15-ton inverted-U-shaped combination device and production process for producing sponge titanium

A combined device and production process technology, applied in the field of sponge titanium reduction distillation reaction device, can solve problems affecting product quality, high energy consumption of products, and evaluation of customer quality, so as to improve market competitiveness, reduce production energy consumption, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

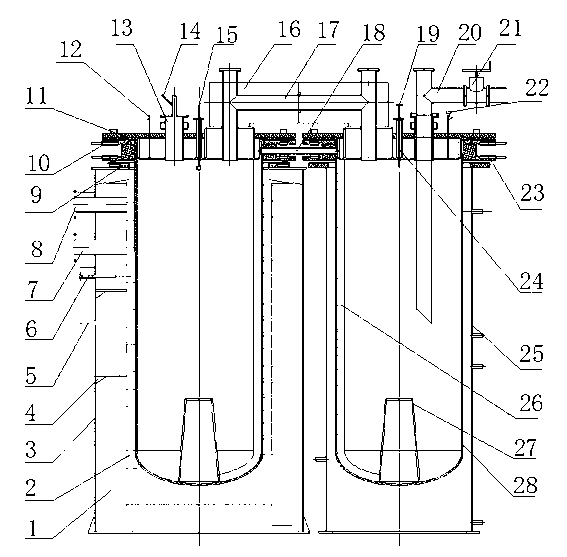

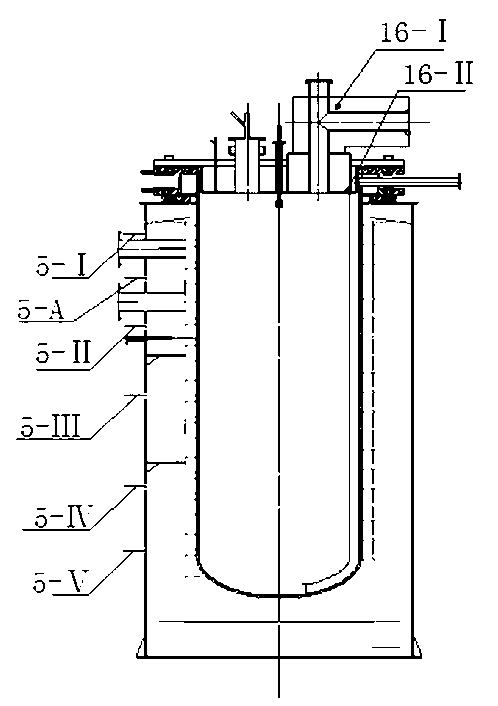

[0029] A 15-ton inverted U-shaped combined device for producing sponge titanium is composed of a reaction furnace, a reaction tank 28, a reactor cover 11, and a cooling water jacket 25. Wherein, the reactor 28 includes a parallel cold-end reactor and a hot-end reactor, and the two reactors are connected through the upper reactor cover 11, the cold-end reactor is located in the cooling water jacket 25, and the hot-end reactor is located in the reaction furnace. Inside.

[0030]Wherein, the reaction furnace is composed of aluminum silicate fiber cotton 1, resistance band 2, furnace shell 3, bracket 4, thermocouple 5, furnace shell evacuation tube 6, air inlet 7 and air outlet 8, and the resistance furnace lining material Aluminum silicate fiber cotton 1 is used. The furnace shell 3 is provided with a bracket 4 to prevent the aluminum silicate fiber cotton from sinking. The resistance band 2 is fixed on the fiber cotton 1 with corundum nails. The thermocouple 5 is used to monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com