Manufacturing method of glue-free self-sinking floor

A manufacturing method and flooring technology, applied in elastic flooring, buildings, building structures, etc., can solve the problems of long process flow, increased production cost, complex process of glue-free self-sinking floor composite process, etc., achieve shortened process flow, convenient maintenance, The effect of inhibiting the adhesion and growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

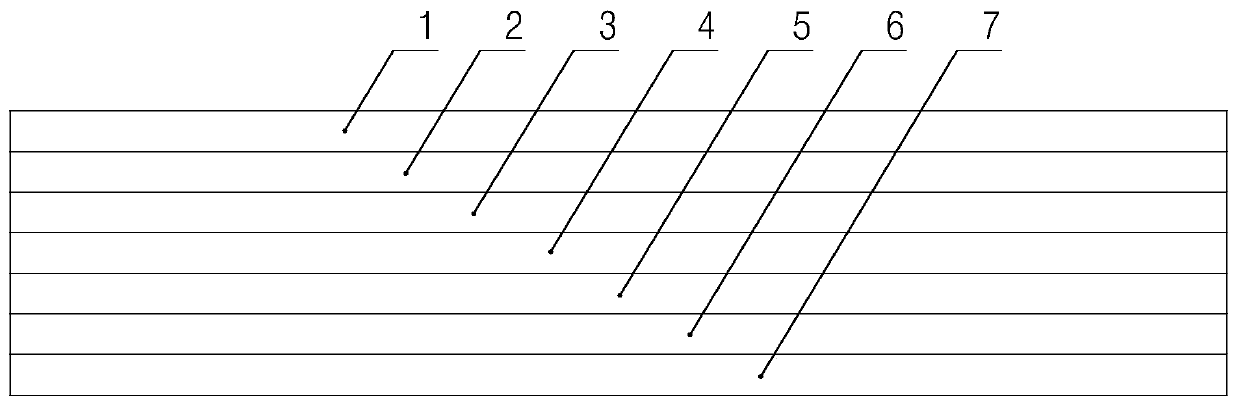

[0028] A specific embodiment of the glue-free self-sinking floor and its manufacturing method according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] like figure 1 As shown, a glue-free self-sinking floor according to the present invention includes: a wear-resistant layer 1, a printed color film layer 2, a base material upper layer 3, a grid fiber layer 4, and a base material middle layer 5 arranged in sequence from top to bottom , the base material lower layer 6 and the anti-slip film layer 7; the base material upper layer 3, the base material middle layer 5 and the base material lower layer 6 are all stabilized by 14.5-15.5% PVC resin powder and 0.7-0.8% DOTP environmental protection calcium zinc agent, 0.7-0.8% of carbon black, 8.5-9.5% of environmentally friendly plasticizers and 74-75% of calcium carbonate, and the PVC resin in the upper layer 3 of the substrate, the middle layer 5 of the substrate and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com