Quick-response tungsten-rhenium thermocouple welding device

A welding device and fast-response technology, applied in welding equipment, arc welding equipment, welding rod characteristics, etc., can solve the problems of uncontrollable coupling quality and low coupling rate, and achieve the effects of saving manpower, simple composition, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

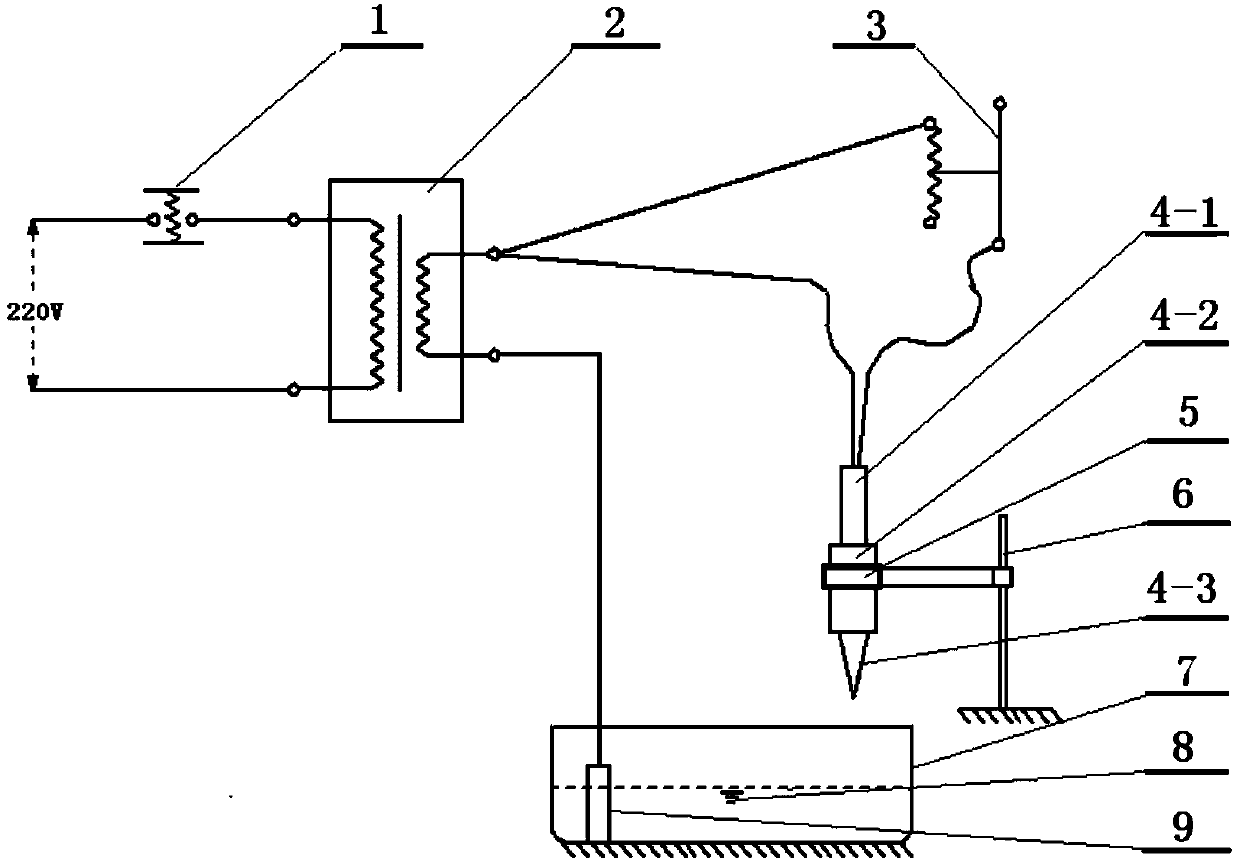

[0021] Such as figure 1 As shown, according to the technical solution of the present invention, this embodiment provides a specific composition of a fast-response tungsten-rhenium thermocouple welding device, including a control switch 1, a transformer 2, a rheostat 3, a thermocouple 4, a support 5, and a clamp 6 , glass vessel 7, conductor 8, electrode plate 9, wherein:

[0022] The control switch 1 is a contact switch. After pressing, the power supply is connected to the thermocouple discharge circuit and then disconnected instantaneously. One terminal is connected to the input terminal of the adjustable transformer 2 through a wire, and the other terminal is connected to the 220V power supply. .

[0023] The transformer 2 outputs the voltage required by the thermocouple welding circuit, and the voltage can be adjusted. One output end is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com