Waterproof asphalt and waterproof coiled material

A waterproofing membrane and bitumen technology, applied in textiles and papermaking, building insulation materials, building components, etc., can solve the problems of high saturation content, W200 waterproof bitumen softening point, penetration, unfavorable high temperature performance technical indicators, etc. The effect of improving low temperature performance, improving production stability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

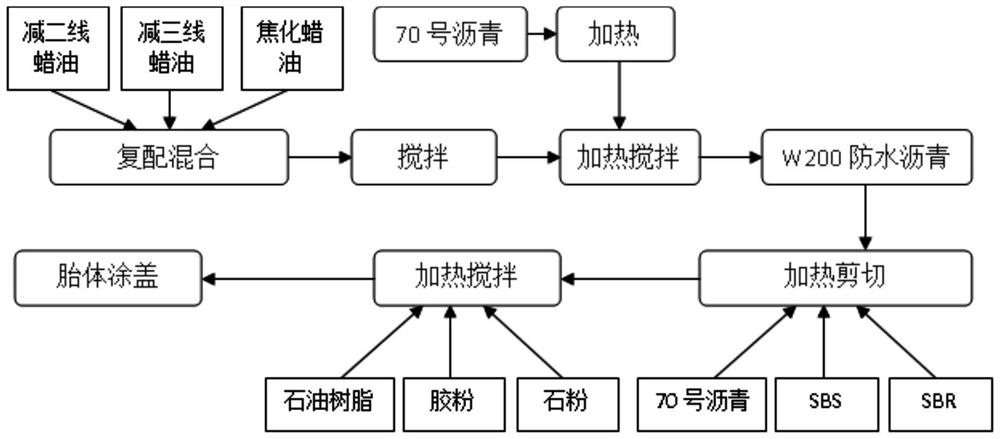

[0050] In the present invention, the preparation method of the blended crude oil preferably includes:

[0051] Blend crude oil and coker wax oil to obtain blended crude oil.

[0052] In the present invention, the preparation method of No. 70 bitumen preferably comprises:

[0053] The residual oil obtained by distilling the blended crude oil.

[0054] In the present invention, the No. 70 asphalt preferably includes:

[0055] 0-15wt% asphaltenes;

[0056] 15-25wt% saturated content;

[0057] 35-45wt% aromatic components;

[0058] 20-30wt% colloid;

[0059] <3.0 wt% wax.

[0060] In the present invention, the weight content of the asphaltenes is preferably 3-12%, more preferably 5-10%, most preferably 6-8%; the mass content of the saturated components is preferably 18-22%, more preferably Preferably 20%; the mass content of the aromatic component is preferably 38-42%, more preferably 40%; the mass content of the colloid is preferably 22-28%, more preferably 24-26%, most pr...

Embodiment 1

[0113] Waterproof bitumen formula: 53 parts by weight of No. 70 bitumen, 47 parts of base oil;

[0114] The formula of the base oil is: minus 17 parts by weight of the second-line wax oil, minus 7 parts by weight of the third-line wax oil;

[0115] The blended crude oil formula is: 100 parts by weight of crude oil, 10 parts by weight of coker wax oil.

[0116] The preparation method of the base oil is as follows: compound and mix 17 parts of the second-line wax oil and 7 parts of the third-line wax oil, and stir at room temperature for 0.5 h to obtain the base oil.

[0117] The preparation method of the waterproof bitumen is: heating No. 70 bitumen to 138°C, compounding and mixing with base oil at a ratio of 53:47 by weight and heating, the heating temperature is 140°C, and the stirring time is 0.5h to obtain No. W200 waterproof bitumen.

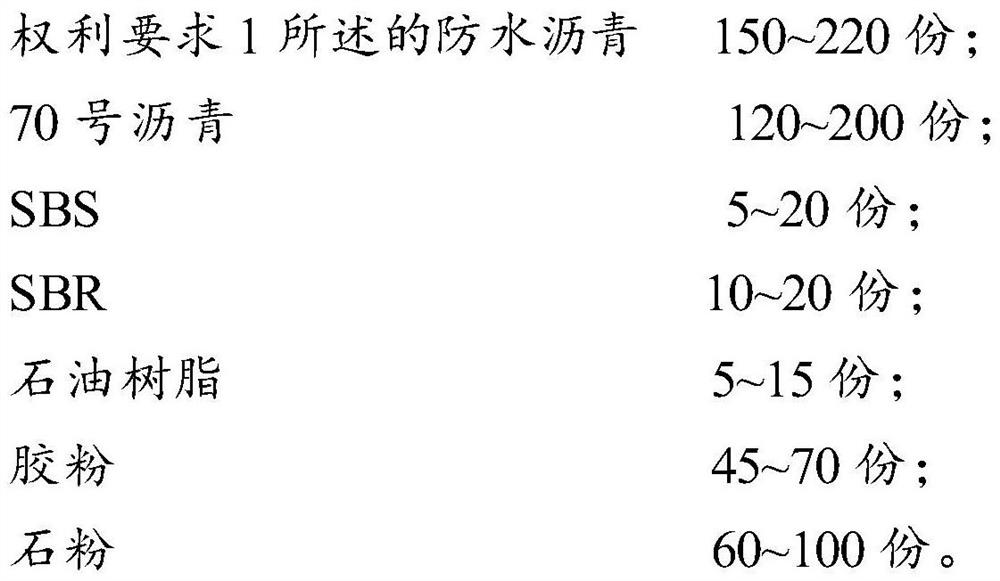

[0118] The preparation method of the waterproof membrane is as follows: mix and heat 150 parts by weight of the above-mentioned waterproof...

Embodiment 2

[0122] The formula of the waterproof asphalt is: 56 parts by weight of No. 70 asphalt, and 44 parts by weight of base oil.

[0123] The formula of the base oil is: minus 17 parts by weight of the second-line wax oil, minus 7 parts by weight of the third-line wax oil.

[0124] The blended crude oil formula is: 100 parts by weight of crude oil, 5 parts by weight of coking wax oil.

[0125] The preparation method of the base oil is as follows: compound and mix 17 parts of the second-line wax oil and 7 parts of the third-line wax oil, and stir at room temperature for 0.5 h to obtain the base oil.

[0126] The preparation method of the waterproof bitumen is: heating No. 70 bitumen to 138°C, and compounding and mixing with base oil at a weight ratio of 56:44, the heating temperature is 140°C, and the stirring time is 0.5h to obtain No. W200 waterproof bitumen.

[0127] The preparation method of the waterproof membrane is as follows: mix and heat 150 parts by weight of the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com