Patents

Literature

46results about How to "Up to standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

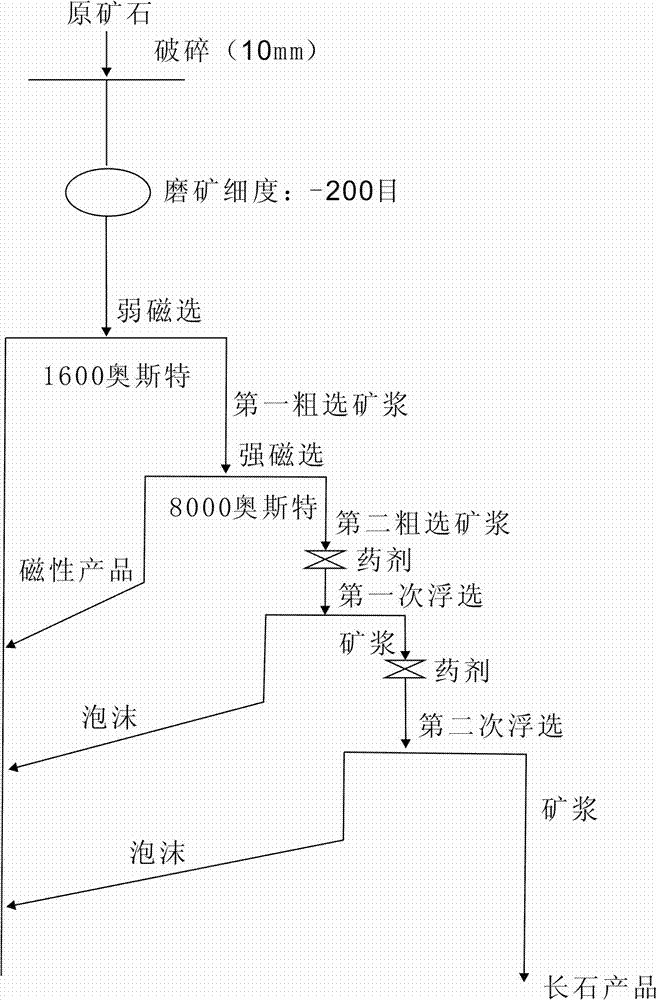

Feldspar quarry beneficiation process

The invention discloses a feldspar quarry beneficiation process which includes conducting breaking and grinding on feldspar quarry raw ore, adopting SLon magnetic separators to conduct strong magnetic separation and weak magnetic separation, then conducting secondary floatation to obtain feldspar concentrate with the content of Fe2O3 smaller than 0.1%. The beneficiation process is characterized in that under the condition that the raw ore is ground to certain fineness, a weak SLon magnetic separator and a strong SLon magnetic separator are sequentially adopted to conduct magnetic separation, then floatation is conducted under the specific process condition to enable the content of iron in the feldspar quarry raw ore to be reduced to below 0.1% to obtain good feldspar quarry and reach the use standard in the glass industry. The process turns waste into wealth, adopts the mode that magnetic separation is conducted first and then floatation is conducted, the content of medicament added later is greatly reduced, the pollution is small, and the cost is lower.

Owner:四川南江新兴矿业有限公司

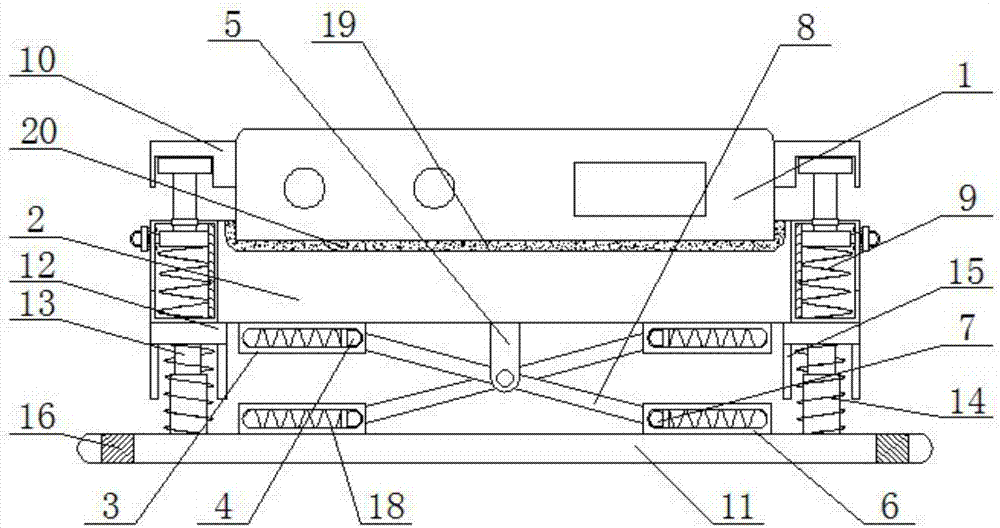

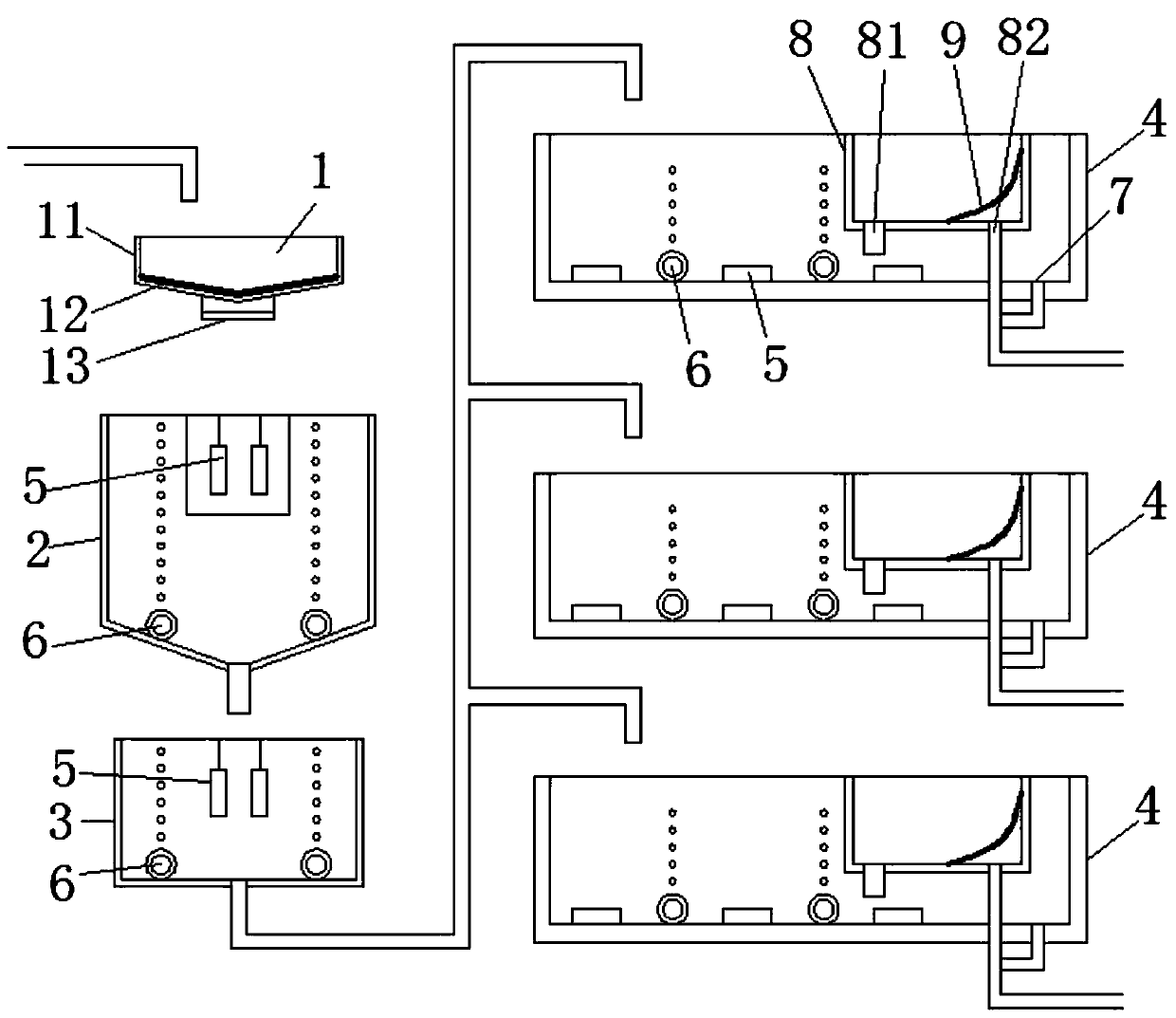

Vehicle-mounted communication equipment

The invention discloses vehicle-mounted communication equipment. The vehicle-mounted communication equipment comprises a shell, wherein a fixed seat is arranged at the bottom of the shell; first sliding frames are arranged on both sides of the bottom of the fixed seat; first slide blocks are arranged inside the first sliding frames; the first slide blocks are matched with the first sliding frames;a rotating block is arranged in the middle of the bottom of the fixed seat; second sliding frames are arranged at the bottoms of the first sliding frames; second slide blocks are arranged inside thesecond sliding frames; and the second slide blocks are matched with the second sliding frames. The invention relates to the technical field of communication. The vehicle-mounted communication equipment has efficient buffering performance; the problem of damage to the communication equipment caused by vibration is solved; the service life of the communication equipment is prolonged; the maintenanceand replacement frequency of the communication equipment is lowered; and the working efficiency of the communication equipment is increased. Meanwhile, the communication equipment is convenient to mount and detach, can be detached and mounted rapidly without carrying any specific tool, and meets the requirement of a user on a usage effect.

Owner:安徽尚易信息技术有限公司

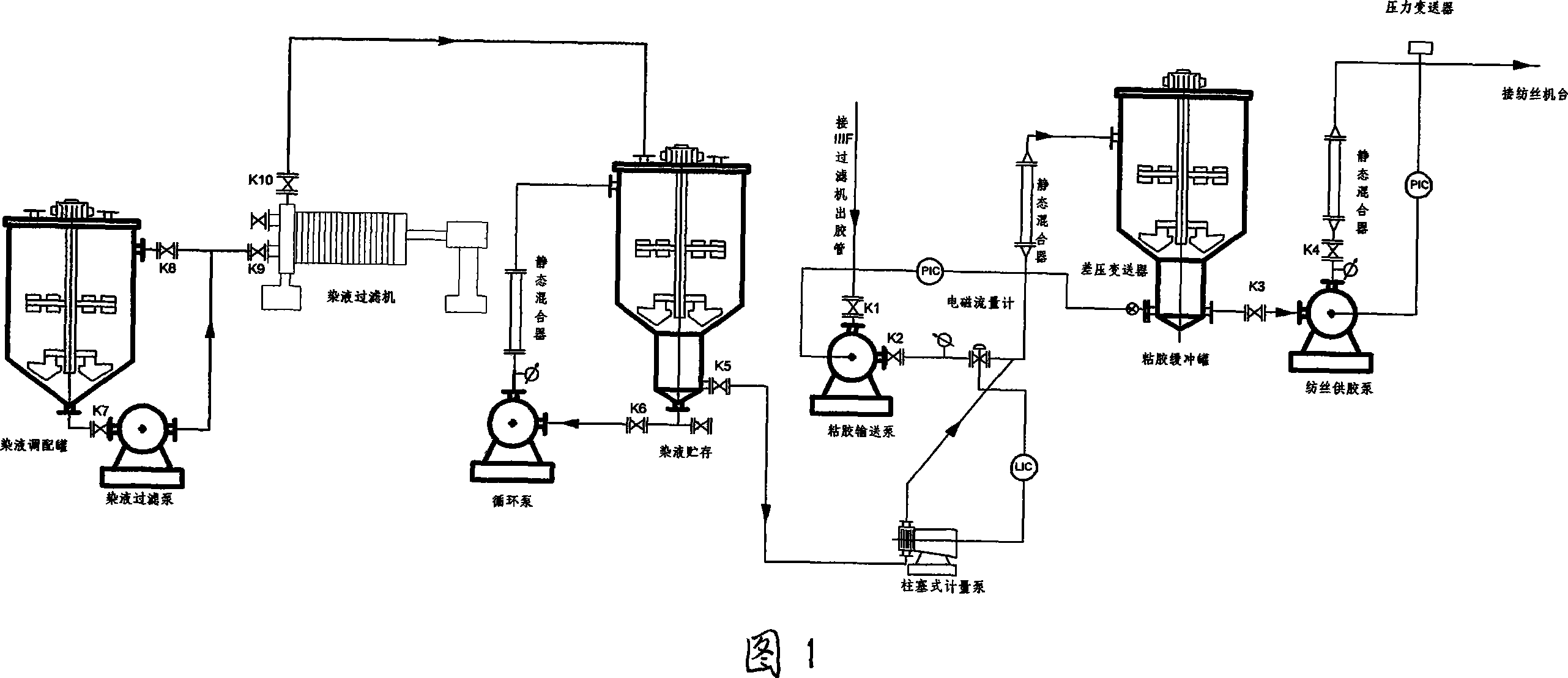

Method for producing spinning dyeing viscose fiber and spinning dyeing viscose fiber thereof

InactiveCN101104961AGuaranteed recovery before spinningGuaranteed spinning oxidation color developmentMonocomponent cellulose artificial filamentYarnYarnOxidizing agent

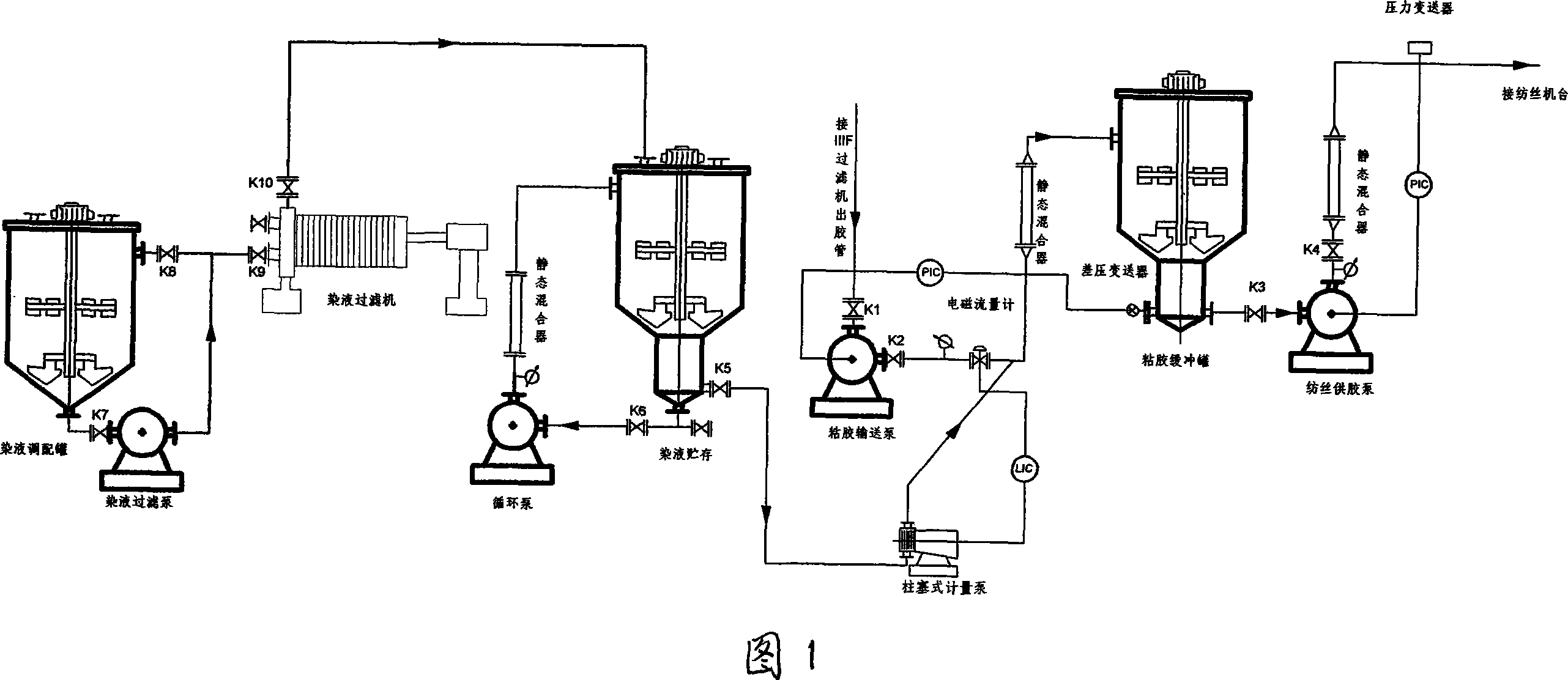

The invention discloses a method of spinning dyed viscose fibers and dyed viscose fibers produced by the method, and overcomes the problems in the prior art of colored viscose fibers. The method comprises adding a reducer and an oxidizer in the dye, mixing the resulting mixture with a viscose glue to obtain colored viscose glue, and spinning. During the processes from formation to refining of reduced spinning threads or after the spinning process is completely, reduced threads are oxidized and stained under an acidic or alkaline condition to form spinning dyed viscose fibers. Based on the research of dyeing mechanism, the invention breaks through the conventional process of pre-spinning dyeing and late finishing, and directly produces colored viscose fibers. The invention realizes the monofilament dyeing and improves the dyeing uniformity, color fastness and color brightness, enriches the color tone, and meets the standard of stitch yarn. Additionally, the invention can greatly reduce the production cost and avoid the contamination of the subsequent processing. The product has beautiful color, uniform dyeing, comfortable feel and wide application range.

Owner:YIBIN HIEST FIBER

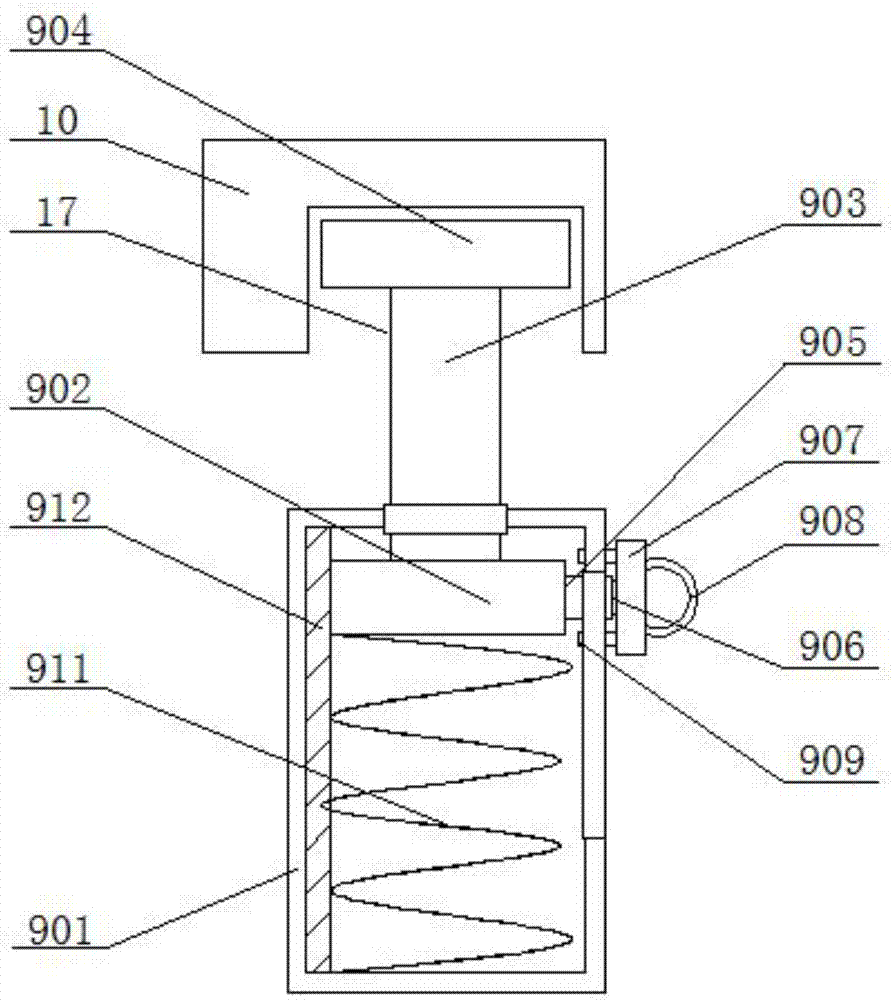

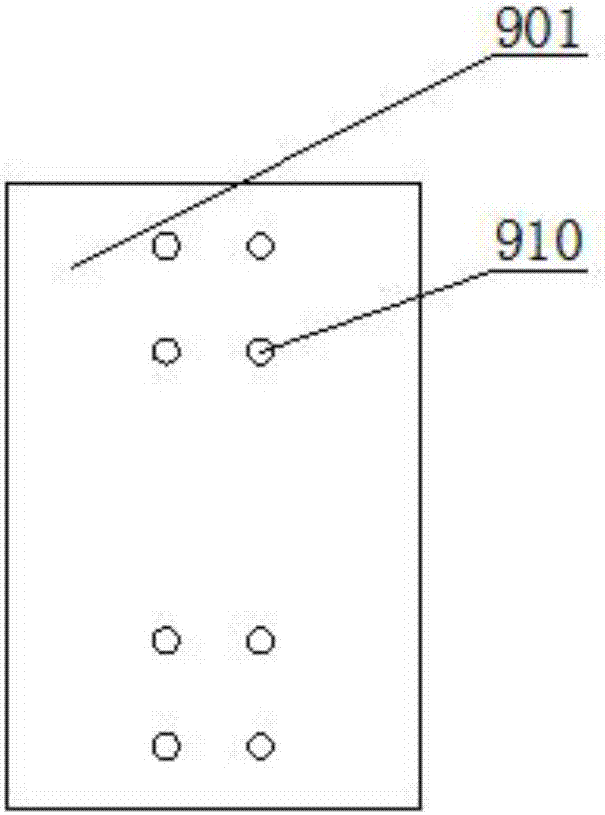

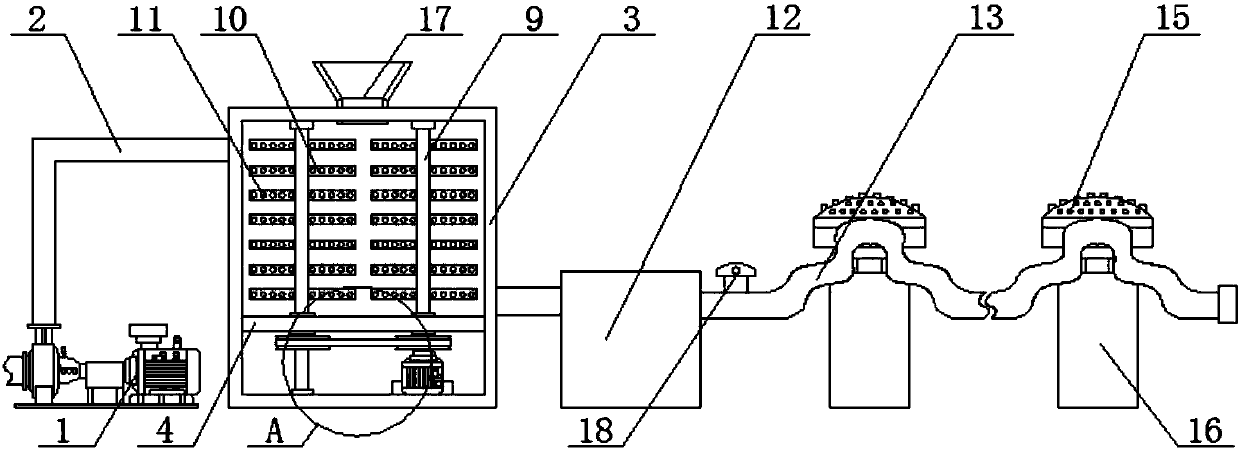

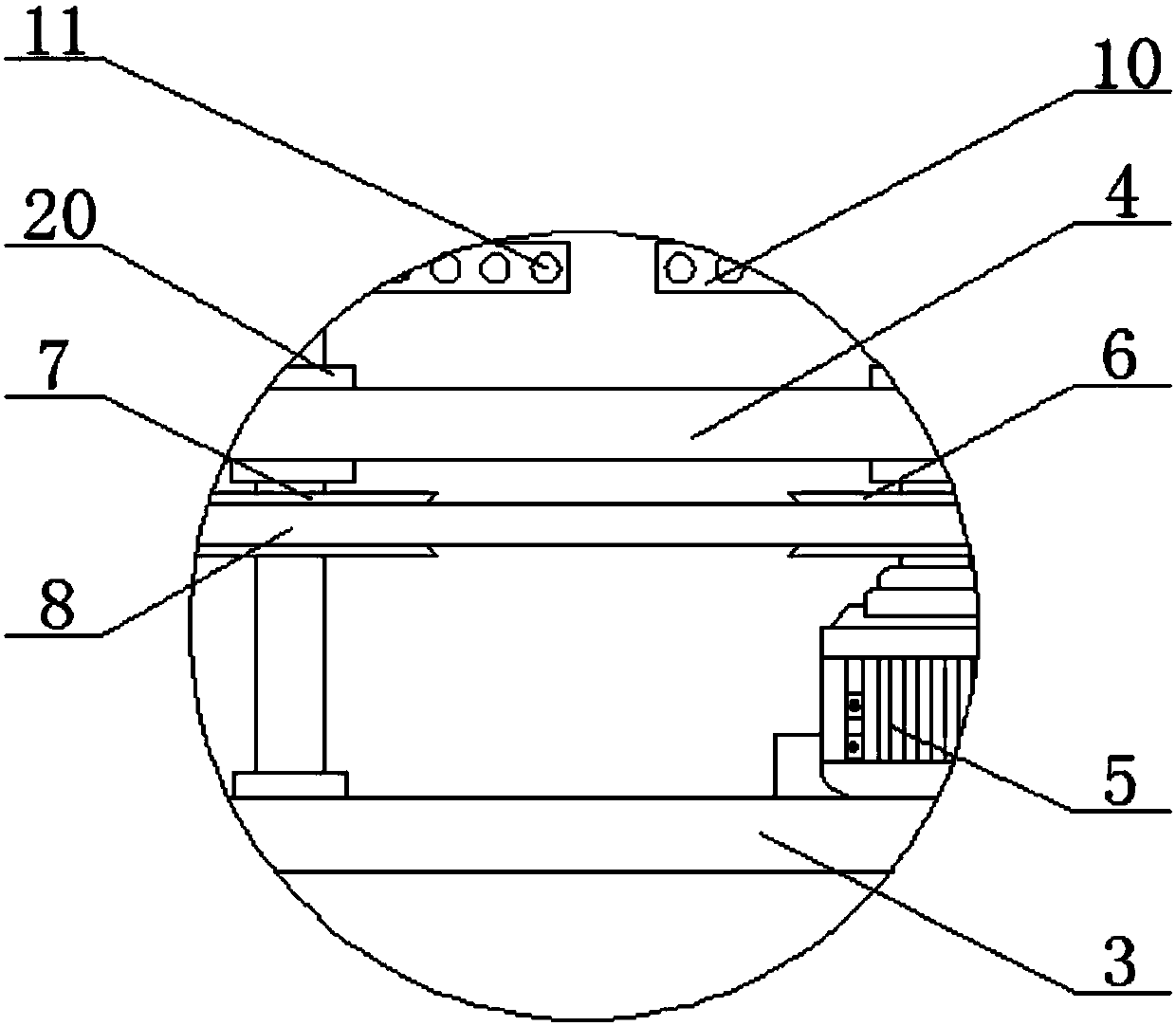

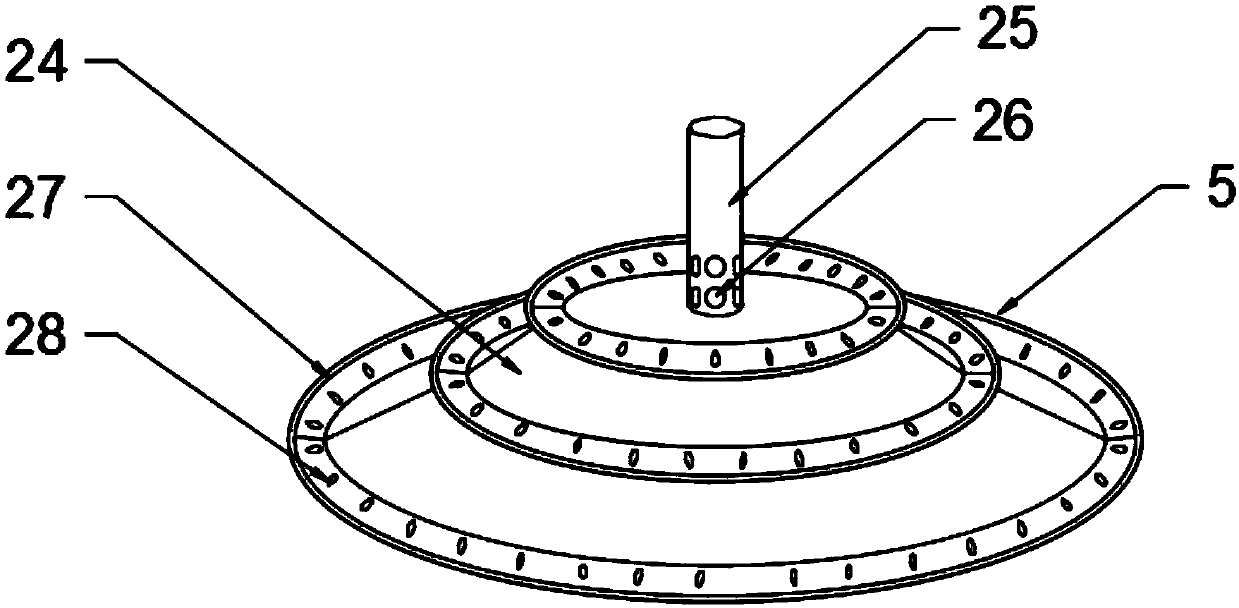

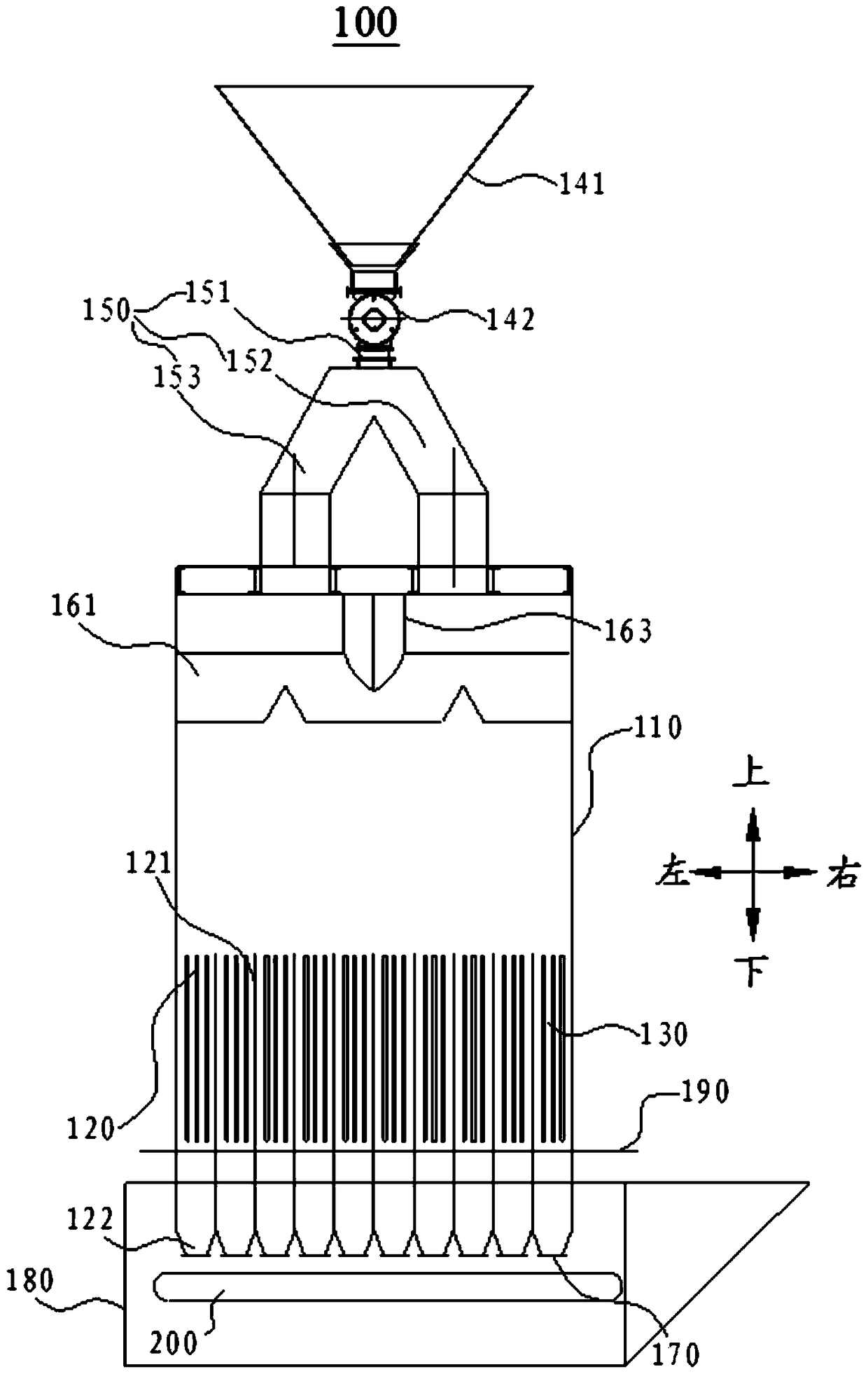

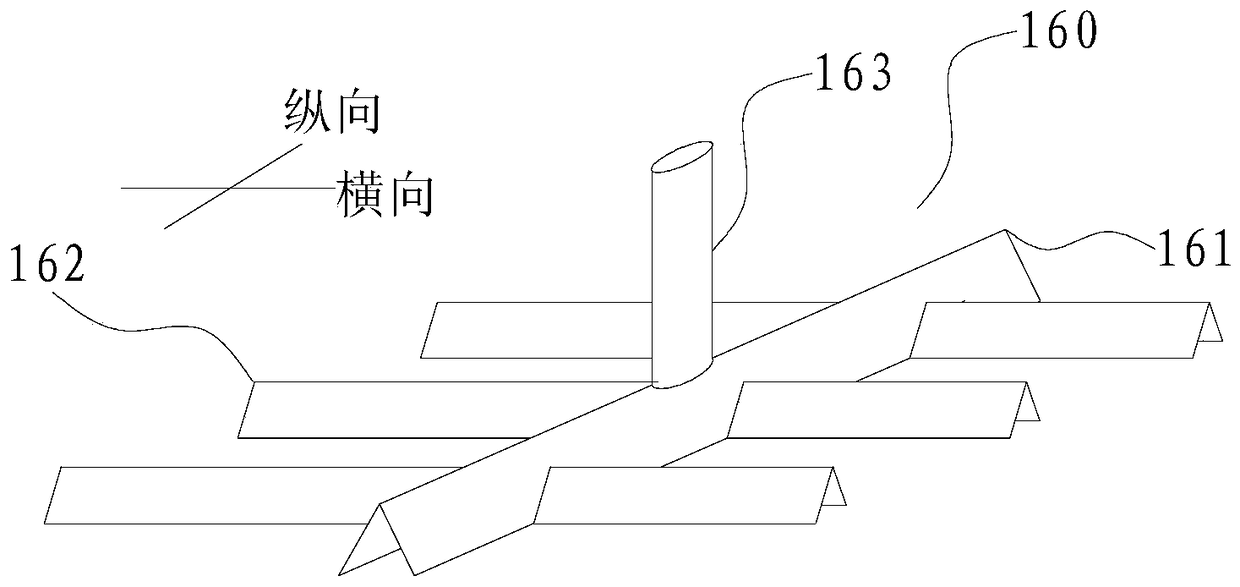

Agricultural planting irrigation device

InactiveCN107926623AExpand the range of water sprayReduce utilizationTransportation and packagingRotary stirring mixersAgricultural engineeringMaterial resources

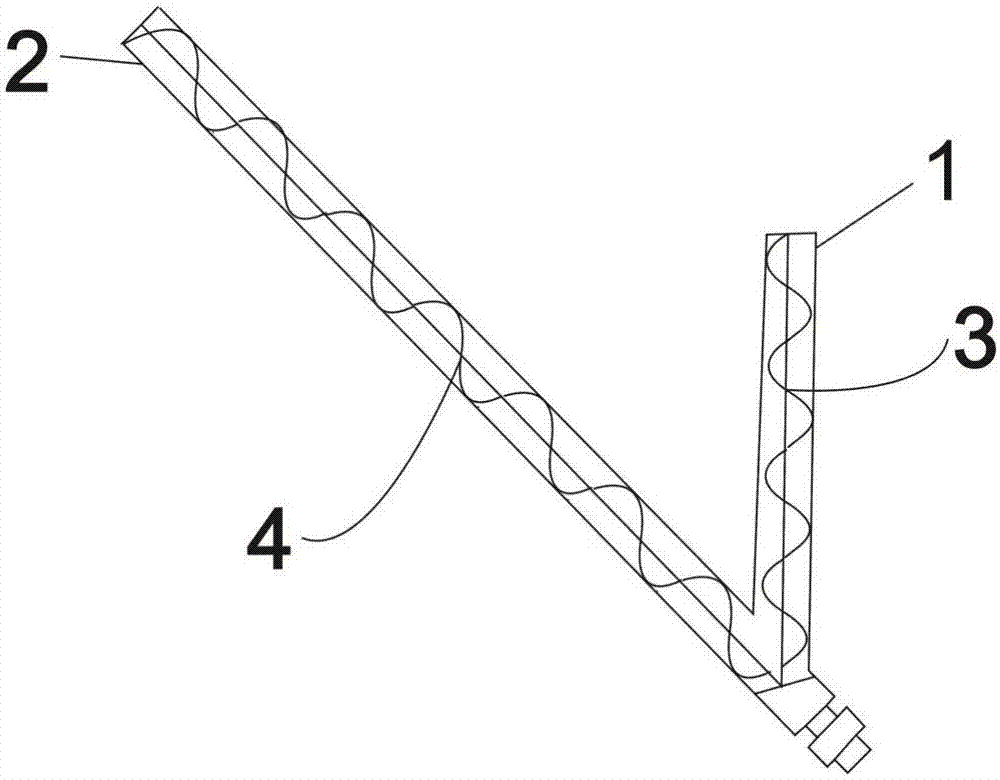

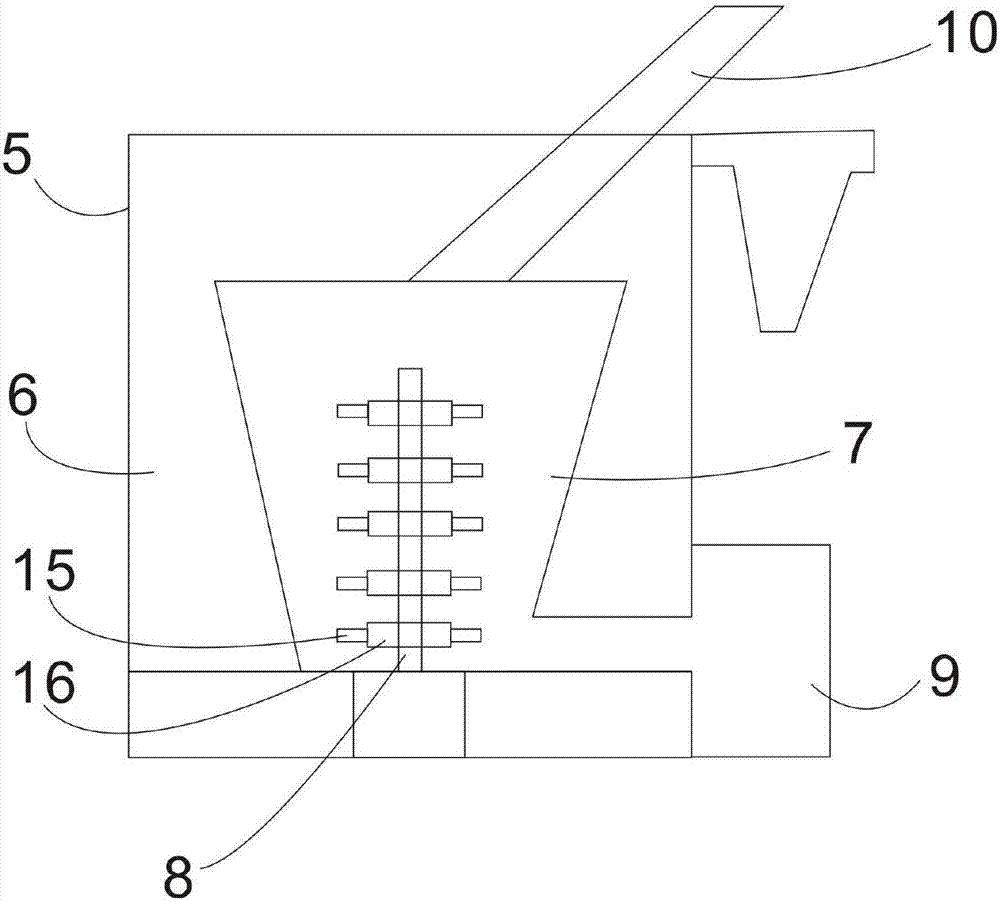

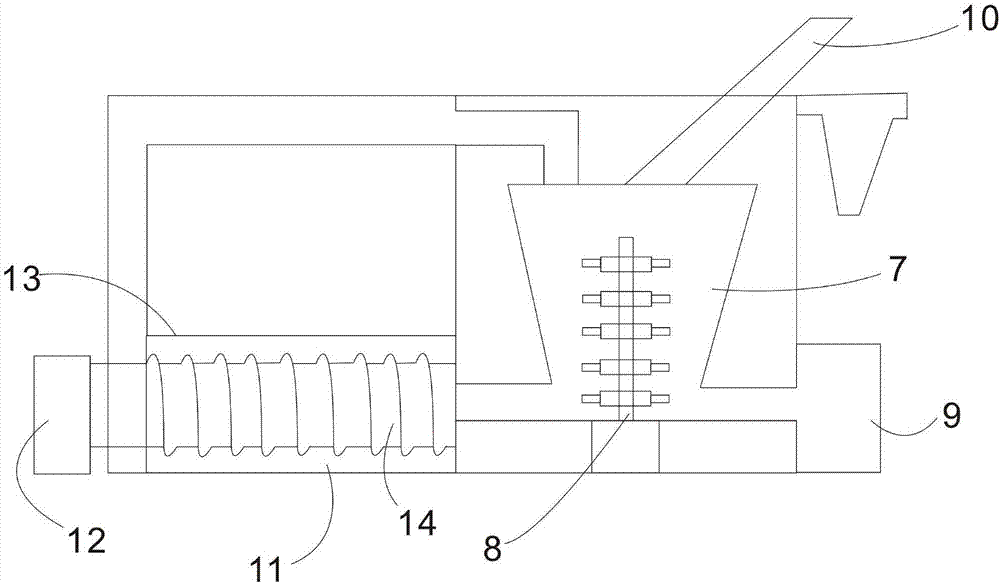

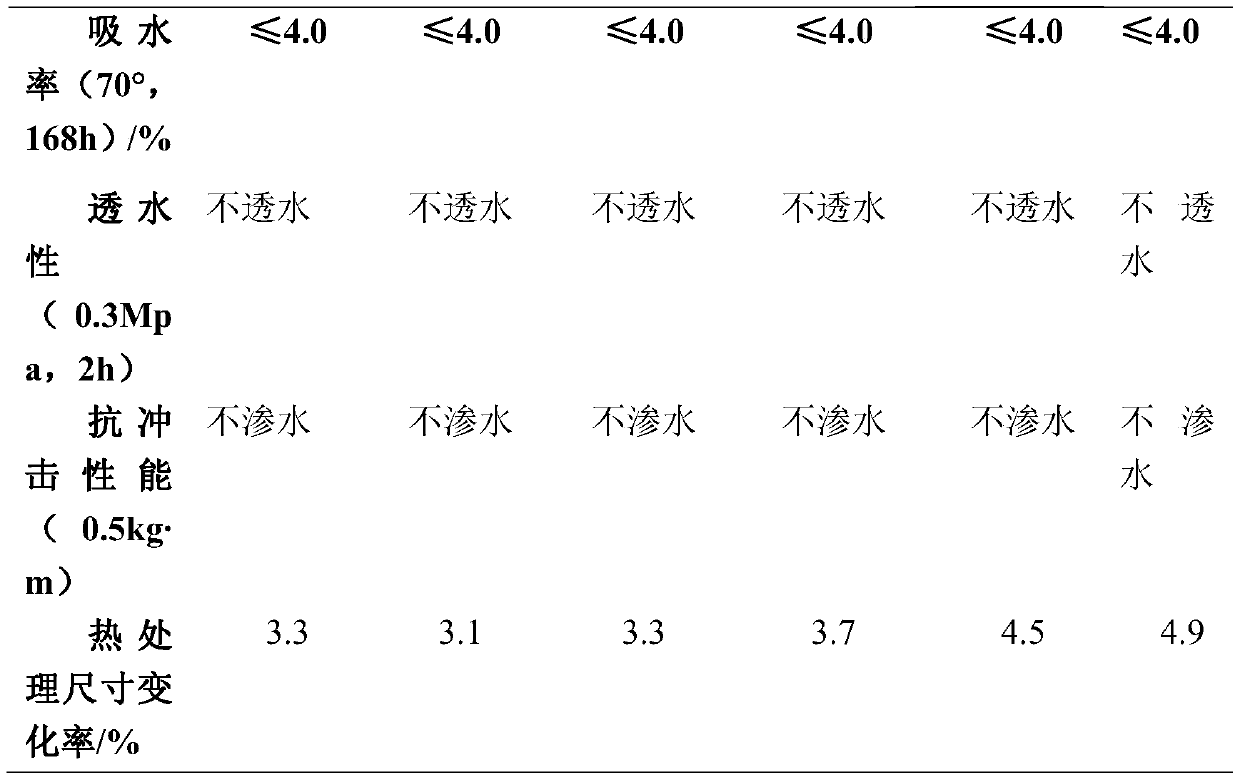

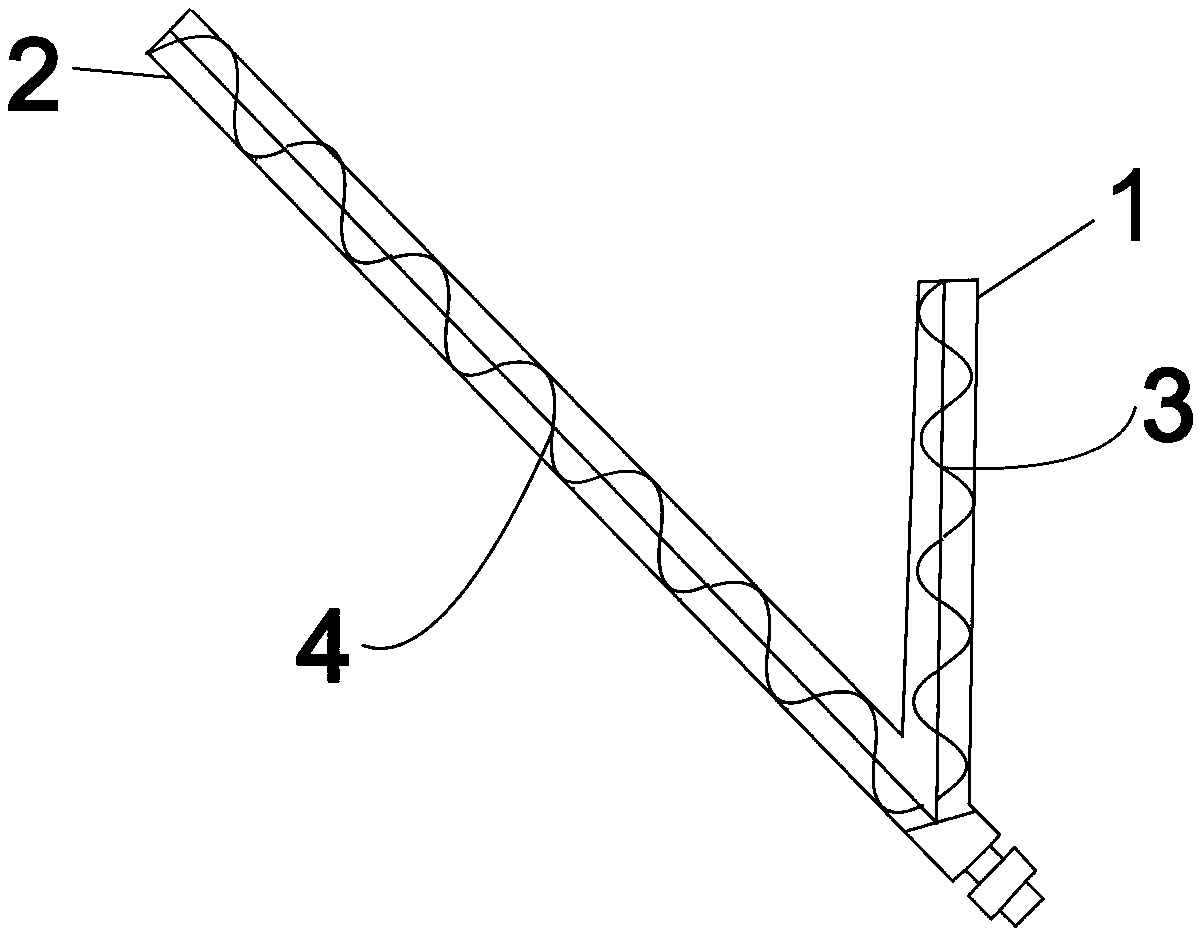

The invention discloses an agricultural planting irrigation device comprising a water pump (1). A water outlet of the water pump (1) is communicated with a water conveying pipe (2), and one side of the water pump (1) is provided with a mixing box (3). One end of the water conveying pipe (2) is disposed inside the mixing box (3), a partition (4) is disposed inside the mixing box (3), and the bottomof an inner cavity of the mixing box (3) is provided with a first motor (5). According to the agricultural planting irrigation device, the problem of excessive waste of manpower and material resources and uneven irrigation of conventional agricultural planting irrigation devices are solved.

Owner:张文凯

Nutrition mixture for birds care

InactiveCN1883295ALess investmentAvoid deathAnimal feeding stuffAccessory food factorsChemistryNutrition

The invention provides a fowl nourishing agent for preventing vertical communicable diseases of fowl, which comprises (by weight ratio) sodium chloride 5-10 parts, potassium chloride 150 parts, sodium hydrogen carbonate 5-10 parts, vitamin B 1-5 parts, vitamin B2 1-5 parts, norfloxacin 3-7 parts, and glucose 53-80 parts.

Owner:TIANJIN SHENGJI GRP CO LTD

Viscose fiber spinning dyeing embroidery thread and producing method thereof

InactiveCN101104971AGuaranteed recovery before spinningGuarantee the production requirements of spinning oxidation color developmentYarnDye addition to spinning solutionYarnEngineering

The invention discloses a viscose fiber spinning dyed stitch yarn and the production process thereof, and overcomes the problems of tinted yarn, such as poor spinning property, high production costs, dull color of product and failure to produce stitch yarns. The raw materials used in the invention comprises a dyeing viscose glue which is a mixture of color paste and viscose glue, a base solution, a reducer and an oxidizer. Reduced threads made from the dyeing viscose glue are directly processed to viscose fiber spinning dyed stitch yarns in the refining procedure, with the action of oxidizer and acid or base. The invention has the advantages of uniform dyeing, high color fastness and color brightness, rich colors, compliance with the standards of stitch yarn, reduced production costs, no contamination of the next processing, comfortable feeling, and wide application range.

Owner:YIBIN HIEST FIBER

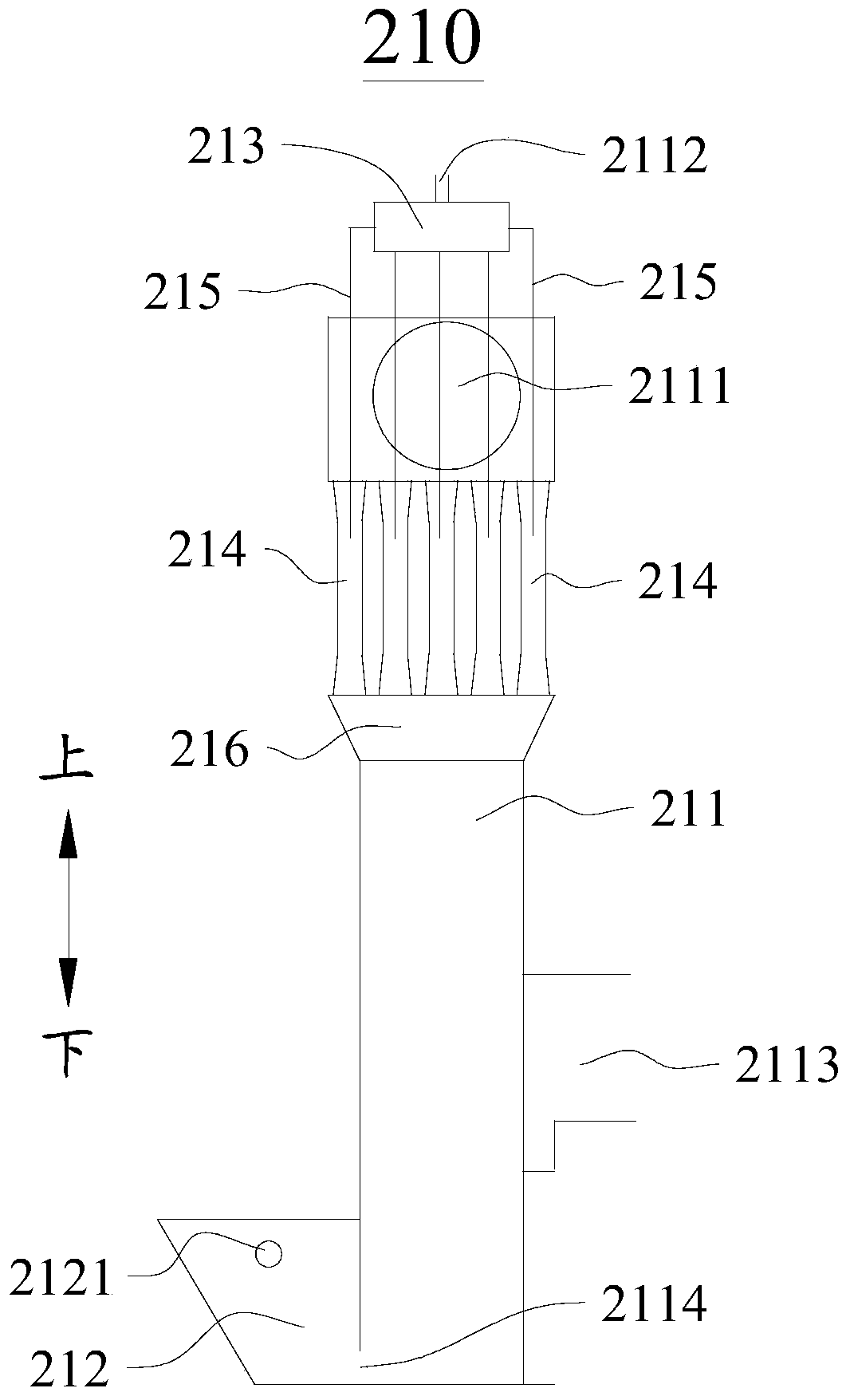

Method for producing nonfat dried insect pupa protein powder at low temperature

ActiveCN107469939AMix thoroughlyComplete extraction and separationFatty-oils/fats productionGrain treatmentsInsect pupaEconomic benefits

The invention discloses a method for producing nonfat dried insect pupa protein powder at a low temperature. The method comprises the following steps that (1) fresh and alive insect pupas are thoroughly cleaned and then dried, then the dried insect pupas are subjected to coarse crushing, the dried insect pupas subjected to coarse crushing are fed into a rotary delivery extractor and subjected to continuous counter-current extraction at the temperature of 10-15 DEG C with liquefied butane as solvent, and afterwards filter residues obtained through extraction of the rotary delivery extractor are nonfat dried insect pupas; and (2) the nonfat dried insect pupas which are dried are delivered into a special pulverizer to be pulverized into the nonfat dried insect pupa protein powder. By means of the method, the residue amount of raw oil is small, the smashing fineness meets the requirement of food-grade protein powder raw materials and medical protein powder raw materials, the quality guarantee period is long, and the economic benefits are high.

Owner:青岛新农康源生物工程有限公司

Spinning and dyeing method for viscose

InactiveCN101058898AGuaranteed RestoreGuaranteed recovery before spinningMonocomponent cellulose artificial filamentCelluloseTextile dyeing

The present invention discloses a dyeing method of textile dyeing cellulose viscose, in order to overcome the drawbacks of the prior dyeing method can not guarantee the oxidation-reduction process be controlled effectively in colored cellulose viscose production. The method adds reducing agent and oxidizer into color paste, adds the standby color paste into viscose, the dyeing viscose is prepared after mixing fully, then the dyeing viscose forms reduced thread-line after ejected from spinnerette; in the textile process of reduced thread-line from forming to degumming or when the textile process is completed, the thread-line starts color development on the role of oxidant and acids or alkali, the color is fixed into desired color after reaction is completed. The invention breaks the traditional technology of the traditional ordinary cellulose viscose is colored before textile and is dyed and finished in late processes, it can achieve single filament dyeing, improve dyeing uniformity, color stability and color brightness of thread-line, and achieve the use standard of cotton embroidery thread, as well as decrease production costs significantly; the follow-up processing is pollution-free, the color of produces is bright, dyeing is uniform, hand feeling is comfortable and application is wide.

Owner:YIBIN HIEST FIBER

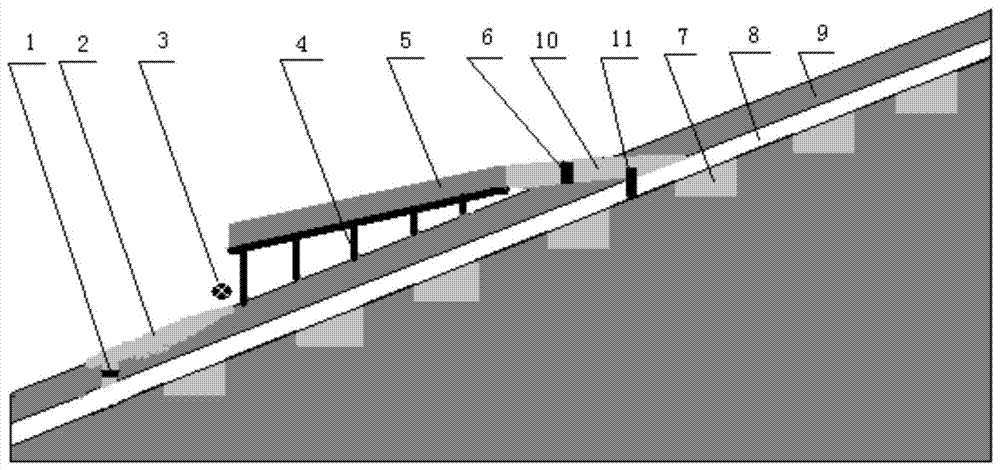

Water resource storage and comprehensive utilization system

InactiveCN107574799ADoes not affect flood dischargePlay a complementary roleWater-power plantsHydro energy generationWater desalinationTerrain

A water resource storage and comprehensive utilization system includes a water discharging gate, an artificial lake, a power generating set, a viaduct bridge, an aqueduct, a water feeding gate, deep water channels, a diversion canal, and a water raising dam; the aqueduct is laid on the viaduct bridge, river water on an upstream of a river is guided to a downstream certain position to form the artificial lake, and water storage, power generating and water cleaning can be achieved; the deep water channels are dug in a bed of the river and the artificial lake, and in this way, the water storage amount is increased, land occupation can be avoided, and river flood discharge cannot be affected. The artificial lake can be dug in places which are near cities or flat areas, do not have a lake forming condition, are high in terrain, and cannot allow rivers to flow, the artificial lake can receive water from the river channel and processed and discharged city sewage, the wetland environment of the artificial lake can clean the water, and power generating can be achieved. The water resource storage and comprehensive utilization system is simple, cheap and effective, can solve the problem of water shortage of cities or north areas to the greatest extent, and has a certain advantage in comparison with the South-to-North water diversion project and a sea water desalination project.

Owner:李效雨

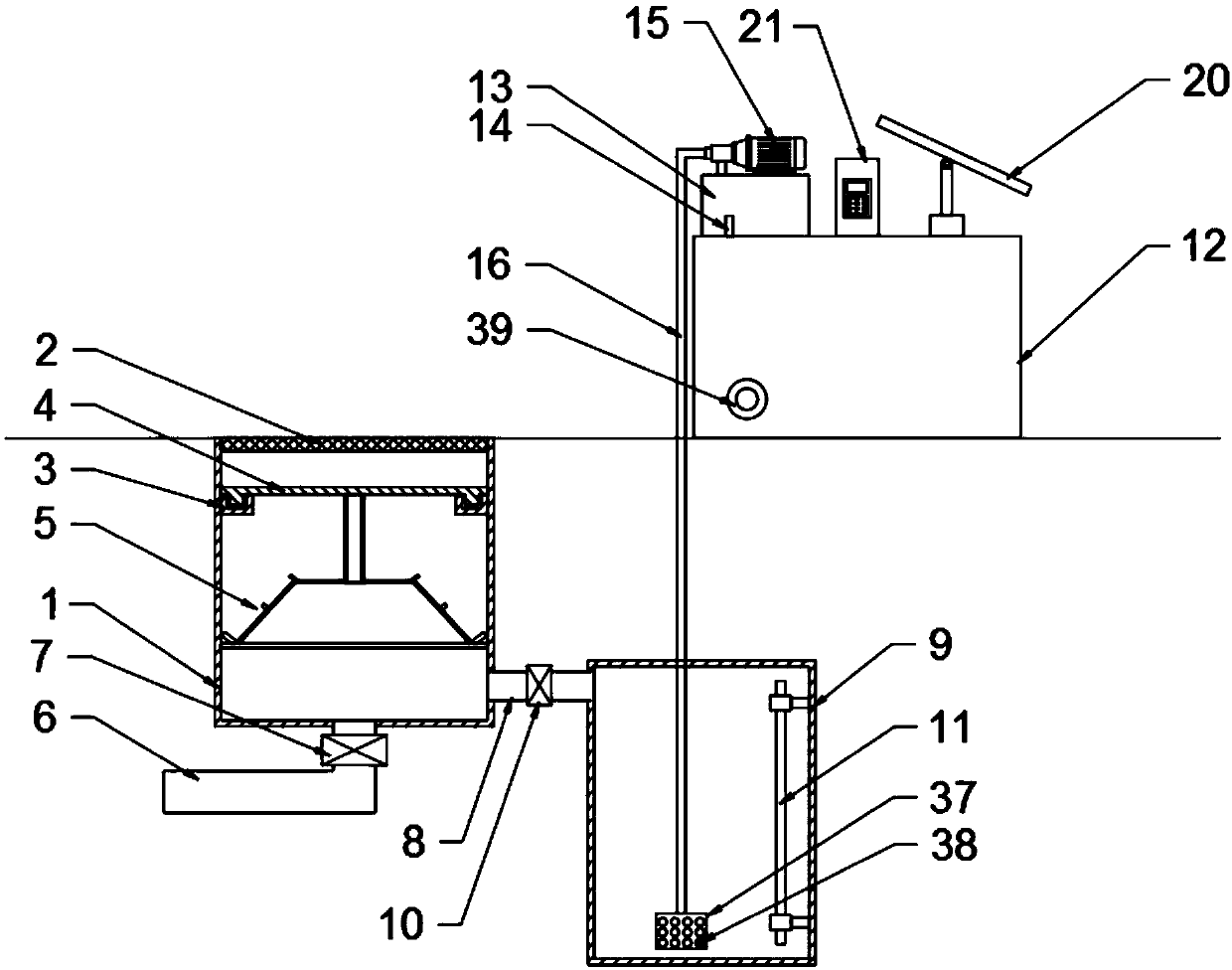

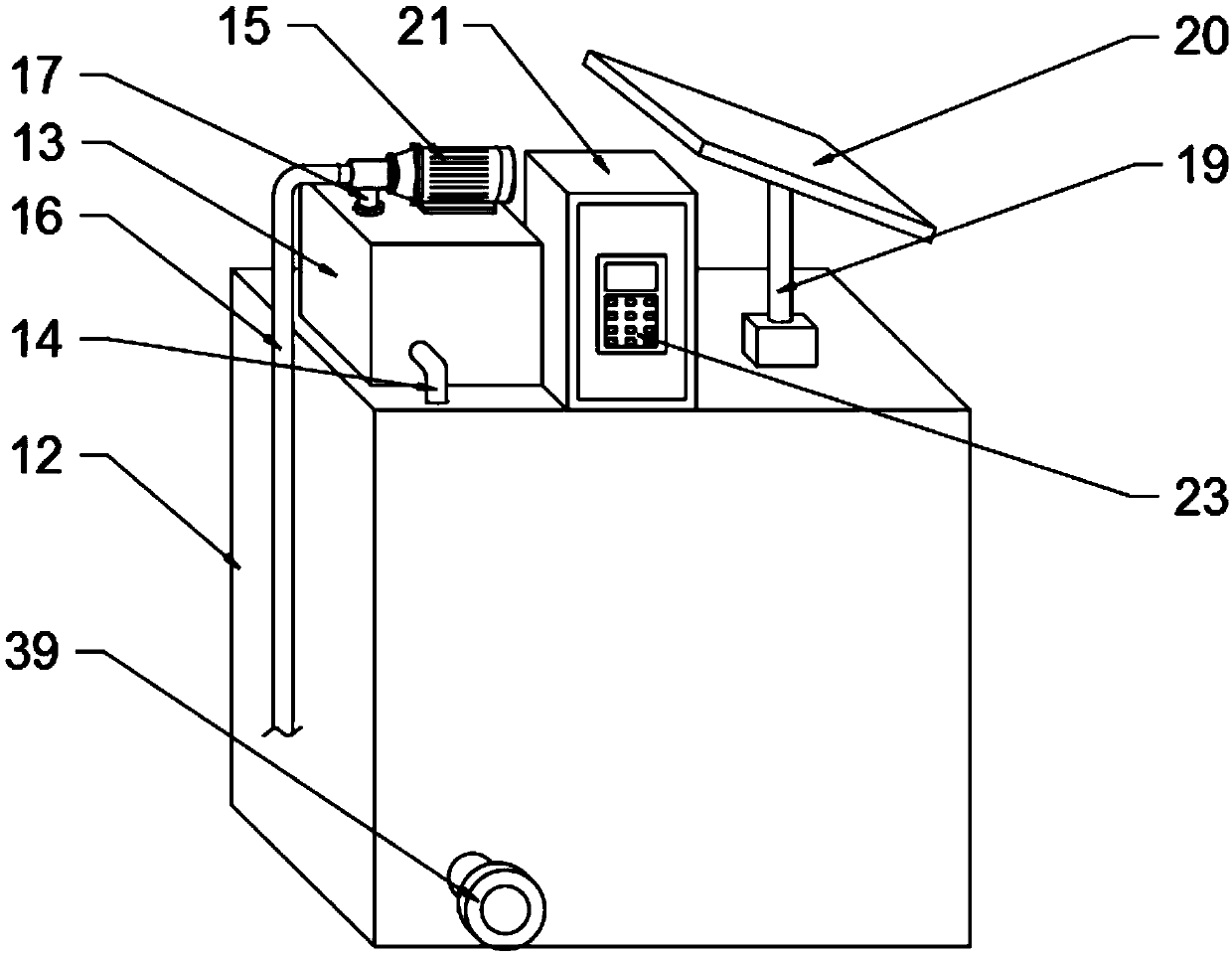

Rainwater recycling system and method

InactiveCN109577418AEasy to cleanIncrease contact areaGeneral water supply conservationProgramme control in sequence/logic controllersWater storage tankEnvironmental engineering

The invention discloses a rainwater recycling system and method. The system comprises a drain tank, a grate, a first filter mechanism, a drain pipe, a first electromagnetic valve, a first connection pipe, a water collection tank, a second electromagnetic valve, a first liquid level sensor, a water storage tank, a second filter mechanism, a second connection pipe, a water pump, a second liquid level sensor, a supporting frame, a photovoltaic panel, a cabinet, a storage battery, a controller, a flow guide plate, connecting rods, a countersink, water inlet holes and a connection valve. The grateis arranged at the upper end of the drain tank, and clamping seats are fixedly mounted on the lower side of the grate corresponding to two side ends of the inner wall of the drain tank. A kettle coveris arranged at the upper end of an emulsification kettle body. By arrangement of the first filter mechanism, rainwater is scattered and slides downward along the peripheries of stage plates; by step-by-step arrangement of retaining plates, large-size impurities in rainwater are retained, so that primary filtration of rainwater is realized; by arrangement of a hanging connection structure of the first filter mechanism, quickness and convenience in impurity clearing are achieved.

Owner:贵州瑞泰实业有限公司

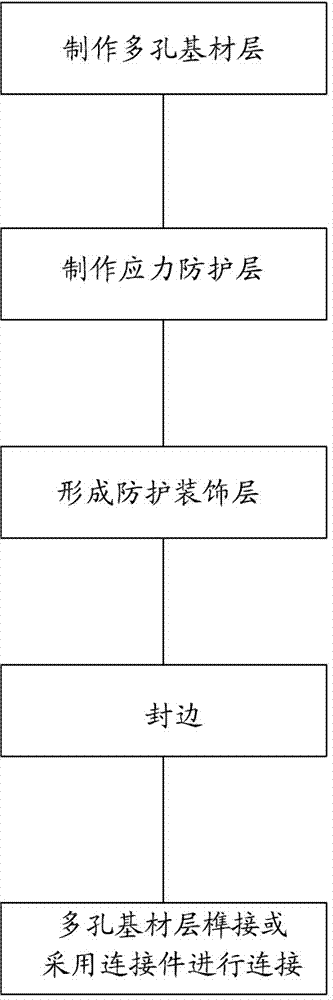

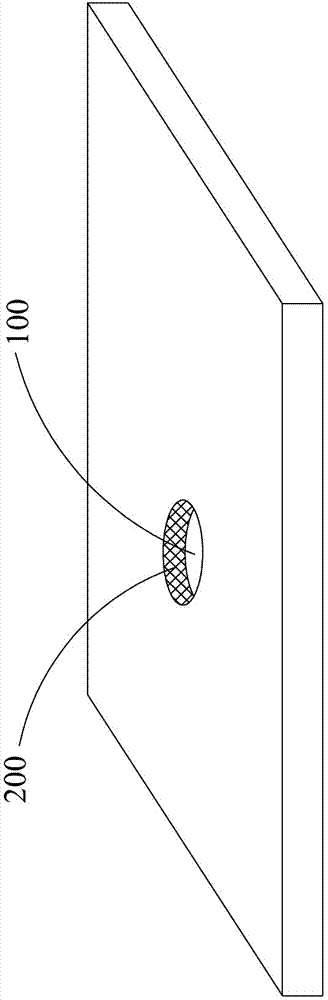

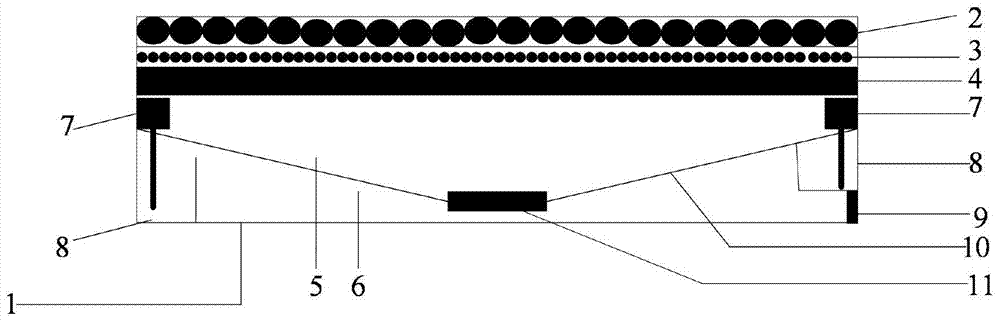

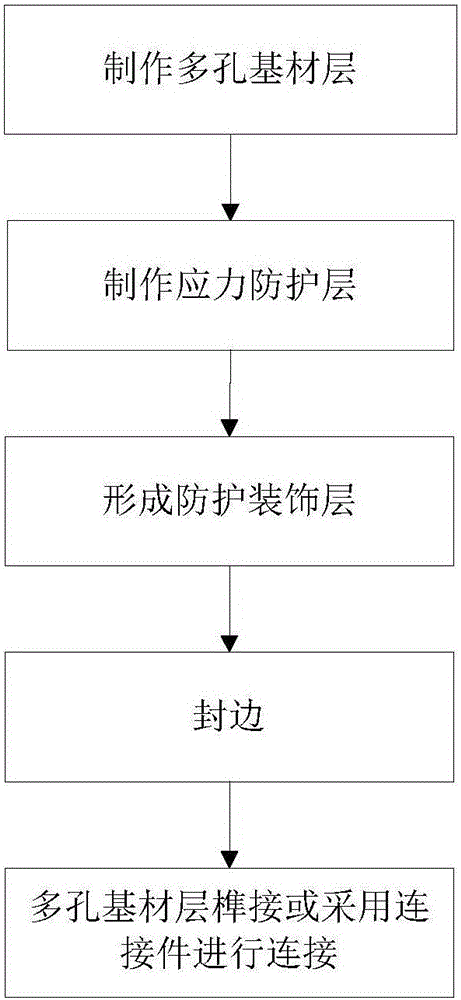

Processing method of porous material and porous material plate

InactiveCN103481553AStable structureStructure is recyclablePaper/cardboard layered productsDomestic articlesComposite materialMortise and tenon

The invention provides a processing method of a porous material. The processing method of the porous material is characterized by comprising the following steps: A, manufacturing a porous base material layer which is manufactured by using one layer of porous base material or by mutually superposing multiple layers of porous base materials; B, manufacturing a stress protective layer and adhering the stress protective layer to the porous base material layer; C, forming a protective decorative layer on the surface of the stress protective layer; D, performing edge sealing on the porous base material layer; E, connecting or mutually joggling the plurality of porous base material layers through connecting pieces. The processing method of the porous material provided by the invention is applicable to various porous materials; mortise and tenon joint structures are arranged on the manufactured plate and are assembled and spliced or connected through connecting pieces, so the plate has a firm structure, can be recycled and can reach to the using standard of the traditional wood furniture and appliances; the protective decorative layers made of different materials can be used and the various materials are mutually combined, so the whole performance is greatly improved. The invention further discloses a porous material plate.

Owner:MYS GRP CO LTD

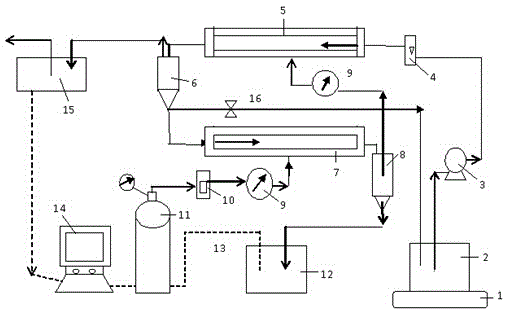

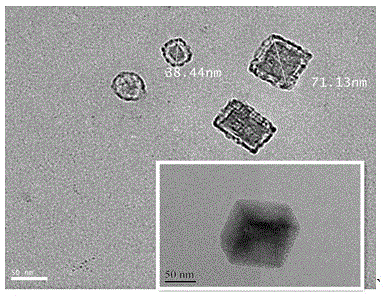

Co-production method for nano calcium carbonate through marsh gas purification

InactiveCN105154160AUp to standardEfficient removalCalcium/strontium/barium carbonatesMaterial nanotechnologyCarbonizationEngineering

The invention provides a method for purifying marsh gas to make the methane content of the marsh gas reach the automotive fuel gas standard and obtaining high-added-value nano calcium carbonate in the purifying process. The method includes the steps that quick lime is slaked and filtered to obtain lime milk refined slurry, and the lime milk refined slurry is added into a storage tank of a carbonization device and added with a dispersant; marsh gas is injected into membrane reactors for a carbonization reaction, online monitoring is carried out, and when the pH value is smaller than 7, the reaction is stopped. The membrane reactor a and the membrane reactor b of the process represent a purification stage and a carbonization stage respectively, and the calcium carbonate product carbonized completely is obtained while it is ensured that the marsh gas is completely purified. Calcium carbonate emulsion obtained after the reaction is centrifuged to obtain a calcium carbonate filter cake and dried and smashed to obtain the nano calcium carbonate product. By using the novel membrane reactors, while high-purity biomethane is obtained by purifying the marsh gas, the high-performance nano calcium carbonate can be obtained.

Owner:NANJING TECH UNIV

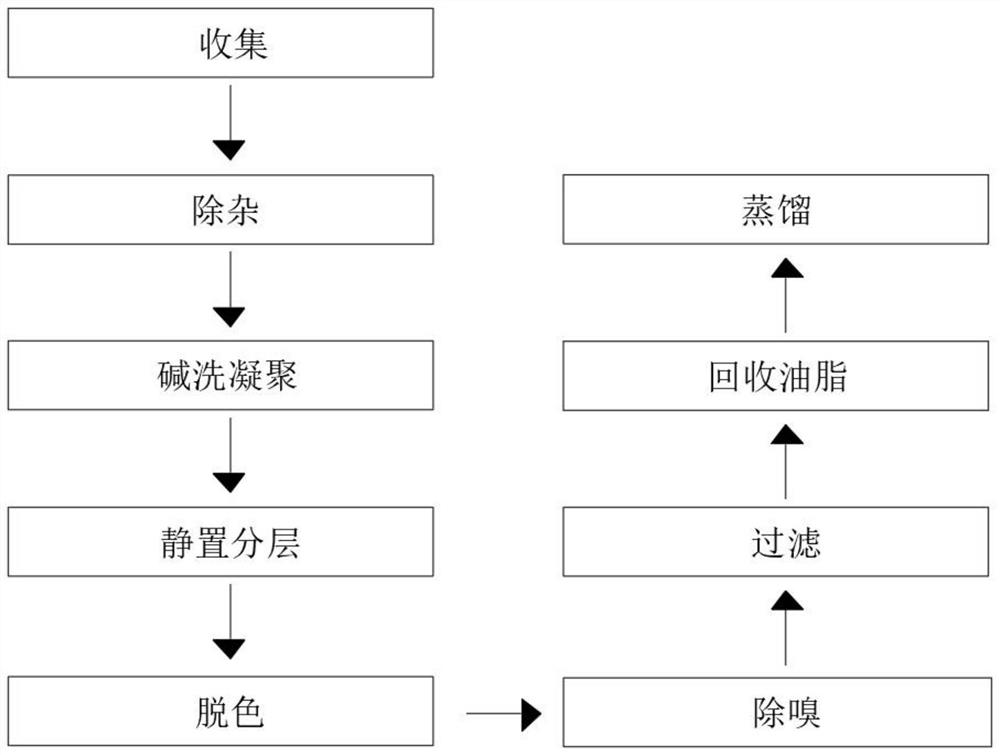

Method for degreasing and purifying waste edible oil

PendingCN114507564AEasy to handleIncrease valueFatty-oils/fats refiningFiltration separationIron sulfatePhosphate

The invention discloses a method for degreasing and purifying waste edible oil, and relates to the technical field of waste edible oil treatment. The method mainly comprises the following steps: collecting, removing impurities, carrying out alkali washing condensation, standing for layering, decolorizing, deodorizing, filtering, recovering grease, distilling, uniformly mixing H-type modified polypropylene fibers, ferroferric oxide powder, ground phosphate rock and polyferric sulfate, and filling into a reaction tank to form a primary filter layer, the weight ratio of the H-type modified polypropylene fiber to the ferroferric oxide powder to the polyferric sulfate is 8: 2: 1: 1. According to the method disclosed by the invention, the waste oil becomes clear refined oil through decoloration, odor in the waste oil is effectively removed through deodorization, and impurities and other harmful substances in the waste oil are removed through impurity removal, filtration and other steps, so that the value of the oil is increased; the feed oil use standard is reached.

Owner:深圳市腾浪再生资源发展有限公司

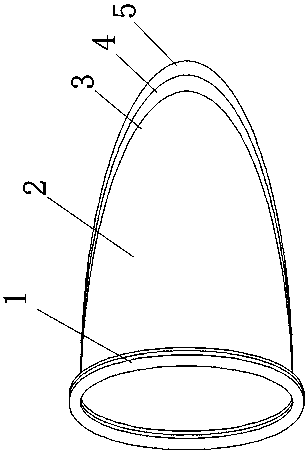

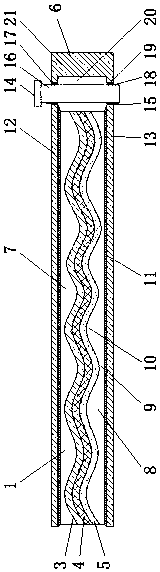

Water purification membrane structure for desalinating seawater

InactiveCN108217843AReduce solubilityUp to standardGeneral water supply conservationSeawater treatmentFiltration membraneUltrafiltration

The invention discloses a water purification membrane structure for desalinating seawater. The water purification membrane structure comprises a fixing ring and a water purification membrane, whereinthe fixing ring is movably connected with the water purification membrane; the water purification membrane comprises a filtration membrane, a reverse osmosis membrane and an ultrafiltration membrane;the filtration membrane is located on the innermost side of the water purification membrane; the reverse osmosis membrane is located on the outer side of the filtration membrane; the reverse osmosis membrane is located between the filtration membrane and the ultrafiltration membrane; the ultrafiltration membrane is located on the outer side of the reverse osmosis membrane; the fixing ring comprises a pressurization device, a first magnet and a second magnet; the first magnet is located at the top of the second magnet; the pole N of the first magnet is laminated with the pole S of the second magnet; the pole N of the first magnet is downward and the pole S of the first magnet is upward; the pole S of the second magnet is upward and the pole N of the second magnet is downward; the pole N, which is laminated with the second magnet, of the first magnet is provided with multiple arc-shaped grooves and arc-shaped bulges. The water purification membrane structure for desalinating the seawaternot only can be used for filtering sewage to form purified water, but also can be used for filtering the seawater to form fresh water through the reverse osmosis membrane.

Owner:WUXI AOYUTE NEW TECH DEV

Method for rapidly detecting state of asphalt pavement

PendingCN112964712AQuick analysisAccurate analysisImage enhancementImage analysisComputer graphics (images)Engineering

A method for rapidly detecting the state of an asphalt pavement comprises the following steps of: step 1, drilling a core of a road to obtain a cylindrical road test piece; 2, carrying out side surface shooting around the cylindrical road test piece by using an region-array camera, performing matching alignment and reconstruction on all photos, carrying out panoramic image synthesis to obtain a composite image, and marking the composite image; 3, recognizing the composite image by adopting an artificial neural network, and optimizing by adopting a Gaussian weight method and a secondary marking method to obtain a recognition result image; 4, carrying out binarization calculation and processing on an identification result image, filling existing cracks and holes, and carrying out particle segmentation on adhesion among aggregate particles; and after the identification result is processed, analyzing the morphological characteristics and spatial position distribution of the aggregate particles in the identification result. According to the method, various parameter performances of the asphalt mixture can be rapidly, accurately and quantitatively analyzed, so that the purpose of rapidly detecting the road state is achieved.

Owner:CENT SOUTH UNIV

Preparation method of anticorrosive recombined bamboo material

InactiveCN111203946AHigh densityUp to standardPlywood pressesWood treatment detailsPutrefying bacteriaOrganic chemistry

The invention discloses a preparation method of an anticorrosive recombined bamboo material. The preparation method comprises the following steps of (1) taking moso bamboos, cleaning the moso bamboos,cutting off the moso bamboos, removing bamboo outer skin and tabasheer, and performing splitting to obtain bamboo bundles; (2) feeding the bamboo bundles into water to be boiled, and heating the bamboo bundles with high-pressure steam to obtain pretreated bamboo bundles; (3) conducting air drying on the pretreated bamboo bundles with hot air, soaking the pretreated bamboo bundles in phenolic resin glue, and performing paving and assembling in the grain direction; and (4) feeding the paved and assembled bamboo bundles into a mold for pressurizing and heating, and carrying out thermosetting molding. According to the preparation method, parameters of all the steps are scientifically and accurately controlled, nutritional ingredients beneficial to bacterial reproduction in the moso bamboos can be lost and pyrolyzed in the water boiling and high-pressure steam heating process, energy supply of putrefying bacteria is cut off, and the preservative effect is achieved; and meanwhile, the density of the recombined bamboos can be increased in the subsequent thermocuring process, the putrefied bacteria are difficult to permeate in the radial direction, the corrosion resistance of a recombinedbamboo material is enhanced again, and the obtained product has excellent corrosion resistance.

Owner:ZHEJIANG FORESTRY ACAD

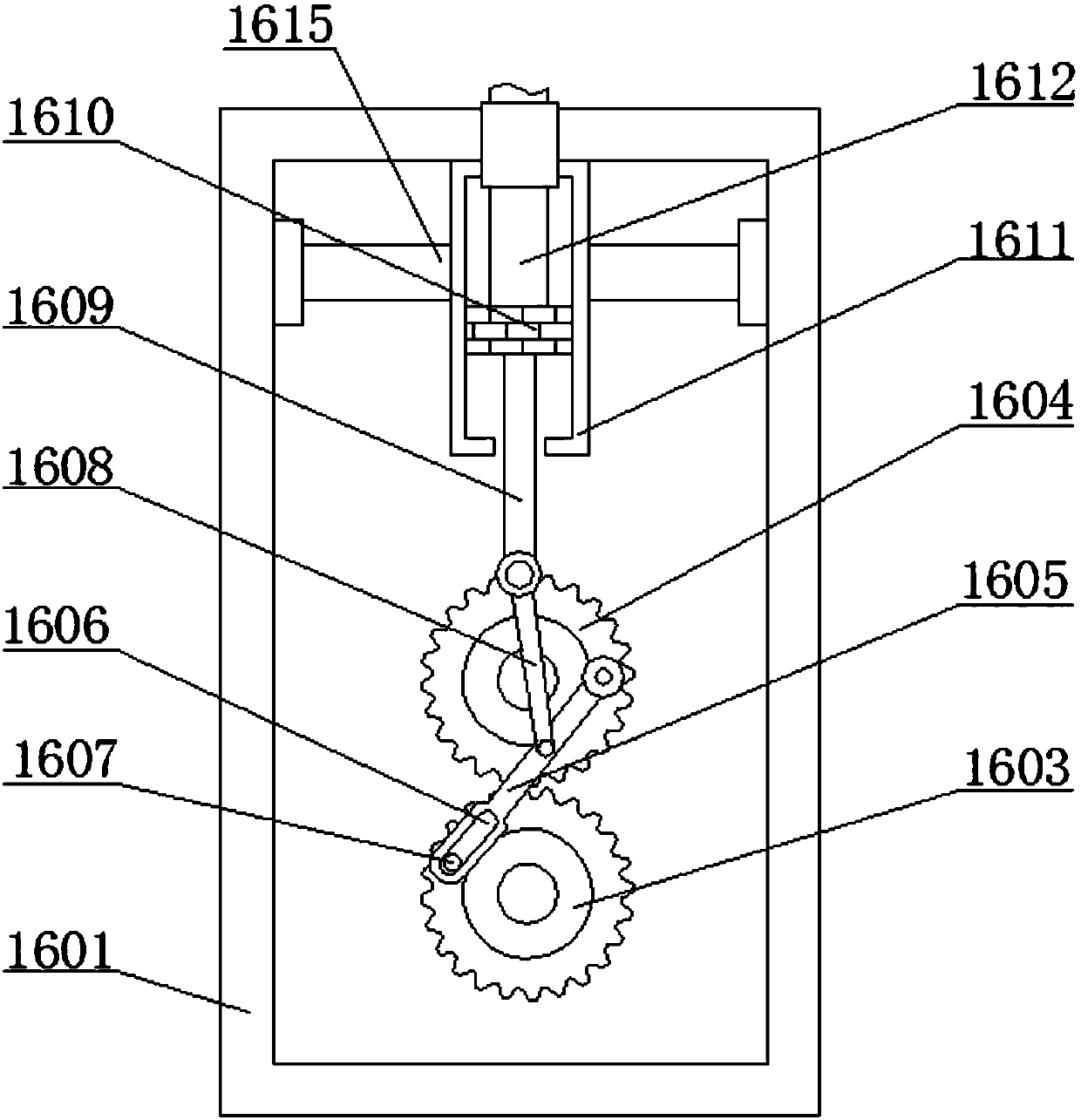

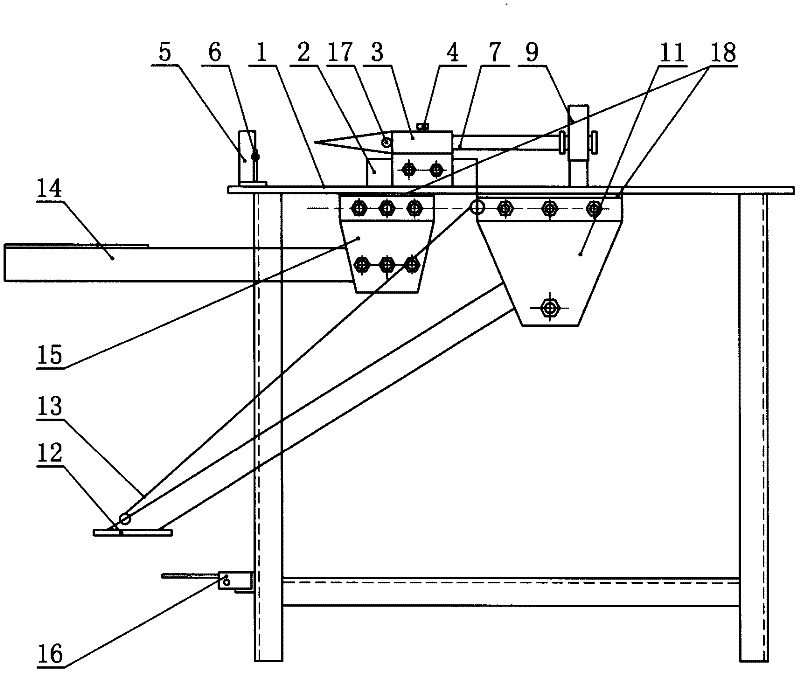

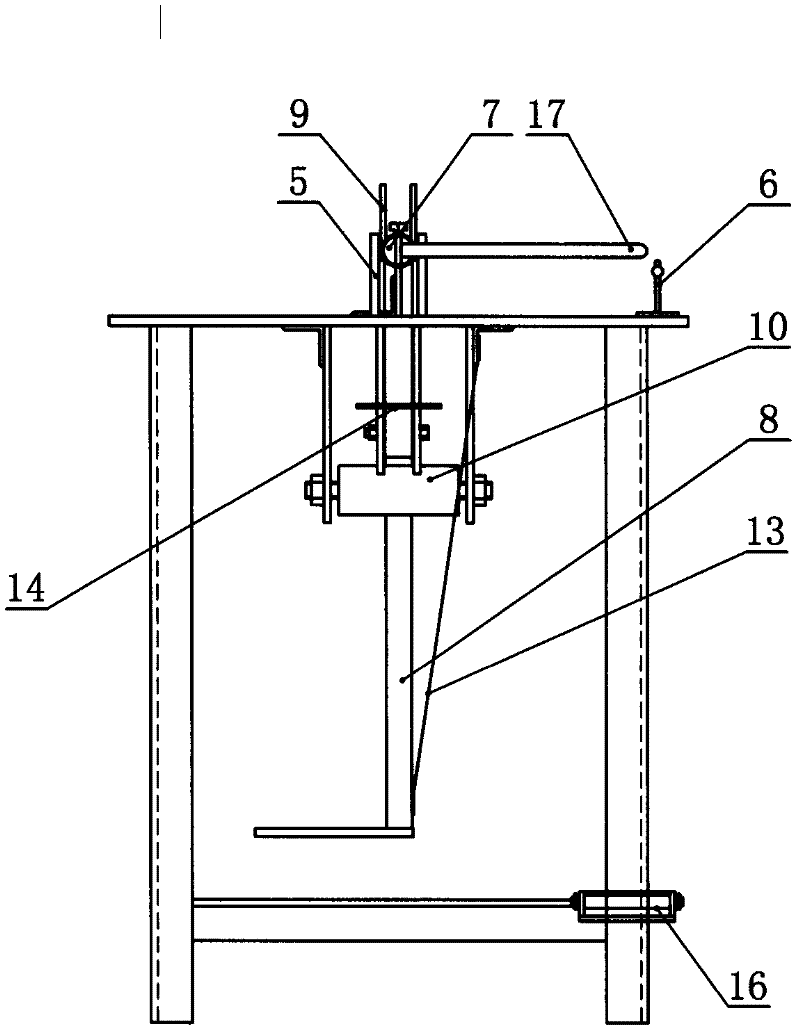

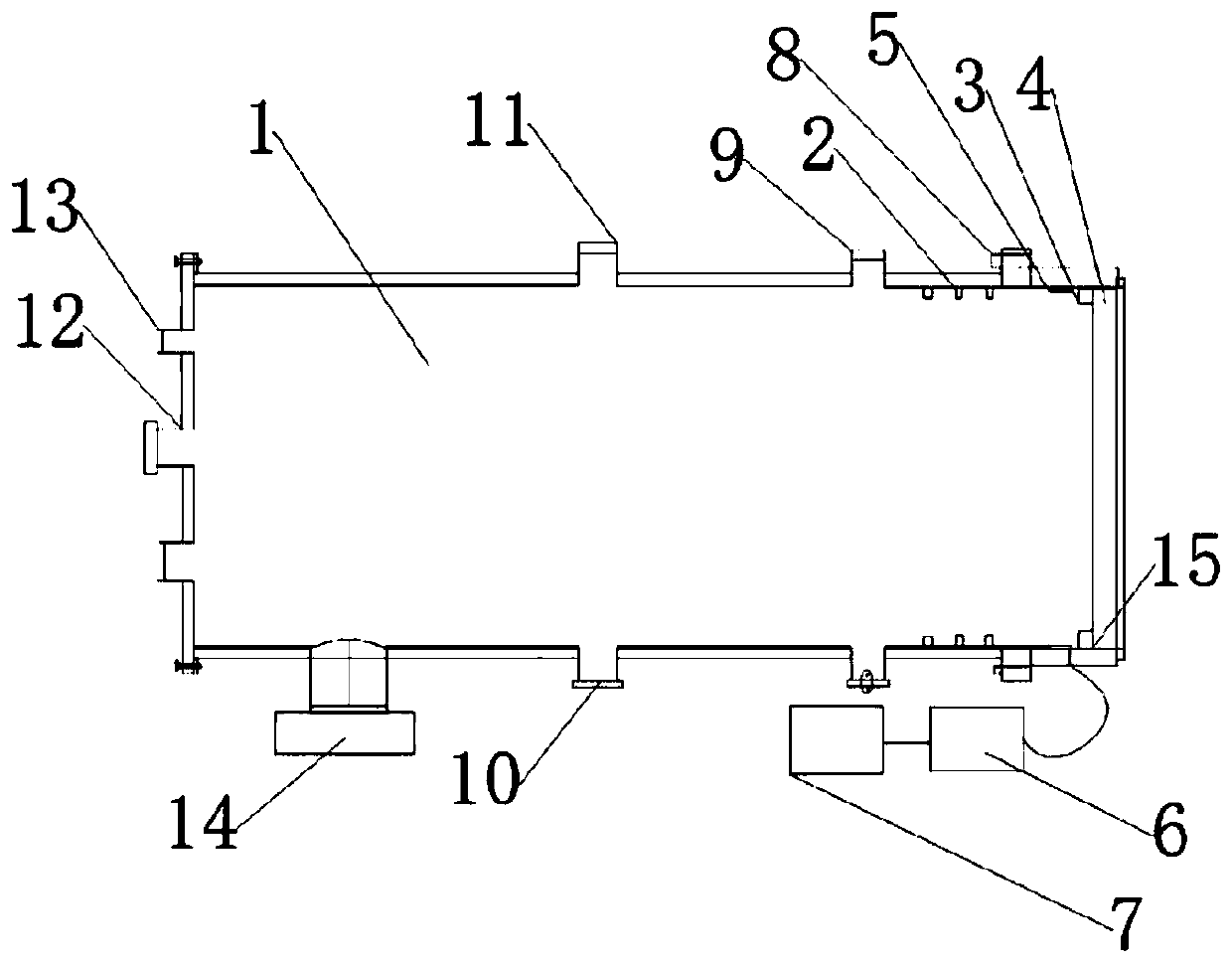

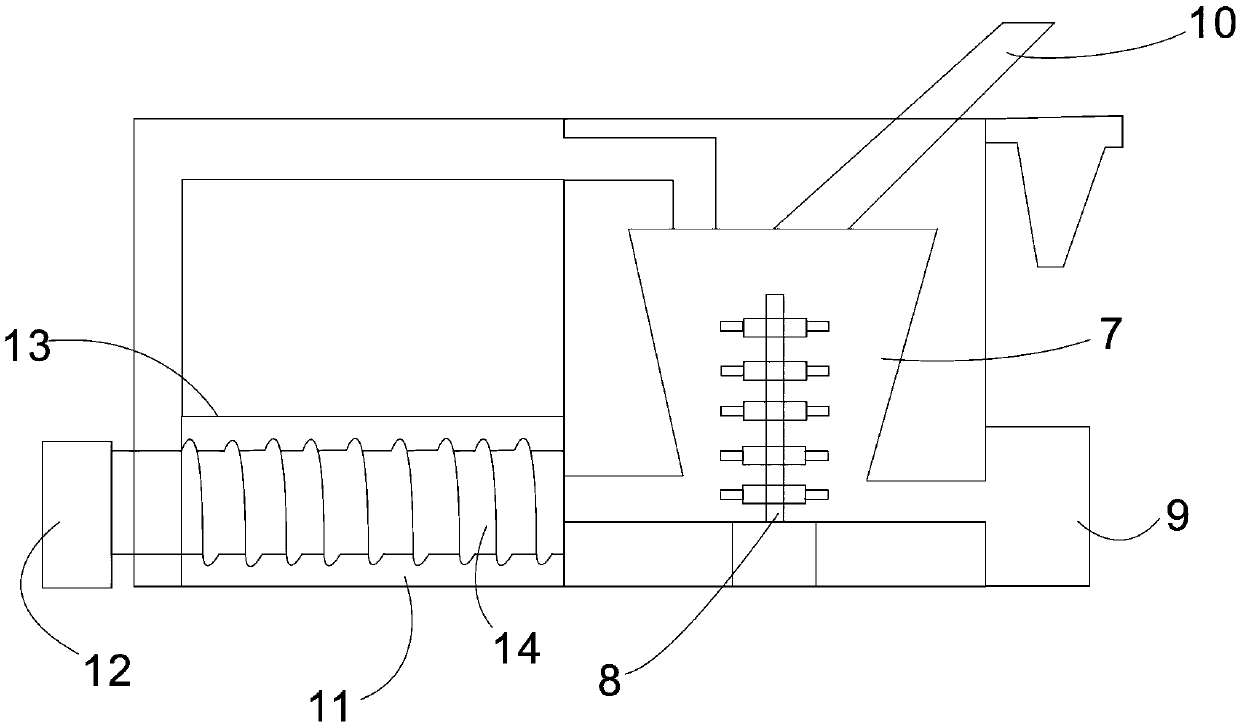

Steel wire rope splicing machine

InactiveCN102373635ALabor-saving plugging workQuick and easy pluggingRope making machinesEngineeringBolt connection

The invention discloses a steel wire rope splicing machine, which comprises a work table, a rope blocking vertical plate, a flat sharp cone and a rotating shaft support frame, wherein a sharp cone support frame is fixedly arranged on the work table, a shaft sleeve is connected onto the sharp cone support frame through a screw bolt, a sharp head of the flat sharp cone is sheathed into the shaft sleeve, a rod system pulling fork is clamped in a groove arranged at the tail end of the flat sharp cone, the rope blocking vertical plate is arranged on the work table and is positioned on the same straight line with the flat sharp cone, the tail end of the rod system pulling fork is fixedly connected onto a fulcrum rotating shaft, the tail end of a pedal is fixedly connected onto the fulcrum rotating shaft, the fulcrum rotating shaft is connected onto the rotating shaft support frame through a shaft, the two support frames are welded at the bottom surface of the work table, and the rotating support frame is arranged on one support frame through screw bolts. The steel wire rope splicing machine has the advantages that the labor is saved, high speed, convenience and safety are realized, and the efficiency is high. A rope core of a spliced steel wire rope is not damaged, the splicing position is flat and smooth, the appearance is attractive, the splicing requirement is met, the regulation standard is reached, the manufacture is simple, the cost is low, and the operation is simple.

Owner:枣庄矿业集团高庄煤业有限公司

Cultivation method for quantitatively enriching organic selenium for black corn

InactiveCN111248039AHigh and safe and controllable organic selenium contentIncrease productionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSulfate zincZinc sulphate heptahydrate

The invention discloses a cultivation method for quantitatively enriching organic selenium for black corn. The cultivation method comprises the following steps: spraying a selenium-enriched nutrient solution at a big flare stage, a heading stage and a filling stage of a growth phase of the black corn separately. The selenium-enriched nutrient solution is prepared from selenium-enriched fertilizerand water, and the selenium-enriched fertilizer is prepared from sodium selenite, monopotassium phosphate, magnesium sulfate and zinc sulfate heptahydrate. By use of the selenium enriching method, theblack corn can have higher, safe and controllable organic selenium content, selenium elements required by a human body are supplemented, the total selenium content is 0.35-4.0 mg / Kg, the organic selenium content is 0.25-3.1 mg / Kg, the daily selenium intake of the human body is satisfied, the yield and economic values of the black corn are increased, and wider prospects are provided for wide planting of the black corn in a northeast region.

Owner:LIAONING UNIVERSITY

Low sulfur diesel lubricant

InactiveCN107267233AImprove the lubrication effectUp to standardLiquid carbonaceous fuelsFuel additivesPolyolSulfur

The invention belongs to the technical field of fuels, and in particular relates to a low sulfur diesel lubricant which is made from the following raw materials by weight: 40-80 parts of polyols, 15-30 parts of Isocarbamide, 10-20 parts of Triisopentylamine and 1-10 parts of vinyl n-butyl ether. The low sulfur diesel lubricant can make the lubrication effect of low sulfur diesel oil good, and does not affect the performance of the diesel oil, can be added to the low sulfur diesel oil, and can adapt to various diesel engines.

Owner:马健

Antireflection film cleaning and reusing device and cleaning method

PendingCN111359996AWash evenlyTo achieve the purpose of useCleaning processes and apparatusPlasma generatorEngineering

The invention discloses an antireflection film cleaning and reusing device and belongs to the technical field of antireflection film cleaning devices. By placing an antireflection film and a substrateoptical component vertically in a vacuum chamber by using a clamp, one end of the vacuum chamber is sealed by a blind plate while the other end of the vacuum chamber is sealed by quartz glass. A vacuum unit is started, and a vacuum pump reduces air pressure in a cavity to a preset value quickly, so that the vacuum degree in the chamber meets a plasma generation condition, and therefore, proper reaction gas such as oxygen and argon is introduced from an inflating end. Electrodes distributed in the cavity in an encircling manner are controlled by a plasma generator to generate a plasma field, and the plasma is acted to the optical component and the antireflection film on the surface of the optical component, so that a service purpose that organic pollutants on the surface of the antireflection film of the film are removed is achieved finally.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Novel factory culture system and method

PendingCN110122396AReduce eutrophicationImprove the ecological environmentClimate change adaptationPisciculture and aquariaWater resourcesAquatic organisms

The invention discloses a novel factory culture system, and belongs to the field of ecological culture. The system comprises a filter device, an ecological filter pond, a water tempering and storing pond and at least one culture pond which are sequentially arranged in the water flow direction, wherein a microecological activation bag for activating microbial metabolism are arranged in the ecological filter pond; the water tempering and storing pond is used for tempering and storing water; a water outlet is formed in the bottom of the culture pond, provided with a grid plate for blocking aquatic organisms from passing through, and is connected with the filter device. The system not only can effectively reduce the cultivation cost and consumption of water resources, but also can improve cultivation efficiency.

Owner:上海泰缘生物科技股份有限公司

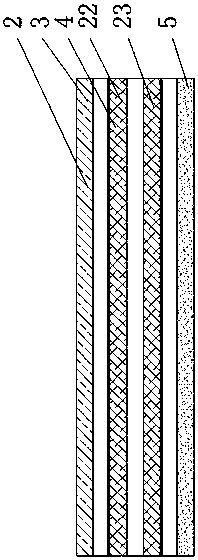

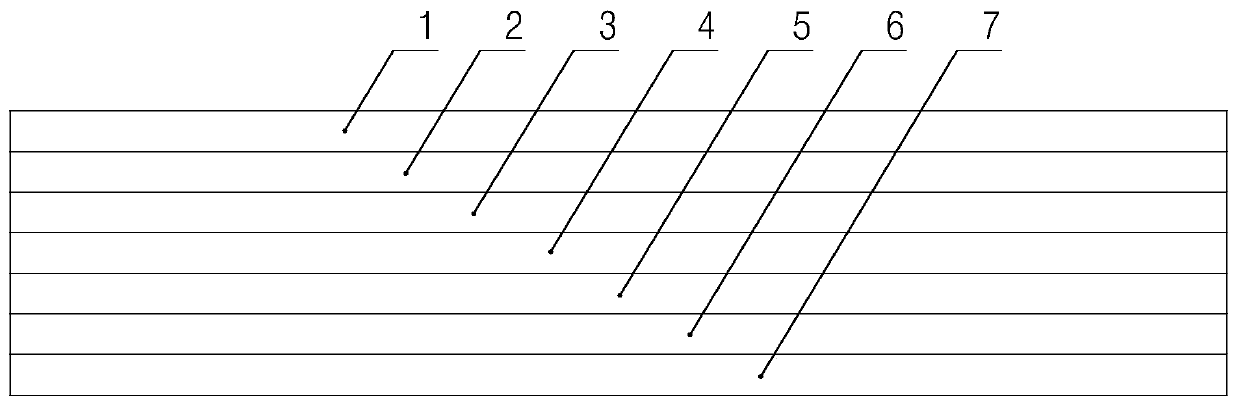

Manufacturing method of glue-free self-sinking floor

InactiveCN110130613AScale upShort processFlooring insulationsResiliently-mounted floorsPlasticizerColor film

The invention discloses a glue-free self-sinking floor capable of simplifying a process flow. The glue-free self-sinking floor capable of simplifying the process flow comprises an abrasion-resistant layer, a printed color film layer, a base material upper layer, a grid fiber layer, a base material middle layer, a base material lower layer and an anti-slip film layer which are sequentially arrangedfrom top to bottom; the base material upper layer, the base material middle layer and the base material lower layer are each prepared from the following components in percentage by weight: 14.5-15.5%of PVC resin powder, 0.7-0.8% of an environment-friendly calcium zinc stabilizer, 0.7-0.8% of carbon black, 8.5-9.5% of plasticizer and 74-75% of calcium carbonate. The invention further discloses amanufacturing method of the glue-free self-sinking floor. According to the glue-free self-sinking floor capable of simplifying the process flow and the manufacturing method of the glue-free self-sinking floor, the proportion of the filler calcium carbonate can be greatly increased by improving the formula of a base material, so that a unified formula is adopted in the base material upper layer, the base material middle layer and the base material lower layer, the process flow is greatly shortened, and the manufacturing cost is reduced; and in addition, the production cost is further reduced byimproving the composite process.

Owner:张家港隽新家居建材有限公司

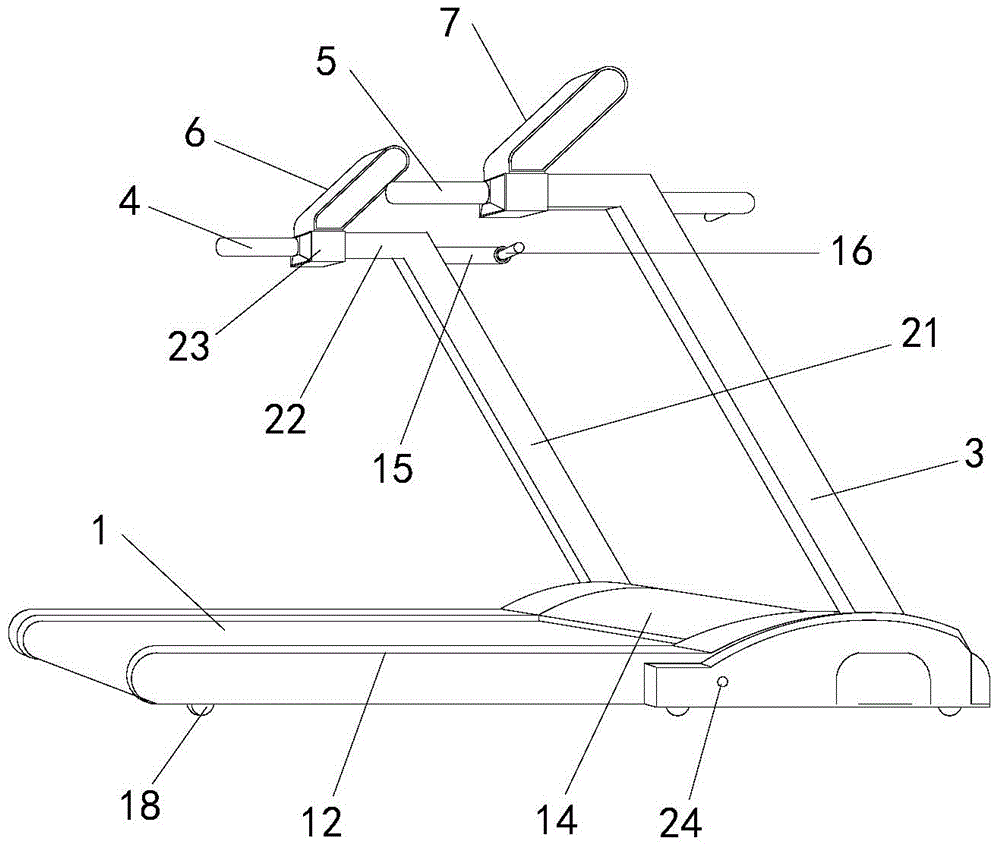

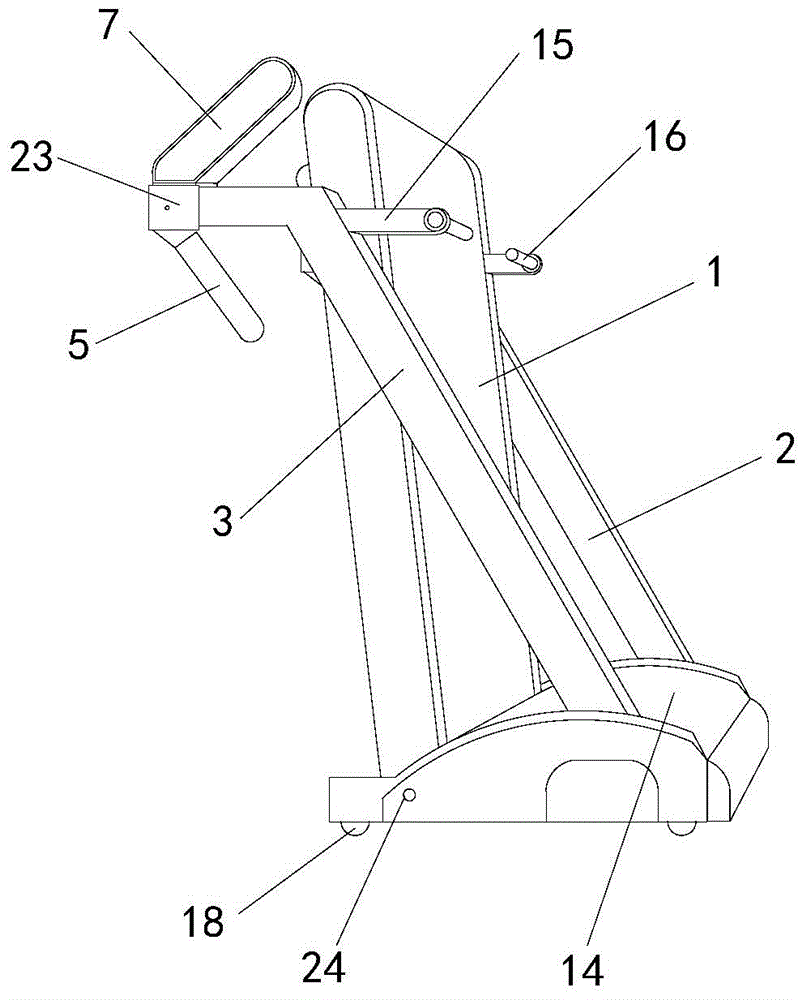

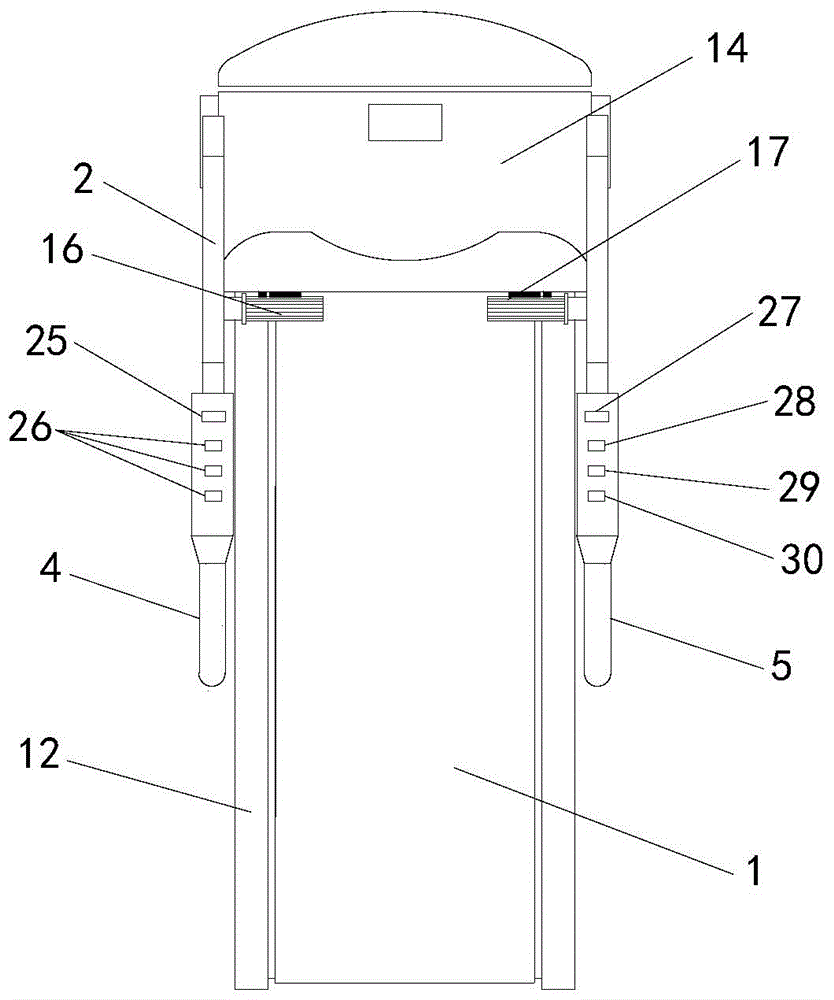

Non-sheltered treadmill

InactiveCN105582646ADoes not interfere with visionEmotional problemsMovement coordination devicesCardiovascular exercising devicesElectrical and Electronics engineeringHandrail

The invention discloses a non-sheltered treadmill, which comprises a running platform which is provided with a caterpillar track, a power mechanism for driving the transmission of the caterpillar track and two main arm rods, wherein the two arm rods are arranged on two sides of a same end of the running platform in an opposite mode; armrests, which are located on two sides of a runner, are arranged on the main arm rods; and operating panels are arranged on the armrests. According to the non-sheltered treadmill disclosed by the invention, the operation panels are not arranged in the front, so that the sight of the runner is not sheltered; in addition, the treadmill is simple and convenient to operate; and the concentration degree of the runner is improved and the runner feels happy, so that an exercise effect is enhanced.

Owner:李宗彦

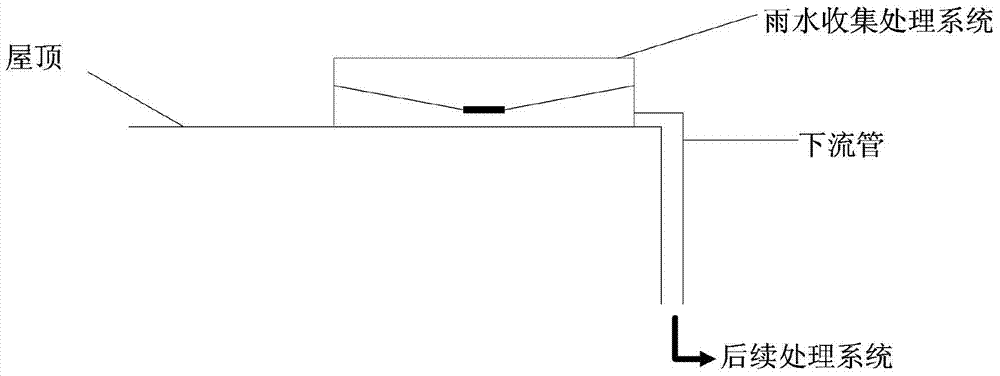

A rainwater collection and treatment system on the roof of a building

ActiveCN105735405BEfficient use ofUp to standardRoof improvementGeneral water supply conservationReverse osmosisRainwater harvesting

Owner:山东宏阳型材科技股份有限公司

Porous material processing method and porous material plate

InactiveCN106182913AUp to standardSturdy and recyclablePaper/cardboard layered productsDomestic articlesStress protectionMulti material

The invention provides a porous material processing method, which is characterized by comprising the following steps of A, manufacturing a porous base material layer, wherein a porous base plate layer is manufactured by mutually superimposing one or a plurality of layers of porous base materials; B, manufacturing a stress protection layer, and attaching the stress protection layer to the porous base material layer; C, forming a protection decoration layer on the surface of the stress protection layer. The porous material processing method is applicable to various porous materials; mortise and tenon structures are arranged on the manufactured plate; the structures are assembled and spliced or are connected through connecting elements; the structure is firm; the cyclic utilization is realized; the use standards of traditional wood furniture and tools can be reached; various protection decoration layers made of different materials can be used, and various materials are mutually combined, so that the integral performance is greatly improved. The invention also discloses a porous material plate.

Owner:MYS GRP CO LTD

A kind of method and application thereof by biomass liquefaction preparation wood oil

ActiveCN109628171BAchieve complete liquefactionImprove utilization efficiencyLiquid carbonaceous fuelsSulfidationProcess engineering

Owner:台州立拓能源有限公司

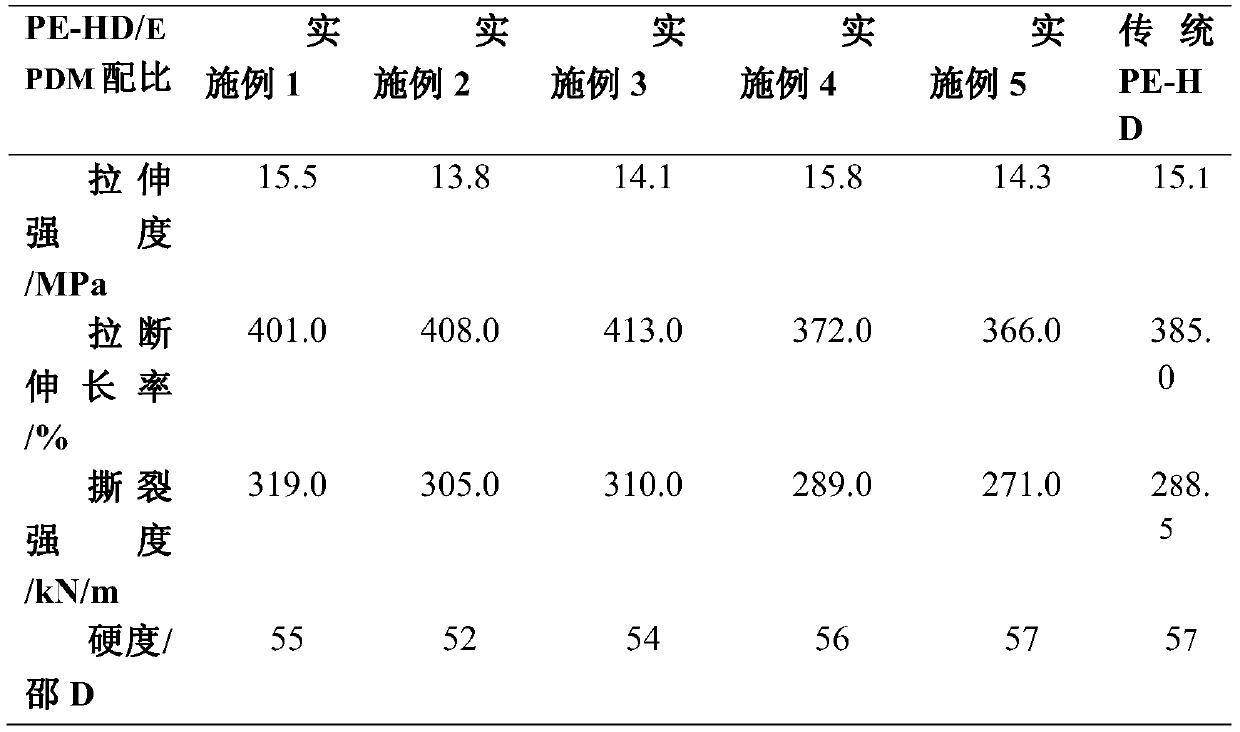

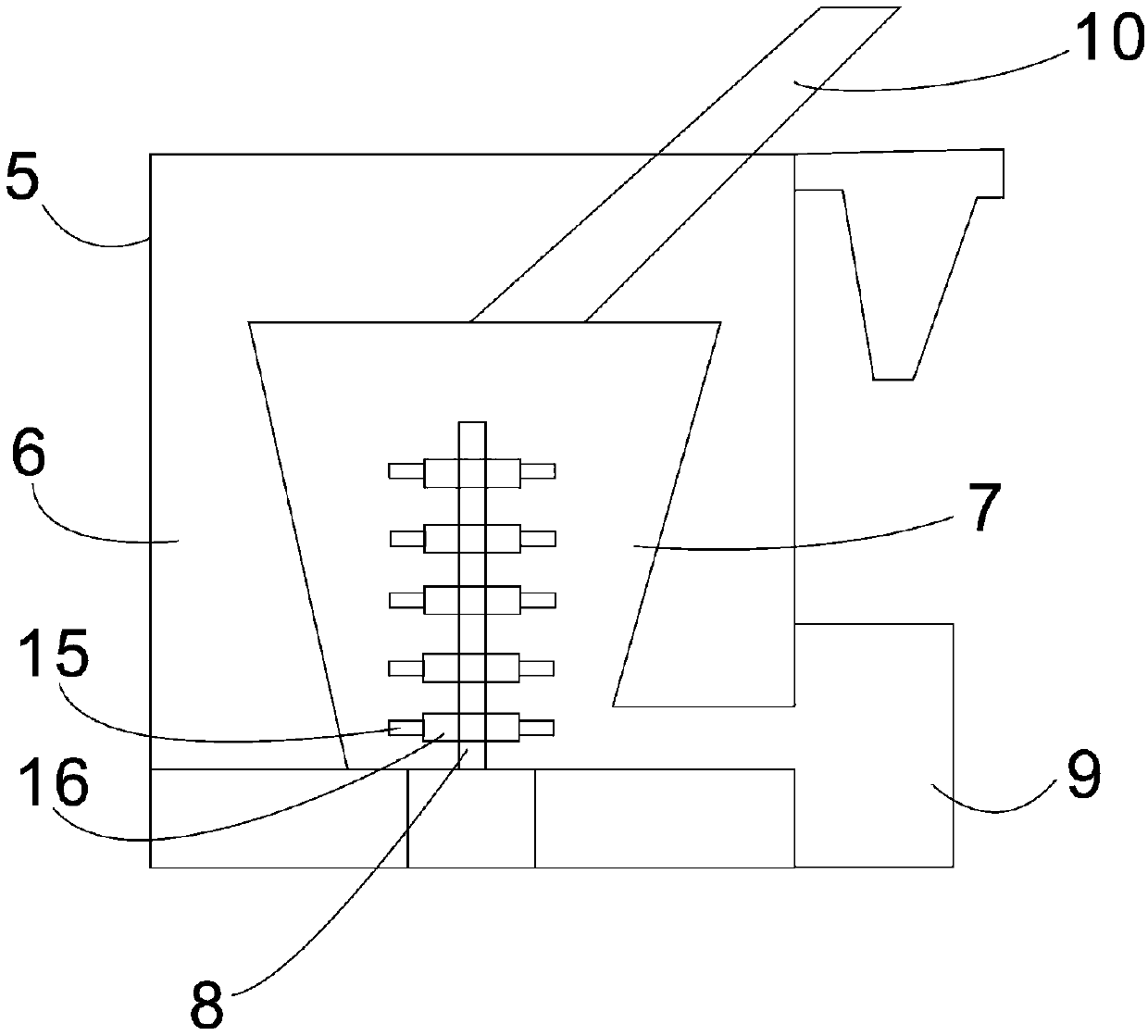

Size-stable seawater impermeable material and preparation method thereof

The invention discloses a seawater impermeable PE-HD waterproof coiled material with small temperature deformation resistance and a preparation method of the seawater impermeable PE-HD waterproof coiled material. According to the method, a certain amount of EPDM rubber powder is added, PE-HD-g-MAH is used as a compatilizer, mixing and co-melting are conducted by using a double-screw extrusion mode, and finally extruding and tabletting are performed to prepare the coiled material. Compared with a traditional PE-HD waterproof coiled material, the waterproof coiled material prepared by the methoddisclosed by the invention has the advantages that the defects that the traditional PE-HD waterproof coiled material is large in deformation and poor in waterproof effects in the laying process are overcome, the size change can be within 3.5% under the temperature change condition of 35-60 DEG C, the tensile strength and the tear resistance are improved, other mechanical properties are relativelygood, and the using standard of the waterproof coiled material is met.

Owner:SOUTHERN POWER GRID PEAK LOAD & FREQUENCY REGULATION GENERATING CO LTD

Tundish seating brick containing reclaimed material and preparation method of tundish seating brick

ActiveCN114538940AUp to standardHigh strengthMelt-holding vesselsCeramic materials productionBrickGraphite

The invention relates to a tundish seating brick containing reclaimed materials and a preparation method of the tundish seating brick. The refractory material comprises the following components in parts by weight: 60-85 parts of regenerated tundish cover waste, 10-30 parts of high bauxite, 2.5-4 parts of liquid resin, 3-6 parts of graphite, 0.5-3 parts of quartz powder, 0.5-2 parts of silica powder and 0.5-2 parts of kyanite. The content of aluminum oxide in the regenerated tundish cover waste is greater than 70%; through the design of the tundish seating brick containing the reclaimed materials, the technical problem that in the prior art, the cost of an aluminum-magnesia carbon brick is high is solved.

Owner:北京利尔高温材料股份有限公司

A method for low-temperature production of defatted insect pupae protein powder

ActiveCN107469939BMix thoroughlyComplete extraction and separationFatty-oils/fats productionGrain treatmentsInsect pupaEconomic benefits

Owner:青岛新农康源生物工程有限公司

Organic material dry distillation cracking gasification furnace and organic material treatment method

ActiveCN104232121BUp to standardElectrical coke oven heatingBiofuelsProcess engineeringMaterials processing

Owner:SHAN DONG HI LINK ELECTRICITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com