Manufacturing method of solar battery packaging glass and kiln furnace used for manufacture

A solar cell and encapsulation glass technology, applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of inability to produce glass with special functions, etc., and achieve long service life, high smoothness, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

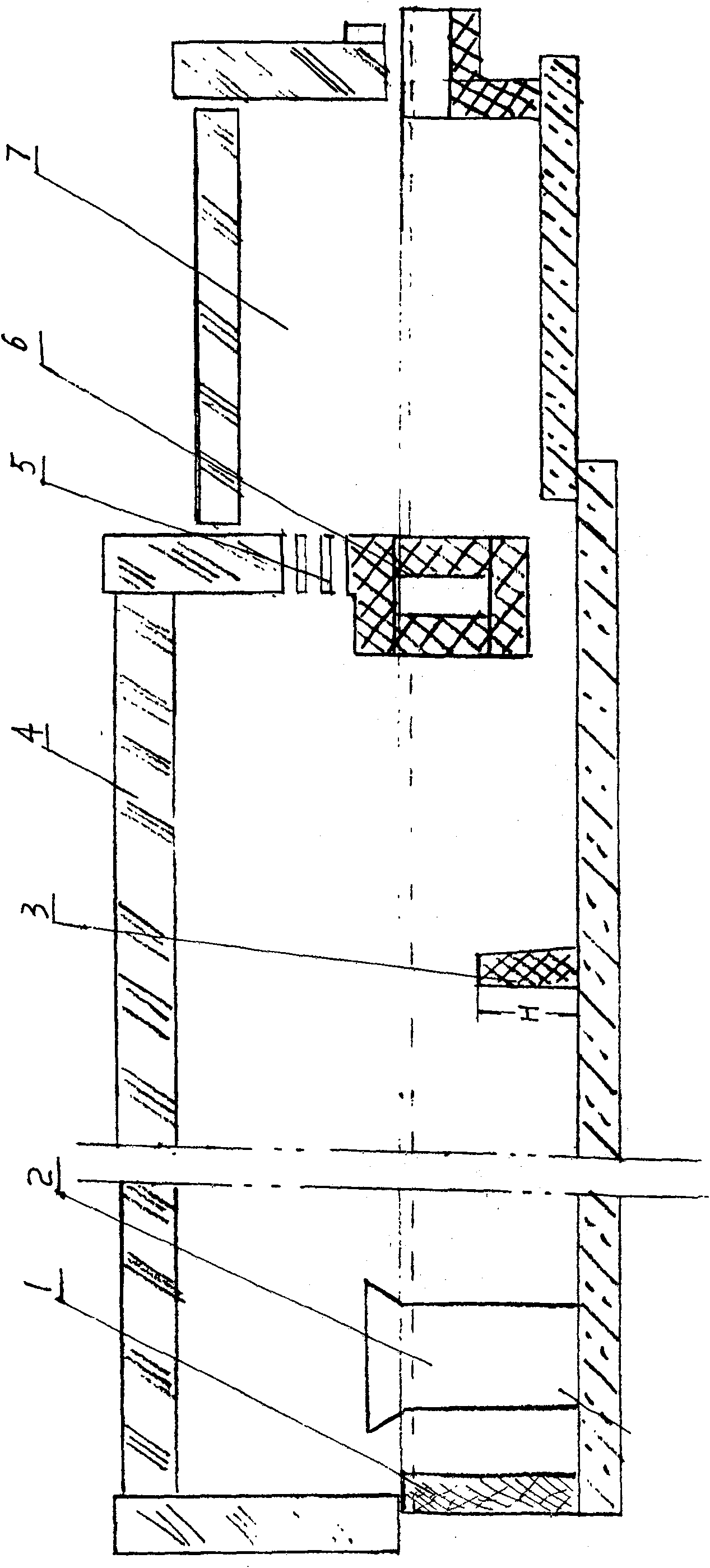

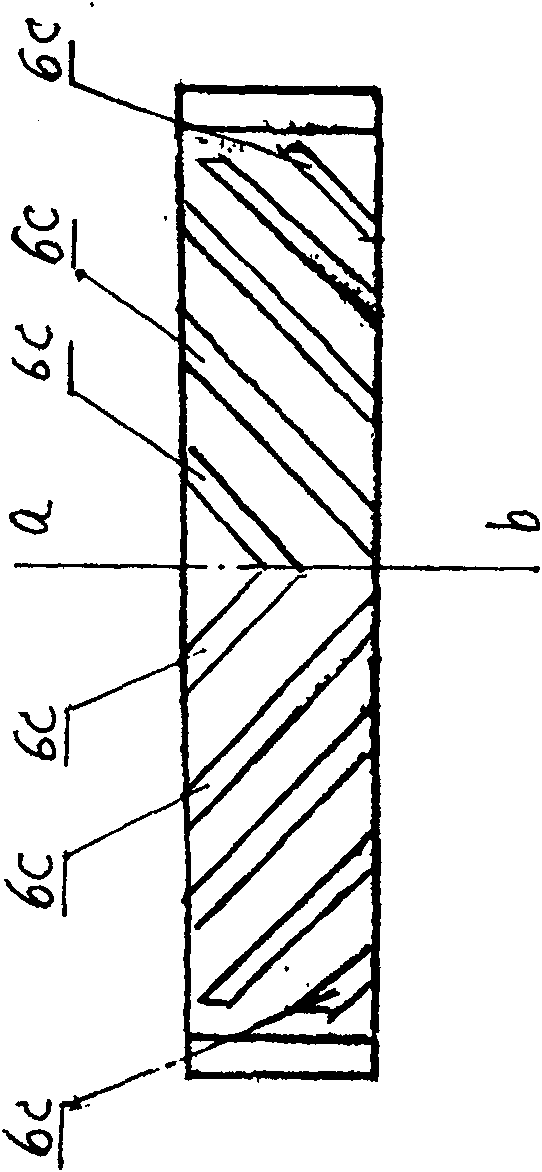

Image

Examples

Embodiment 1

[0012] Embodiment 1: The solar cell encapsulation glass produced is as follows, a, selecting raw materials: selecting quartz sand, soda ash, calcite, potassium carbonate, alumina, mirabilite, magnesia and broken glass as raw materials; The iron content of the raw materials such as potassium carbonate, alumina, mirabilite and magnesium oxide is tested, and the content of iron in each raw material can be used within the range of 0-0.0001% of its weight; the selected broken glass should be colorless;

[0013] b. Processing of the selected raw materials: The selected quartz sand raw materials are washed with an acidic solution made of sulfuric acid and water, and iron is removed. The washed quartz sand should be tested. When the iron content in the quartz sand is 0-25ppm, it can be used; the broken glass should be cleaned;

[0014] c. According to the glass components produced, calculate the weight of various raw materials required, and weigh various raw materials that have been p...

Embodiment 2

[0020] Embodiment 2: the production method in the present embodiment and the steps are the same as those of the embodiment 1, but in step b, add the acid liquid made of water with nitric acid to wash the selected quartz sand raw material, except the iron in it;

[0021] In step c, when weighing and mixing the raw materials, use a stainless steel container to hold them, and use stainless steel tools to mix and transport them; when the raw materials are added to the kiln for melting, the hot spot temperature in the kiln is 1540-1555 ℃, and the temperature of the cooling part is 1165- 1190℃, the fluctuation range of glass liquid level in the furnace is 0-0.5mm;

[0022] The temperature at the outlet of the molten glass in the furnace is 1090-1120°C. Other steps and requirements are the same as in Example 1.

[0023] In this embodiment, the height H of the kiln sill is 720 mm, and other structures are the same as those in Embodiment 1.

Embodiment 3

[0024] Example 3 Production method and steps in the present embodiment are similar to those in Example 1, but in step b, the selected quartz sand raw material is washed with the acid solution that hydrochloric acid adds water to make, and the iron in it is removed;

[0025] In step c, when weighing and mixing raw materials, use stainless steel or aluminum containers to hold them, and use stainless steel or aluminum tools to mix and transport; The temperature is 1170-1240℃, and the fluctuation range of the glass liquid level in the furnace is 0-0.6mm;

[0026] The temperature at the outlet of the molten glass in the furnace is 1105-1120°C. For the convenience of storage and product transportation, the annealed glass products should also be cut, packaged or boxed.

[0027] Other steps and technical requirements are the same as in Example 1.

[0028] In this embodiment, the height H of the kiln sill is 740 mm, and other structures are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com