Lost foam casting wax pattern repairing method

A technology of lost foam casting and repair method, applied in casting and molding equipment and other directions, can solve problems such as fixed-point repair of cylindrical wax mold, increase wax mold repair work steps, reduce wax mold repair efficiency, etc., to avoid increase and decrease. Work steps, avoid the effects of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

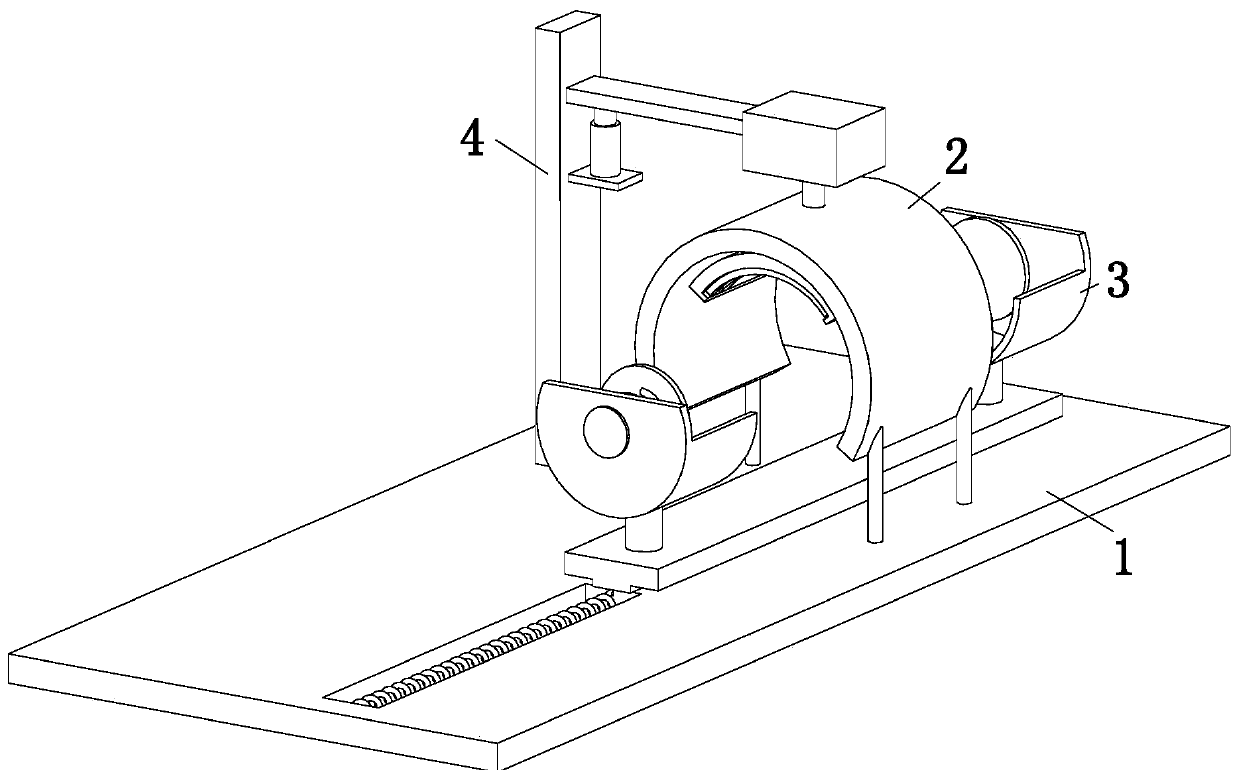

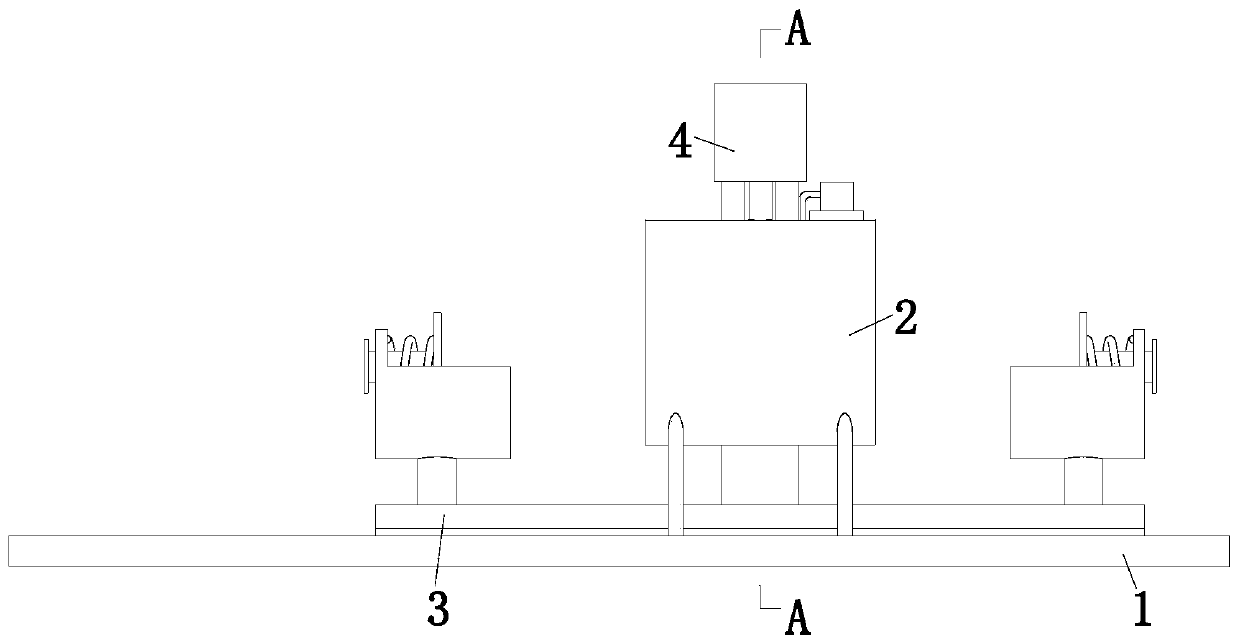

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

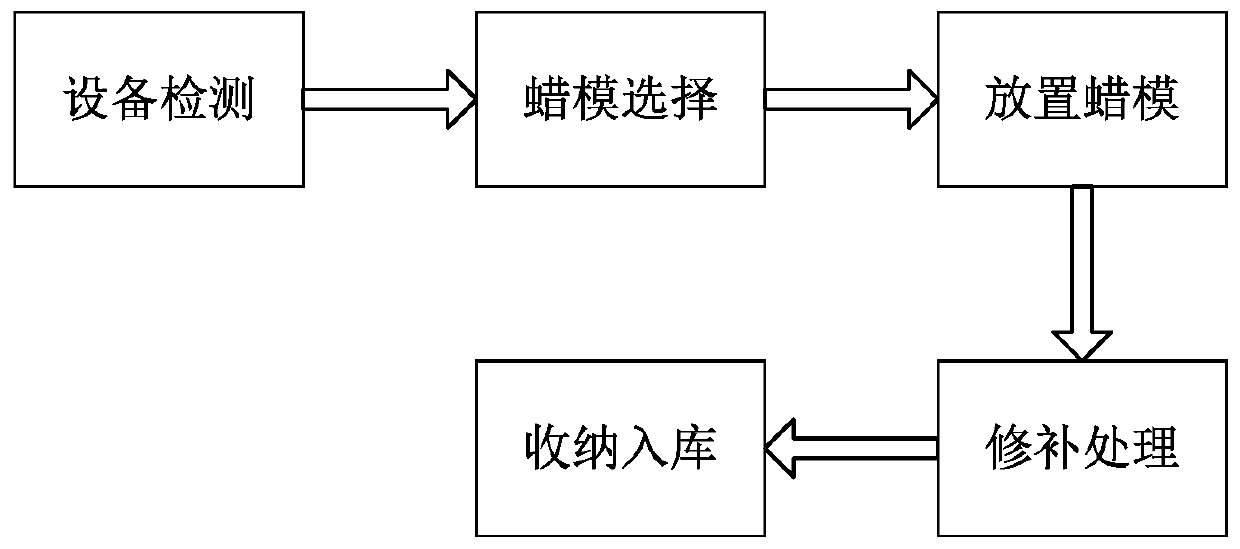

[0034] like Figure 1 to Figure 7 As shown, in order to achieve the above object, the present invention adopts the following technical scheme, a method for repairing a lost foam casting wax pattern, which uses a lost foam casting wax pattern repairing equipment, the lost foam casting wax pattern repairing equipment includes a base plate 1, The ring frame 2, the holding device 3 and the repairing device 4, when using the above lost foam casting wax model repairing equipment to repair the lost foam casting wax model, the specific method is as follows:

[0035] S1. Equipment inspection: Before the equipment is used, the equipment is routinely inspected manually;

[0036] S2. Wax model selection: manually select defective wax models and remove dust or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com