Free carbon-free casting powder for ultra-low carbon steel automobile sheet

A technology for ultra-low carbon steel and mold flux, which is applied in the field of mold flux for continuous casting in iron and steel smelting, can solve the problems of increasing cost, affecting the spreading performance of mold flux, prolonging RH time, etc. Good quality, white spot prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] industrial test

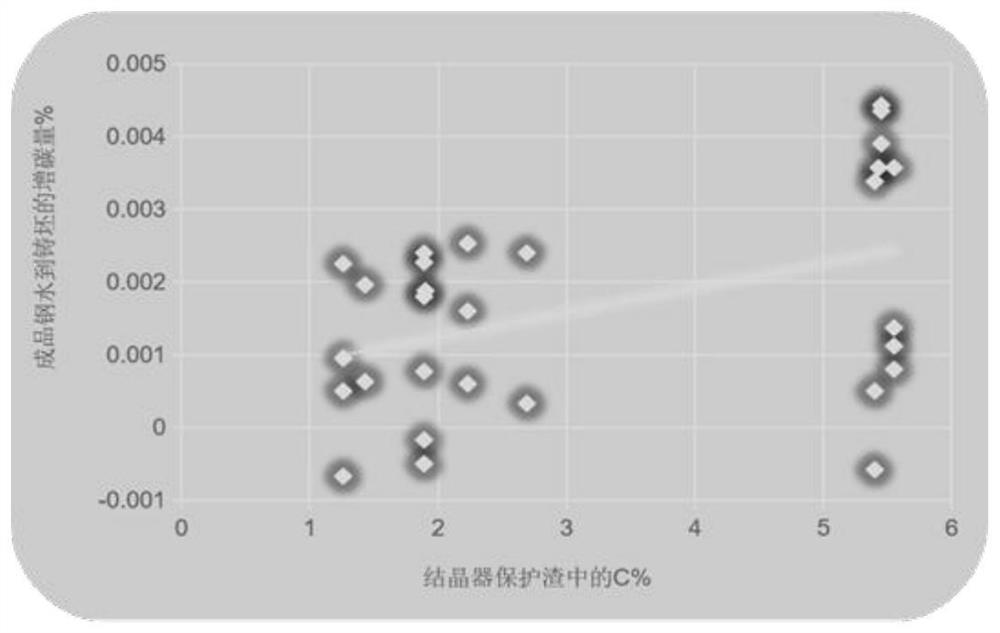

[0055] In Wuhan Iron and Steel No. 3 steelmaking track B1B1-2 / B1A1-2Z test 5 furnaces, a total of 9 steel samples were taken from the two furnaces, and the carbon content was verified by infrared testing. The data analysis showed the C content in the mold mold slag and the finished molten steel to the casting slab The relationship between carbon addition is as figure 2 , the test shows that the carburization of finished steel and the carbon content in powder slag have a linear growth relationship, so controlling the carbon content in powder slag is helpful to control the carbon content in finished steel.

[0056] The industrial tests of 6 furnaces were carried out in Baosteel Steelmaking Plant for 3 times. The chemical composition and main physical properties of the 2 kinds of test slags are shown in Table 1. Steel type: high-oxygen aluminum-coated steel, the composition is shown in Table 2, C: 20ppm; mold slag in the mold: no sintering, no slag stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com