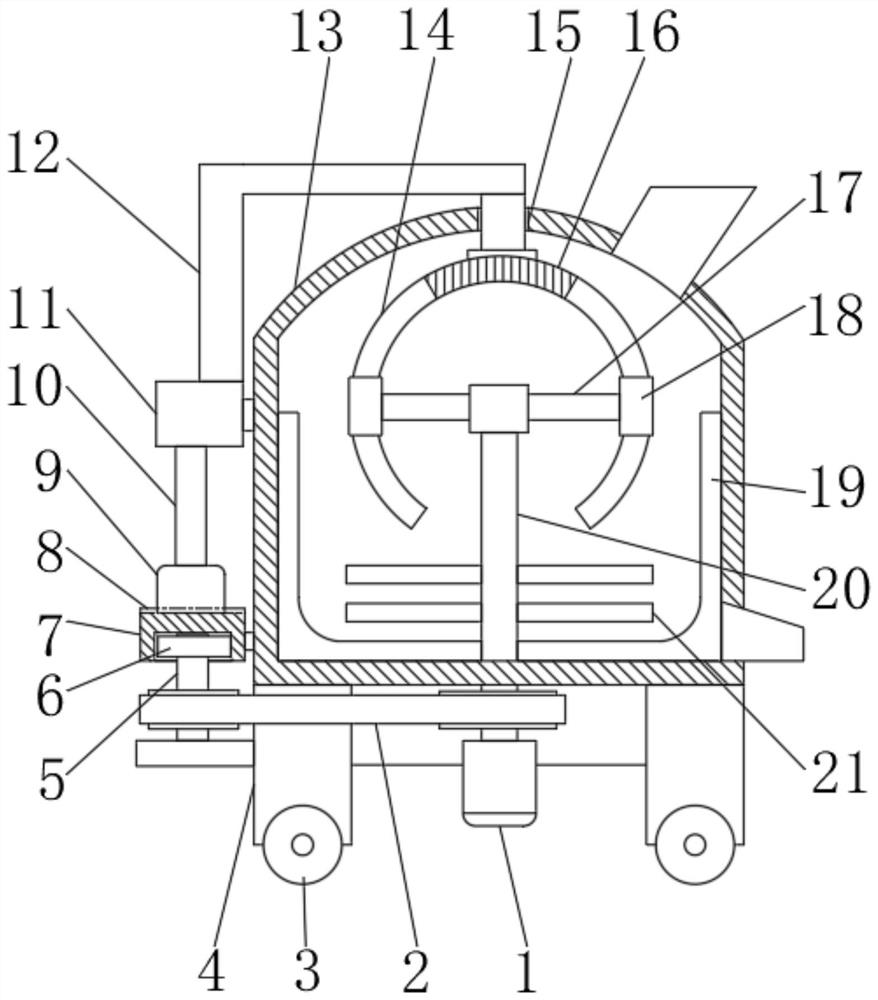

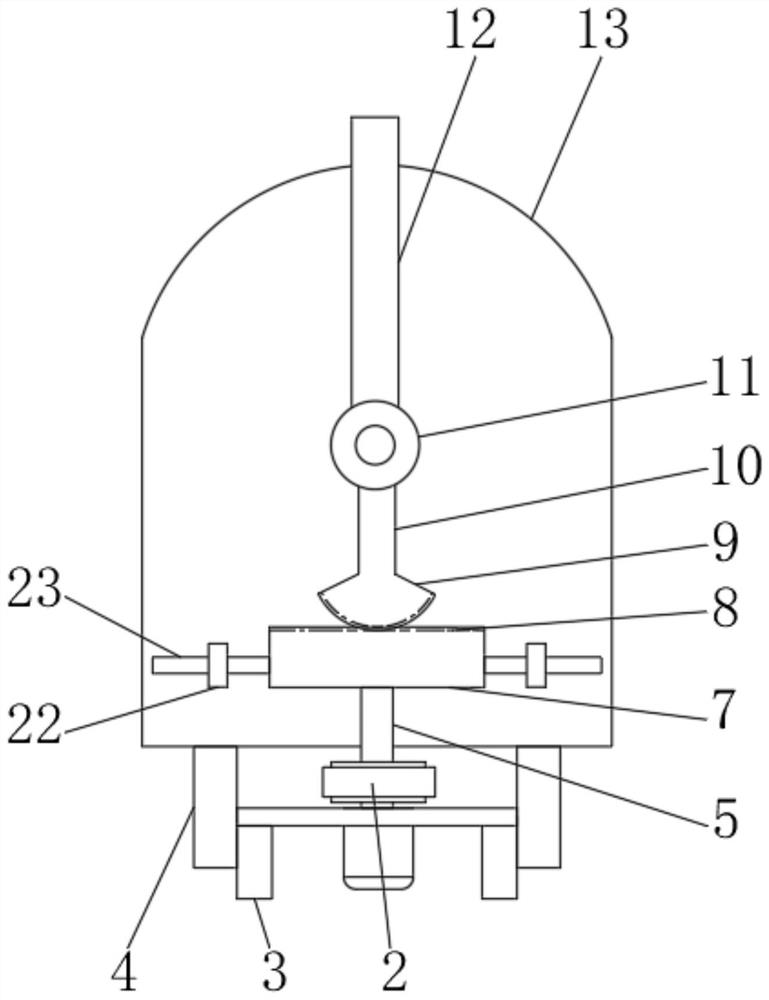

Putty powder stirring device for building field

InactiveCN112371029AAchieve hybridCompact structureShaking/oscillating/vibrating mixersRotary stirring mixersGear wheelElectric machinery

The invention discloses a putty powder stirring device for the building field, and relates to the technical field of building construction. The putty powder stirring device comprises a box body, a motor is arranged at the lower end of the exterior of the box body, the output end of the motor is connected with a stirring shaft, a plurality of stirring blades are evenly arranged at the end, penetrating through the box body, of the stirring shaft, the uppermost end of the stirring shaft is fixedly connected with a support, limiting blocks are symmetrically and fixedly connected to the two ends ofthe support, the limiting blocks are movably connected into a limiting groove formed in a stirring rod, a main shaft is in transmission connection with the stirring shaft close to the motor through abelt transmission set, a first sector gear is in key connection with the main shaft, and the first sector gear is in meshing transmission with a rack plate. Through linkage type transmission, combined rotation of the stirring rod is achieved, the stirring blades on the stirring shaft fully mix raw materials in the box body in an up-down all-around mode, and the uniform mixing and stirring qualityof putty powder is guaranteed. The device is compact in structure and convenient to move, the raw material requirement of a construction site is completely met, the construction progress is accelerated, and the working efficiency is improved.

Owner:曹传辉

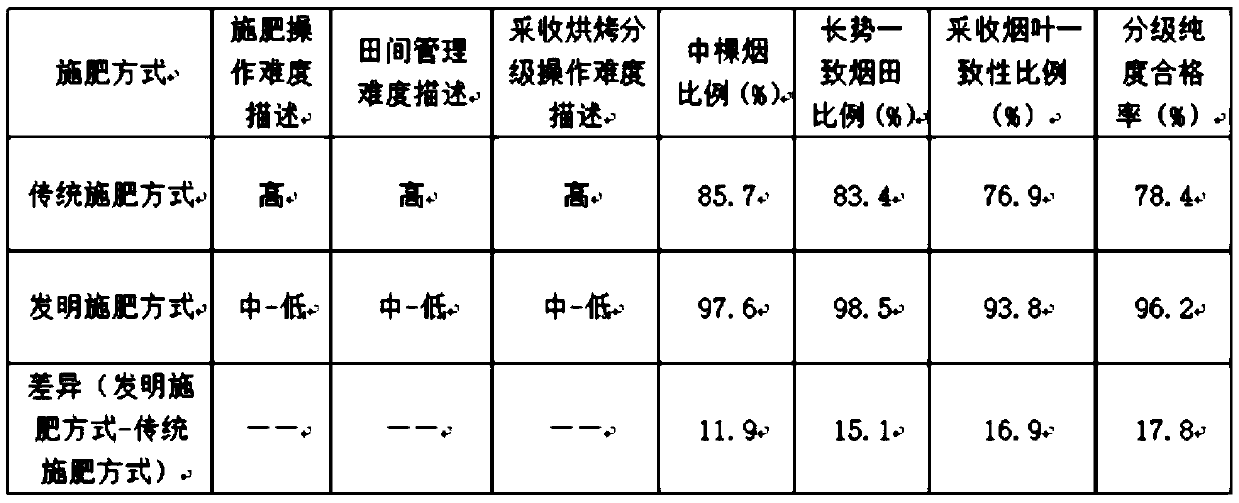

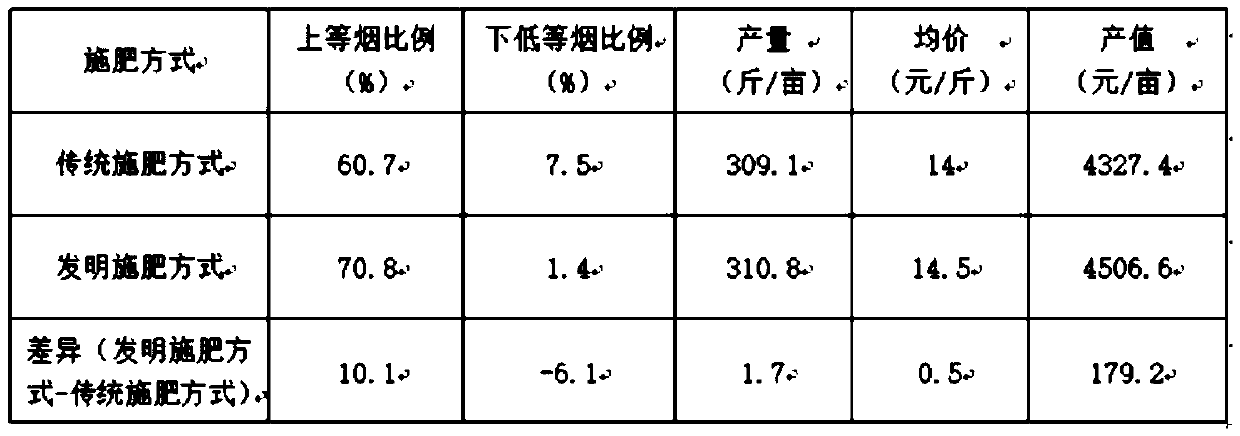

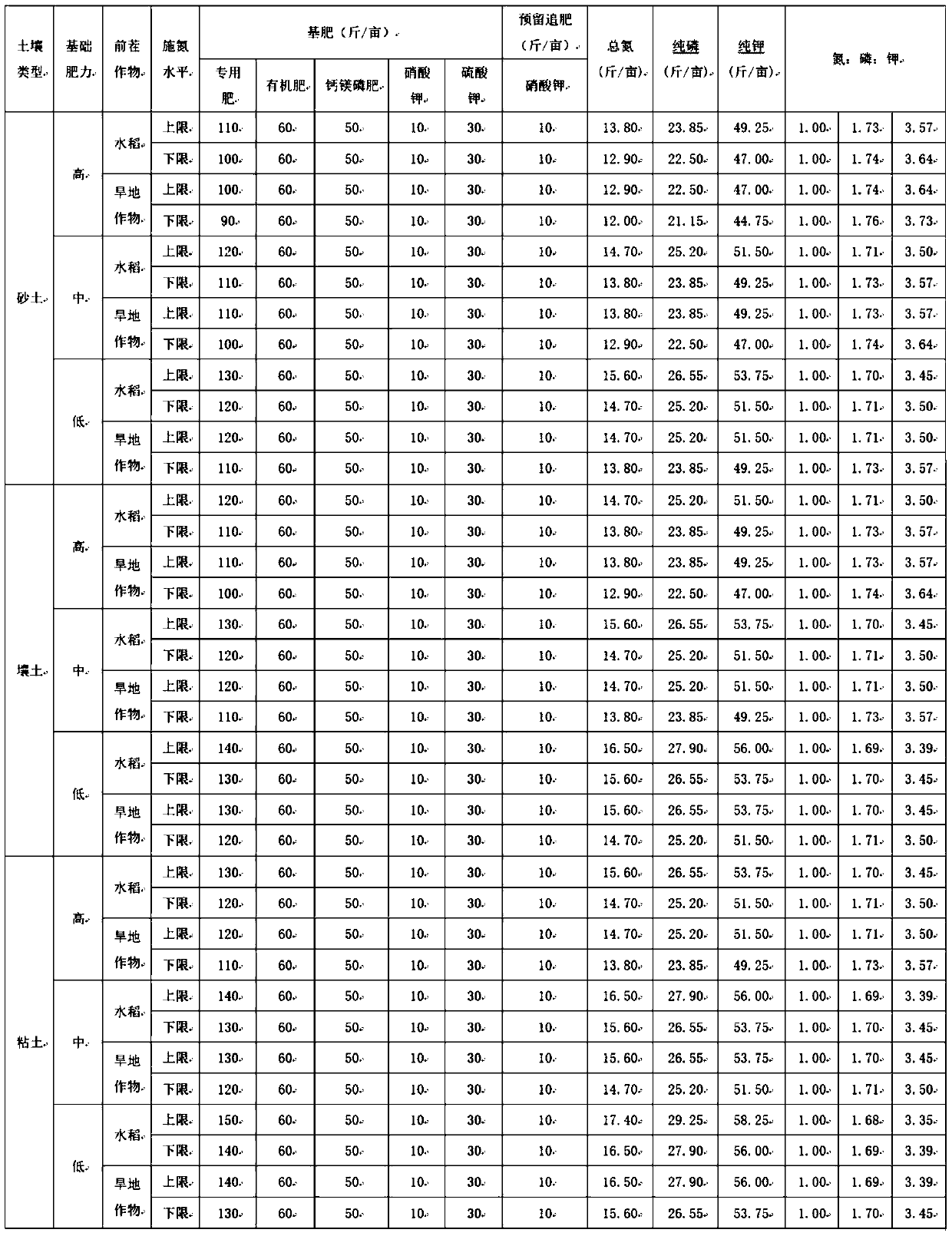

Precise tobacco fertilizing method under large-scale planting condition

PendingCN110651581ASimple and fast operationImprove consistencyFertilising methodsTobacco cultivationAgricultural scienceAgricultural engineering

The invention discloses a precise tobacco fertilizing method under a large-scale planting condition. The method is characterized in that base fertilizer and fertilizer for top dressing are applied ina classified manner, 85-90% of nitrogen application rate is used as the base fertilizer, 10-15% of the nitrogen application rate is used as the fertilizer for top dressing, the base fertilizer is applied to furrows during furrowing through a method including comprehensive quantification, field measuring and label insertion, uniform mixing, equal-quantity packing, delivery according to fields and application by specially-assigned people, and the top dressing is performed by using a watering machine during transplanting and 25-30 days after transplanting. The method has the advantages that the method is scientific and practical, simple and convenient to operate and high in operability, and the method is accumulatively popularized in more than 0.6 million mu of tobacco fields in the southerntobacco growing areas of Anhui; the method is accurate and uniform in fertilizing, capable of increasing medium-tobacco proportion, tobacco growth vigor consistency and tobacco quality level, capableof increasing the tobacco planting benefits of large-scale farmers, capable of effectively satisfying the requirements of cigarette industry enterprises and capable of promoting the high-quality development of the tobacco growing areas.

Owner:ANHUI WANNAN TOBACCO LEAF

A kind of preparation method of pure natural privet fruit anthocyanin

ActiveCN105017201BPromote development and utilizationLow costOrganic chemistryLigustrum quihouiFood resources

Owner:JILIN UNIV

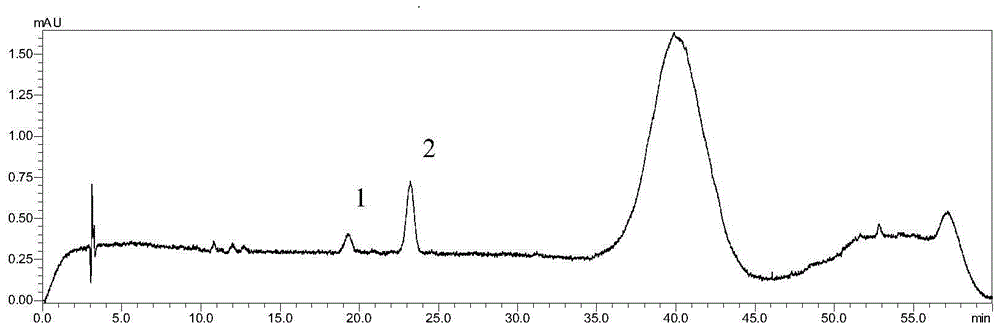

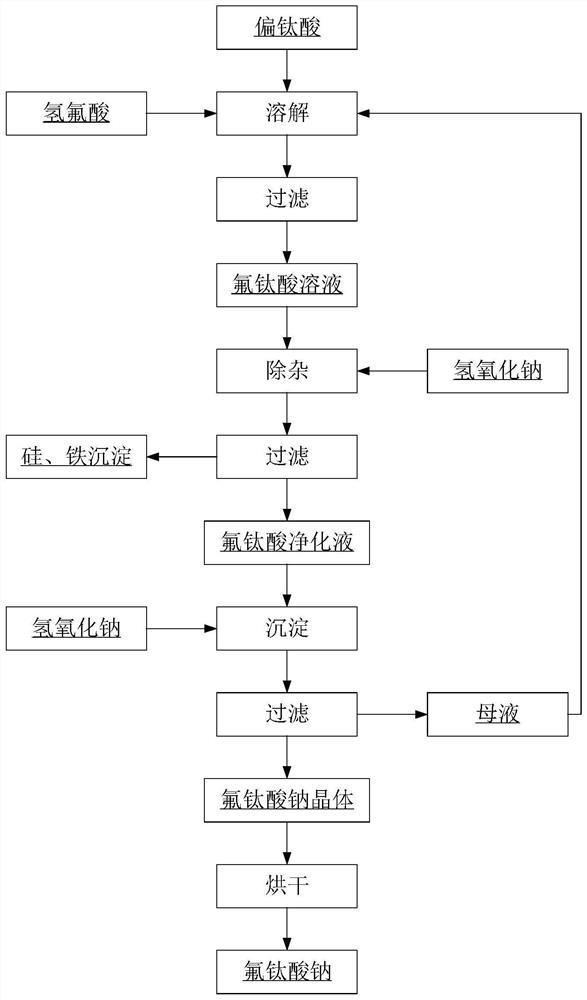

A method for preparing high-purity sodium fluorotitanate

ActiveCN109384259BMeet raw material demandGood indicator stabilityTitanium compoundsFluoride productsManganese

The invention relates to a method for preparing high-purity sodium fluorotitanate. The method comprises: adding NaOH solution to the fluorotitanic acid solution, controlling the molar ratio of NaOH to silicon in the solution to be (1.1-1.8):1, and stirring Reaction, solid-liquid separation after the reaction is completed, to obtain a fluotitanic acid purification solution; adding NaOH solution to the obtained fluotitanic acid purification solution, stirring the mixed solution to react, and solid-liquid separation after the reaction to obtain sodium fluotitanate. The present invention prepares high-purity sodium fluorotitanate products with silicon content <0.03%, iron content <0.01%, chromium, manganese and other main impurities content <0.002%, purity ≥ 99.5%, and good product index stability through the above method , which can meet the raw material demand of downstream metal titanium or titanium alloy production. The invention simultaneously simplifies the preparation process of the sodium fluorotitanate, reduces the difficulty of process implementation, improves industrial applicability, and has good application prospects.

Owner:HEBEI IRON AND STEEL

Method for preparing battery grade lithium phosphate composite material

ActiveCN102881900BHigh tap densityNo pollution in the processCell electrodesO-Phosphoric AcidLithium hydroxide

Owner:GUANGZHOU LIBODE NEW MATERIAL

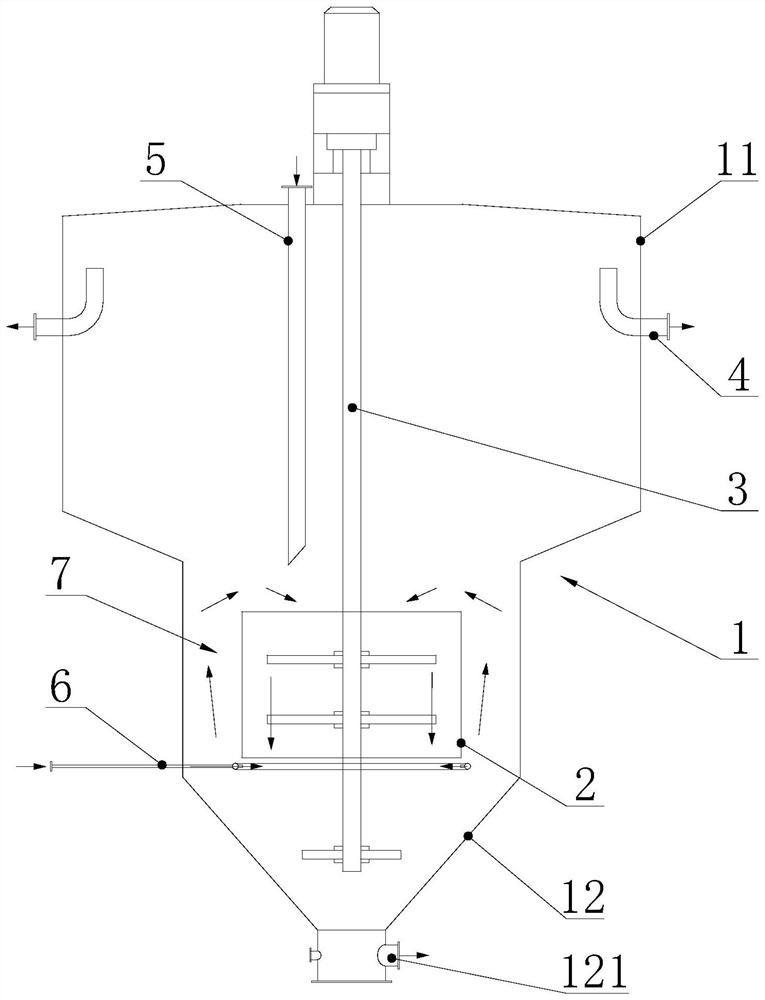

A kind of brine impurity removal device and impurity removal process

A brine impurity removal device, including a cylindrical shell, a guide tube, and a stirring device, the cylindrical shell is composed of an upper cylindrical shell and a lower conical shell, the conical The bottom of the section shell is provided with a salt mud outlet, and the opening and closing are controlled by a valve. The diameter of the guide tube is smaller than the inner diameter of the cylindrical section shell. There is a distance between the opening of the lower end of the cylinder and the shell of the conical section, and the stirring blades of the stirring device are arranged in the inner space of the guiding cylinder, which is used to mix the liquid in the hollow of the guiding cylinder and drive the liquid to flow downward , the upper part of the cylindrical shell is provided with a brine overflow port, the cylindrical shell is provided with a brine conveying pipe, and the discharge port of the brine conveying pipe is located at the upper part of the inner hollow of the guide cylinder, and the cylindrical shell The impurity removal agent conveying pipe is arranged on the top, and the outlets of the impurity remover conveying pipe are multiple, evenly distributed along the circumference of the guide cylinder, and located at the lower part of the inner cavity of the guide cylinder.

Owner:重庆天原化工有限公司

Method for preparing low acid-value fatty acid methyl ester

ActiveCN102153465BHigh reactivityShort reaction timeOrganic compound preparationCarboxylic acid esters preparationDistillationSolid acid

The invention relates to a method for synthesizing low acid-value fatty acid methyl ester by esterification reaction and aims at providing the method with the characteristics that a process is simple; a catalyst and a product are easy to separate and can be recycled; the reaction conversion rate is high; and the obtained fatty acid methyl ester has low acid value. The method for preparing the lowacid-value fatty acid methyl ester sequentially comprises the following steps of: 1, feeding fatty acid and a resin catalyst together or feeding the fatty acid and a solid acid catalyst together, andthen heating the mixture with stirring; 2, after a temperature of a reaction system is raised to 50 to 80 DEG C, dropwise adding methanol into the reaction system, distilling the methanol and water generated in the reaction process, sampling and monitoring the reaction conversion rate in the reaction process and finishing the reaction until the acid value reaches below 0.5mgKOH / g, wherein the pressure of the reaction system is in the range of 10 to 101Kpa and the reaction time is in the range of 4 to 6 hours; and 3, after finishing the reaction, filtering out the catalyst, carrying out reduced pressure distillation on filtrate to separate out excessive methanol and water to obtain a finished product and directly recycling the resin catalyst or the solid acid catalyst.

Owner:ZANYU TECH GRP CO LTD

A method for selectively reclaiming lithium and preparing lithium carbonate from waste lithium batteries

ActiveCN108550939BSimple purification processLow costWaste accumulators reclaimingProcess efficiency improvementDecompositionAluminium

The invention discloses a method for selectively recovering lithium from waste lithium batteries and preparing lithium carbonate. The method comprises the following steps: mixing waste battery positive electrode powder with a nitrating agent to obtain a mixture, performing a nitration reaction on the mixture to obtain a nitrate product, calcining the nitrate product is at 200-550 DEG C to obtain calcined sands, leaching the calcined sands, performing solid-liquid separation to obtain a lithium-rich filtrate, adjusting the pH value of the lithium-rich filtrate to be 10 or more, performing solid-liquid separation to obtain a purified liquid, adding the purified liquid to a soluble carbonate solution, carrying out a reaction, performing solid-liquid separation, and performing water washing and drying on the obtained filter residues to obtain the lithium carbonate. A principle that the decomposition temperature of lithium nitrate is obviously higher than that of corresponding nitrates of copper, cobalt, aluminum and manganese is ingenious utilized to realize selective separation and recovery of lithium, and the lithium recovery rate in the invention is 20% or above more than that of conventional wet technologies. The high-purity lithium carbonate can be obtained without a complicated purification process, and the method has the advantages of simple process, low cost, high recoveryefficiency of valuable metals, and convenience for industrial production and application.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com