A continuous production method for highly isotactic poly(1-butene)

A technology of isotactic polybutene and production method, which is applied in the field of high molecular polymers, can solve problems such as failure to meet the needs of downstream users, the impact of deep processing of downstream products, and large fluctuations in product quality, so as to achieve good transportability and ensure product quality. The effect of continuous and stable quality and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

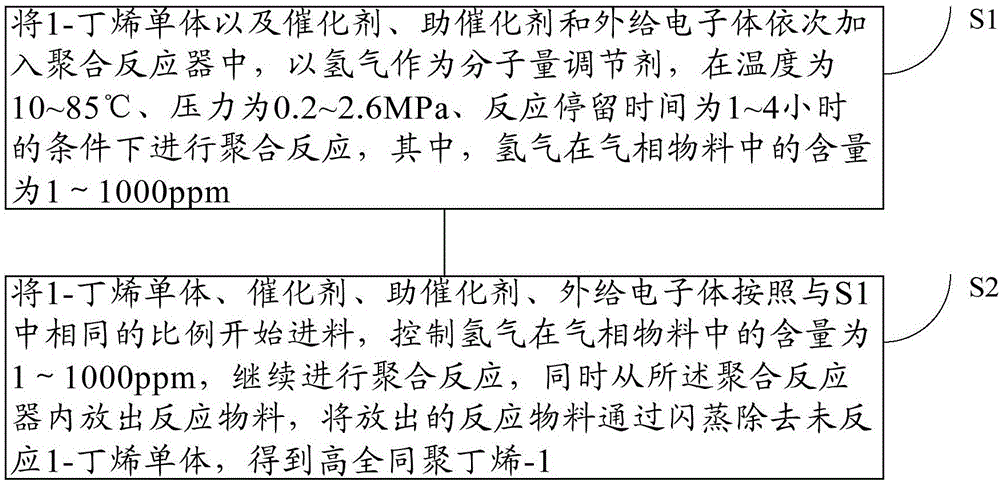

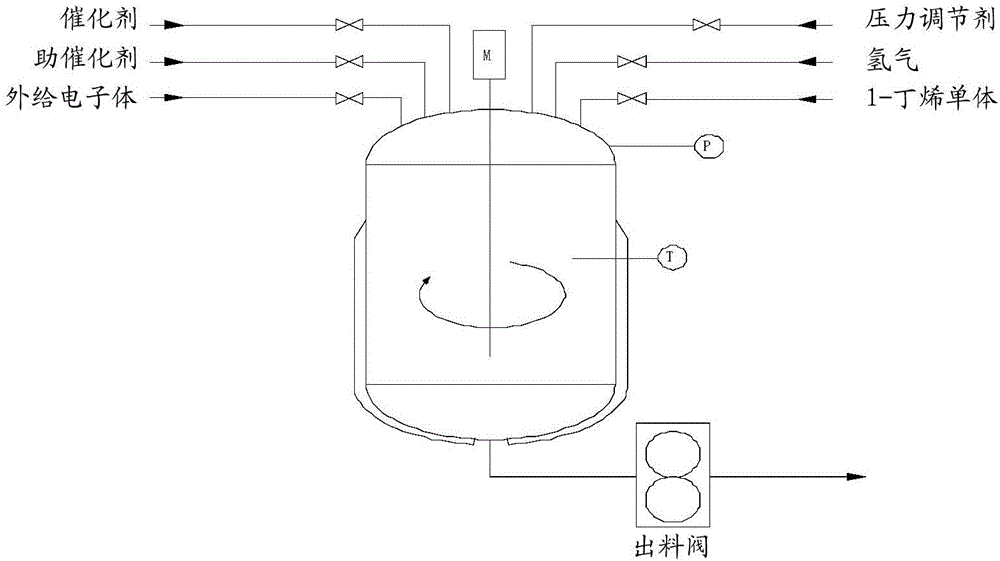

[0048] 1) Add 1-butene monomer figure 2 When the polymerization reactor shown reaches a certain liquid level, stop feeding, control the temperature rise program to heat the temperature to 10°C, and control the system pressure at 0.2Mpa by nitrogen; start stirring and then add the supported titanium catalyst, co-catalyst and external feed according to a certain proportion. Electron body, add hydrogen at the same time, the content of hydrogen in the gas phase material is 1ppm. Time to 4 hours.

[0049] 2) By controlling the feed rate, the 1-butene monomer, catalyst, cocatalyst, and external electron donor are fed according to the same ratio as in step 1), and the system pressure is adjusted to maintain 0.2Mpa, and the hydrogen is in the gas phase material The content is 1ppm, and at the same time, the outlet valve at the bottom of the reactor is opened to send the reaction materials to the flash tank to ensure that the materials in the reactor reach an equilibrium state. Afte...

Embodiment 2

[0051] 1) Add 1-butene monomer figure 2 The polymerization reactor shown in the figure stops feeding when it reaches a certain liquid level, controls the temperature rise program to heat the temperature to 50°C, and controls the system pressure at 1.0Mpa by helium; start stirring and then add the supported titanium catalyst, co-catalyst and external catalyst according to a certain proportion. Electron donor, while adding hydrogen, the content of hydrogen in the gas phase material is 1000ppm. Count down to 2.5 hours.

[0052] 2) By controlling the feed rate, start feeding 1-butene monomer, catalyst, cocatalyst, and external electron donor according to the same ratio as in step 1), adjust the system pressure to maintain 1.0Mpa, and hydrogen is in the gas phase material The content in the reactor is 1000ppm, and at the same time, the discharge valve at the bottom of the reactor is opened to send the reaction material to the flash tank to ensure that the material in the reactor ...

Embodiment 3

[0054] 1) Add 1-butene monomer figure 2 When the polymerization reactor shown reaches a certain liquid level, stop feeding, control the temperature rise program to heat the temperature to 55°C, and control the system pressure at 2.3Mpa by methane; start stirring and then add the supported titanium catalyst, co-catalyst and external feed according to a certain proportion. Electron body, add hydrogen at the same time, the content of hydrogen in the gas phase material is 100ppm. Count down to 1.5 hours.

[0055] 2) By controlling the feed rate, the 1-butene monomer, catalyst, cocatalyst, and external electron donor are fed according to the same ratio as in step 1), and the system pressure is adjusted to maintain 2.3Mpa, and the hydrogen is in the gas phase material The content is 100ppm, and at the same time, the discharge valve at the bottom of the reactor is opened to send the reaction material to the flash tank to ensure that the material in the reactor reaches an equilibriu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com