Patents

Literature

48results about How to "No melting phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

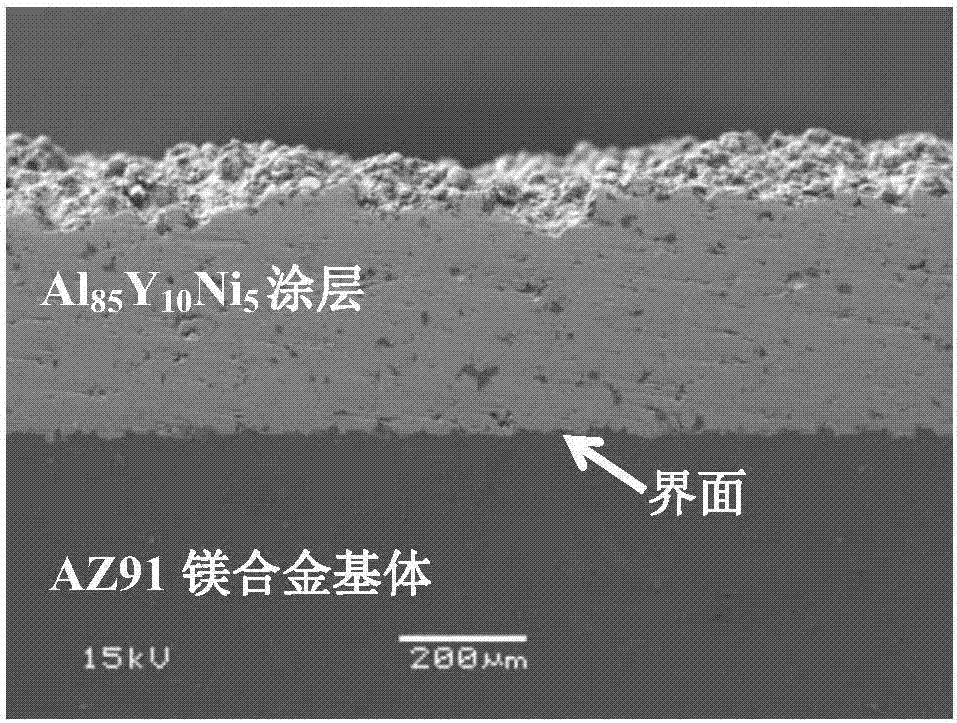

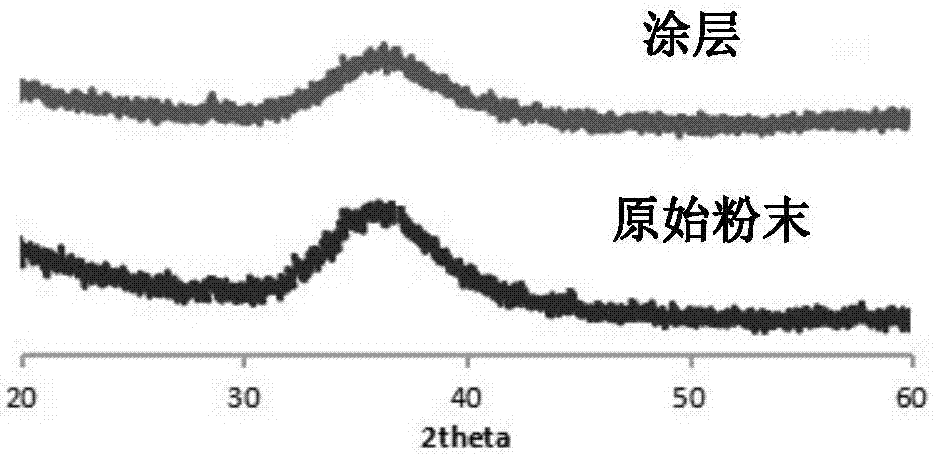

Preparation method of amorphous alloy coating on surface of magnesium alloy

The invention provides a preparation method of an amorphous alloy coating on the surface of a magnesium alloy. The preparation method comprises the steps that Al85Y10Ni5 aluminum base amorphous alloy powder is dried for 8-12 h at 80 DEG C, wherein a drying oven is vacuumized to be 10<2>-10<3> Pa; and the alloy powder is placed into a cold spraying system, a high-pressure gas serves as the gas source, the gas pressure is 1.5-3 MPa, the powder feeding amount is controlled to be 10-12 g / min, and it is guaranteed that the alloy powder is sprayed out of a spray gun at the speed of 500-1200 m / s. According to the preparation method provided by the invention, a low-temperature cold spraying mode is adopted, the powder particle temperature is not greater than 150 DEG C, the Al85Y10Ni5 aluminum base amorphous alloy powder is kept in a solid state in the whole spraying process and free of the fusion phenomenon, and therefore, the amorphous alloy powder is free of oxidation and phase change phenomena; and high-speed flying particles deposit to form the coating after colliding with the surface of a substrate at a high speed, the material of the coating has an amorphous structure consistent with that of the original powder, amorphous oxidation and crystallization do not exist, and the compact amorphous alloy coating with the complete amorphous structure can be obtained.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Modified phenolic aldehyde insulation foamed material preparation method

The invention discloses a modified phenolic aldehyde insulation foamed material preparation method, which belongs to the foamed material field. According to the invention, an organic-inorganic nanocomposite is taken as a modifier, the modifier, a surfactant, a foaming agent and an acidic curing agent are added in phenolic resin, the resulting mixture is dumped in a die, mechanically stirred, and foamed at certain temperature to obtain the modified phenolic aldehyde insulation foamed material. According to the invention, agglomeration problem of the inorganic nano modifier can be effectively overcome, the compatibility of the inorganic nano particle and organic resin can be increased, the mechanical strength of phenolic aldehyde cystosepiment is effectively enhanced, and the technical problems of high toughness and efflorescence degree of the traditional phenolic aldehyde cystosepiment can be solved, the density of prepared phenolic aldehyde foamed material is moderate, and the phenolic aldehyde foamed material has characteristics of good flame resistance and toughness, and low efflorescence degree.

Owner:东北大学秦皇岛分校

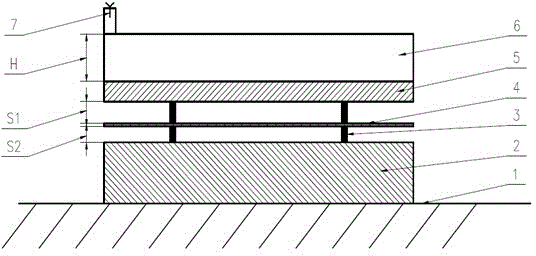

Explosive welding method for improving bonding strength of aluminum-carbon steel composite material

ActiveCN104526150AReduce heat consumptionExtended service lifeWelding/soldering/cutting articlesNon-electric welding apparatusCarbon steelAluminum composites

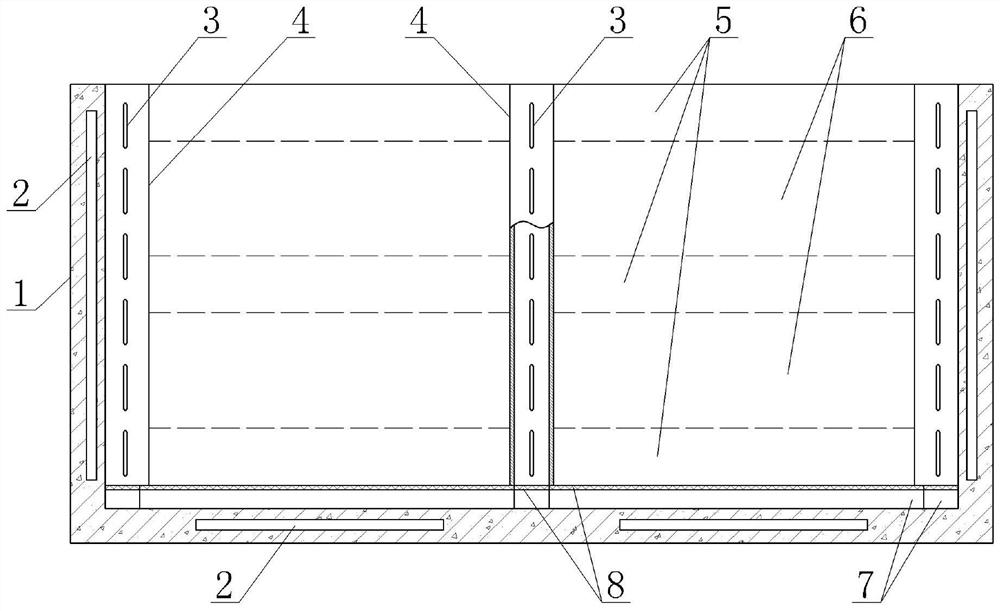

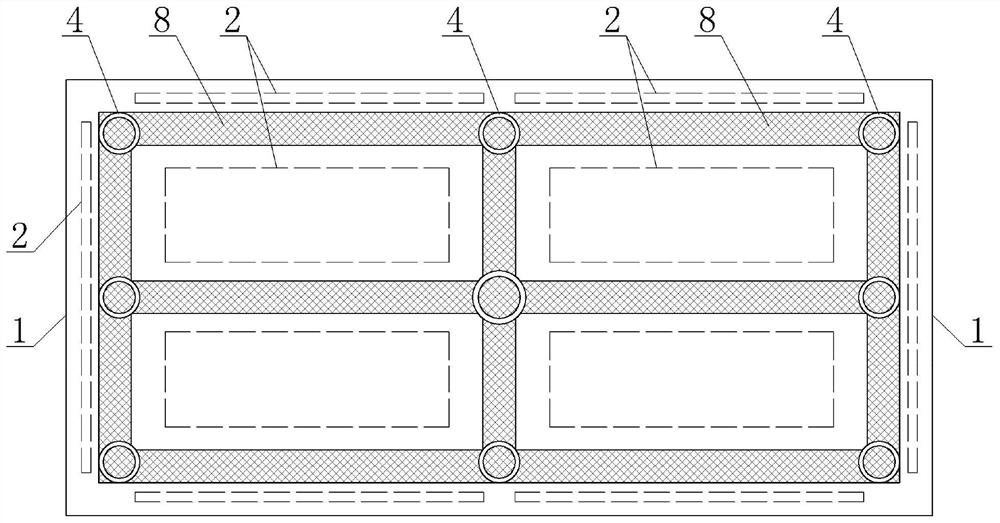

An explosive welding method for improving the bonding strength of an aluminum-carbon steel composite material comprises the steps of respectively conducting surface polishing on the explosive welding faces of a carbon steel base layer (2), a carbon steel middle thin layer (4) and an aluminum composite layer (5), horizontally arranging the base layer on a foundation (1), arranging the upper end face of the base layer on the carbon steel middle thin layer through supporting of superposed copper pieces (3), forming a separation distance S2 between the middle thin layer and the base layer, arranging the composite layer on the upper end face of the middle thin layer through supporting of the superposed copper pieces, forming a separation distance S1 between the composite layer and the middle thin layer, finally laying explosive (6) with density of 0.5-0.8 g / cm<2> and thickness H on the upper end face of the composite layer and burying detonators (7), wherein the detonation speed is controlled to be 2000-2600 m / s, the composite layer can sequentially bumps the middle thin layer and the base layer through one-time explosive welding, the three-layer integrated aluminum-carbon steel composite material is formed, heat energy consumption is obviously reduced, a melting phenomenon does not occur, and the interface bonding strength is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

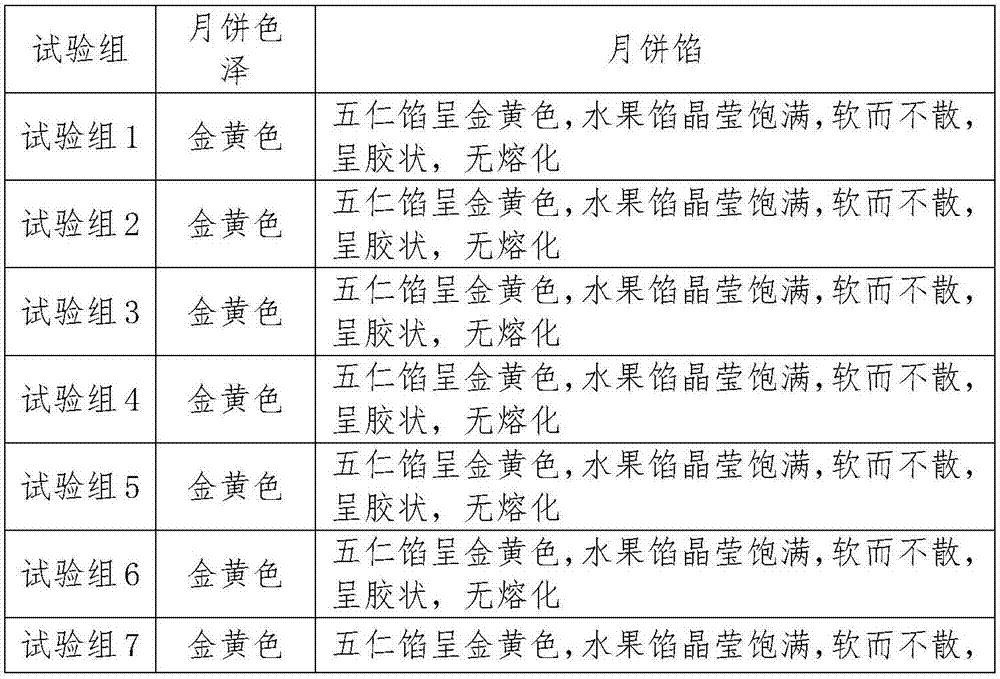

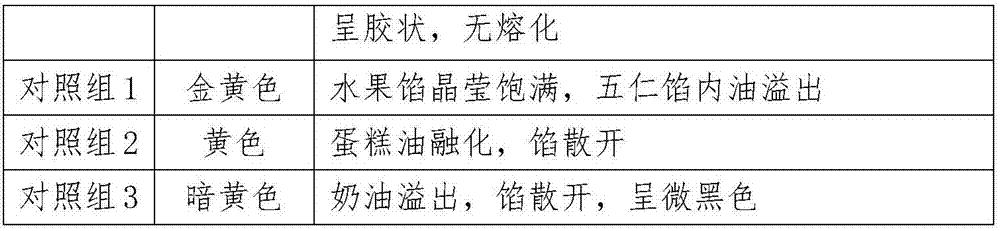

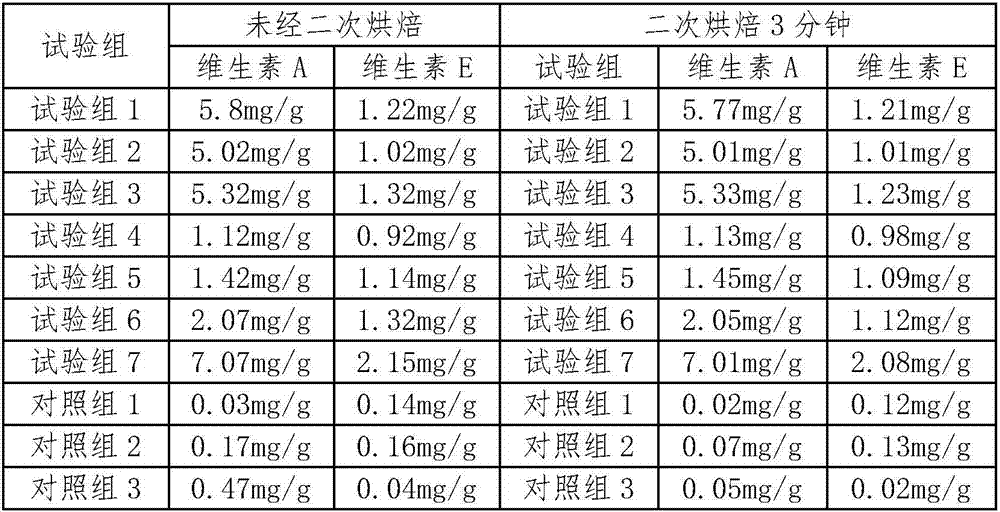

Fruit mooncakes and preparation method thereof

InactiveCN107484806AImprove tasteRemove toxins from the bodyDough treatmentModified nutritive productsPumpkin seedRice flour

The invention provides fruit mooncakes. The fruit mooncakes comprise cake coats, wherein fillings are wrapped in the cake coats and comprise five-kernel fillings and fruit fillings; the fruit fillings are put in pectin; and the five-kernel fillings comprise the following raw materials in parts by weight: 17-20 parts of walnut kernels, 3-5 parts of peanut kernels, 3-5 parts of black sesame kernels, 3-5 parts of pumpkin seeds, 4-5 parts of apricot kernels, 8-13 parts of honey, 20-25 parts of prepared polished glutinous rice flour, 3-5 parts of milk powder and 0.1-0.3 part of alkaline water. The made fruit mooncakes disclosed by the invention contain the fruit fillings with the pectin, can optimize the mouth feel of the fruit mooncakes, have the crispy fragrance and fruit fragrance of the fruit mooncakes when being eaten, can prevent nutrient components in fruit flesh fillings from being destroyed in the baking and making process of the fruit mooncakes to the maximum extent. Even if the mooncakes are baked, the phenomenon that the pectin melts can also be avoided.

Owner:贵州馥香斋蔡氏食品有限公司

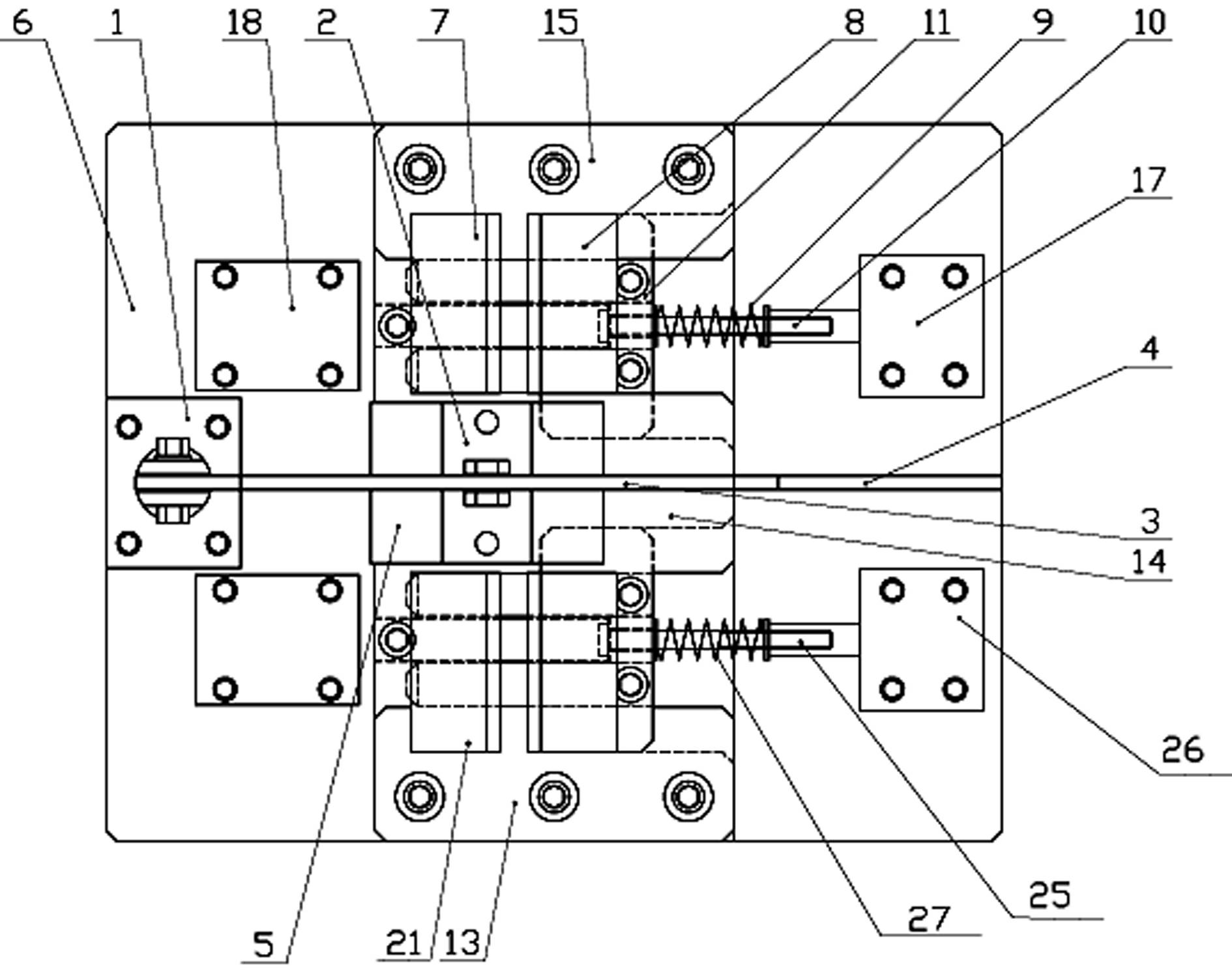

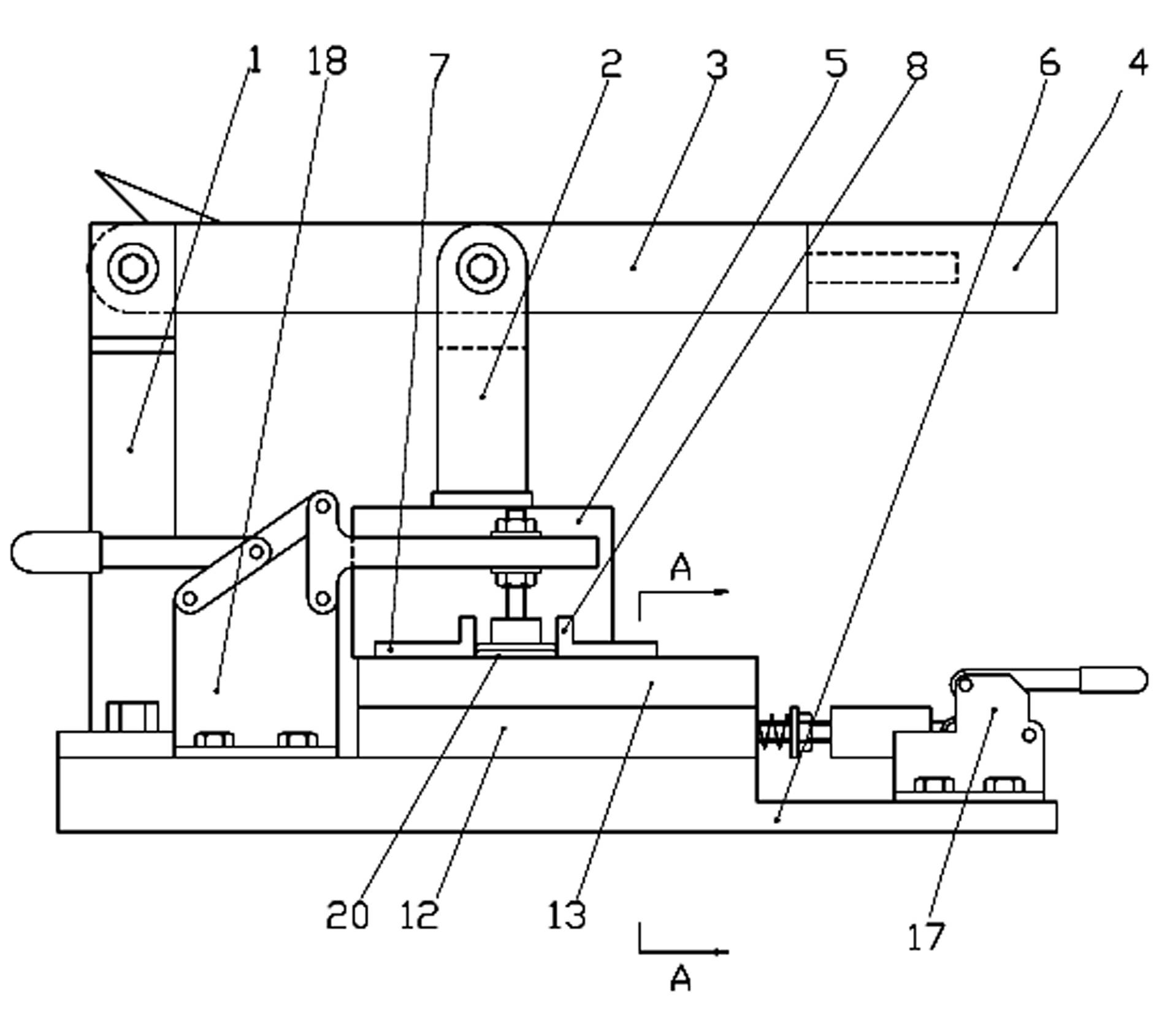

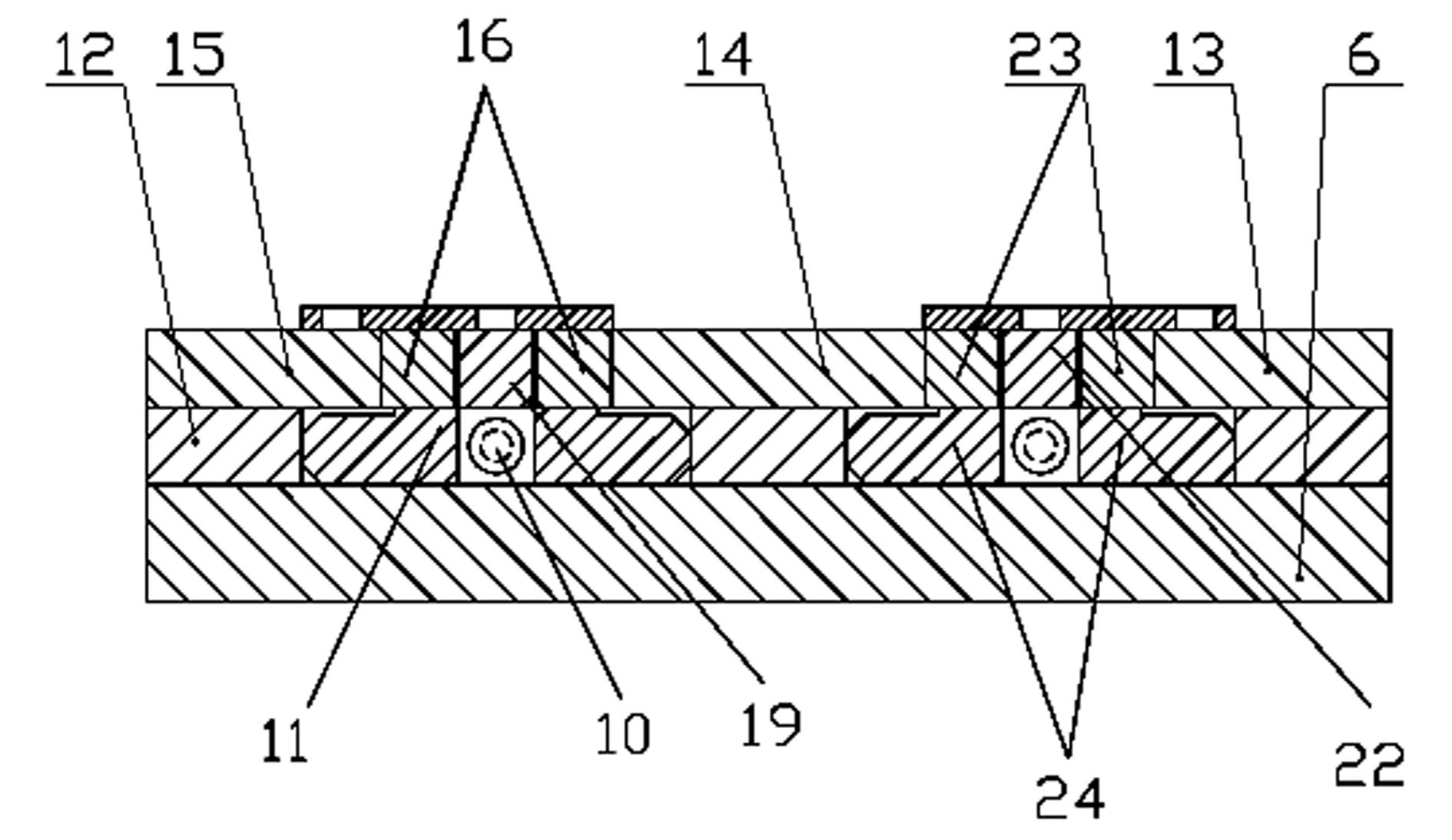

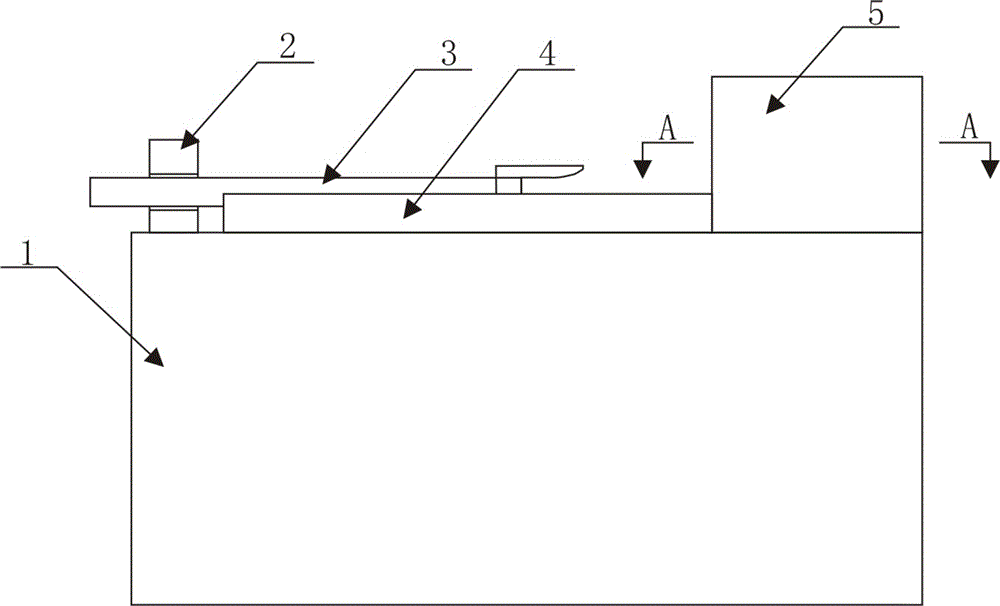

Copper clad aluminum flat wire welding device

InactiveCN102380683AGuaranteed clampingNo damageHeating appliancesSoldering auxillary devicesEngineeringCopper

The invention relates to a copper clad aluminum flat wire welding device, which comprises a bottom plate, wherein an E-shaped plate is arranged on the bottom plate; the two notches of the E-shaped plate form two chutes with the bottom plates; a sliding slides in each chute and is connected with a quick clamp through a screw on which a spring is sleeved; the upper part of each pushing block is connected with a pushing strip which is provided with a right clamping block; a left pressure block, a middle pressure block and a right pressure block are arranged above the E-shaped plate; two fixed pushing strips are arranged above and below the left end part of the E-shaped plate respectively; each fixed pushing strip is connected with a left clamping block; the other ends of the two left clamping blocks are connected with the pressure block right and the pressure block left respectively; two quick pressure tools are arranged on the bottom plate; the center of each quick pressure tool is aligned with the center of a corresponding block; the bottom end of a support is fixed on the bottom plate; the top end of the support 1 is hinged with a lifting rod; the middle part of the lifting rod ishinged with a suspending frame; and the lower end of the suspending frame is connected with a heating block. The device can quickly position and the welding temperature is controllable.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

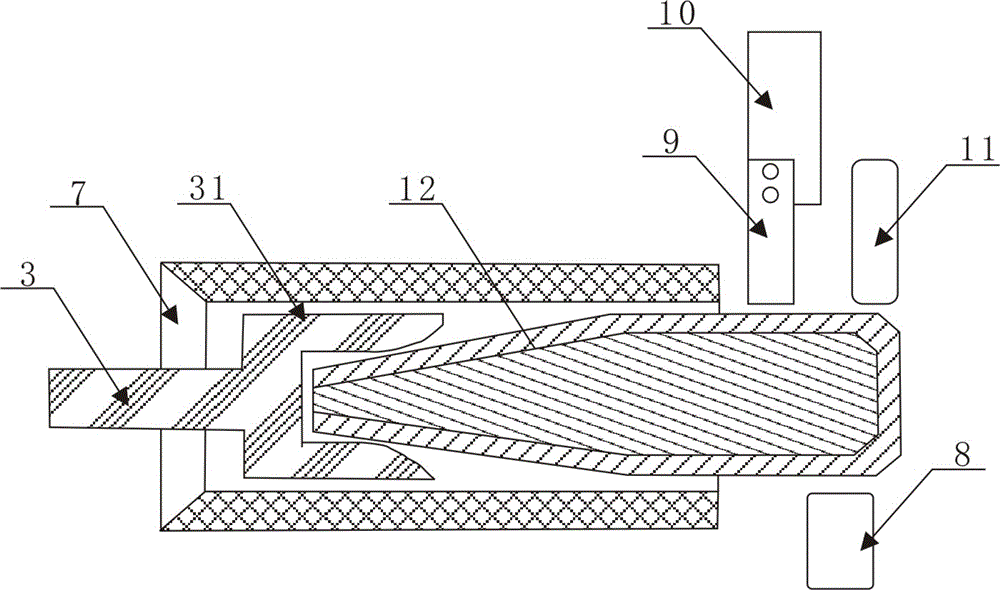

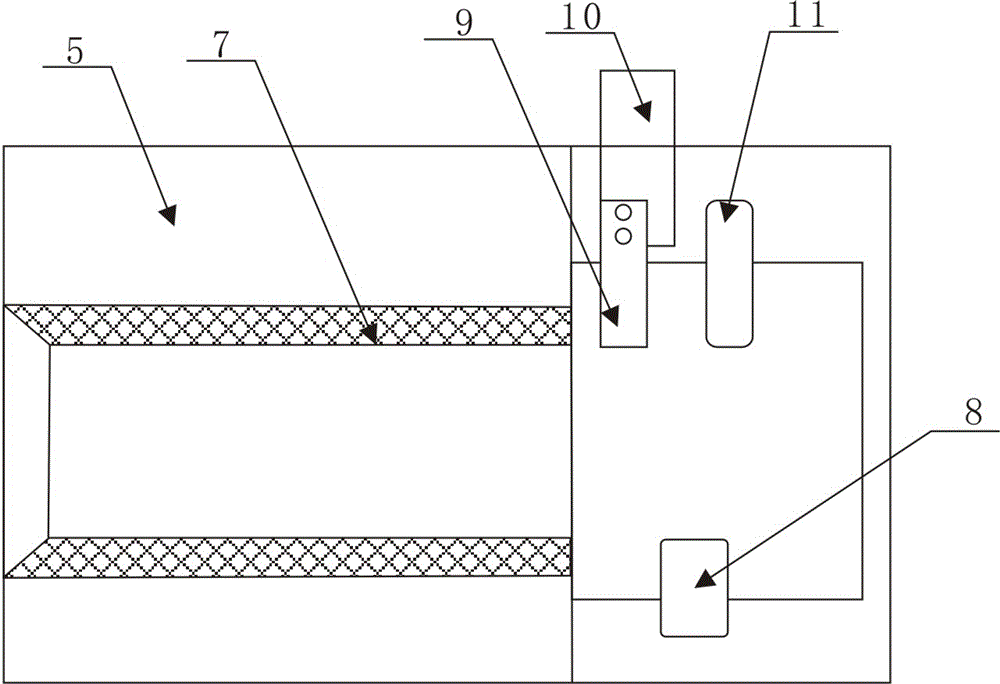

Impact shearing method and device for charged shot

The invention discloses an impact shearing method and device for a charged shot. The impact shearing method for the charged shot comprises the steps that an impact shearing load not smaller than 450 t is applied to the shot in the radial direction of the shot so as to fracture the shot, and then an explosive is taken out of the fractured shot. The impact shearing method for the charged shot solves the problems that TNT wastewater is generated when TNT is recovered through a TNT charged shot steam spilling recovery method, and serious environment pollution is generated when non TNT charged shots (such as trinitrotoluene-nitronaphthalene charged shots, TNT-RDX-A1 charged shots and desensitized RDX-Al charged shots) are burnt out or bombed out in the field. The impact shearing device for the charged shot comprises a device body, a shearing tool, a fixing sleeve and a pushing device, wherein the shearing tool is arranged on the device body, connected with a power mechanism and used for shearing the shot in the radial direction, the fixing sleeve is installed on the side face of the shearing tool and used for locating the shot, and the pushing device is connected with the power mechanism and used for feeding the shot into the fixing sleeve along a feeding channel and making the shearing portion of the shot right face the shearing tool.

Owner:郝俊修

High-ductility silver tin oxide contact material preparation method

InactiveCN109609794AImprove ductilityEnhanced Intersinter DiffusionTransportation and packagingMetal-working apparatusMaterials preparationWire rod

The invention discloses a high-ductility silver tin oxide contact material preparation method. The method comprises the following steps that (1) the silver tin oxide contact material ratio is preparedas required, the corresponding amount of silver, the corresponding amount of tin and the corresponding amount of an additive are calculated and weighed and then atomized to be made into powder afterbeing melted, and silver-tin alloy powder is obtained; (2) the silver-tin alloy powder is subjected to wet milling under the protective atmosphere condition, and silver-tin alloy powder subjected to ball milling is obtained; (3) the silver-tin alloy powder subjected to ball milling is oxidized, and silver tin oxide composite powder is obtained; (4) the silver tin oxide composite powder is subjected to molding, and a silver tin oxide blank is obtained; (5) the silver tin oxide blank is subjected to sintering under the condition that the oxygen partial pressure is higher than or equal to 0.8 Mpaand the temperature is 900-960 DEG C, and a high-ductility silver tin oxide ingot blank is obtained; and (6) the silver tin oxide ingot blank is subjected to heat extrusion, and a silver tin oxide wire rod or strip is obtained. A silver tin oxide contact material prepared through the method is uniform in structure and high in ductility, and the processability of the material is effectively improved.

Owner:桂林金格电工电子材料科技有限公司

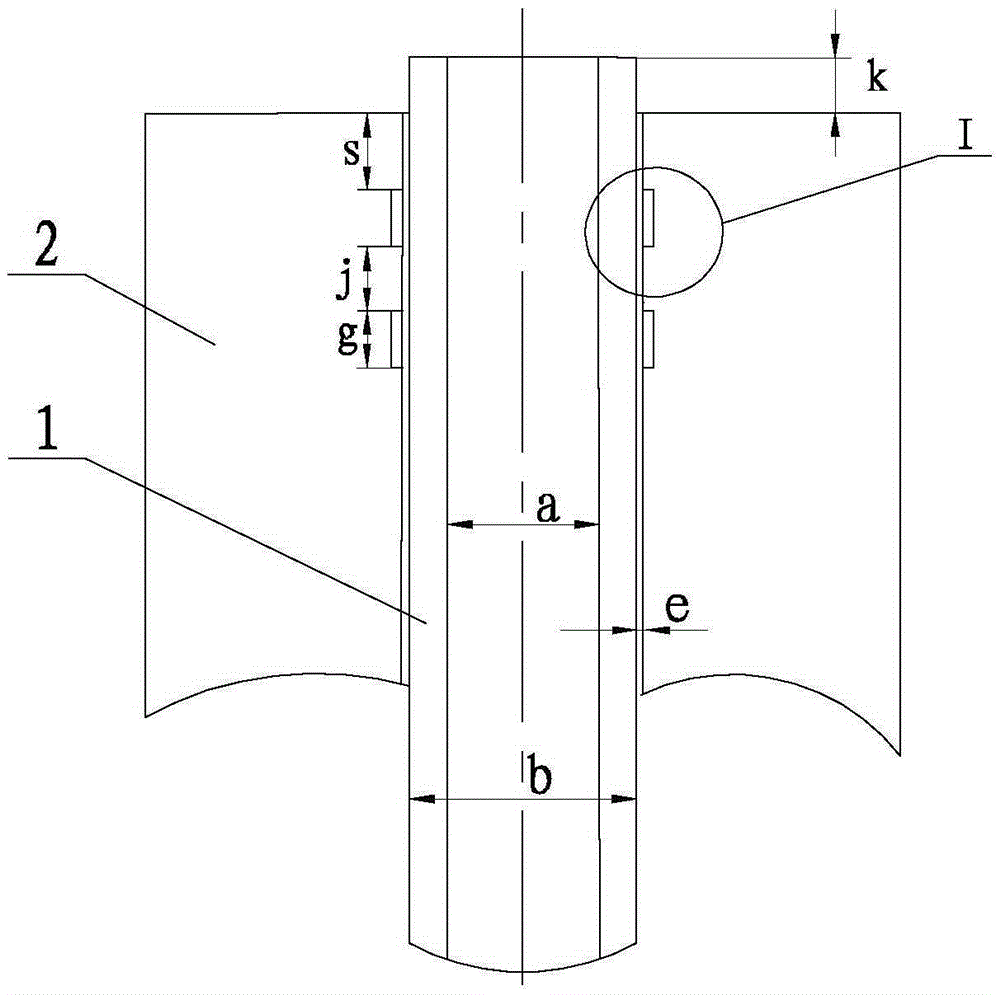

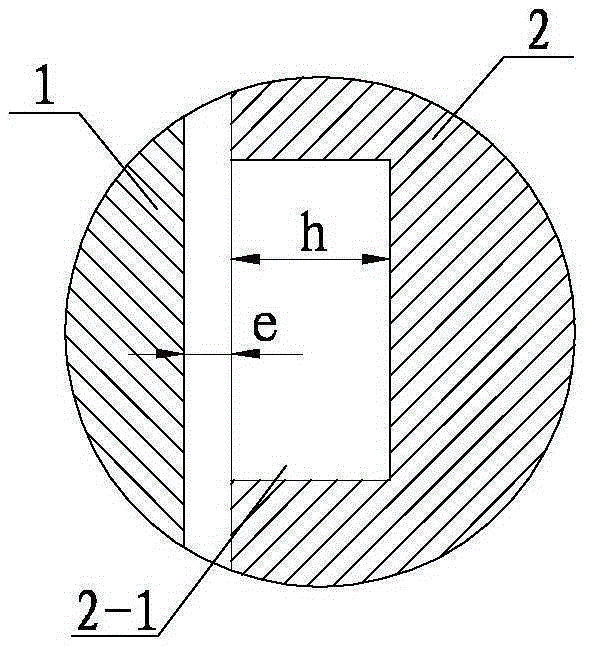

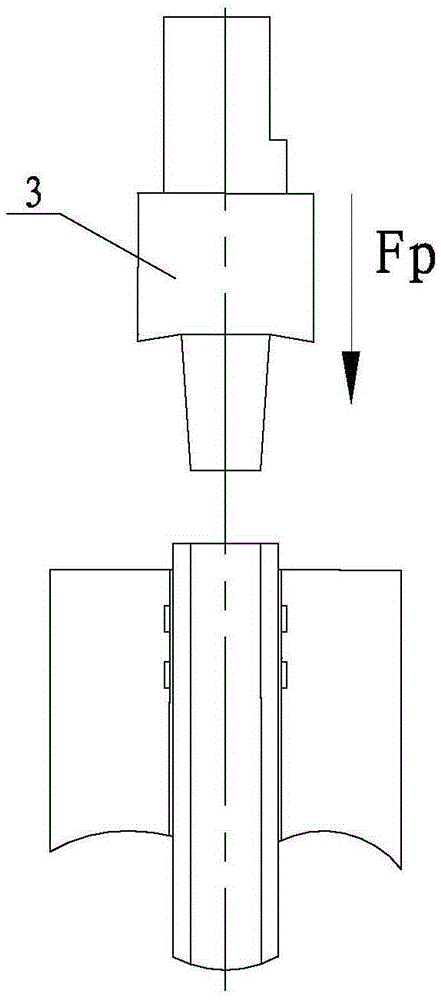

Method for friction-deformation-diffusion welding of circular-groove-assisted reinforcing tube plate

ActiveCN105414738AReduce manufacturing costImprove sealingNon-electric welding apparatusFriction weldingOrganic solvent

The invention discloses a method for friction-deformation-diffusion welding of a circular-groove-assisted reinforcing tube plate, and aims to solve the problems that a high-temperature joint loosens, crevice corrosion occurs, the production process is complex and the cost is high when a tube and a tube plate of a heat exchanger are connected according to an expanded jointing method, a fusion welding method as well as a method integrating the expanded jointing method and the fusion welding method. The method provided by the invention comprises the following steps: (1) one or more circular grooves are formed in the inner wall of the tube plate; (2) the surfaces of the tube and the tube plate are scrubbed by adopting an organic solvent or a cleaning agent; (3) the tube and the tube plate are clamped in a clearance fit manner; (4) friction welding is performed, wherein the diameter of the large end of a friction needle is larger than the inner diameter a of the tube and smaller than the outer diameter b of the tube, so that the circular grooves can be fully filled with a thermoplastic tube material gradually to form mechanical meshing under the squeezing action of the friction needle; (5) when a shaft shoulder of a friction head is pressed in the upper surface of the tube plate at a depth of t, the friction head keeps rotating at a high speed and remains for 3-15 seconds, and then is lifted at a constant speed, so as to obtain a heat exchanging tube for friction-deformation-diffusion welding of the circular-groove-assisted reinforcing tube plate. The method is applicable to tube plate welding.

Owner:HARBIN INST OF TECH

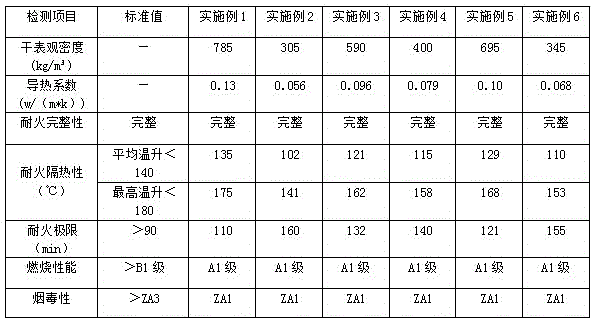

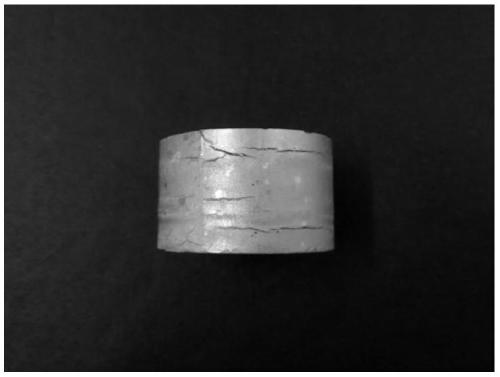

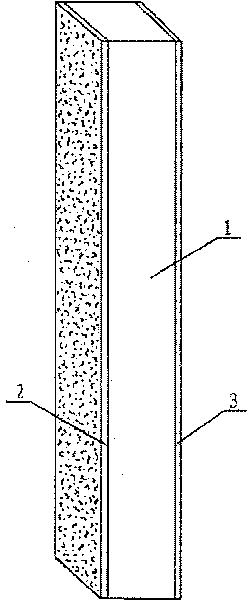

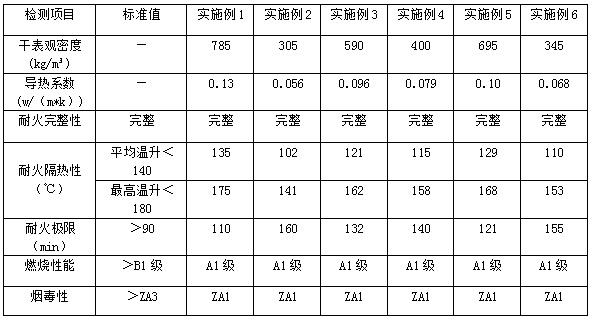

Preparation method of inorganic fireproof door core material

ActiveCN105481461ARapid hardening early strengthImprove fire performanceCeramicwareFoaming agentSulfate

The invention discloses a preparation method of an inorganic fireproof door core material, and belongs to the technical field of fireproof materials. The preparation method of the inorganic fireproof door core material is characterized by comprising the following steps that 1, cement slurry is prepared, wherein 1 part of sulfate aluminum cement, 0.002-0.01 part of water reducing agent, 0.002-0.01 part of basalt fiber and 0.3-0.4 part of water are mixed to be uniform for use; 2, a foam body is prepared, wherein a foaming agent is diluted, and the foam body is prepared; 3, the foam prepared in the second step and the cement slurry prepared in the first step are mixed according to the proportion of 2-6 mL / g, stirring is conducted to be uniform, the obtained mixture is poured into a mold, standard curing is conducted for 24 h, demolding is conducted, and then natural curing or standard curing is conducted for 7-28 days, and the inorganic fireproof door core material is obtained. When the inorganic fireproof door core material is subjected to a flame, dripping matter does not exist on the surface, the phenomena of curling and melting do not exist, and the inorganic fireproof door core material has the advantages of being good in use property and fireproof property and environmentally friendly.

Owner:JIAHUA SPECIAL CEMENT

Preparation method of silver tin oxide contact material for improving sintering property of ingot blank

The invention discloses a preparation method of a silver tin oxide contact material for improving the sintering property of an ingot blank. The method comprises the following steps that 1) according to the material proportion of a silver tin oxide contact needing to be prepared, silver, tin, and additives with the corresponding dosage are calculated and weighed, the mixture is melted and then atomized to prepare powder to obtain silver-tin alloy powder; 2) the silver-tin alloy powder is oxidized to obtain silver tin oxide composite powder; 3) the silver tin oxide composite powder is subjectedto wet grinding under a protective atmosphere condition so as to obtain the ball-milled silver tin oxide composite powder; 4) the ball-milled silver tin oxide composite powder is formed to obtain a silver tin oxide blank body; 5) the obtained silver tin oxide blank body is placed at the condition with the oxygen partial pressure higher than or equal to 0.8 Mpa, and the temperature of 900-960 DEG Cto be sintered to obtain the silver tin oxide ingot blank; and 6) the obtained silver tin oxide ingot blank is subjected to hot extrusion to obtain a silver tin oxide wire rod or a silver tin oxide strip material. The silver tin oxide contact material prepared by the method is uniform in structure and good in processing performance.

Owner:桂林金格电工电子材料科技有限公司

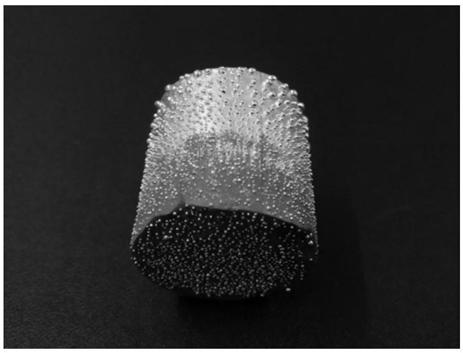

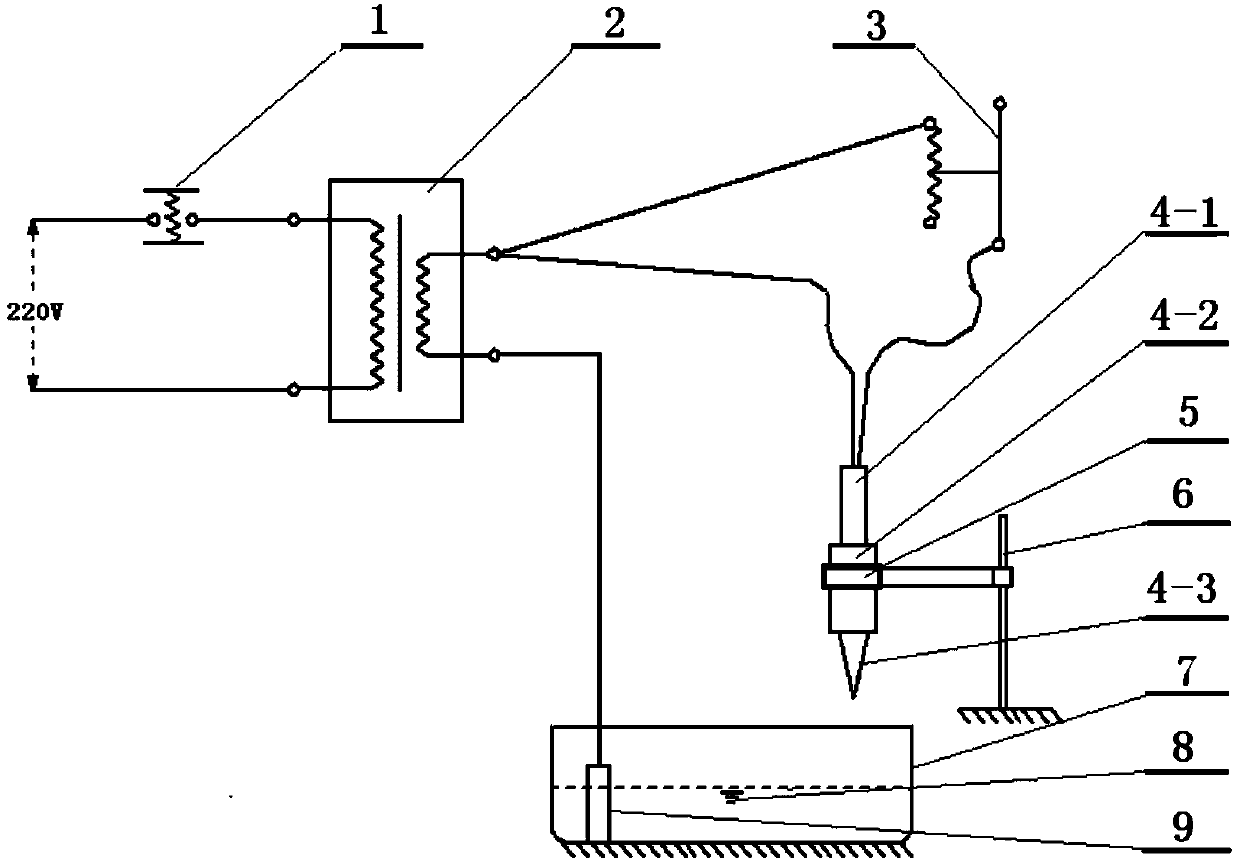

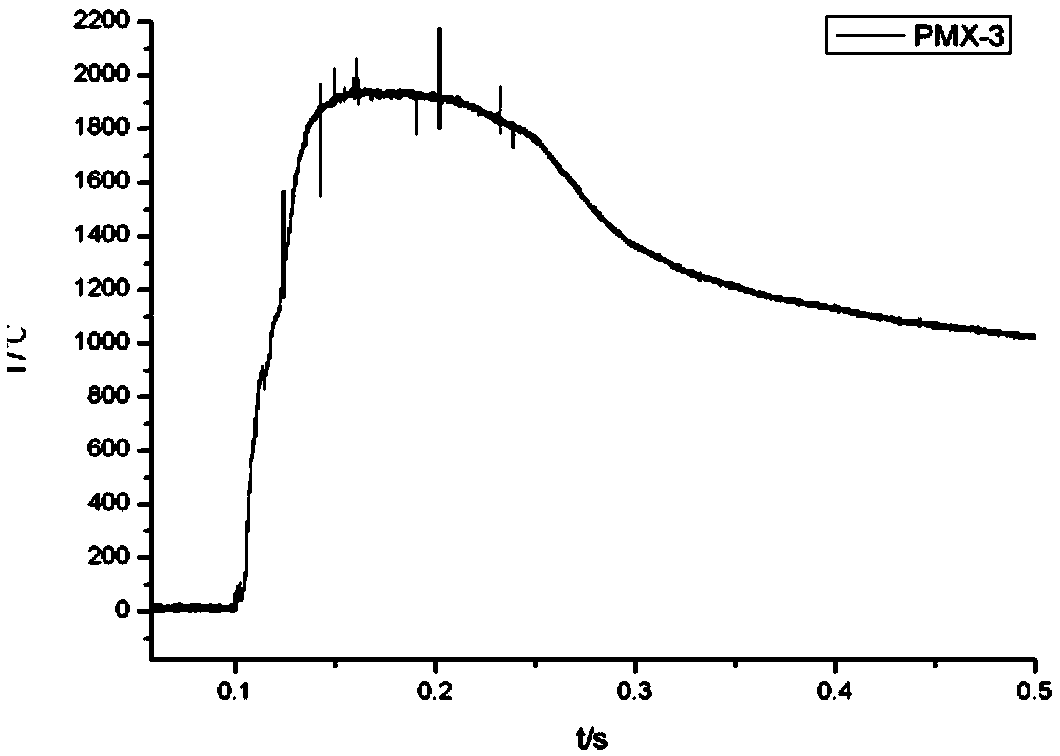

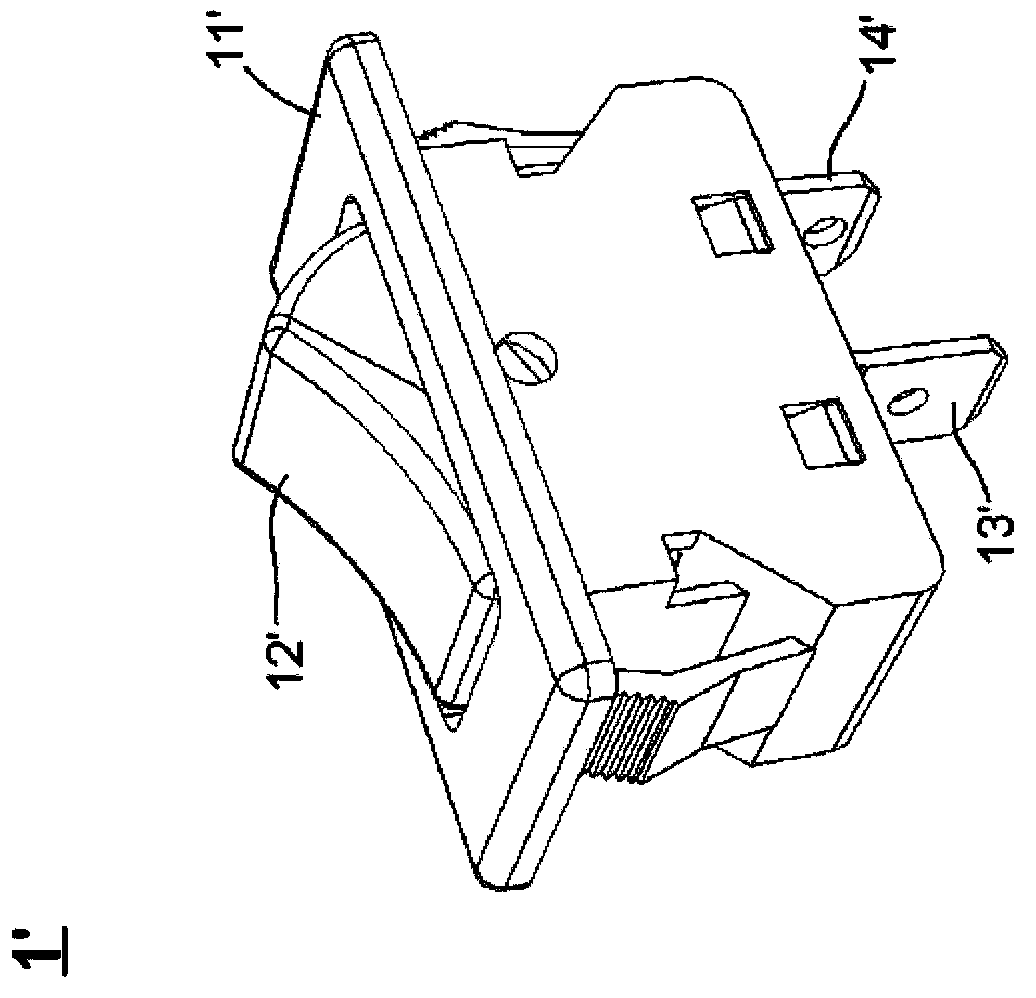

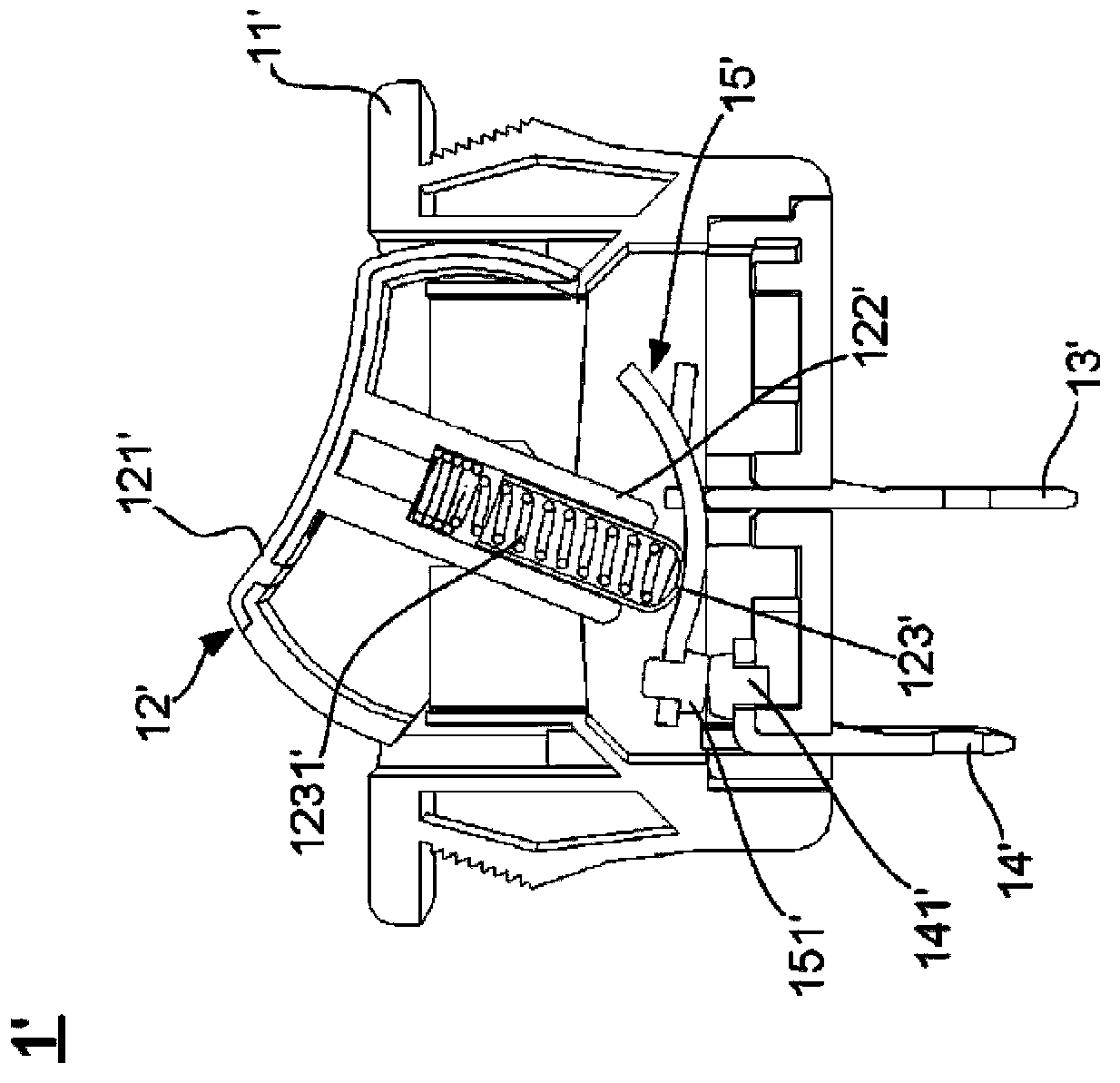

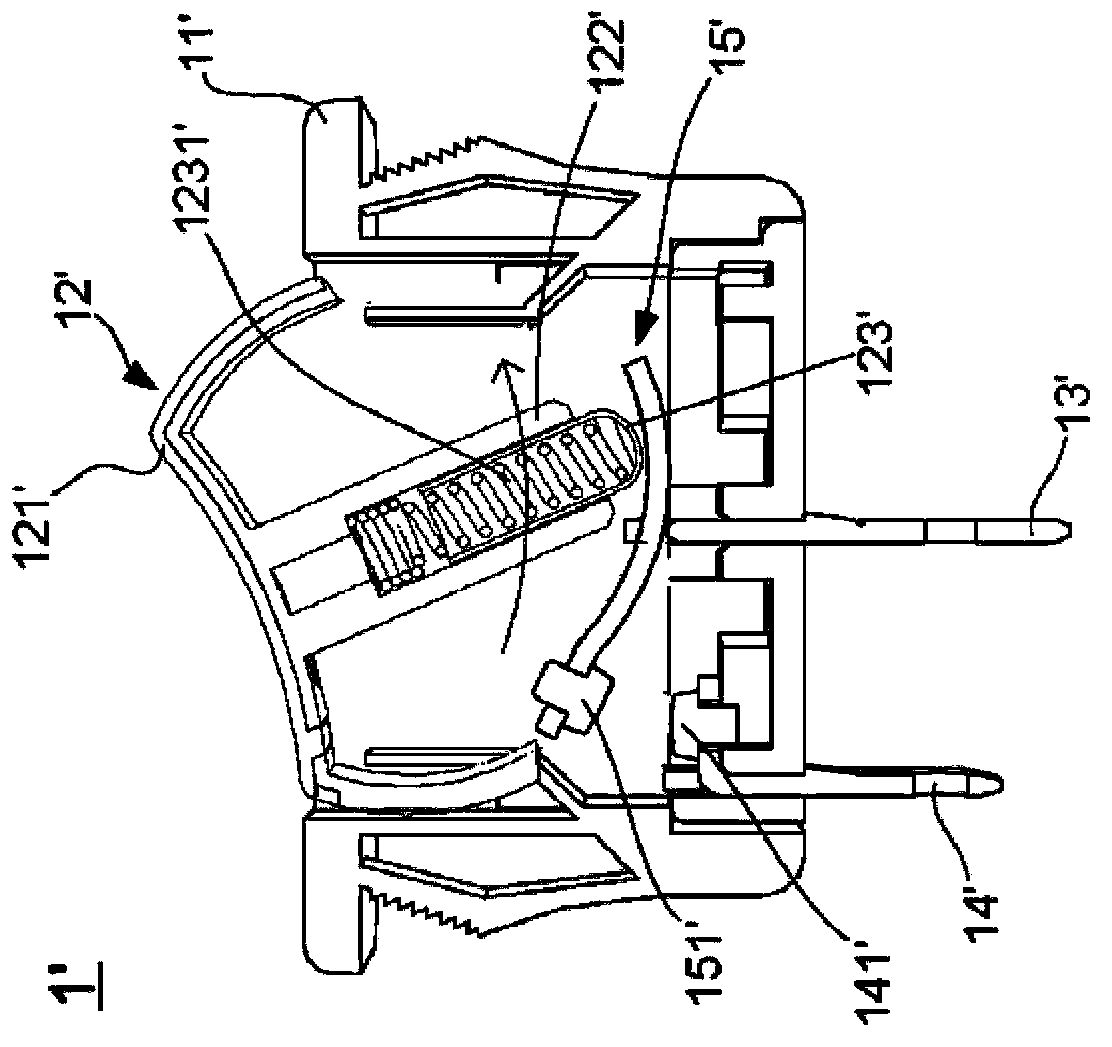

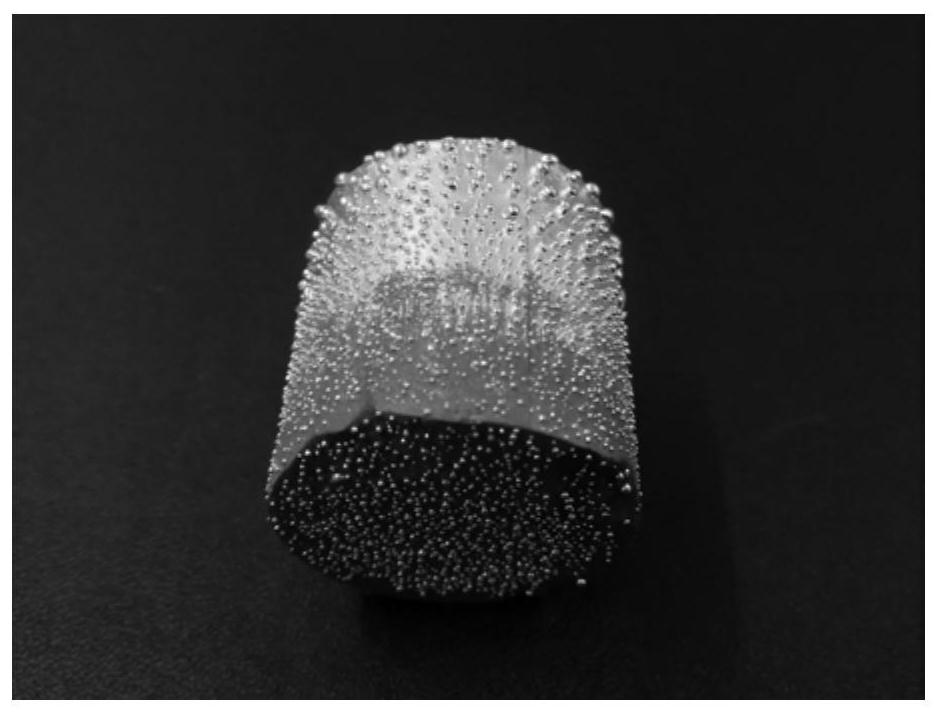

Quick-response tungsten-rhenium thermocouple welding device

ActiveCN109530847AAvoid heating and meltingNo melting phenomenonWelding electrode featuresRheniumTransformer

The invention discloses a quick-response tungsten-rhenium thermocouple welding device. The device mainly comprises a transformer, a rheostat, a support seat, a clamp, an electric conductor, an electrode plate and the like, wherein the rheostat is used for adjusting the resistance of a discharge circuit of a thermocouple, and realizing the consistency of discharge currents of two thermo wires of the thermocouple; and the electric conductor is a gallium alloy, so that the welding strength of the thermocouple and the purity of thermo nodes are guaranteed. The device has the following remarkable advantages: the device is simple in composition and convenient to operate; and the welded tungsten-rhenium thermocouple is high in forming rate, small in thermo node size, short in response time, and capable of meeting the quality control requirement of quick response of thermal effect measurement for an explosion field.

Owner:XIAN MODERN CHEM RES INST

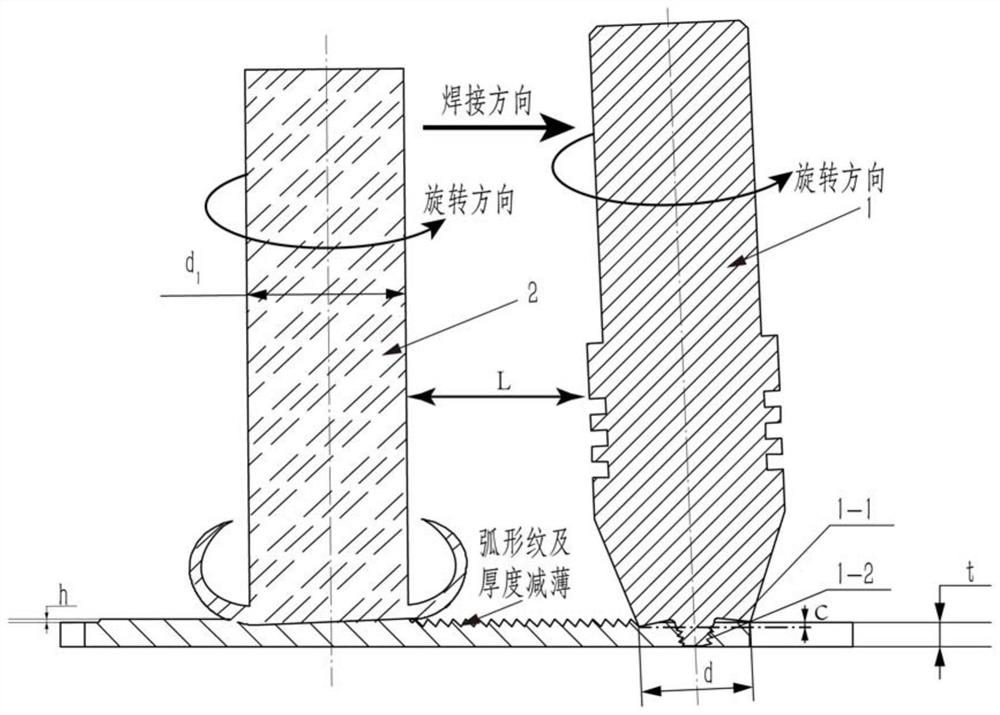

A Friction Stir Welding Method for Suppressing Weld Thinning and Thickening Weld

ActiveCN109967855BIncrease the area of actionAct as surface rougheningNon-electric welding apparatusOrganic solventSurface oxidation

The invention provides a friction stir welding method for restraining welded joint thinning and thickening a welded joint. The friction stir welding method includes the steps that firstly, cleaning isconducted before welding, an oxide film on the surface of a sheet to be welded is removed by mechanical polishing, and then organic solvents or cleaning agents are adopted to wipe the surface of thesheet to be welded to remove sundries; secondly, materials and shapes of a stirring head and a consumptive friction head are selected, the material and the shape of the stirring head are determined according to the properties and the thickness of the sheet to be welded, the consumptive friction head is made of the same material as the sheet to be welded, and the diameter of the consumptive friction head is equal to or larger than that of shaft shoulders of the stirring head; thirdly, positioning is conducted, the relative position of the sheet to be welded is adjusted to make the axis of the stirring head and the axis of the consumptive friction head face the center line of a to-be-welded position of the sheet to be welded, and the consumptive friction head is arranged directly behind thestirring head; and fourthly, welding is carried out. The friction stir welding method eliminates welded joint thinning and achieves welded joint thickening, so that the service life of the welded joint is remarkably prolonged.

Owner:HARBIN INST OF TECH

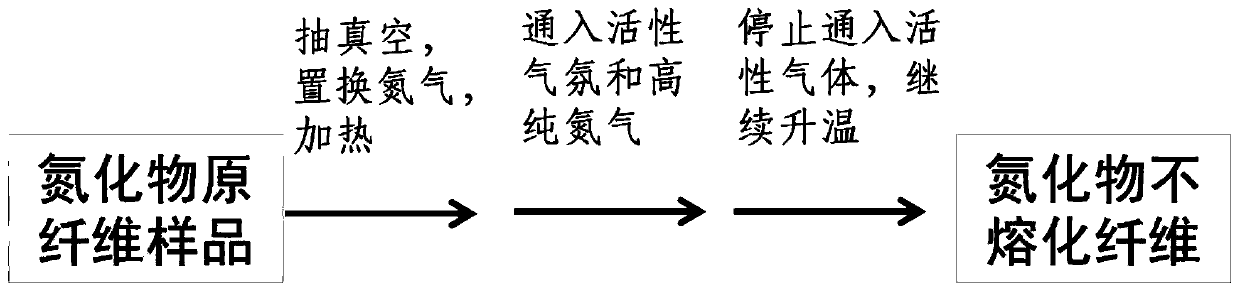

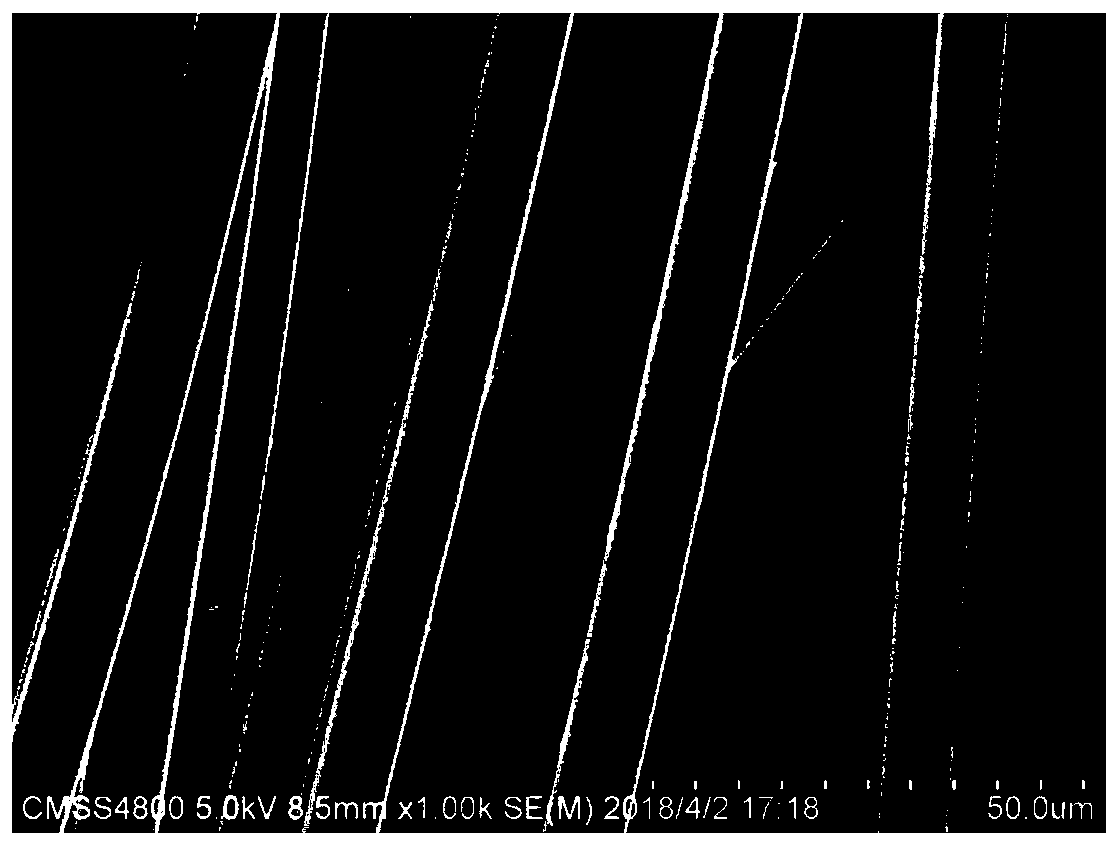

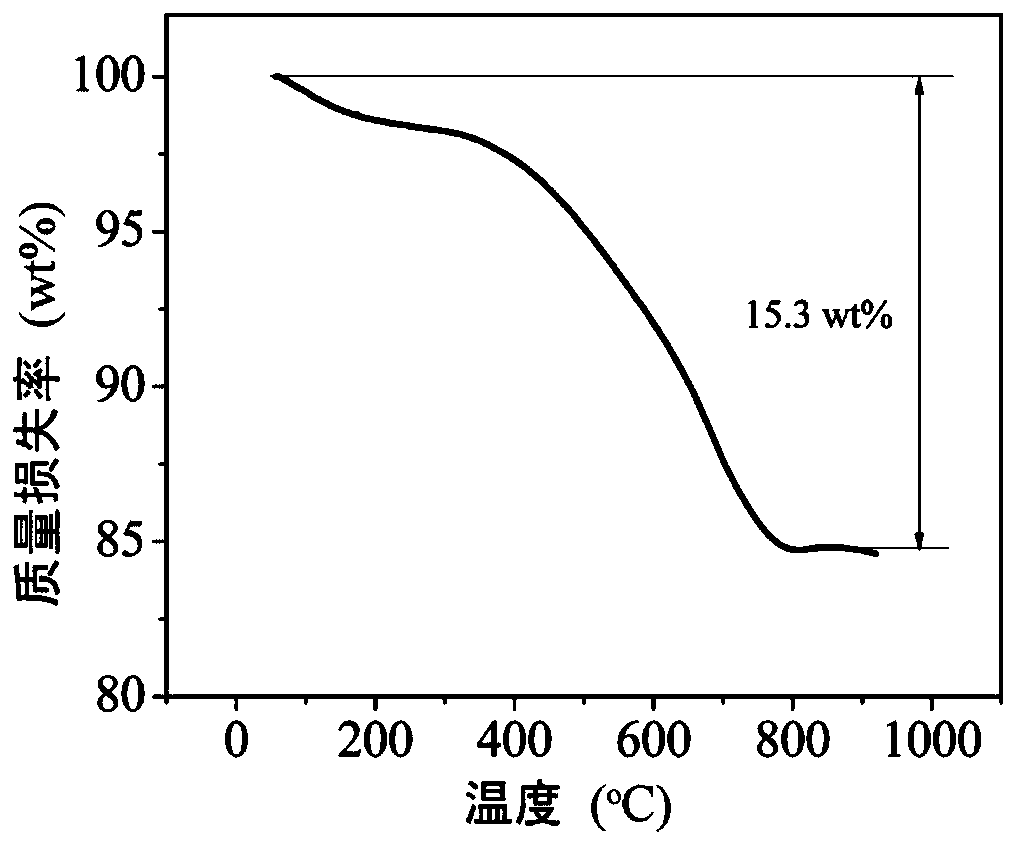

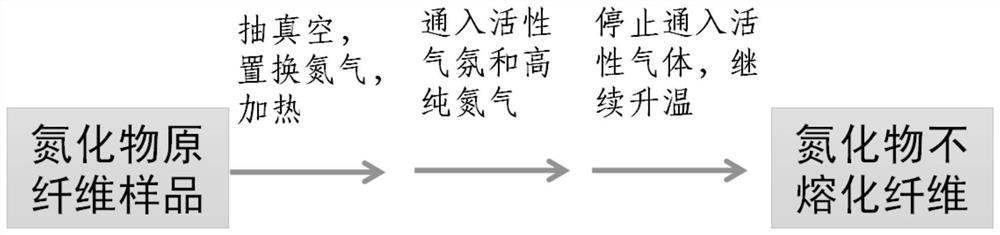

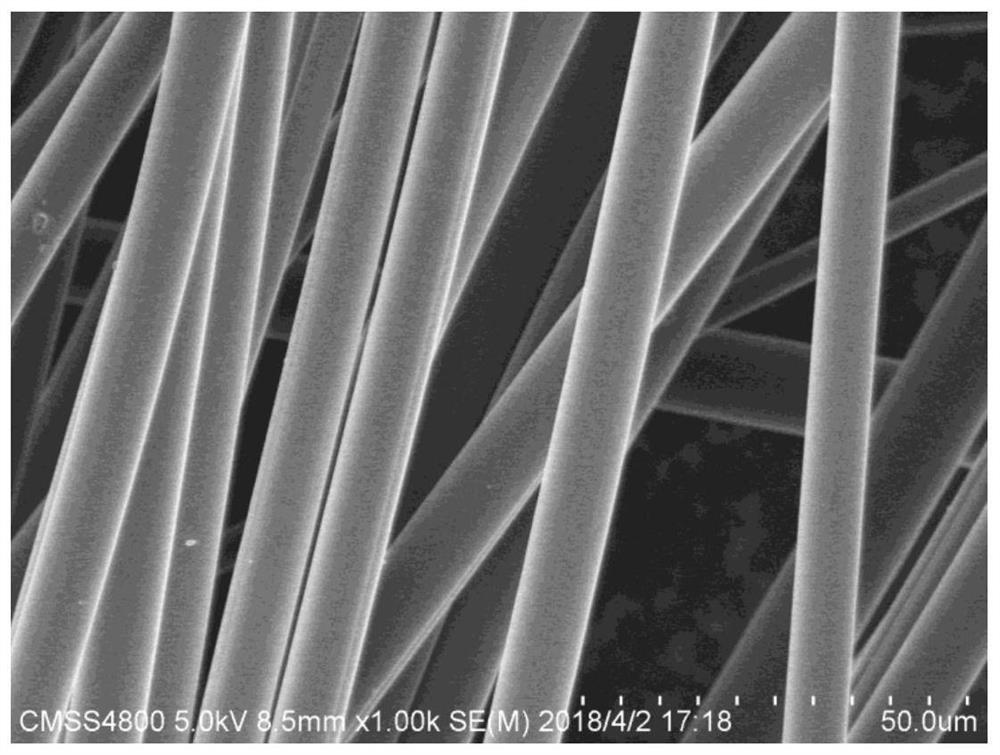

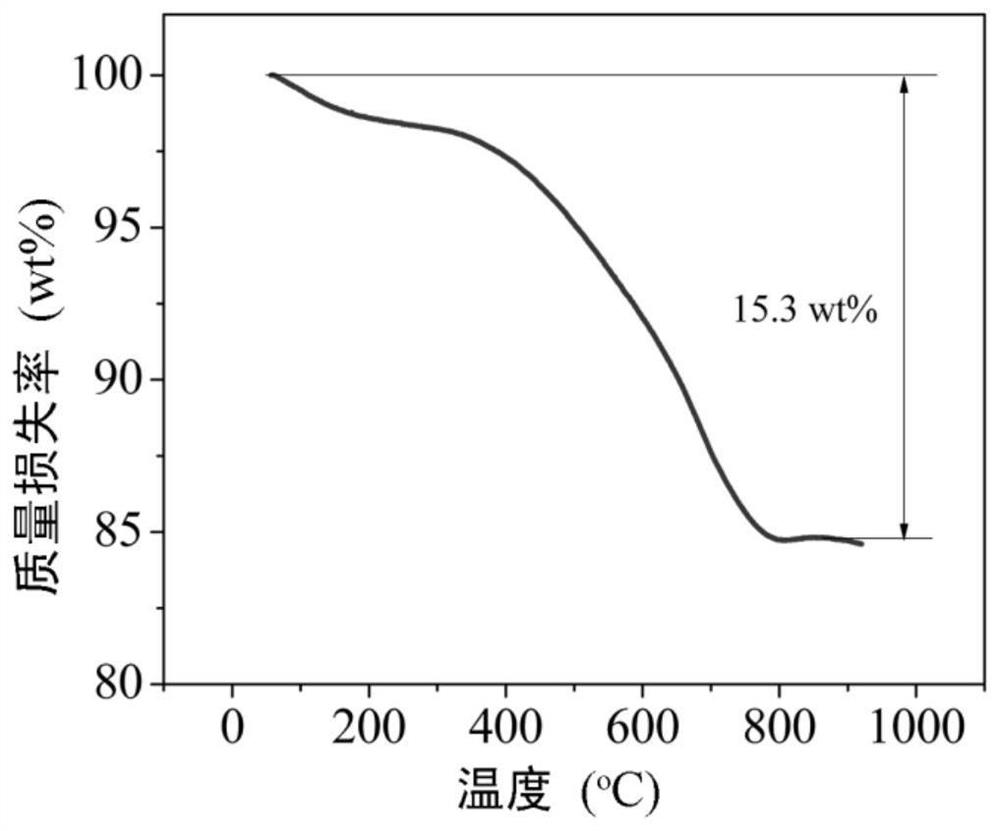

Nitride fiber thermal cross-linking assisted atmosphere non-melting method

ActiveCN110952170ALow cost of preparationReduce pollutionInorganic material artificial filamentsArtificial filament chemical after-treatmentPhysicsHeat conservation

The invention discloses a nitride fiber thermal cross-linking assisted atmosphere non-melting method. The non-melting method comprises the following steps: (1) a nitride fibril sample is placed in a non-melting atmosphere furnace, and air is vacuumized and replaced with nitrogen; (2) the temperature in the non-melting atmosphere furnace increases from room temperature to 40-60 DEG C under a nitrogen atmosphere, then an active gas is introduced, and the flow ratio of the active gas to the nitrogen is (2:1)-(1:10); (3) the temperature in the non-melting atmosphere furnace is continuously raisedfrom 40 -60 DEG C to 100-150 DEG C, heat preservation is performed at 100-150 DEG C for 0.5-3 hours, and then the active gas introduction is stopped; (4) the temperature in the non-melting atmospherefurnace is continuously raised from 100-150 DEG C to 300-400 DEG C, heat preservation is performed at 300-400 DEG C for 0.5-2 hours, then, heating is terminated and cooling is performed to obtain non-molten fibers. Compared with a separate atmosphere non-melting cross-linking or thermal cross-linking method, the non-molten fibers obtained by the method provided by the invention are more uniform, and the cross-linking reaction degree is higher; and the process control, in comparison, is simpler and the production cost is lower.

Owner:NAT UNIV OF DEFENSE TECH

Durable fireproof material

The invention discloses a durable fireproof material. The fireproof material components include: 4-8 parts by mass of dichloromethane, 10-13 parts by mass of sodium lauryl sulfate, resin, 9-13 parts by mass of sodium silicate, 3-8 parts by mass of lithium dihydrogen phosphate airgel. The material of the invention has good aging resistance and weather resistance.

Owner:蒲雪萍

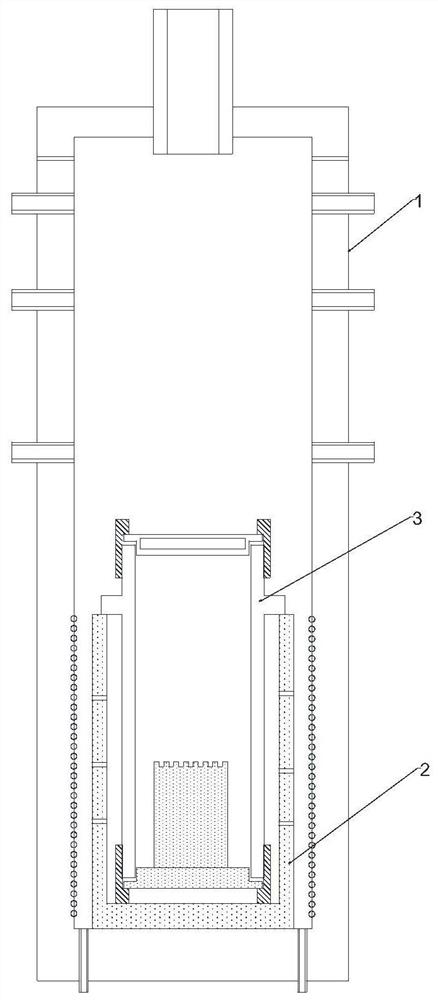

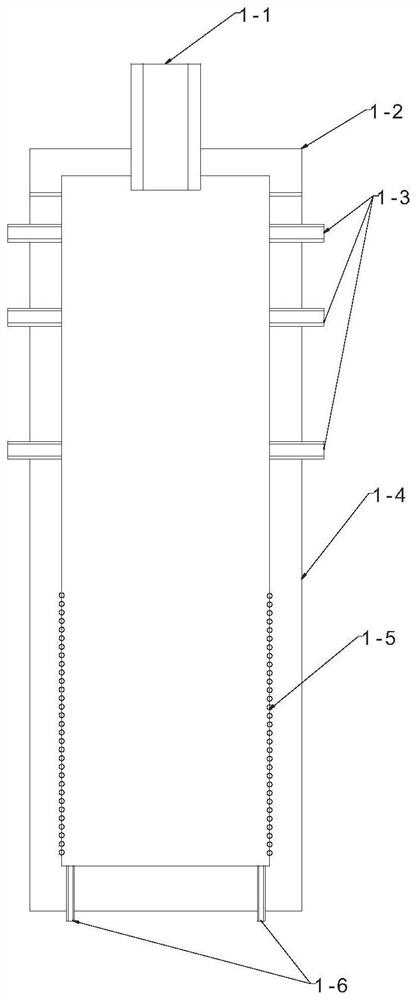

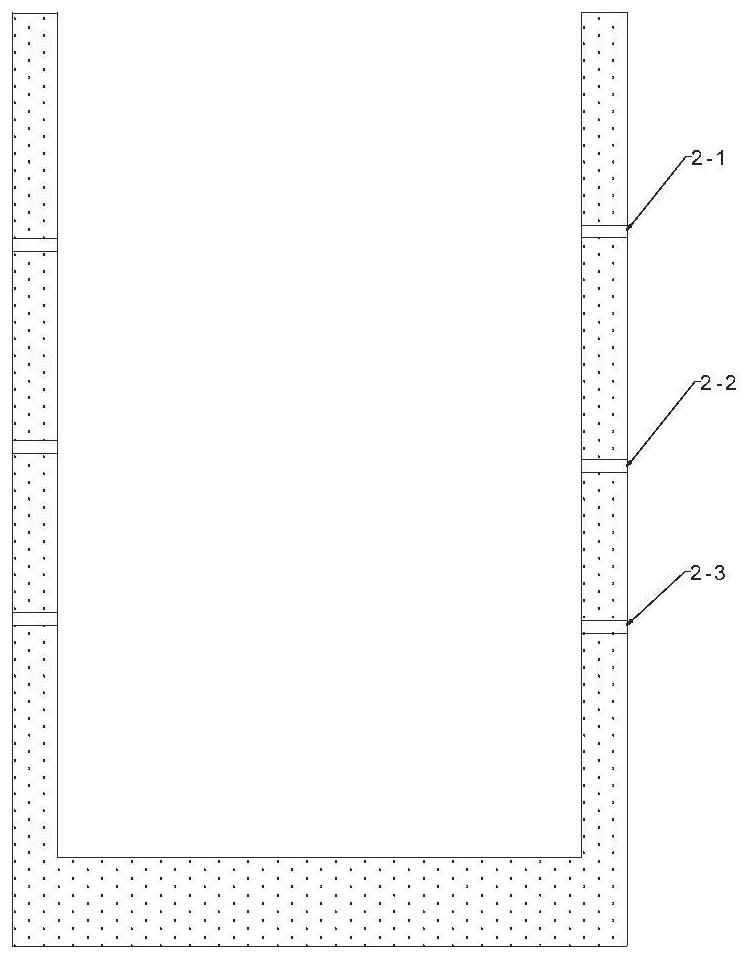

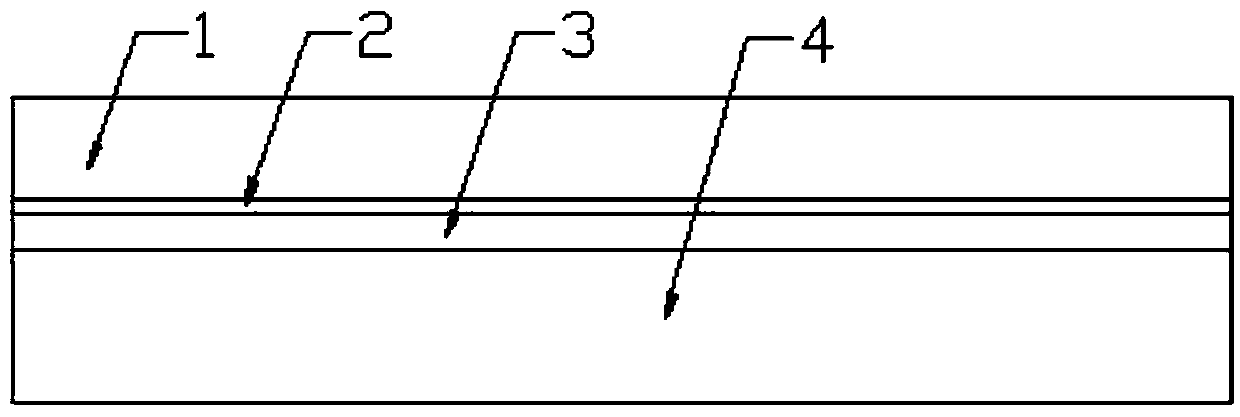

Fuel rod fission product release simulation device and using method thereof

ActiveCN112037950AThe experimental results are accurateBorder intactNuclear energy generationNuclear monitoringHeating furnaceBurnup

The invention discloses a fuel rod fission product release simulation device and a using method thereof. The simulation device comprises a heating furnace, a crucible and a fuel rod simulator, whereinthe fuel rod simulator is used for simulating a cladding and a pellet of a prototype fuel element; the crucible is used for supporting the fuel rod simulator and providing a gas circulation flow channel at the same time, the crucible can contain liquid melt when the fuel rod simulator is molten, and the melt is prevented from damaging the heating furnace; and the heating furnace is used for heating the fuel rod simulator. The invention provides a fission product release characteristic experimental device which does not contain radioactive isotopes and has a structure similar to that of a realfuel rod in physical and chemical processes for a fission product release characteristic experiment, and the fission product release characteristic experimental device can be used for researching release characteristics of various fission products with different reactor types and different serious burnup accidents.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Fire-resistant cloth made of fiber material

InactiveCN107650477AImprove wear resistanceNo meltingSynthetic resin layered productsCoatingsFiberAdhesive

The invention discloses fire-resistant cloth made of a fiber material. The fire-resistant cloth comprises a wear-resistant layer, an adhesive, a waterproof layer and a bottom coating, wherein the wear-resistant layer is located on the outermost side, the bottom face of the wear-resistant layer is connected with the surface of the waterproof layer, the adhesive is arranged between the wear-resistant layer and the waterproof layer, the wear-resistant layer is fixedly connected with the waterproof layer with the adhesive, the waterproof layer is located on the upper side of the bottom coating, and the bottom face of the waterproof layer is connected with the surface of the bottom coating. According to the fire-resistant cloth, as the wear-resistant layer is made of a wear-resistant nylon oxford material, the wear resistance of the cloth is improved, the cloth is more durable, and the wear phenomenon does not occur easily; as a PTFE membrane is additionally arranged between the wear-resistant layer and the bottom coating, the cloth achieves a waterproof effect, and articles in the cloth are prevented from being wetted; as the bottom coating is made of an organic silicon resin material,the cloth will not be molten in ink jet printing, and meanwhile the thickness of the cloth is increased, which makes the cloth product stiffer and more attractive.

Owner:东台市黄海耐火材料厂

Push switch structure far away from hot spot

The present invention relates to a push switch structure far away from a hot spot. The push switch structure far away from the hot spot mainly comprises a supporting terminal, a compression spring, a switch spring leaf, an electrical terminal and a switch slide bar set. According to the present invention, the compression spring, the switch spring leaf and a switching member of the switch slide bar set are connected in a similar stacking manner, so that the overall occupation space of the push switch structure can be saved effectively. In addition, with the special structure design of the supporting terminal, the compression spring, the switch spring leaf, the electrical terminal and the switch slide bar set, when two contacts are contacted tightly, a certain distance exists between the switching member of the switch slide bar set and the contact point of the two contacts, so that the switching member is far away from the hot spot formed by the contact point, and accordingly, the switching member is not melted even though the push switch structure is used for a long time.

Owner:SOLTEAM ELECTRONICS

Composite pnenolic aldehyde foam heat-insulating board for building and forming method thereof

InactiveCN101148515BImprove brittlenessHigh compressive strengthClimate change adaptationSynthetic resin layered productsEpoxyFire retardant

The heat insulating composite foamed phenolic plate for building includes one heat insulating foamed phenolic plate produced with foamed phenolic resin 100 weight portions, polyurethane 10-25 weight portions, epoxy resin 0.5-5 weight portions, fire retardant 10-20 weight portions, surfactant 0.5-2 weight portions, polyglycol 5-15 weight portions, glass fiber 0.5-2 weight portions, foam homogenizing agent 5-10 weight portions, foaming agent 5-10 weight portions and acid curing agent 5-10 weight portions; and one sprayed layer in the surface of the heat insulating foamed phenolic plate and comprising cement 100-150 weight portions, water 80-100 weight portions, emulsion of acrylate copolymer 90-110 weight portions, hydroxyethyl cellulose 3-6 weight portions and defoaming agent 0.5-2 weight portions. The heat insulating composite foamed phenolic plate has high toughness, less pulverizing, high strength and good construction performance.

Owner:郎云峰

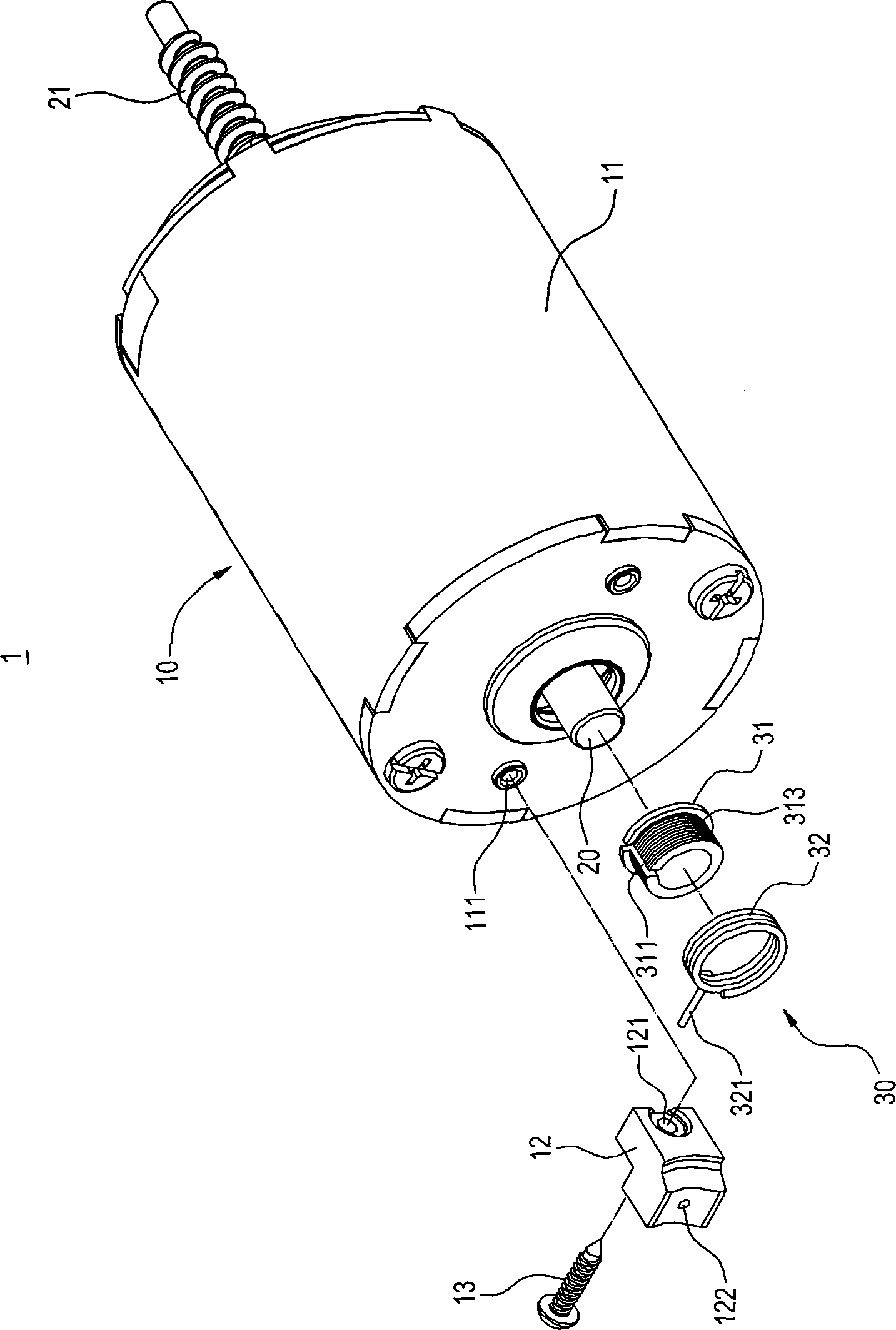

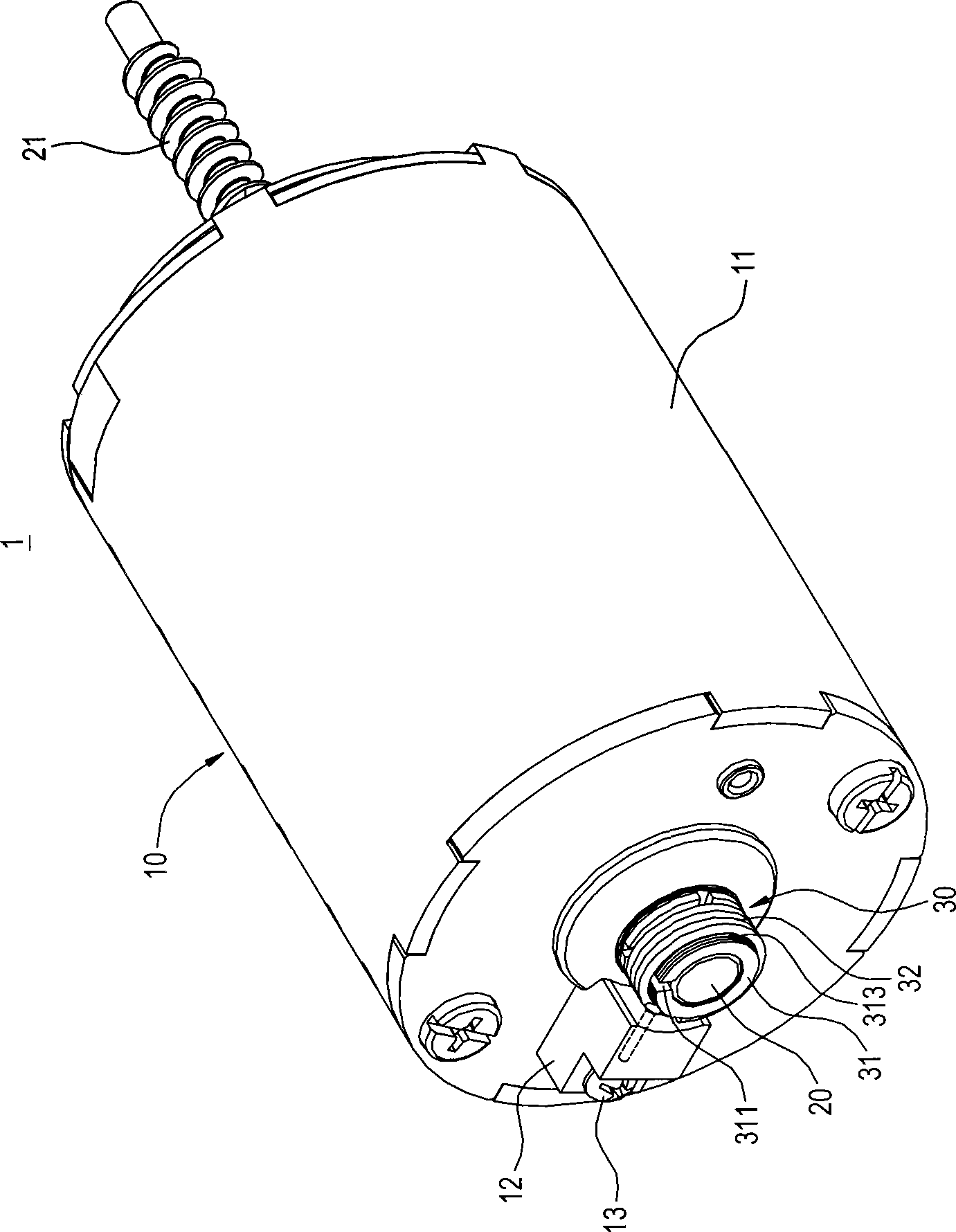

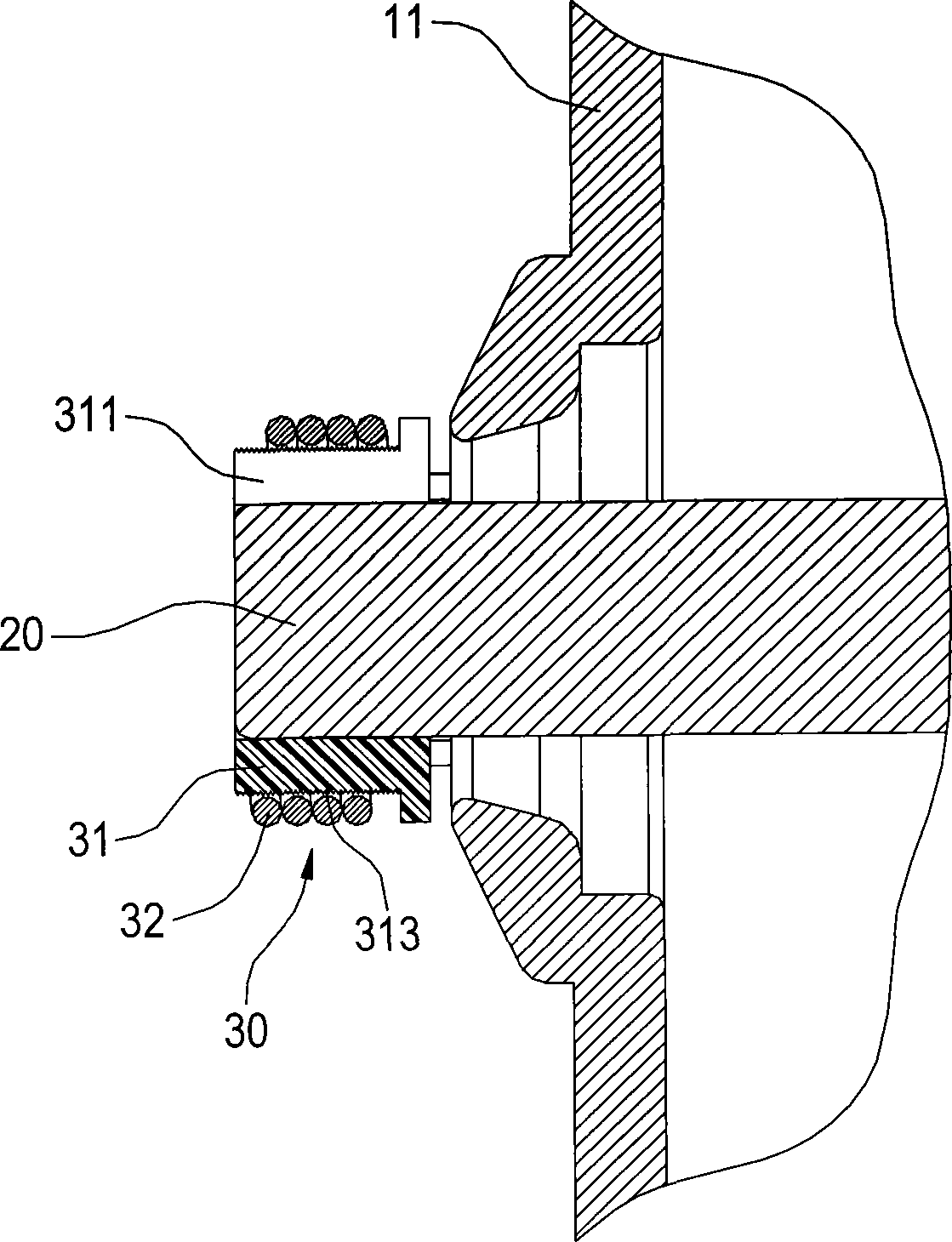

Motor with braking and decelerating mechanism and for actuating device

ActiveCN102808872BDoes not affect transmission performanceImprove use comfort performanceSelf acting brakesBraking membersCoil springEngineering

The invention discloses a motor with a braking and decelerating mechanism and for an actuating device. The motor comprises a body, a rotary shaft and the braking and decelerating mechanism, wherein the rotary shaft is penetratingly connected at the center of the body, the braking and decelerating mechanism comprises a frictional component and a spiral spring, the frictional component is connected on the peripheral edge of the rotary shaft in a sleeved manner, the spiral spring is elastically clamped on the periphery of the frictional component, one end of the spiral spring is positioned on the body, and the spiral spring can press the frictional component to brake the rotary shaft to decelerate when the rotary shaft rotates unidirectionally. Consequently, the motor with the braking and decelerating mechanism and for the actuating device is prolonged in service life due to low loss of the spiral spring, and good in braking and decelerating performance due to large contact area between the frictional component and the rotary shaft.

Owner:第一传动科技股ふん有限公司

A kind of preparation method of inorganic fireproof door core material

ActiveCN105481461BRapid hardening early strengthNo melting phenomenonCeramicwareFoaming agentSulfate

The invention discloses a preparation method of an inorganic fireproof door core material, and belongs to the technical field of fireproof materials. The preparation method of the inorganic fireproof door core material is characterized by comprising the following steps that 1, cement slurry is prepared, wherein 1 part of sulfate aluminum cement, 0.002-0.01 part of water reducing agent, 0.002-0.01 part of basalt fiber and 0.3-0.4 part of water are mixed to be uniform for use; 2, a foam body is prepared, wherein a foaming agent is diluted, and the foam body is prepared; 3, the foam prepared in the second step and the cement slurry prepared in the first step are mixed according to the proportion of 2-6 mL / g, stirring is conducted to be uniform, the obtained mixture is poured into a mold, standard curing is conducted for 24 h, demolding is conducted, and then natural curing or standard curing is conducted for 7-28 days, and the inorganic fireproof door core material is obtained. When the inorganic fireproof door core material is subjected to a flame, dripping matter does not exist on the surface, the phenomena of curling and melting do not exist, and the inorganic fireproof door core material has the advantages of being good in use property and fireproof property and environmentally friendly.

Owner:JIAHUA SPECIAL CEMENT

Pet comb processing technology

The invention discloses a pet comb machining process. The pet comb machining process comprises a machining process A of a handle, a machining process B of a rubber sleeve and a combining process C for assembling the handle and the rubber sleeve, wherein in the process A and the process B, the pre-heating of a machine is divided into three sections; the first section is a temperature at a nozzle, the second section is a temperature in a material storage region and the third section is a temperature in a screw barrel; the temperatures of the three sections are higher than a dissolving temperature of raw materials entering the machine; when the raw materials enter the screw barrel, the raw materials can be primarily heated and dissolved in a conveying process of the screw barrel; then the raw materials enter the material storage region and are further sufficiently dissolved in the material storage region; the temperature of the material storage region is higher than the temperature of the screw barrel so that the mobility of the raw materials is improved when the raw materials enter the material storage region, and furthermore, the aim of sufficiently dissolving is achieved; and the material storage region further has a material storage function so that the raw materials sprayed out by the nozzle can be uniformly dissolved and the spraying amount of each time is the same.

Owner:SUZHOU SHENGKANG PLASTIC ELECTRIC

A preparation method of silver tin oxide contact material improving sinterability of ingot

The invention discloses a preparation method of a silver tin oxide contact material for improving the sintering property of an ingot blank. The method comprises the following steps that 1) according to the material proportion of a silver tin oxide contact needing to be prepared, silver, tin, and additives with the corresponding dosage are calculated and weighed, the mixture is melted and then atomized to prepare powder to obtain silver-tin alloy powder; 2) the silver-tin alloy powder is oxidized to obtain silver tin oxide composite powder; 3) the silver tin oxide composite powder is subjectedto wet grinding under a protective atmosphere condition so as to obtain the ball-milled silver tin oxide composite powder; 4) the ball-milled silver tin oxide composite powder is formed to obtain a silver tin oxide blank body; 5) the obtained silver tin oxide blank body is placed at the condition with the oxygen partial pressure higher than or equal to 0.8 Mpa, and the temperature of 900-960 DEG Cto be sintered to obtain the silver tin oxide ingot blank; and 6) the obtained silver tin oxide ingot blank is subjected to hot extrusion to obtain a silver tin oxide wire rod or a silver tin oxide strip material. The silver tin oxide contact material prepared by the method is uniform in structure and good in processing performance.

Owner:桂林金格电工电子材料科技有限公司

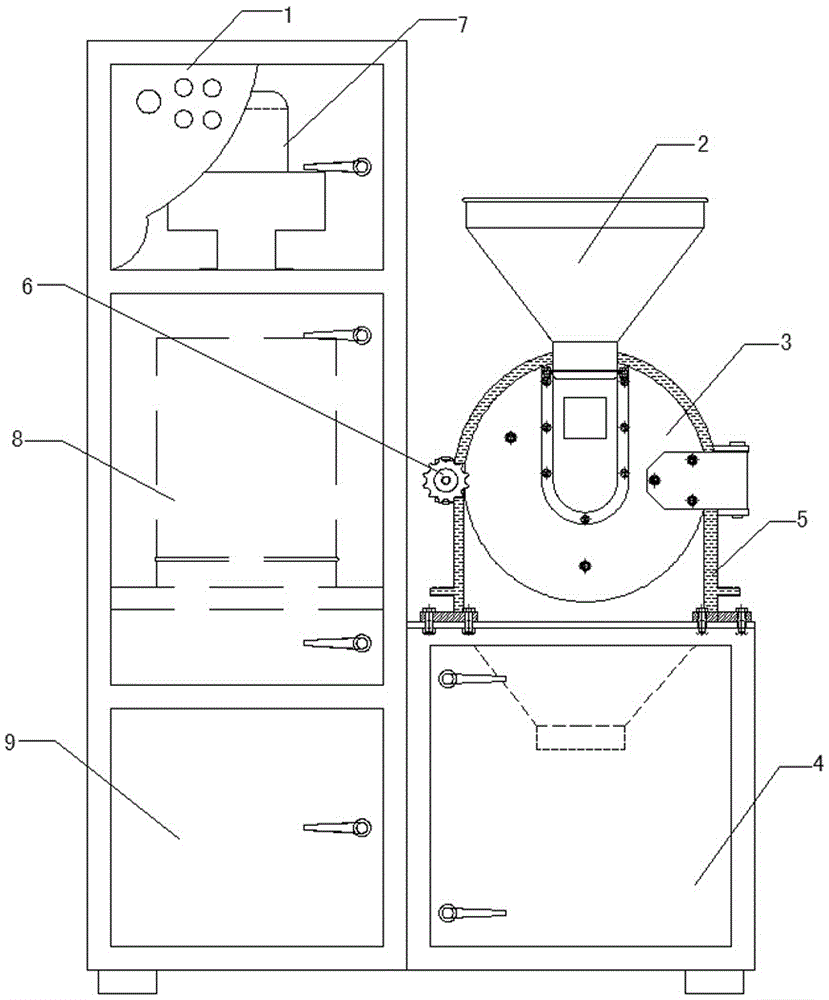

An external water cooling pulverizer

The invention discloses a water-cooled pulverizer, which includes a motor room, a casing, and a material collection box arranged at the bottom outlet of the casing, and the casing includes an upper hopper, a lower hopper, a crushing cavity, and a movable toothed disc. , and a fixed toothed plate connected to the casing through a hinge, a number of impellers are welded on the movable toothed plate and the fixed toothed plate, the size of the movable toothed plate coincides with the size of the fixed toothed plate, and It includes a cooling water channel arranged between the pulverizer casing and the pulverizing chamber. The pulverizer has a simple structure, firmness, stable operation, good crushing effect, and no dust pollution. It solves the melting phenomenon of heat-sensitive materials during the crushing process, improves the utilization rate of materials, and reduces production costs. The material can be directly discharged from the mill cavity of the main machine, and the particle size can be obtained by replacing the mesh screen with different apertures. Ensure material cleanliness.

Owner:NANJING YAOTIAN DRYING EQUIP

Green organic fertilizer fermentation process

PendingCN113716987ALow costLarge capacityBio-organic fraction processingAnimal corpse fertilisersAgricultural engineeringHumin

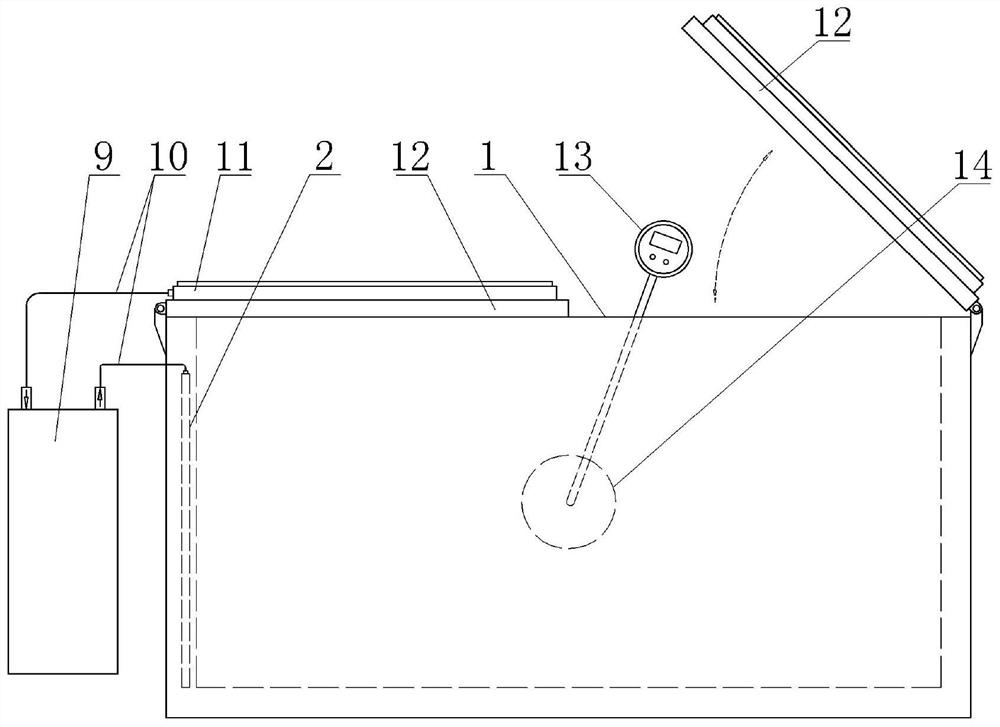

The invention provides a green organic fertilizer fermentation process which comprises the steps of pool building, material preparation, feeding and fermentation, an electric heating plate embedded in a fermentation pool is used for heating, a specified material is selected for fermentation, the initial heating speed of a green organic fertilizer in the pool can be remarkably increased, and then the fermentation speed is increased; the groove and the ventilation pipe at the bottom of the tank can provide a good environment for gas circulation in the fermentation tank and promote fermentation, ventilation in the fermentation tank can enable temperature airflow in the fermentation tank to circulate inside and outside, decomposition is fast, humus formation is facilitated, and thus fermentation time can be shortened. The problem that industrial production of the green organic fertilizer is difficult is solved; the obtained green organic fertilizer is high in quality and long-acting, can replace the existing efficient chemical fertilizer, can improve the soil quality, and is harmless to a human body.

Owner:陈成华

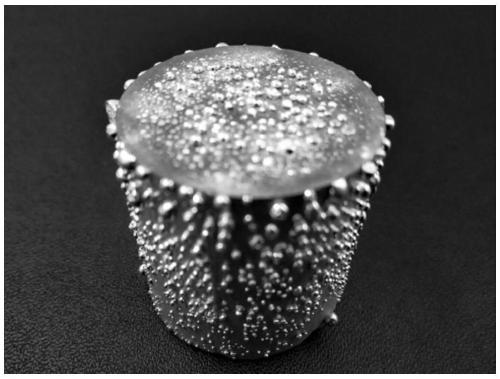

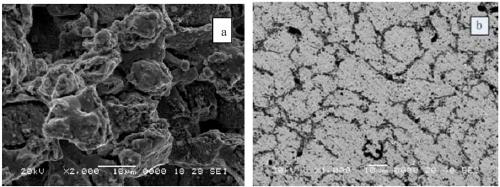

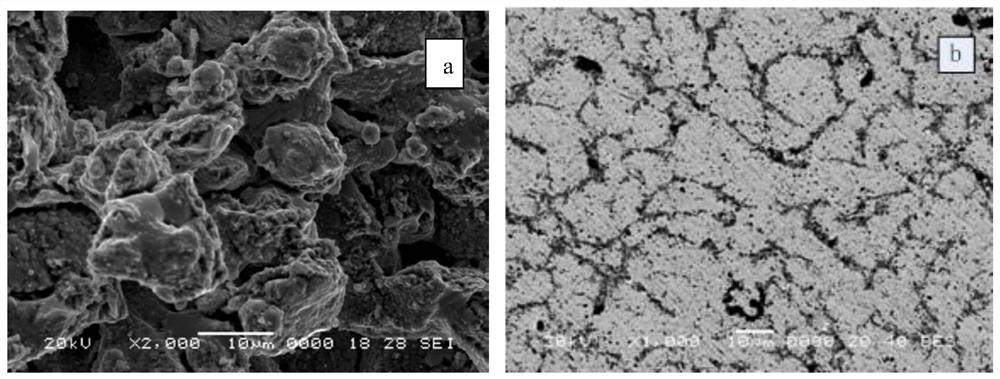

A kind of preparation method of titanium powder or titanium alloy powder special for porous titanium film

ActiveCN109226775BNo melting phenomenonAvoid incomplete hydrogenationTransportation and packagingMetal-working apparatusHydrogenation reactionTitanium alloy

The invention discloses a preparation method of titanium powder or titanium alloy powder special for porous titanium film. The method comprises: 1. placing the pressed titanium block or titanium alloy block in a furnace; 2. vacuumizing the furnace and keeping it warm ; 3. Fill hydrogen into the furnace to carry out self-propagating hydrogenation reaction; 4. Titanium block or titanium alloy block absorb hydrogen and saturate to obtain titanium hydride block or titanium hydride block; 5. Crushing and sieving; 6. Coarse powder crushing; 7. Titanium powder or titanium alloy dehydrogenation powder obtained by heat preservation and dehydrogenation; 8. Titanium powder and titanium alloy powder obtained by crushing, sieving, magnetic separation and flotation. The present invention utilizes the heat released by the hydrogenation reaction to meet the heat energy supply required for the continuation of the hydrogenation reaction to carry out a self-propagating hydrogenation reaction, reducing the increase in heat generated by the reaction, avoiding incomplete hydrogenation of the titanium block or titanium alloy block, and improving the efficiency of the titanium block or titanium alloy block. The degree of hydrogenation embrittlement of titanium alloy block can finally obtain finer and uniform titanium powder or titanium alloy powder, which improves the quality of titanium powder or titanium alloy powder.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

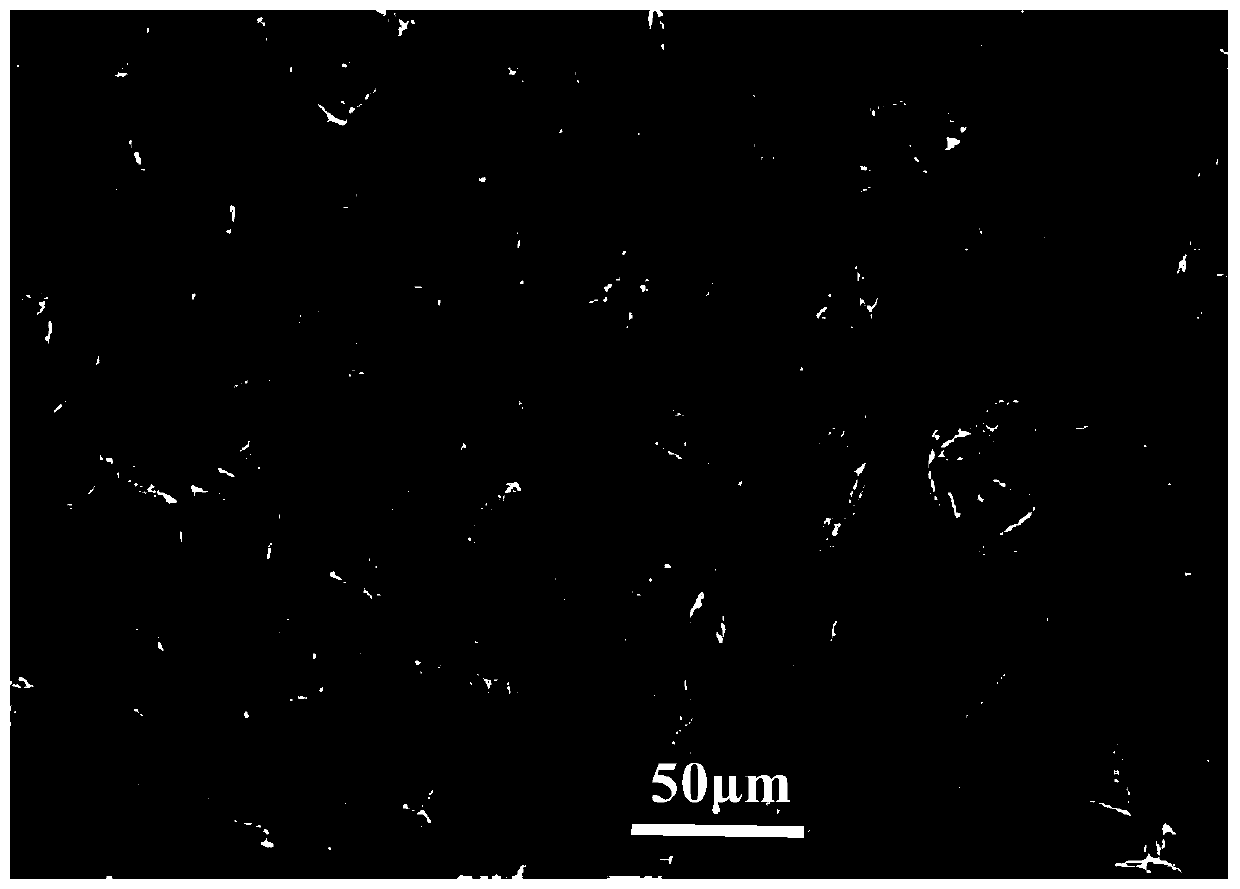

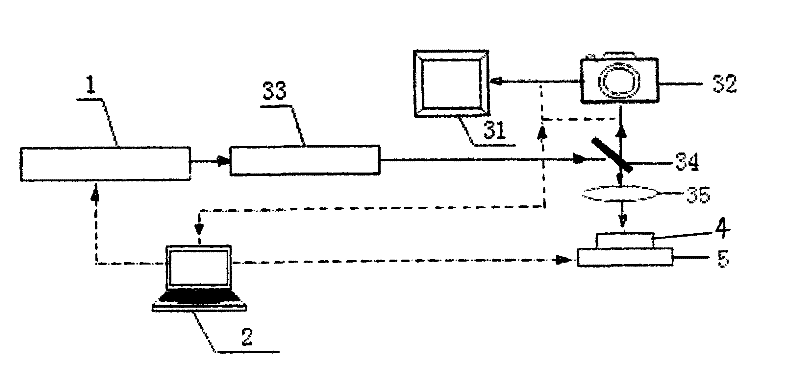

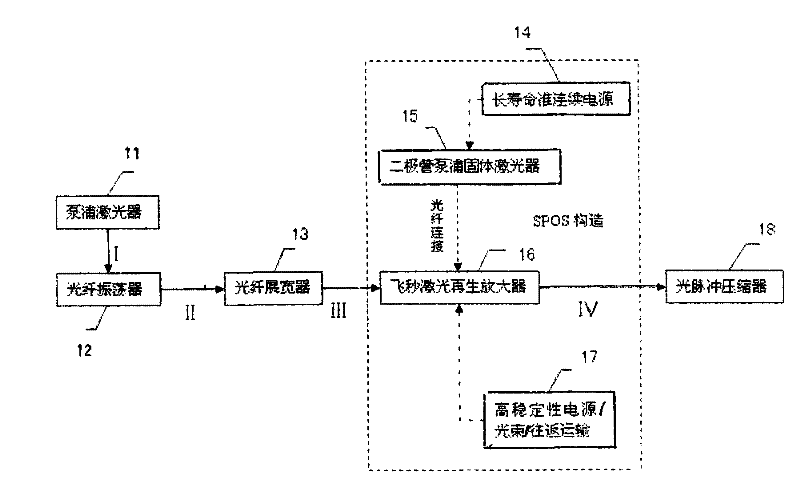

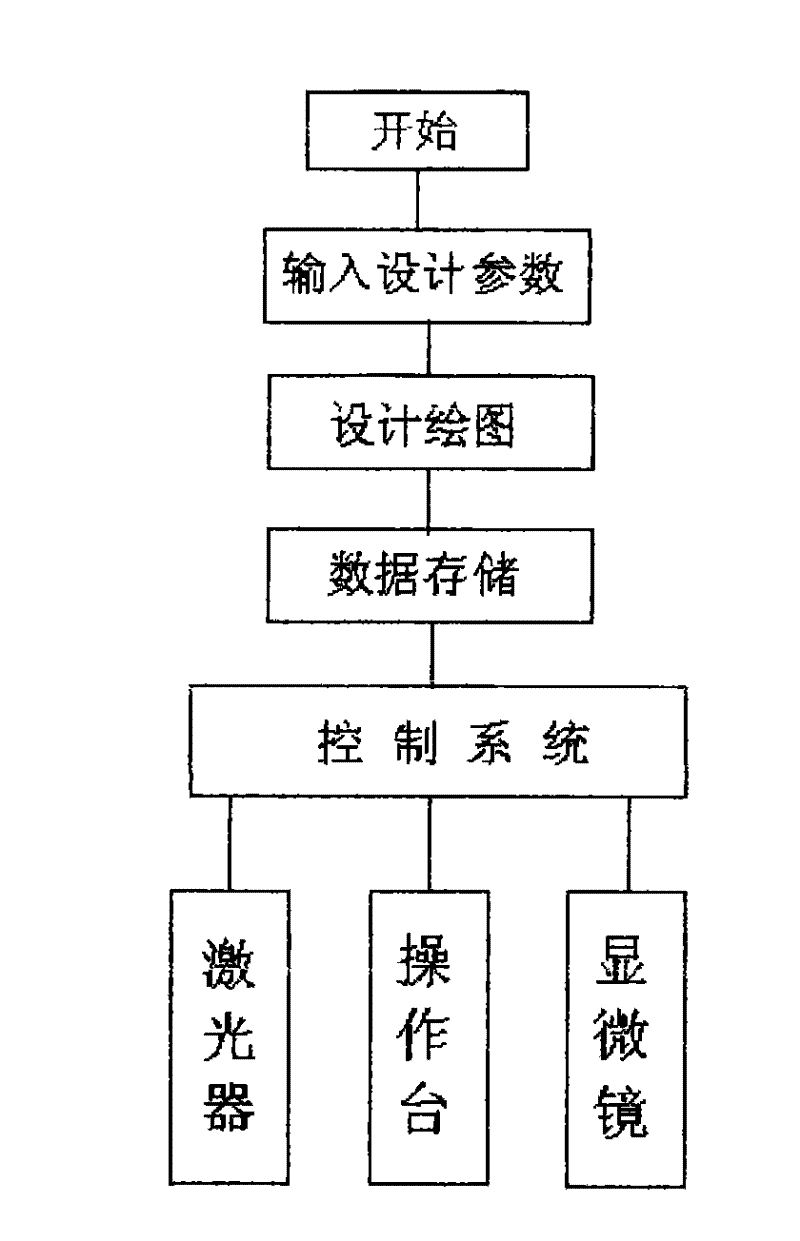

Micro-fine processing system of femtosecond laser for material surface modification

InactiveCN101480757BImprove machining accuracyImprove accuracyLaser beam welding apparatusHeat-affected zoneFemto second laser

The invention discloses a micro-fine processing system for the surface modification of materials using femto-second laser, comprising a femto-second laser, a micro-light path system, a high-precision three-dimensional working platform and a control system host machine, wherein the femto-second laser acquires an emitted laser beam to focus and irradiate onto processed components on the three-dimensional working platform through the micro-light path system; the micro-light path system comprises a microscope for the observation of processing, a light batch system with a CCD monitor imaging unit,and the three-dimensional working platform is connected with the control system host machine in a control way. The micro-fine processing system uses the femto-second laser as a processing light source to precisely process the surface modification of material through the characteristics of unique ultra-short duration and ultra-strong peak power of the femto-second laser, the cooperation of the optical system and the high-precision three-dimensional working platform and the control of a software program in order to achieve the ultra-precise processing in the sub-micron level for no presence of heat affected zone during the processing and to provide a useful tool for automobile industry, semiconductor, communication industry, and the like needing the high-precision processing.

Owner:陕西午禾科技有限责任公司

Thermal insulating and fireproof board for external wall

ActiveCN102321336BImprove fire and flame retardant performanceImprove insulation effectExternal wall insulationSODIUM DODECYL BENZENE SULFONATE

The invention relates to a thermal insulating and fireproof board for an external wall. The board is prepared by mixing a boron modified phenolic resin composite material with a refractory aggregate, butyronitrile or butylbenzene, inorganic acid or organic acid, a mixture of silicone and sodium dodecyl benzene sulfonate, and a carbon dioxide gas and then curing the materials. With good fireproof and flame resistant performances as well as good thermal insulation property, the thermal insulating and fireproof board for an external wall in the invention also has high strength, and its combustion performance can reach the national A1 grade standard.

Owner:CHONGQING YUWANTONG NEW MATERIAL TECH

Atmosphere non-melting method assisted by thermal crosslinking of nitride fibers

ActiveCN110952170BIncrease the degree of cross-linkingImprove non-melting effectInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberNitrogen gas

The invention discloses an atmosphere non-melting method assisted by thermal crosslinking of nitride fibers. The non-melting method comprises (1) placing a nitride fibril sample in a non-melting atmosphere furnace, vacuumizing and replacing it with nitrogen; (2) Under the nitrogen atmosphere, the temperature in the non-melting atmosphere furnace is raised from room temperature to 40-60°C, and then the active gas is introduced, and the flow ratio of the active gas to the nitrogen gas is (2:1)-(1:10 ); (3) continue to raise the temperature in the non-melting atmosphere furnace from 40 to 60°C to 100 to 150°C, and keep it at 100 to 150°C for 0.5 to 3 hours, then stop feeding the active gas; (4) continue to The temperature in the non-melting atmosphere furnace is raised from 100-150°C to 300-400°C, and kept at 300-400°C for 0.5-2h, then the heating is stopped and cooled to obtain the non-melting fibers. Compared with the single atmosphere non-melting cross-linking or thermal cross-linking method, the non-melting fiber obtained by the method provided by the invention is more uniform, and the degree of cross-linking reaction is higher; compared with the process control, the production cost is lower.

Owner:NAT UNIV OF DEFENSE TECH

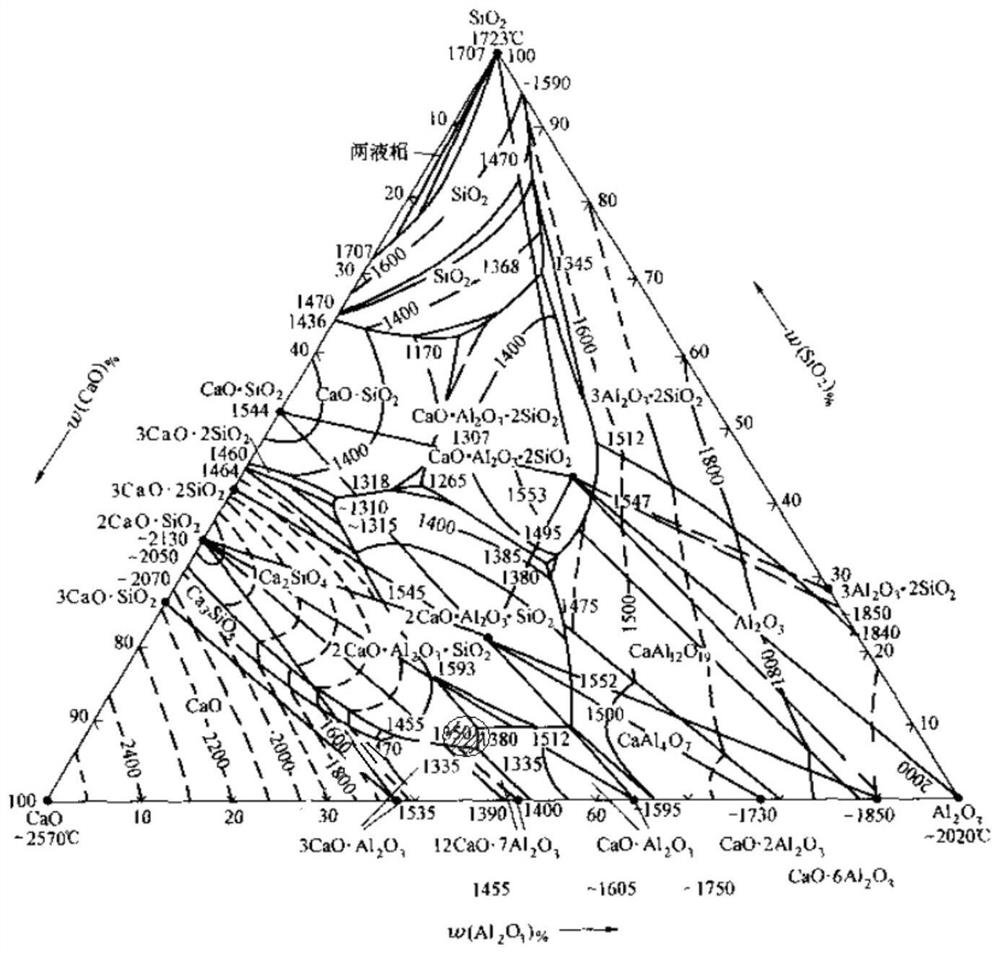

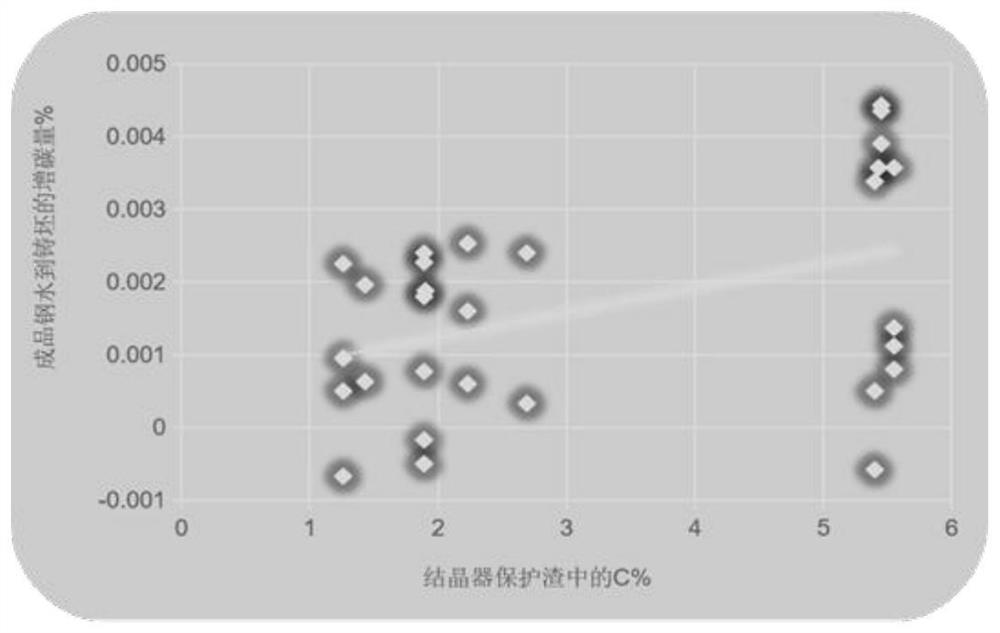

Free carbon-free casting powder for ultra-low carbon steel automobile sheet

The invention relates to free carbon-free casting powder for an ultra-low carbon steel automobile sheet. The casting powder comprises calcium, magnesium, strontium, barium, titanium, zirconium, chromium, manganese, aluminum, silicon, mixed or single rare earth oxide and CaF2, and the melting temperature of the obtained composite oxide or mixture is 1240-1300 DEG C. The slagging reaction temperature between the materials of the free carbon-free casting powder is high, so that the melting speed of the casting powder is controlled. In the melting process of the free carbon-free casting powder, the melt separation phenomenon is avoided, and the surface quality of a casting blank is good. The solubility of molten slag of the free carbon-free casting powder in water is low, and the environmental pollution is small. The free carbon-free casting powder uses little or no framework materials such as carbonaceous materials, so that the cost is reduced, and recarburization of molten steel is prevented. The free carbon-free casting powder does not contain Na2O, and can prevent the generation of'white spots' of a tin-plated steel plate. The free carbon-free casting powder can be applied to all types of steel, so that all the casting powder is changed from black to white, and the damage of carbon black to human health is prevented.

Owner:武汉钢铁有限公司

Fireproof door core and preparation method thereof

InactiveCN108409274ARapid hardening early strengthImprove stabilitySolid waste managementCeramicwareMaterials scienceClosed cell

The invention discloses a fireproof door core, comprising, by weight, 10 parts of closed-cell expanded perlite, 15 parts of gypsum, 20 parts of cement, 7 parts of coated nano flyash, 5 parts of silicafume, 5 parts of magnesium sulfate, 4 parts of floating beads, 5 parts of calcined kaolin, 2 parts of sodium methyl silicate, 3 parts of calcium stearate, 1 part of a foaming agent, 2 parts of glassfiber, and 1 part of polypropylene fiber. The fireproof door core has good fireproof performance, is harmless to human bodies and environment, and has good toughness and stability.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com