Automatic production line for plastic pipeline processing

An automated production line and plastic pipe technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to sort large quantities of processed parts in real time, inability to identify raw material specifications, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

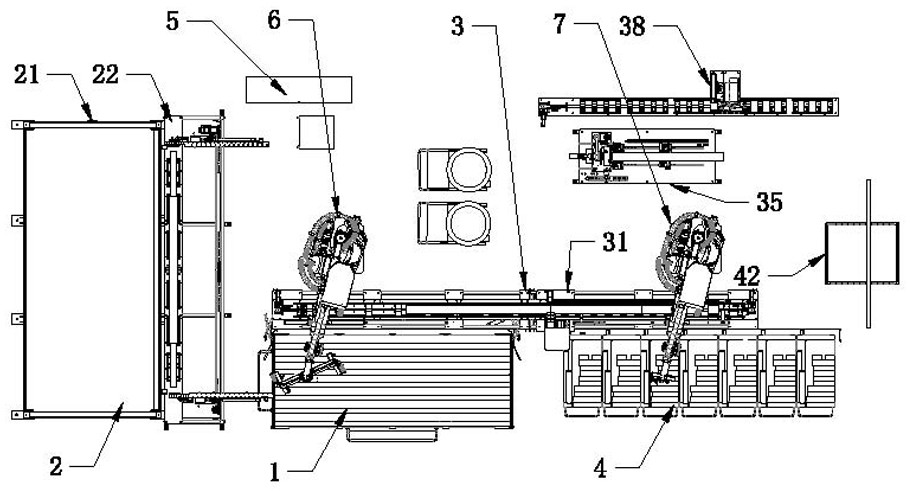

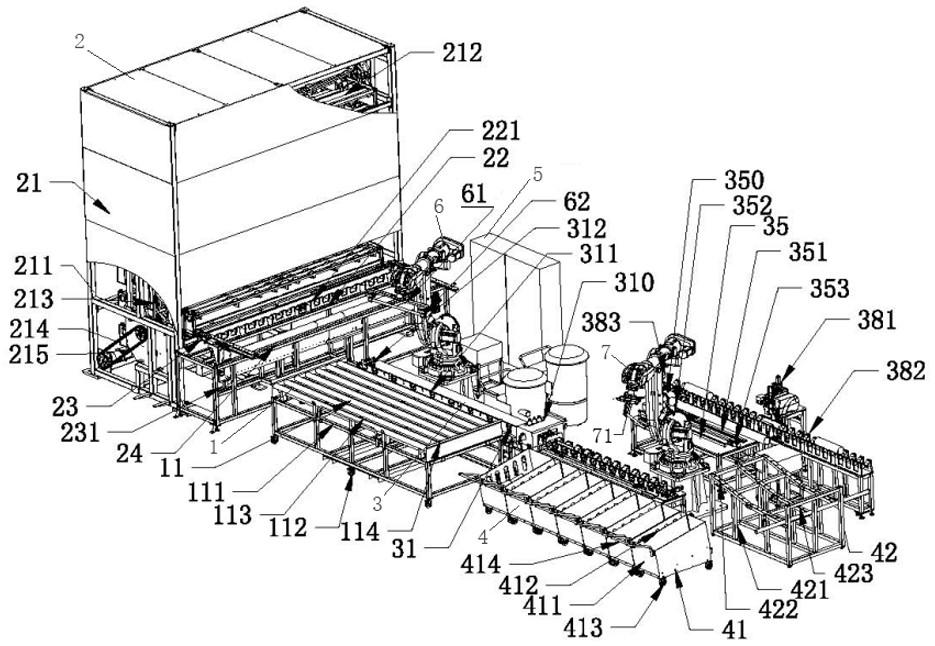

[0012] see figure 1 with figure 2 , the present invention is an automatic plastic pipe processing production line, a pipe processing device and a control device for controlling the work of the production line. A finished product sorting device is provided next to the pipeline processing device, a raw material feeding device is provided at one end of the finished product sorting device, and a pipeline storage device is provided at the other side of the raw material feeding device; The raw material feeding device includes a feeding trolley and a feeding robot arranged next to the feeding trolley. The feeding trolley is arranged within the working range of the feeding robot. The two ends of the feeding trolley are respectively connected to the finished product sorting device and The pipeline storage device is adjacent; a loading jaw is connected to the arm of the loading robot.

[0013] The feeding trolley 11 includes a vehicle frame 111, on the upper end of the vehicle frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com