A method of adding alumina powder to prepare boron carbide aluminum composite ceramic powder

A technology of composite ceramics and boron carbide aluminum, which is applied in the field of adding alumina powder to prepare boron carbide aluminum composite ceramic powder, which achieves the effects of high hardness, high raw material utilization rate, and reduced dust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

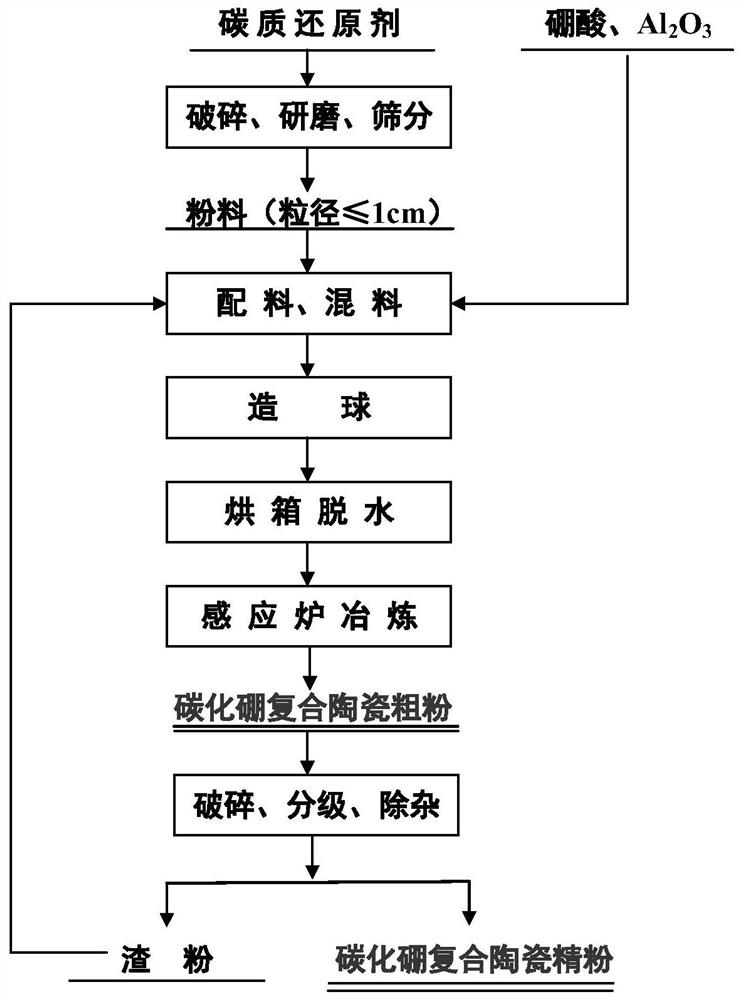

[0032] 1. Grinding and screening the carbonaceous reducing agent;

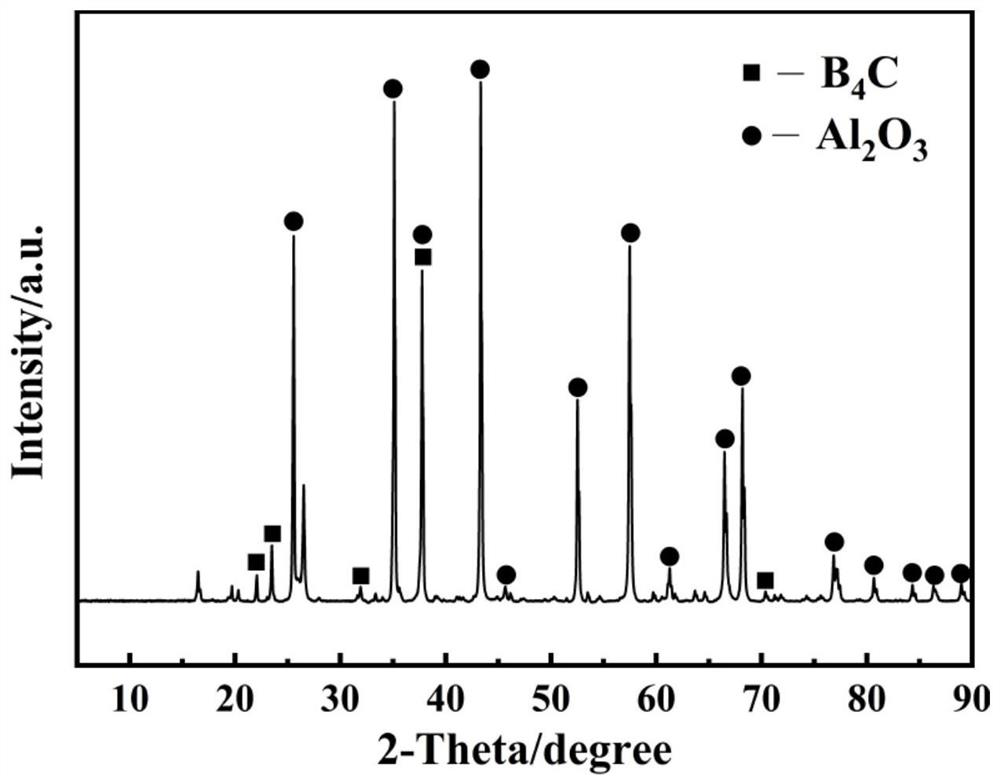

[0033] 2. Boric acid powder, carbonaceous reducing agent powder, Al 2 o 3 The powder is compounded according to a certain weight ratio: 77% boric acid, 5% graphite, 5% petroleum coke, 3% charcoal, 5% activated carbon, and then add 5% Al to the prepared raw materials 2 o 3 .

[0034] 3. Press the mixed material into a 10mm thick mass on a high-pressure ball press;

[0035] 4. Dry the pressed lump wet material, the drying temperature is 60°C, and the drying time is 8 hours;

[0036] 5. Put the dried agglomerate into the induction furnace for high-temperature smelting, the smelting temperature is 1300°C, and the smelting time is 100min, and the boron carbide composite ceramic coarse powder is prepared;

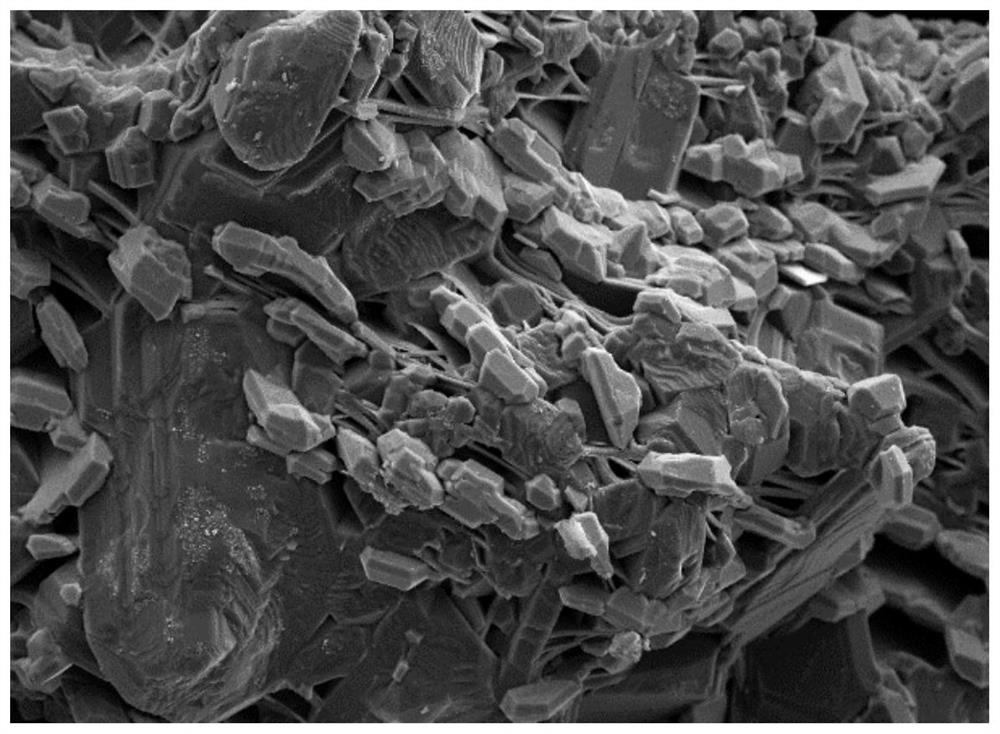

[0037] 6. Crushing the boron carbide composite ceramic coarse powder, grading and removing impurities to obtain boron carbide composite ceramic fine powder;

[0038] 7. Recycle the slag powder for reuse.

Embodiment 2

[0040] 1. Grinding and screening the carbonaceous reducing agent;

[0041] 2. Boric acid powder, carbonaceous reducing agent powder, Al 2 o 3 The powder is compounded according to a certain weight ratio: 60% boric acid, 8% graphite, 8% petroleum coke, 5% charcoal, 9% activated carbon, and then add 10% Al to the prepared raw materials 2 o 3 .

[0042] 3. Press the mixed material into a 15mm thick mass on a high pressure ball pressing machine;

[0043] 4. Dry the pressed lump wet material, the drying temperature is 80°C, and the drying time is 11 hours;

[0044] 5. Put the dried agglomerate into the induction furnace for high-temperature smelting, the smelting temperature is 1600°C, and the smelting time is 80 minutes, and the boron carbide composite ceramic coarse powder is prepared;

[0045] 6. Crushing the boron carbide composite ceramic coarse powder, grading and removing impurities to obtain boron carbide composite ceramic fine powder;

[0046] 7. Recycle the slag pow...

Embodiment 3

[0048] 1. Grinding and screening the carbonaceous reducing agent;

[0049] 2. Boric acid powder, carbonaceous reducing agent powder, Al 2 o 3The powder is compounded according to a certain weight ratio: 45% boric acid, 5% graphite, 5% petroleum coke, 10% charcoal, 20% activated carbon, and then add 15% Al to the prepared raw materials 2 o 3 .

[0050] 3. Press the mixed material into a 25mm thick mass on a high-pressure ball press;

[0051] 4. Dry the pressed lump wet material, the drying temperature is 100°C, and the drying time is 6 hours;

[0052] 5. Put the dried agglomerate into the induction furnace for high-temperature smelting, the smelting temperature is 2300 ° C, and the smelting time is 30 minutes, and the boron carbide composite ceramic coarse powder is prepared;

[0053] 6. Crushing the boron carbide composite ceramic coarse powder, grading and removing impurities to obtain boron carbide composite ceramic fine powder;

[0054] 7. Recycle the slag powder for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com